The 3M Novec line, known for its effective performance in various applications, including fire suppression and electronics cleaning, is facing a significant shift as 3M begins phasing out PFAS products. As industries prepare for the transition, the need for reliable replacements becomes critical. This blog will explore both immediate drop-in solutions and long-term alternatives, ensuring that businesses can continue operations with minimal disruption.

For more information, refer to this article: 3M Novec Phase-out: Its Broad Applications and Reasons for Discontinuation

The need for 3M Novec replacements

Liquid Cleaning Products: 3M Novec 71DA Engineered Fluid, 3M™ Novec™ 7100 Engineered Fluid, 3M Novec 71DE Engineered Fluid, 3M Novec 71IPA Engineered Fluid, 3M™ Novec™ 7100DL Engineered Fluid, 3M Novec 7200 Engineered Fluid, 3M Novec 72DA Engineered Fluid, 3M Novec 72DE Engineered Fluid, 3M Novec 7300 Engineered Fluid, 3M Novec 73DE Engineered Fluid

Aerosol Cleaning Products: 3M Novec Contact Cleaner Plus, 3M Novec Electronic Degreaser, 3M Novec Flux Remover

For industries where Novec products play a critical role, such as in fire protection systems or electronic cleaning processes, sudden disruptions can be costly. However, Novec users do not need to worry because there are available 3M Novec replacements. Identifying suitable alternatives ensures that businesses can maintain their operations effectively while adapting to evolving standards and expectations.

Direct 3M Novec replacement: Drop-in solution

Drop-in replacements are designed to substitute directly for 3M Novec products with minimal changes to existing systems. The key benefits include:

- Seamless transition: Drop-in replacements contain identical formulations and molecules to those found in 3M Novec products, ensuring that the same equipment and processes can be utilized without modifications. Qualifying is optional.

- Maintained performance: These alternatives are engineered to replicate the performance characteristics of Novec products, ensuring the high standards of performance are maintained.

- Cost efficiency: Using drop-in replacements can be more cost-effective than overhauling systems or adapting to entirely new products.

Drop-In Replacements for 3M Novec

Here’s example of specific drop-in replacements for various 3M Novec products:

Prostech offers a wide range of 3M Novec drop-in replacements to meet your specific needs. Contact us today for a quotation and expert guidance on the best solutions for your business.

Concerns of Drop-In Replacements

While drop-in replacements offer numerous advantages, there are several concerns that need careful consideration. Firstly, compatibility issues must be addressed to ensure that the replacement integrates seamlessly with existing systems, avoiding any unexpected failures. Additionally, although not all PFAS compounds are currently banned, the regulatory landscape is rapidly evolving, and future bans or restrictions could further limit the availability of PFAS-based products. Industries that rely on PFAS should proactively explore a more long-term solution to mitigate the impact of potential future regulations.

For a more sustainable approach, consider exploring long-term solutions!

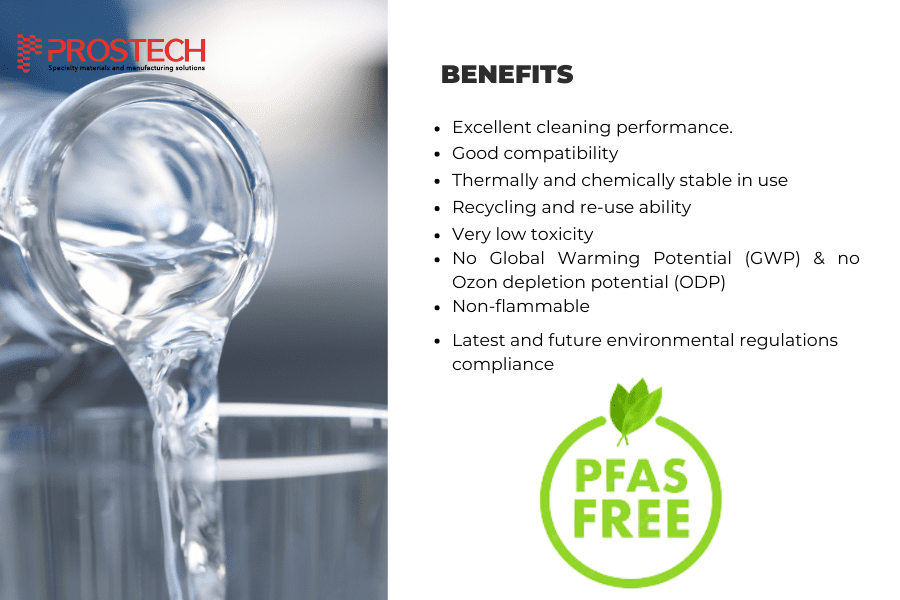

Long-term solution: Switching to PFAS-Free Alternatives

PFAS-free solvents address regulatory compliance while maintaining cleaning performance. These solvents are not only viable long-term replacements for Novec but are also being researched for enhanced performance and cost-effectiveness. Their low surface tension allows them to penetrate tight or hard-to-reach areas, ensuring complete contamination removal. Additionally, PFAS-free solvents can be used in co-solvent cleaning procedures, providing an environmentally friendly solution for degreasing while maintaining high cleaning standards. They can also dissolve fluorinated, silicon, and light oils in mono-solvent cleaning processes, with minimal cleaning, rinsing, and drying times.

