Choosing the right potting compounds is crucial for protecting sensitive electronic components from harsh environmental conditions. These materials are used to protect devices from moisture, provide insulation, and help manage heat. With options like epoxy, silicone, and polyurethane, each material offers distinct advantages depending on your application’s specific requirements. In this guide, we’ll explore the key differences between these potting compounds and help you determine which one is the best fit for your needs, ensuring long-lasting protection and optimal performance.

Three common types of potting compounds

When selecting a potting compound for your application, understanding the unique characteristics of each type is crucial. The three main types of potting compounds commonly found in electronics manufacturing are epoxy, silicone, and polyurethane. Each offers specific advantages and is suited for different environments and performance needs. Below is a detailed breakdown of each potting compound.

|

|

|

| Epoxy Potting Compounds | Silicone Potting Compounds | Polyurethane (PU) Potting Compounds |

1. Epoxy Potting Compounds

Epoxy resins have earned their place in electronics due to their robust combination of qualities. These resins offer:

- High mechanical strength, providing solid protection against wear and tear.

- Resistance to elevated temperatures, making them a good option for environments that reach up to 180°C.

- Exceptional chemical resistance, ideal for harsh environments where exposure to chemicals or solvents is a concern.

- Strong adhesion, ensuring a secure bond with substrates like metals, ceramics, and specific plastics.

For instance, epoxy potting is widely applied in electric motors. These motors generate substantial heat and undergo constant mechanical vibrations, which can damage sensitive components. Epoxy provides the necessary insulation and protection, ensuring that the motor operates reliably over time, while also preventing electrical short circuits.

Read the article for detailed information on e-motor potting: E-motor Potting – Optimal Thermally Conductive Solution for EVs Drive

