As the demand for reliable and durable washing machines increases, ensuring the longevity of their internal components, like printed circuit boards (PCBs), becomes crucial. PCB potting for washing machine plays a key role in protecting these sensitive electronics from moisture, vibrations, and harsh operating conditions. By encapsulating the PCB with specialized materials, potting enhances the durability and performance of washing machines, ensuring they meet consumer expectations for long-lasting, high-quality appliances. In this blog, we dive into how PCB potting addresses the demand for reliability, safeguards electronic systems in modern washing machines, and the materials used to enhance durability in such challenging conditions.

What is Potting?

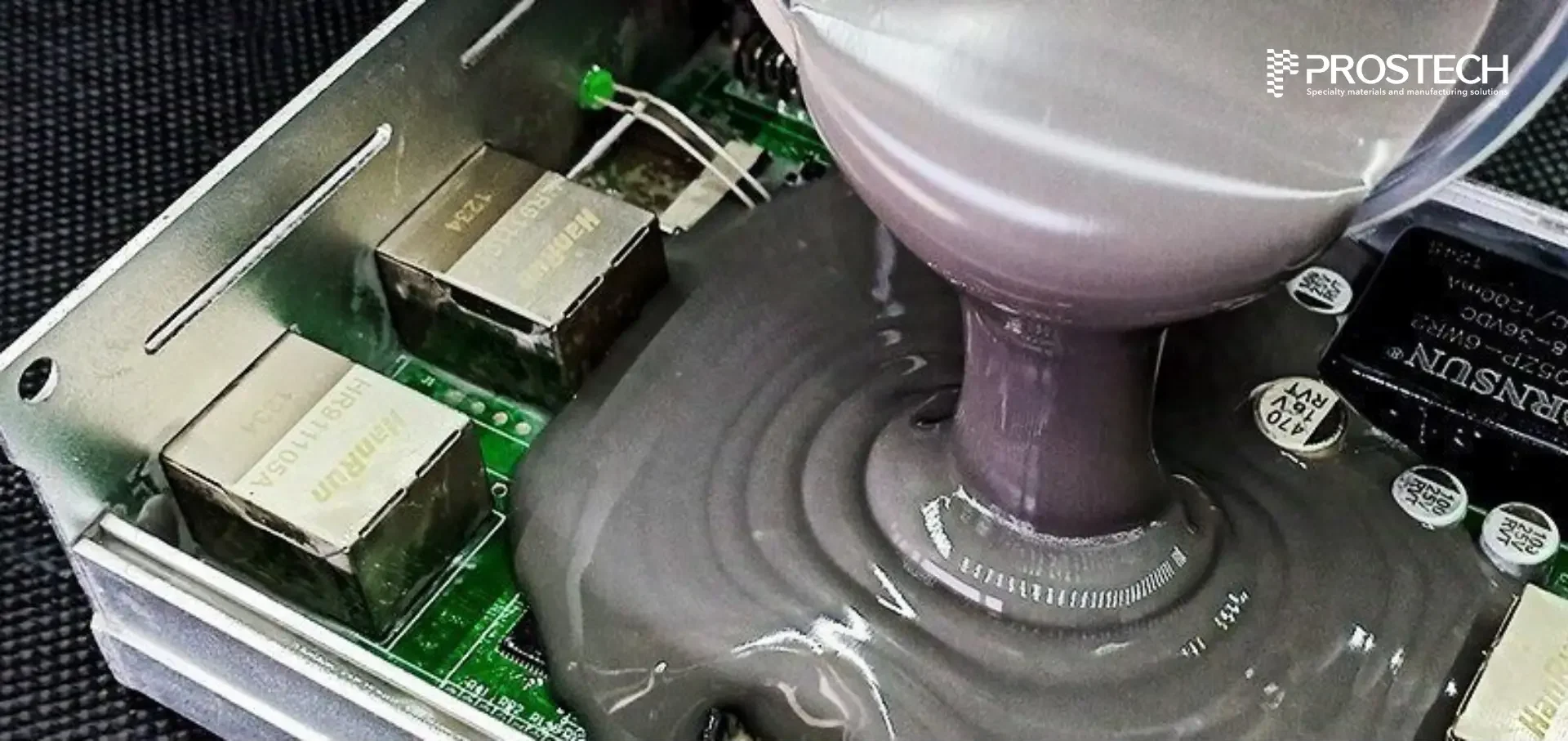

Potting is the process of “filling in” or encapsulating a space with an adhesive, essentially turning the area into a “pot” that is filled with protective material. This method is commonly used in electronics, especially for circuit boards. Since these contain a host of delicate components such as microchips, transistors and resistors, adhesives act as a sealant designed to protect these components from damage, while keeping out moisture, dust and other unwanted elements. They also serve as a protector against impact stress and vibration, which could otherwise easily damage these sensitive products.