Designed to comply with current and future environmental regulations, PFAS-free solvents feature ultra-low to no Global Warming Potential (GWP) and a low atmospheric lifetime, minimizing their impact on global warming. Their low toxicity or non-toxicity is another advantage of this solvent line.

During the use of temporary 3M Novec replacement, you have time to evaluate the new chemistry. When switching to a new solvent and keeping the equipment intact, there will be costs and down time to switching between 2 solvents.

PFAS-Free replacements for 3M Novec products

Here’s example of specific PFAS-Free replacements for various 3M Novec products:

|

Part number |

||

|

Replacement for |

||

|

Application |

|

|

|

PFAS free regulation |

US EPA |

US EPA |

|

Industry |

|

|

For instance, in the electronics industry, it’s critical that cleaning solvents used are nonconductive, noncorrosive, and don’t degrade the quality of parts or materials. The chemical purity and cleanliness of storage containers are also important factors, as incompatible solvents can lead to performance issues or even field failures.

Discover the essential criteria for selecting the right 3M Novec replacements in our detailed guide: Key Criterias for choosing 3M Novec Replacements

Prostech provides a comprehensive selection of 3M Novec alternatives tailored to your requirements. Reach out to us for a quote and professional advice:

Challenges when switching to PFAS-free 3M Novec replacement

However, switching to a PFAS-free alternative presents certain challenges. Firstly, the solvency of PFAS-free solvents may be lower, which can directly impact the effectiveness of the cleaning process. Secondly, it is crucial to ensure that the solvent used is compatible with materials such as sensitive plastics or electronic components to avoid any potential damage.

Additionally, some hydrocarbon solvents, like terpene, may have a stronger odor, so it’s essential to consider whether this will be an issue for your process or for those who will be using it. While PFAS-free solvents may be free of certain chemicals, they are not always nonflammable and may come with trade-offs related to plant ability and regulatory compliance. It is important to note that just because a solvent is PFAS-free does not necessarily mean it is environmentally friendly, as there may be other restrictions associated with this type of chemistry. It is crucial to be aware of these factors when considering the use of PFAS-free solvents.

Change the cleaning process?

It’s time to consider a long-term solution. Stop thinking that cleaning is limited to current solvents and processes. The cleaning method you choose should be tailored to your specific application and requirements. To identify the optimal 3M Novec replacement and adjust your process, consider the type of contamination, the material being cleaned, the desired cleaning performance, and any special requirements.

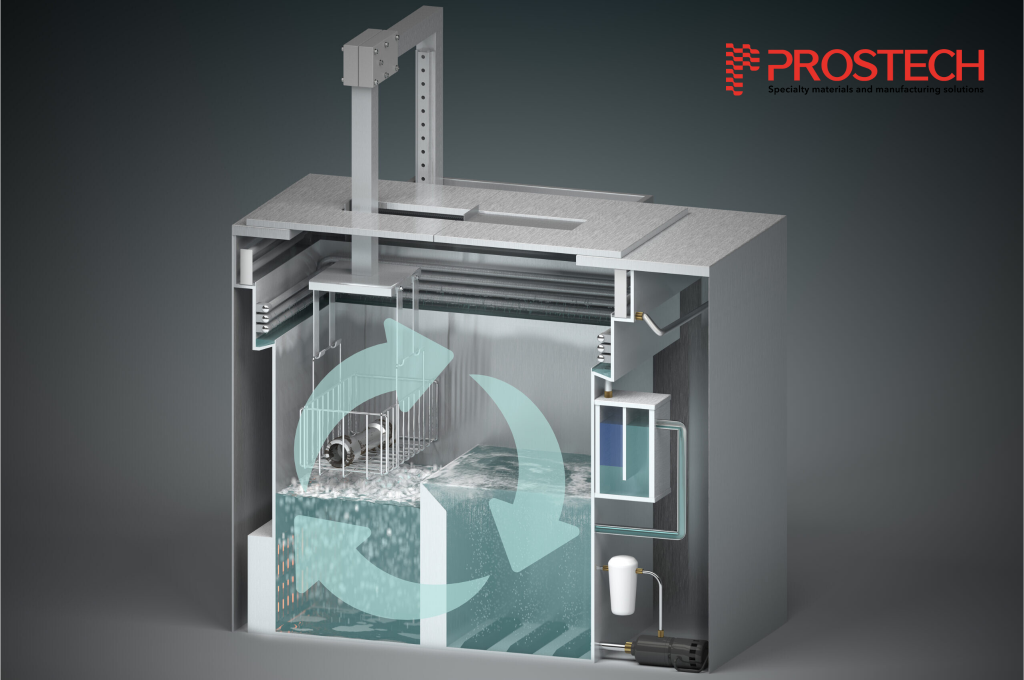

Enhancing solvent cleaning efficiency can be achieved through methods like vapor degreasing and ultrasonic cleaning.

Vapor degreasing, for example, involves condensing solvent vapors onto the object being cleaned, eliminating the need for water or scrubbing. This method effectively removes contaminants from materials such as plastic, glass, metal, gold, and ceramic, without physical agitation.

In addition to solvents, there are alternative methods for industrial cleaning and degreasing that can serve as 3M Novec replacements. However, these methods differ significantly from solvent cleaning and require careful consideration.