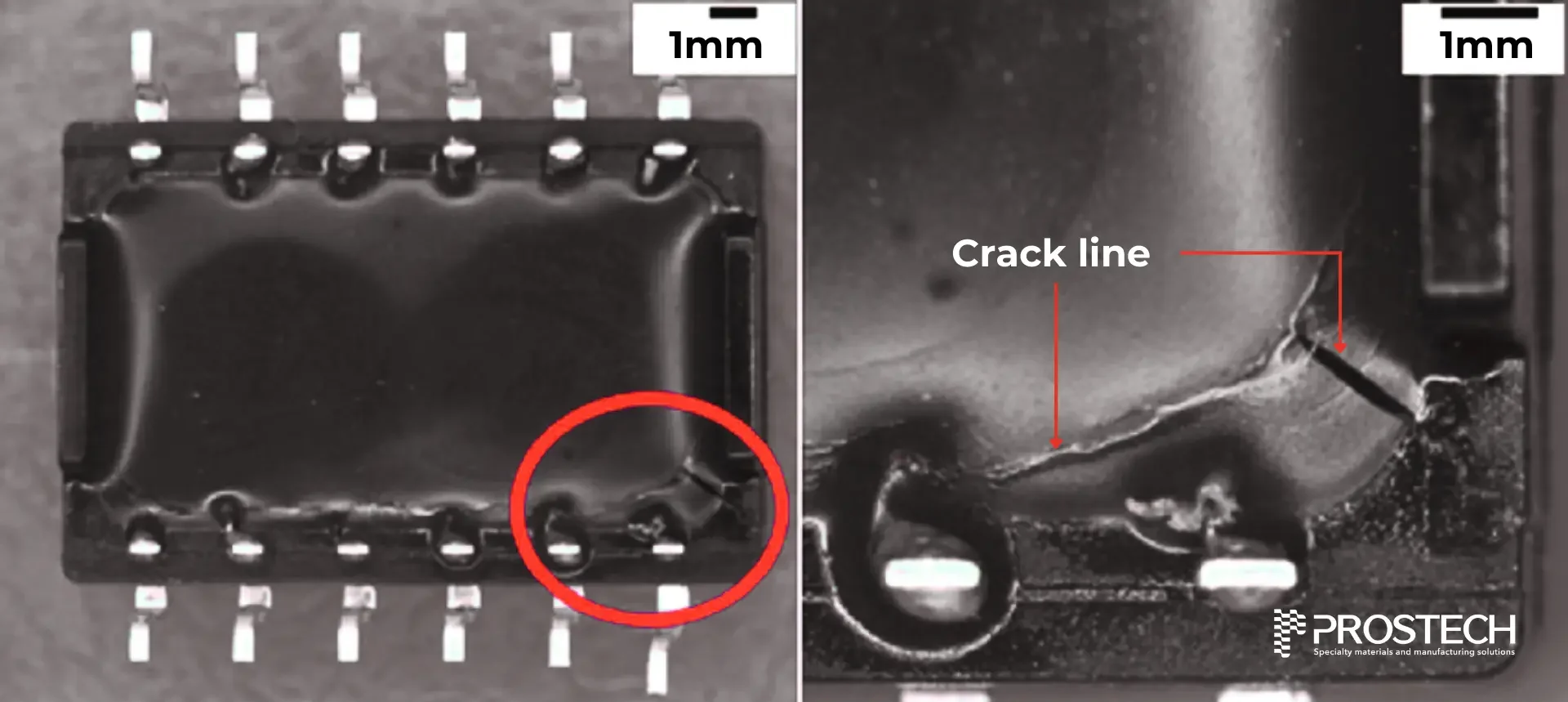

However, in situations where the environment fluctuates rapidly between hot and cold or where flexibility is required, epoxy’s rigidity can be a disadvantage. In such cases, the material may crack, limiting its use where thermal cycling or mechanical flexibility is essential.

2. Silicone Potting Compounds

Silicone compounds excel in environments where flexibility and temperature extremes are the norm. These materials are known for:

- Exceptional temperature tolerance, operating efficiently in conditions from -50°C to 200°C.

- High flexibility, which helps absorb mechanical shocks and withstand thermal cycling without degrading.

- Strong bonding to a variety of substrates, including metals and plastics, making them highly versatile in electronics applications.

- Reworkability, meaning that silicone can be more easily removed and reapplied compared to other potting compounds, making it ideal for applications where future repairs or modifications are anticipated.

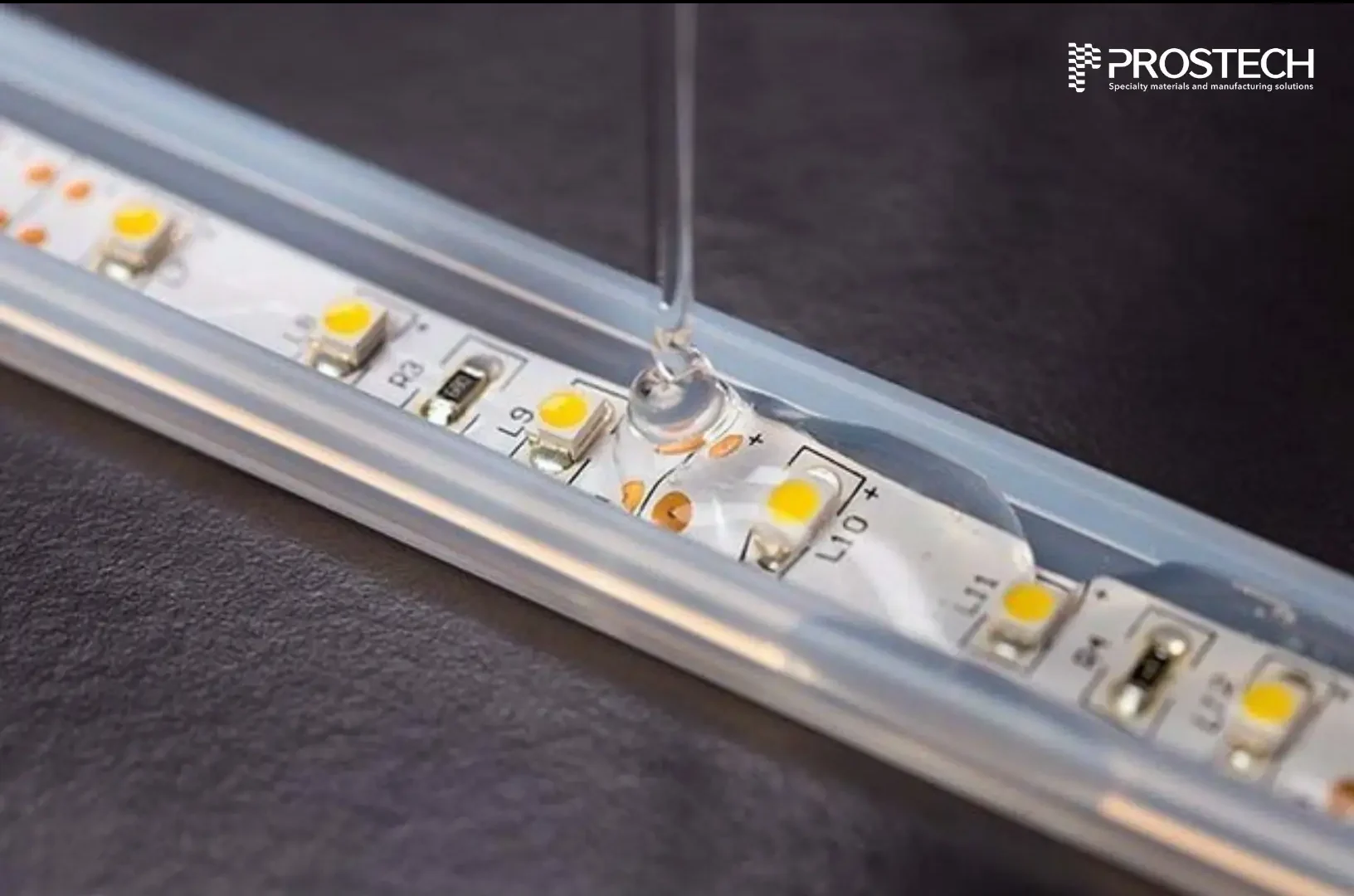

In the LED industry, for example, silicone is often chosen because these devices face rapid temperature changes and require materials that can adapt without cracking. The flexibility and temperature stability of silicone ensure that the LED’s circuitry is protected while also allowing heat to dissipate, preserving performance in harsh environments like outdoor lighting or automotive headlights. Additionally, its reworkable nature allows for easier access to components if adjustments or repairs are needed down the line.

That being said, while silicones provide great versatility, they come at a higher cost and may not offer the same level of chemical resistance that epoxies can deliver.

3. Polyurethane (PU) Potting Compounds

Polyurethane, with its elastomeric nature, balances flexibility and mechanical strength. Its benefits include:

- Moderate temperature resistance, functioning well in environments up to 125°C.

- Adjustable curing times, which makes it easier to customize the processing speed to fit manufacturing timelines.

- Cost-effectiveness, often priced lower than silicone, making it an attractive option for cost-conscious applications.

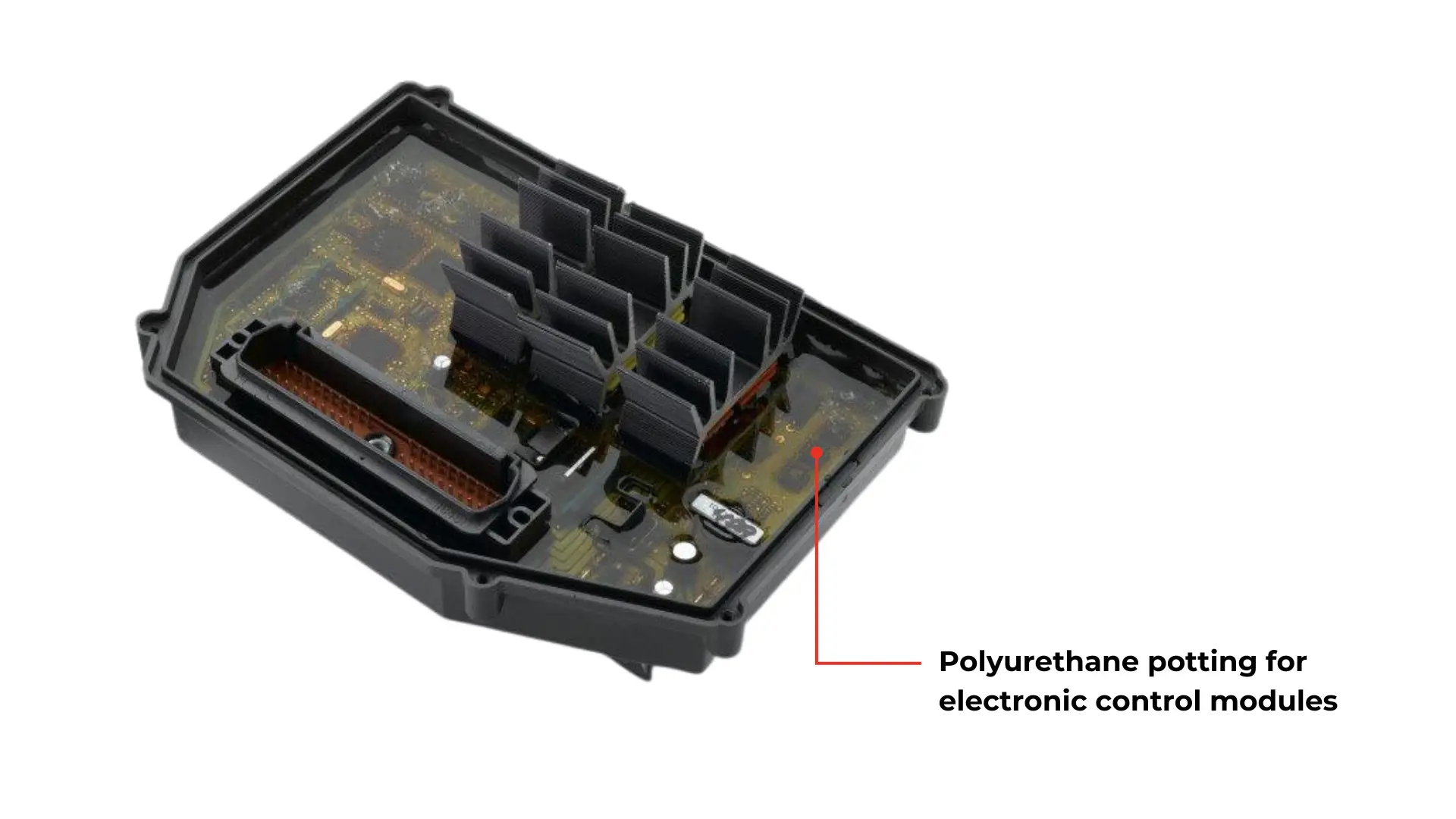

For instance, polyurethane finds favor in automotive sensors, where components are exposed to constant vibration and moderate temperature shifts. Its flexibility absorbs vibrations effectively, ensuring that the sensors remain intact and functional, while offering a relatively low-cost solution.

While polyurethane provides flexibility and ease of processing, its lower temperature tolerance and moderate chemical resistance make it less suitable for high-heat environments or chemically aggressive conditions.

How to Choose the Right Potting Compound

When determining which potting material is best for your specific needs, you should take into account the operating environment, mechanical stresses, and cost considerations. Below is a helpful comparison to guide your selection:

|

Property |

Epoxy |

Polyurethane (PU) |

Silicone |

|---|---|---|---|

|

High Temp Resistance |

Good (up to 180°C) |

Moderate (up to 125°C) |

Excellent (up to 200°C) |

|

Chemical Resistance |

Excellent |

Moderate |

Moderate |

|

Thermal Conductivity |

Good |

Moderate |

Good |

|

Thermal Shock |

Fair |

Good |

Good |

|

Flexibility |

Poor |

Excellent |

Excellent |

|

Thermal Expansion |

Good |

Moderate |

Fair |

|

Electrical Insulation |

Excellent |

Good |

Good |

|

Adhesion to Plastics |

Moderate |

Good |

Fair |

|

Reworkability |

Poor |

Poor |

Excellent |

|

Cost |

Moderate |

Low |

High |

Key Factors to Consider:

- Substrate Material: Different substrates require specific bonding properties.

Substrate Type Recommended Potting Compound Key Requirements Metals (Die-Cast Aluminum, Aluminum, Copper, Iron, Tin) Epoxy, Polyurethane High adhesion, corrosion resistance, thermal conductivity Plastics & Polymers (PC, ABS, PVC, PA) Polyurethane, Acrylic, Epoxy Flexibility, impact resistance, chemical resistance Composites (FRP, CFRP) Epoxy, Silicone High mechanical strength, vibration resistance, non-conductive Ceramics & Glass Silicone, Acrylic, Epoxy High temperature resistance, UV stability, dielectric strength Semiconductors & Coatings (Silicon Wafer, E-Coat AL, NPS) Epoxy, Silicone High purity, low outgassing, corrosion resistance - Temperature Requirements: If your application demands high-temperature endurance, silicone is a strong contender, while epoxy offers mid-range heat tolerance. Polyurethane fits well in lower-temperature environments.

- Mechanical Flexibility: For applications subject to mechanical shock or stress, both polyurethane and silicone offer the flexibility needed to prevent material failure.

- Reworkability: If your product may require future rework or modifications, silicone is the preferred choice due to its ease of removal compared to other potting materials.

- Chemical Exposure: In chemically harsh environments, epoxy offers unmatched resistance, providing long-lasting durability.

- Cost Considerations: Polyurethane is often the most affordable option, with silicone being the most expensive due to its versatility and temperature performance.

Application of Potting in various industries

The choice of the appropriate compounds for potting depends on the specific requirements of the application and environmental conditions. Each type of material offers its own advantages and is suited to different demands during the manufacturing and usage processes. Typical applications of potting for some industries include:

Renewable Energy:

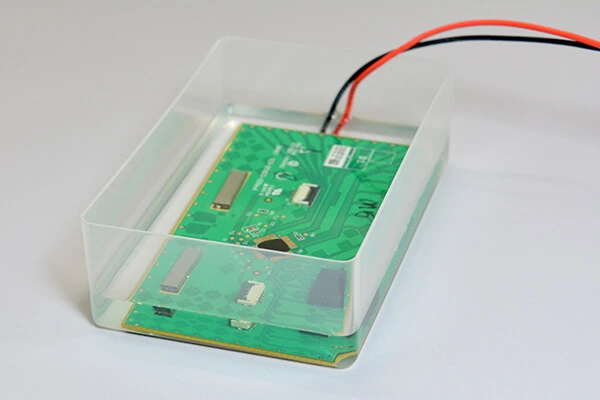

- Power FTC circuit board potting for sail power

- Battery pack potting for solar energy storage systems

- Junction box potting for photovoltaic (PV) modules

- Solar inverter potting

E-Mobility:

- Connector potting for E-Bike

- Insulated-Gate Bipolar Transistor (IGBT) Potting in Automotive Electronics

- High voltage transformer and sensor potting

- On Board Charger (OBC) potting

- Connector potting

- Engine control units (ECUs) potting

- LED headlights and taillights potting

Security:

- Panel potting for security device

- Surveillance camera potting for waterproofing

- RFID reader and biometric scanner potting

- Fire alarm sensor potting

Telecommunications:

- Circuit board potting in power supply (ZTE)

- 5G base station circuit potting

- Fiber optic connector potting

Consumer Electronics:

- Smartphone PCB potting

- Wearable device sensor potting

- Wireless charger coil potting

- Audio equipment (headphones, speakers) potting

- Gaming console power supply potting

Prostech’s potting solution

Featured products:

| Devcon® 10 Minute Epoxy | Tonsan® 1533 White/Black |

| Plexus® EP8080 | |

| Plexus SL8130 | Tonsan® 1522 White/Black |

| Insulcast RTVs 8127 LV | Everwide JE185 |

| Insulcast RTVs 27 HTC | Everwide JE136-5 |

| Insulcast RTVs 8127 LV-C | Everwide PT-398G7 |

| Insulcast RTVS 3-95-1/RTVS 3-95-2 | Arathane VB U6942/Arathane VB U001B |

| Insulcast RTVS 42 CURTIS II CN | Araldite CW 1302/Aradur HY1300 |

With many years of experience in the industrial material, Prostech is ready to assist customers in selecting the right potting compound and providing integrated solutions for production lines to optimize manufacturing efficiency. Contact us for free consultation!