As vehicle manufacturers push for greener, lighter, and more refined designs, interior lamination has emerged as a key focus in automotive engineering. From headliners and instrument panels to seating and trim, laminated components are expected to deliver more than just visual appeal. Automotive interior lamination must meet strict requirements for emissions, durability, bonding performance, and process compatibility — all while keeping up with the fast-paced demands of high-speed production environments.

Trends & Challenges in Automotive Interior Lamination

As vehicle interiors become more advanced, sustainable, and design-driven, manufacturers must navigate a complex set of expectations — many of which are now industry-wide trends shaping the future of automotive interior lamination.

One of the most pressing priorities is emission control. Automakers face increasing pressure to reduce VOC (Volatile Organic Compounds) emissions from both materials and adhesives, especially in response to stricter global regulations and consumer demand for healthier cabin environments. This has driven the rise of low-emission and micro-emission adhesive solutions, particularly in electric and luxury vehicles.

Lightweighting is another major trend, as OEMs look to reduce vehicle weight to boost fuel efficiency or battery range. Laminated parts — including headliners, door panels, and soft trims — must now incorporate lighter materials without sacrificing strength or comfort. This shift has led to the growing use of thin films, lightweight foams, and bio-based composites.

At the same time, aesthetic durability is more important than ever. Consumers expect refined interiors that are resistant to UV exposure, temperature fluctuations, and wear. Laminated surfaces must maintain visual appeal throughout the vehicle’s lifespan.

The need for high-speed production adds another layer of complexity. Adhesives and equipment must support fast cycle times without compromising bond strength or finish quality. As automation increases, process-friendly adhesives that work well with automated lamination lines are in high demand.

Finally, the variety of materials used in interior parts continues to expand. Laminating dissimilar substrates like PU foam, PVC, TPO, leather, or fabric requires versatile adhesive systems that can bond reliably across surfaces, while also adapting to different application methods — from roll coating to spray and slot die.

Solution for automotive industry

Adhesive Solutions for Interior Lamination

To meet these demands, adhesive technologies have evolved significantly. Here are the most widely used adhesive types for automotive interior lamination:

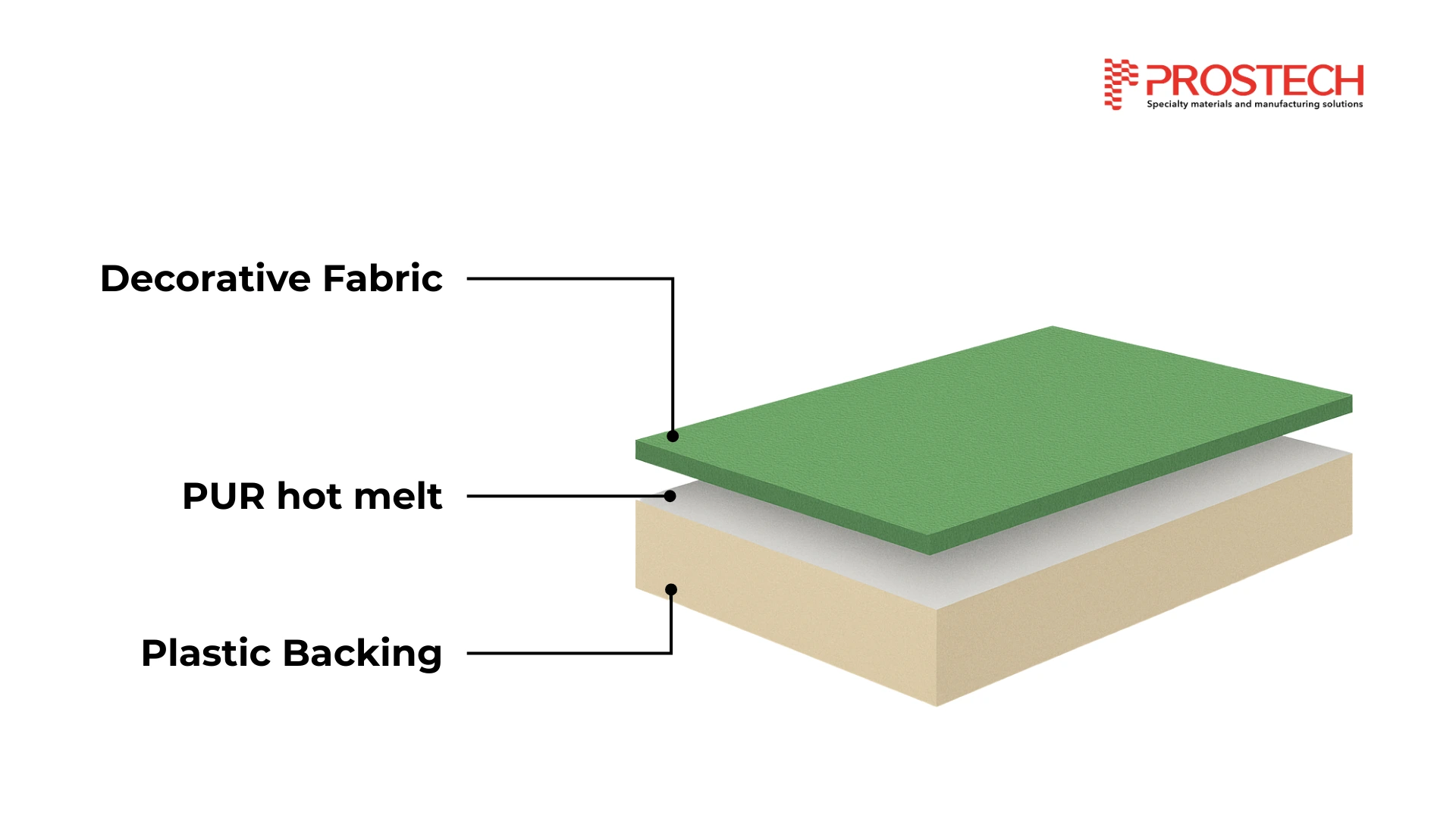

1. Reactive Hot Melt Adhesives (PUR Hot Melt)

Characteristics:

- Chemically reactive after application – forms a strong cross-linked bond upon moisture exposure.

- High initial tack with excellent long-term strength.

- Outstanding resistance to heat, humidity, and aging.

- Bonds a wide range of materials, including low surface energy substrates.

- Forms a flexible yet durable bond line, resistant to plasticizer migration and yellowing.

Applications:

- Door panels: Bonding decorative film or fabric to PU foam or plastic backings.

- Dashboards: Laminating PVC or TPO films to foam layers.

- Headliners: Multi-layer bonding of nonwoven fabric, foam, and textile backings.

- Pillars & consoles: Complex 3D surface lamination requiring reliable bonding on curves and edges.

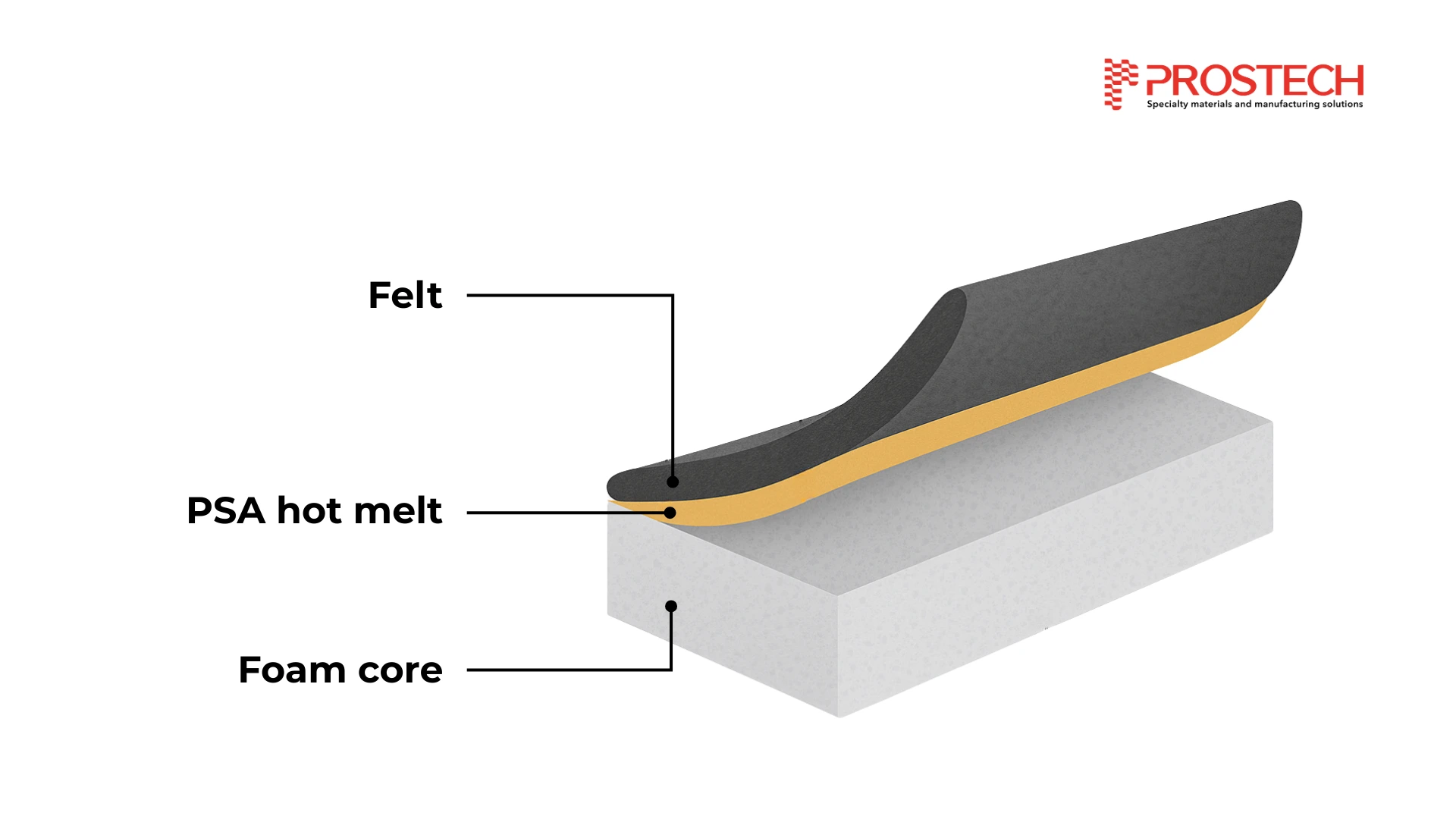

2. Pressure Sensitive Hot Melt Adhesives (PSA Hot Melt)

Characteristics:

- Remains tacky after cooling — does not chemically cure.

- Offers excellent repositionability and easy handling.

- No drying or curing time, ideal for high-throughput production.

- Moderate heat and aging resistance, best for low-stress applications.

Applications:

- Soft trims: Attaching felt or fabric to foam cores where flexibility is key.

- Interior insulation: Temporary or permanent bonding of acoustic and thermal insulation.

- Self-adhesive components: Pre-laminated parts that will be installed at a later stage.

- Decorative inserts: Quick bonding of trim covers in lower load areas.