In addition to potting, other effective protection methods for circuit boards (PCBs) include conformal coating and low-pressure molding.

Why do washing machines need PCB Potting?

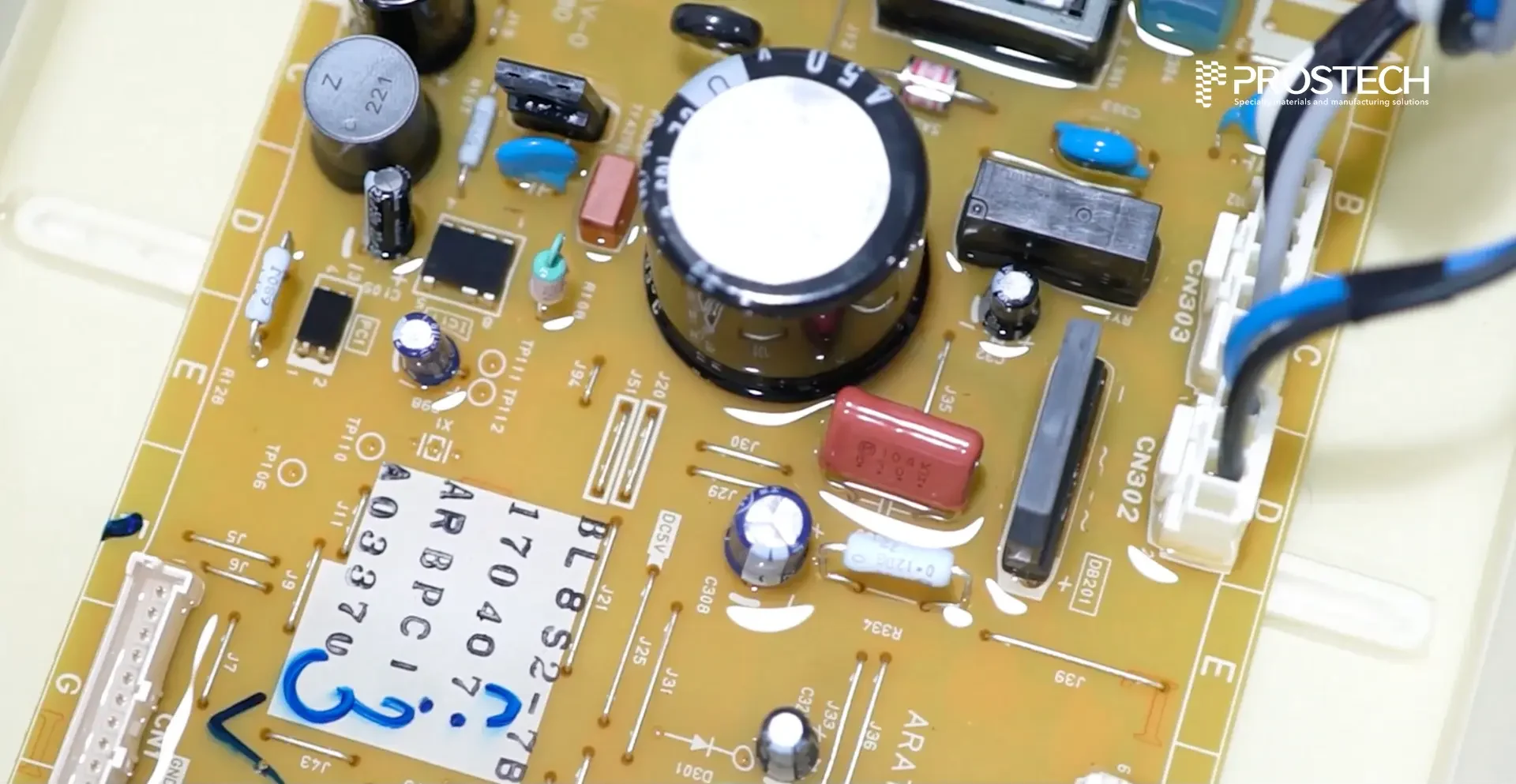

Washing machines, like many other home appliances, face a demanding environment characterized by moisture, vibration, and temperature fluctuations. To ensure optimal performance and longevity, it is imperative to prioritize the protection of the circuit board (PCB), the central control hub of the machine.

PCB protection is not only about protection during the use process but also during the manufacturing process – in which the device must go through thermal and mechanical shock, hazards, and other external factors. When washing machines are in use, on average, one can work effectively for 10 – 20 years. This means the circuit boards must work consistently and effectively for that long.

Specifically, advantages of PCB potting for washing machine are:

- Moisture and Water Resistance: Washing machines operate in environments where water and moisture are constantly present. Potting seals the electronic components, especially the PCB, preventing water from causing short circuits or corrosion.

- Chemical Resistance: detergents, softeners, and other chemicals can come into contact with the washing machine’s electronics. Potting creates a barrier that protects components from these corrosive substances.

- Protection from Vibration and Shock: The mechanical vibrations and shocks that occur during a washing cycle can damage delicate electronic components. Potting provides a protective barrier that absorbs these forces

- Longevity and Durability: Washing machines are expected to last for many years (10–20 years on average). Potting ensures that the electronic components remain functional over this long period, reducing the likelihood of failures and increasing the overall lifespan of the machine.

- Thermal Management: Washing machines experience temperature variations, from the heat generated during the wash cycle to the cold temperatures during standby. Some potting materials provide thermal insulation or dissipation, which helps manage the heat generated by electronic components, especially in high-power applications like motor control units.

Types of Potting compounds

There are three main types of potting compounds – Epoxies, Urethanes, and Silicone, each with unique properties to meet specific protection needs.

1. Epoxies Potting for washing machine

Epoxies offer excellent water and chemical resistance. They have high dielectric strength that makes epoxies ideal for electrical applications where insulation and protection against electrical breakdown are crucial. In addition, epoxies also offer good mechanical strength, making them suitable for ruggedizing components and protecting them from physical damage.

However, epoxies can become brittle when exposed to cold temperatures, which can affect their flexibility and impact resistance. The curing process of epoxies can generate heat and cause shrinkage, which can be problematic for sensitive components. As a result, matching the reactivity and exotherm is an important consideration when selecting a material. Some low-stress potting materials on the market are intended for potting SMT-populated boards, which is an important consideration.

2. Urethanes Potting for washing machine

Urethanes are more flexible than epoxies in general, which can reduce the strain on potted components and improve their durability. Urethane compounds perform well in low-temperature environments, typically down to -40°C or even lower. This makes them suitable for applications in cold climates or devices subject to thermal cycling. In addition, the flexibility of urethane provides excellent resistance to mechanical shocks and impacts, protecting sensitive electronic components from damage.

These potting compounds, however, are generally less resistant to chemicals and high temperatures (above 130°C). Both the isocyanate and polyol components of urethanes can absorb moisture, which can affect their curing properties and long-term performance. This can make them more difficult to work with compared to epoxies or silicones.

3. Silicones Potting for washing machine

Silicones are extremely flexible and can operate at high temperatures up to 200°C. This makes them suitable for environments with significant thermal fluctuations or elevated temperatures. They are also resistant to a wide range of chemicals and liquid water, as well as UV light and ozone. Silicones provide excellent protection against moisture and water ingress, which is crucial for components exposed to wet conditions.

However, silicone potting compounds can be more expensive than other options, such as epoxies or urethanes. While they offer flexibility, they may not be the most rigid option, which could be a concern for certain applications. They also have a relatively high CTE, which can cause issues in high thermal cycling applications.

High performance potting compound for washing machine’s PCB

We supply a wide range of products from various manufacturers, ensuring that you have access to the best solutions for your needs. Our potting solutions are engineered to safeguard against moisture, vibration, and harsh environmental conditions, which are common challenges in washing machines. These compounds offer excellent thermal stability, electrical insulation, and resistance to chemical exposure, ensuring the long-term reliability of the PCB components.

| Product | Properties |

|

|

|

If you’re looking for reliable and high-performance potting products for washing machines, we can help you. The choice of the appropriate compounds for potting pcb in washing machines depends on the specific requirements of the application and environmental conditions. Each type of material offers its own advantages and is suited to different demands during the manufacturing and usage processes. With many years of experience in the industrial material, Prostech is ready to assist customers in selecting the right potting compound and providing integrated solutions for production lines to optimize manufacturing efficiency. Please contact us by leaving your information below: