Product description

Kunshan Hexin HX-700FQ Thermal Paper Roll Cutting Slitting Machine has a photoelectric tracking correction system, the tension of the rewinding and unwinding is controlled by a magnetic powder clutch, the host frequency conversion speed regulation, the up and down movement of the rubber roller is controlled by the cylinder, and it can be laminated and slit at the same time, and it can also be laminated or slit separately. Accurate cutting, fast cutting speed, convenient operation and maintenance, etc.

Features of Kunshan Hexin HX-700FQ Thermal Paper Roll Cutting Slitting Machine

-

Laminating function

-

EPC (edge positioning control) device: Ultrasonic sensor

-

Waste discharge function

-

Magnetic brake and clutch

-

The length counting function automatically stops after it reaches the length you set.

-

2 rewinding inflatable shafts, easy for unloading materials.

Kunshan Hexin HX-700FQ Thermal Paper Roll Cutting Slitting Machine features:

|

Components |

|

|

Unwinding section |

-Chain link automatic lift-up loading system -Floating roller constant tension – Two set Sensor -Self-expandable chuck -Guide & Slide AMT from Taiwan |

|

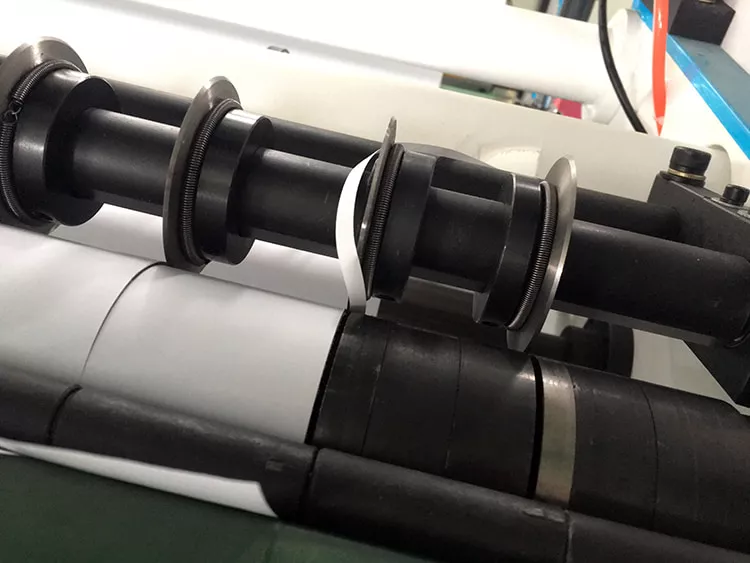

Slitting Section |

-Choices of Razor cutter or Disc cutter -Disc Cutter Assembly adopts the cam self-locking -Cutter with adjustable and moveable blade base. -Meter counter |

|

Rewinding Section |

-0.5”,1”,1.5” or as your request -Center Rewinding technology -Pressure roller -Electromagnetic Clutch from Taiwan |

|

Controlling Section |

–Siemens PLC & HMI from Germany -All the parameters are displayed on the monitor -Low voltage electrical appliances all from Schneider |

|

Trimmed Waste Edge |

– Edge Waste Blower with Expulsion Tube |

|

Optional |

– Friction Differential Shaft for rewinding. -Safety guard for the slitting device. -Emergency Switches on the 4 corners of the cone machine. |

Prostech offers specialty materials (adhesives, tapes, thermal interface materials, insulating materials, sealants, PCB protection materials, …) along with manufacturing solutions. We proudly serve a wide range of industries and are an authorized distributor for leading global manufacturers of industrial materials and equipment. Our product range is designed to deliver customized solutions that address each customer’s unique needs. With years of experience and a successful project history, we are confident in our ability to provide comprehensive material solutions. These solutions effectively tackle the challenges manufacturers face. To explore our full product catalog, simply click here. Our dedicated team is ready to assist with: Moreover, Prostech ensures the safe and accurate global delivery of all materials, including “dangerous goods”, in compliance with legal regulations. For personalized technical support or to receive a quotation, please contact us today.About Prostech

|

Max. Unwinding Width |

700mm |

|

Max. Unwinding Dia |

1000mm |

|

Max. Rewinding Dia |

160mm |

|

Min Slitting Width |

25mm |

|

Machine Max. Speed |

110m/min |

|

Main Power |

2.95kw |

|

Unwinding Shaft |

3’’ (76mm) air-expanding shaft |

|

Rewinding Shaft |

0.5’’, 1’’ or as your request |

|

Weight |

1500kg |

|

Dimension |

2000*1700*1500mm |

CONFIGURATION

|

Name |

Model |

Pieces |

Remark |

|

Computer System |

PLC(Siemens)+4DA+7”Touch Screen(Taiwan)+ Synchronic(Korea) |

1Set |

Siemens+ Weinview |

|

Motor |

2 Sets |

Siemens from Germany |

|

|

Frequency Inverter |

2 Sets |

YASKAWA From Japan |

|

|

Upper/Lower Round Knife |

15 Sets |

||

|

Brake |

From Taiwan |

||

|

Sensor |

2 Sets |

||

|

Tension control |

3 Sets |

||

|

Chuck |

Self expandable chuck |

1 Set |

From Taiwan |

|

Magnetic Clutch |

2 Sets |

From Taiwan |

|

|

Low Voltage Electrical Switch |

SCHNEIDER |

||

|

Blower |

1 Set |

China |

|

|

Cylinder |

Airtac from Taiwan |

||

|

Air Pressure Valve |

SMC from Japan |

||

|

Relay |

CHNT |

Slitting knife