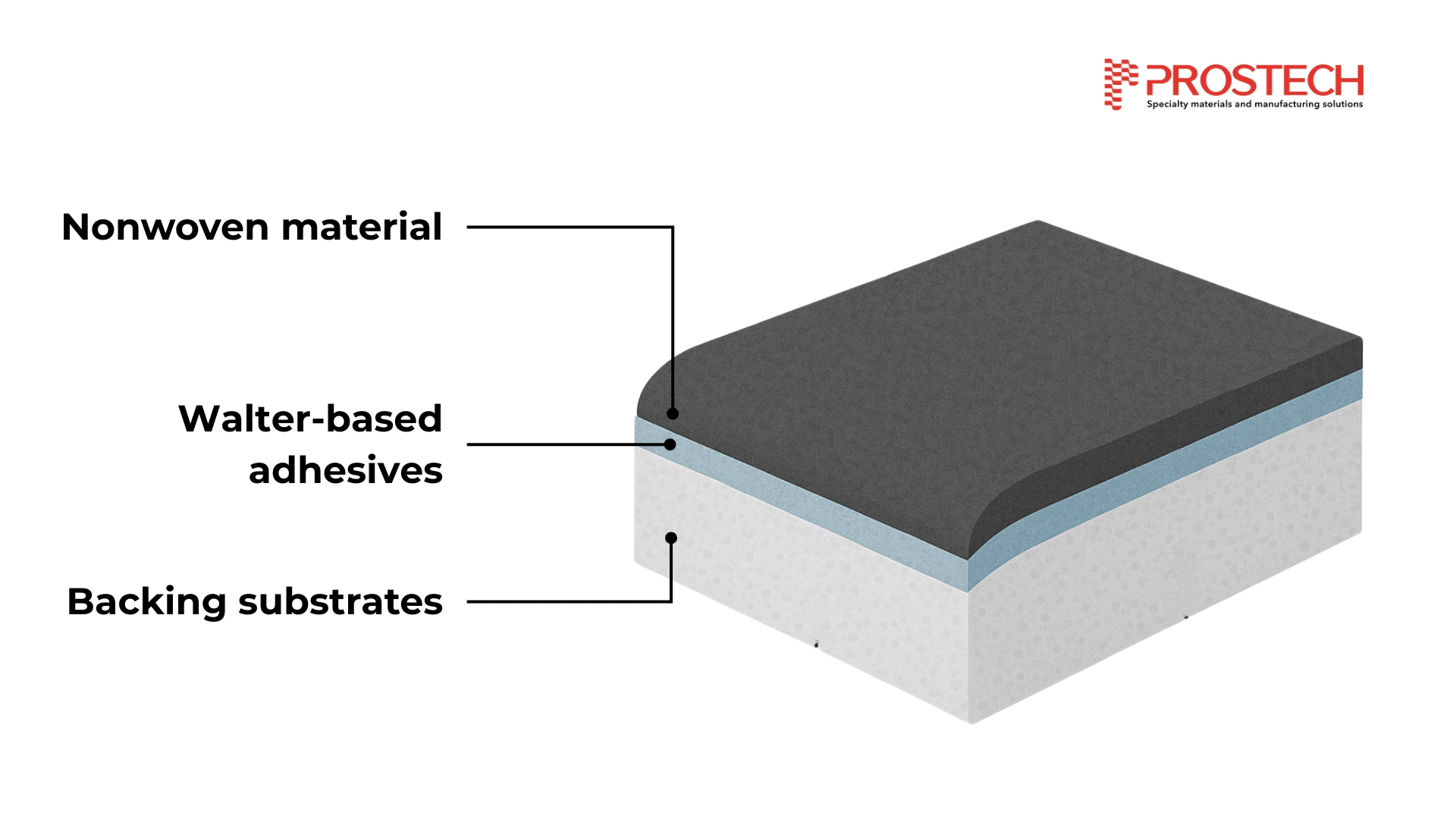

3. Water-Based Adhesives

Characteristics:

- Environmentally friendly with very low VOC emissions.

- Excellent bonding on porous or absorbent materials like fabric, PU foam, or leather.

- Long open time, allowing flexibility in manual or semi-automatic lamination.

- Sensitive to temperature and drying conditions; may require hot press or drying tunnel.

Applications:

- Headliners: Bonding fabric to foam or board layers.

- Seating components: Attaching foam padding to textile or leather.

- General upholstery: Manual lamination tasks in limited-speed production lines.

- Carpet and trunk liners: Economical bonding of nonwoven materials to backing substrates.

4. Micro-Emission PUR Hot Melt Adhesives

Characteristics:

- Contains <0.1% free isocyanate monomer — safer for operators and compliant with EU/REACH regulations.

- Same high performance as traditional PUR hot melts: high green strength, flexibility, and durability.

- Ideal for OEMs prioritizing health & safety without compromising bond quality.

- Often used in closed systems or automation to minimize operator exposure.

Applications:

- EV interiors: Where low-emission, odor-free solutions are essential.

- Luxury interiors: Ensuring premium feel and safety compliance.

- High-speed automated lines: Where both performance and regulatory safety are required.

- Door panels, pillars, and consoles: Especially where sustainability or micro-emission standards must be met.

Prostech offer low-emission hot melt adhesive solutions that meet today’s strict environmental regulations without compromising performance. Our micro-emission PUR hot melts deliver excellent bonding strength, reduce operator exposure to isocyanates, and support a safer, more sustainable production environment — ideal for automotive interior lamination and other demanding applications.

5. Contact Adhesive

Characteristics:

- Contact adhesive works by applying it to both surfaces to be bonded and allowing it to dry until it is no longer tacky to the touch. Then, the two surfaces are pressed together to form a bond.

- It provides high initial tack, allowing for immediate bonding upon contact.

- Excellent heat and moisture resistance, making it particularly suitable for applications that require strong adhesion without extended curing time.

- Applicable to various substrates such as metal, plastic, leather, wood, fabric, rubber, and PU foam.

- Depending on the formulation, contact adhesive may emit high VOC levels, so attention must be paid to environmental and occupational safety regulations.

Applications:

- Headliner: Bonding foam and decorative fabric to the vehicle’s headliner, ensuring the surface does not peel off under thermal stress.

- Dashboard: Attaching decorative components made of fabric, leather, or plastic to the dashboard surface.

- Car Doors: Laminating fabric or decorative films onto door cores or PU foam.

- Interior Trim: Suitable for components that require high adhesion but do not bear heavy loads.

6. Solvent-Based Adhesive

Characteristics:

- Solvent-based adhesives contain volatile organic compounds (VOCs) and are typically used when strong adhesion and fast curing times are required.

- They create strong and durable bonds, especially suitable for non-porous or low-absorption substrates.

- High heat resistance and excellent chemical resistance, enhancing the longevity of interior coatings.

- May emit high VOC levels; therefore, they should be applied in well-ventilated areas or with proper exhaust systems to ensure safety.

- Strong load-bearing capacity, making them ideal for applications requiring long-lasting and robust adhesion.

Applications:

- Seat Upholstery: Bonding fabric, leather, or PU foam to seat frames, ensuring secure adhesion under high load conditions.

- Door Trim: Laminating decorative components such as door panels or surface coverings that need to withstand mechanical stress.

- Dashboard: Attaching PVC, TPO, or leather covers to the dashboard to create a premium appearance and enhance sound insulation.

- Flooring and Carpeting: Applying underlayment or acoustic foam to car floors to provide durable adhesion and high-temperature resistance.

Adhesive Solutions Provider for Automotive Interior Lamination

Automotive interior lamination is no longer just about aesthetics — it’s a complex balance of performance, sustainability, and productivity. Adhesive technologies must rise to the challenge, offering strong, flexible, and emission-conscious bonding solutions. Whether you’re working with high-speed automation or intricate manual lamination, selecting the right adhesive system is critical to delivering high-quality, future-ready interior components.

Prostech understands the technical issues related to interior lamination adhesives. We offer comprehensive solutions, including consulting, materials, and automated adhesive application equipment. We have a global warehousing network to assist customers with logistics procedures. Positioned as a comprehensive supplier, Prostech is constantly striving to become a trusted partner for manufacturers around the world. Contact us by leaving your information below: