- What is Epoxy Adhesive?

- Key Features of Epoxy Adhesives

- Practical Applications of Industrial Epoxy Adhesives

- Classification of High-Performance Epoxy Adhesives on the Market

- 1. Classification by Number of Components

- 2. Classification by Application and Material Surface

- Epoxy Adhesive for Steel

- Epoxy Adhesive for Stainless Steel

- Epoxy Adhesive for Wood

- Epoxy Adhesive for Plastics

- Epoxy Adhesive for Rubber

- High-Temperature Resistant Epoxy

- Insulating Epoxy for Electronics

- Optically Clear Epoxy

- Multi-Purpose Epoxy – Consumer Grade

- Flexible Epoxy – Vibration Resistant

- Fast-Curing Epoxy

- AB Epoxy Adhesive Application Guide

- Conclusion

What is Epoxy Adhesive?

Epoxy Adhesive (AB Epoxy Adhesive) is a type of adhesive chemically based on a polymer containing oxirane groups (epoxide (–CH–(O)–CH₂)) – a highly reactive functional group. In epoxy systems, the epoxy resin reacts with a hardener (curing agent) through a thermosetting polymerization process, forming a strong three-dimensional cross-linked polymer network.

Read more: What is AB glue and its applications?

The curing reaction can occur at either room temperature or elevated temperatures, depending on the type of curing agent used (polyamines, anhydrides, amides, etc.). Once fully cured, epoxy adhesive becomes a thermoset material, meaning it cannot be dissolved in solvents and will not melt when reheated, making it ideal for load-bearing, heat-resistant, or high-durability applications.

Thanks to its unique chemical properties, the epoxide group in epoxy resin can form covalent bonds with a wide range of substrates such as metals, ceramics, engineering plastics, glass, and concrete, delivering superior adhesion compared to conventional adhesives.

What is Industrial Epoxy Adhesive?

Industrial Epoxy Adhesive is a product line engineered to meet demanding requirements for mechanical strength, heat resistance, chemical resistance, and environmental stability. It is an indispensable material in various industries such as automotive – electric vehicles (EV), electronics – semiconductors, precision machinery, construction, aerospace, medical devices, and food processing. Many industrial epoxy formulations are designed to offer electrical insulation, thermal conductivity, vibration resistance, or optical clarity, making them suitable for applications such as structural bonding, potting and encapsulation, and conformal coating of PCB assemblies.

Explore PROSTECH’s high-performance epoxy adhesives here:

Top Industrial Epoxy Adhesives

In this article, PROSTECH will guide you through the essential knowledge of epoxy adhesives and industrial-grade epoxy systems, covering key advantages, limitations, and practical solutions, the most common applications across industries, a curated list of market-leading epoxy products, and technical guidance on using AB epoxy – both manually and via automation. If you’re seeking a high-performance, professional-grade bonding solution, don’t miss any part of this article!

Key Features of Epoxy Adhesives

Advantages of Epoxy Adhesives

- Extremely high adhesion to multiple substrates: Industrial epoxy adhesives are renowned for their ability to form strong and durable bonds on a wide range of materials including metals, engineered plastics, glass, wood, concrete, ceramics, and composites. Thanks to chemical reactions that create covalent bonds with substrate surfaces, epoxy adhesives significantly outperform conventional adhesives that rely solely on physical adhesion. With their superior bonding strength to metal surfaces, epoxy adhesives are widely used to replace rivets and screws in many applications. Read more: Epoxy and Acrylic Structural Adhesive in replacing mechanical fasteners

- Excellent heat, mechanical, moisture, and chemical resistance: Once cured, epoxy becomes a thermoset polymer network, enabling it to withstand temperatures from -50°C to over 200°C, while also offering excellent resistance to moisture, solvents, acids, and alkalis. It maintains its mechanical integrity even in harsh environments, under vibration or outdoor exposure.

- Customizable for electrical insulation or thermal conductivity: Depending on the application, epoxy formulations can be tailored for complete electrical insulation (used in PCBs, LED modules, sensors…) or high thermal conductivity (used in thermal interface adhesives, EV battery potting), by incorporating fillers like Al₂O₃, BN, or SiC.

- Highly versatile in hardness – flexibility – cure speed: Industrial epoxy formulas can be engineered to provide:

-

-

Rigid: for high static load-bearing structural bonding

-

Toughened: to absorb vibration and impact

-

Fast-curing: within minutes, ideal for high-speed assembly

-

Slow-curing: several hours, allows for precise alignment

-

Adjustable viscosity, color, and optical clarity

-

PROSTECH is a leading supplier in Vietnam and across Asia for high-performance industrial epoxy adhesives. We are recognized for our deep technical knowledge of materials and hands-on experience working with world-leading adhesive manufacturers such as 3M, Permabond, ITW (Plexus, Insulcast, Devcon), Huntsman, Momentive, Elantas, H.B. Fuller, and more. For every specific technical requirement, our engineering team will recommend the most suitable epoxy solution based on your production process, substrate type, and application conditions. Contact PROSTECH today!

Disadvantages of Epoxy Adhesives & Solutions

- Slow curing time

Issue: Many industrial epoxy systems require 12–24 hours to fully cure at room temperature.

Solution: Use fast-curing epoxy adhesives or apply moderate heat (40–80°C) to accelerate the curing process.

See more: Epoxy Oven Systems for Two-Component Adhesives

- No repositioning after bonding

Issue: Once epoxy starts to cure, it becomes nearly impossible to reposition bonded parts.

Solution: Choose adhesives with a longer pot life to allow for adjustment time. For production, ensure operators are properly trained from the start.

- Difficult to mix evenly by hand

Issue: Incomplete mixing may cause improper curing → weak bonds.

Solution: Use a static mixing nozzle, or an automated metering & mixing system for better consistency.

See the full article: Mixing Two-Component Epoxy Adhesive – Is it difficult?

- Requires proper surface treatment

Issue: Poor bonding if surfaces contain oil, moisture, dust, or are difficult-to-bond substrates.

Solution: Surface must be treated using Chemical methods (degreasing with surface cleaners), Mechanical (sanding), or advanced techniques like Plasma treatment before application.

PROSTECH offers complete epoxy adhesive solutions, including surface preparation. Learn more: Surface Preparation: Key Treatments for Strong Adhesive Bonds in Manufacturing

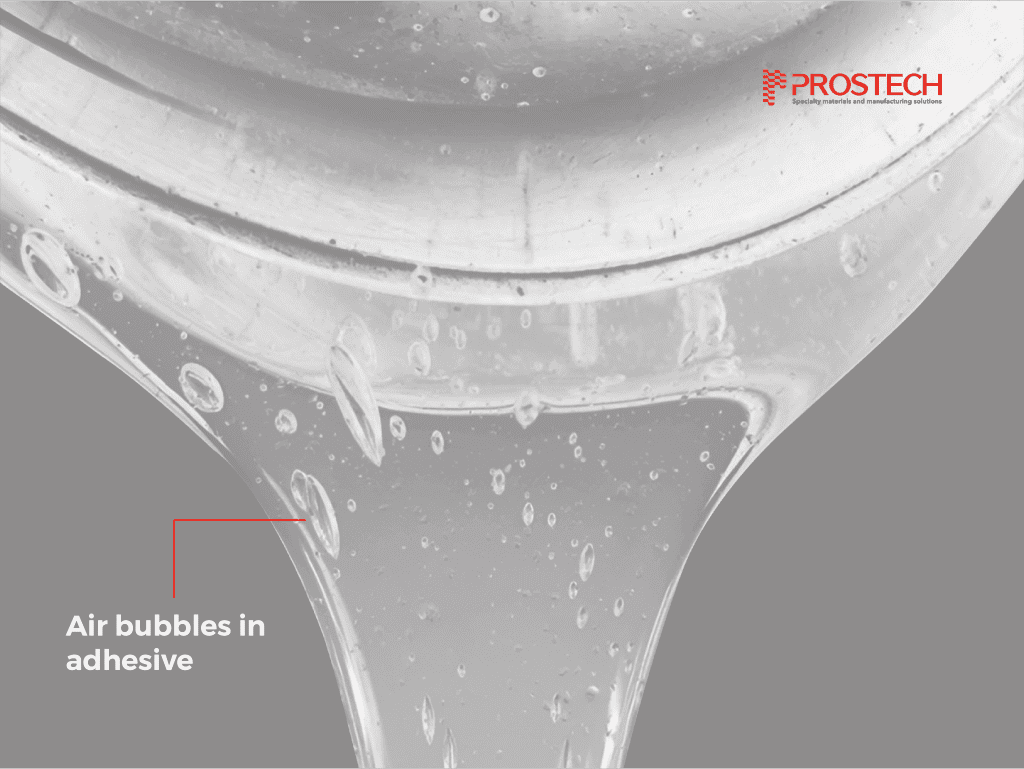

- Air bubbles after mixing

Issue: Epoxy mixture contains air bubbles after mixing.

Solution: Use a vacuum chamber or switch to an automated mixing & dispensing system to eliminate bubbles. Contact PROSTECH for bubble-removal solutions when mixing AB adhesives.

Read more: How to Overcome the Disadvantages of AB Glue

Practical Applications of Industrial Epoxy Adhesives

Epoxy adhesives are not merely bonding agents; they play an essential role in manufacturing and product protection across various modern industries. Thanks to their exceptional heat resistance, chemical resistance, electrical insulation, and flexible formulation properties, industrial epoxy adhesives are vital in the following applications:

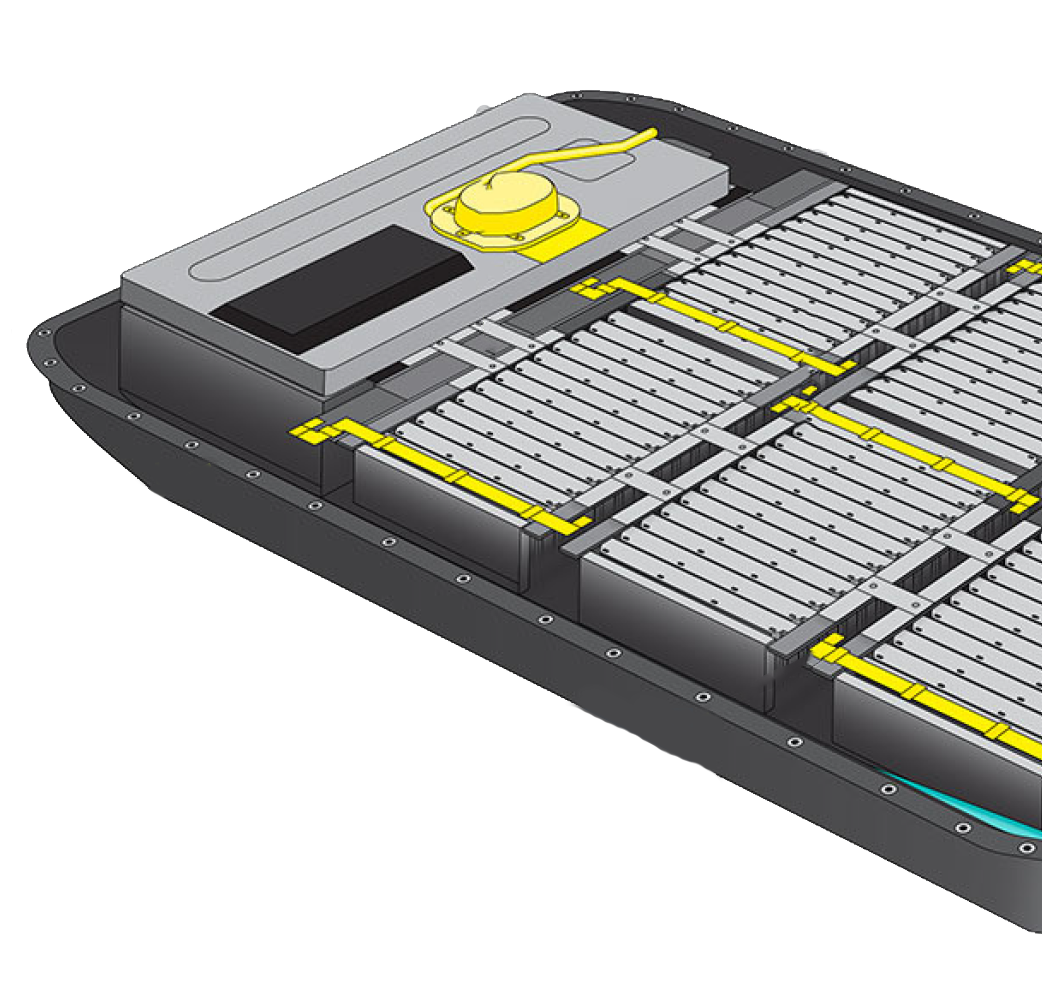

Automotive & Electric Vehicles (EV)

In both traditional and especially electric vehicle (EV) manufacturing, epoxy adhesives are used to bond lightweight materials such as composites, aluminum, and engineering plastics—replacing bolts, rivets, and spot welding—to reduce vehicle weight and increase impact resistance.

Additionally, epoxy plays a critical role in:

-

Securing and dissipating heat from lithium-ion battery modules

-

Bonding electronic control modules (ECU, inverter, onboard charger)

-

Vibration dampening and waterproofing of high-voltage enclosures

The development of thermally conductive and toughened epoxy has been a key enabler for modern EV technologies.

Battery Pack Assembly – Other Adhesive Applications in EV Battery Systems

PROSTECH is a leading industrial materials expert, particularly in vehicle and EV manufacturing. With in-depth knowledge of heat-resistant, thermally conductive, vibration-damping, and composite-to-metal bonding epoxy, we support manufacturers in optimizing structural and electronic component performance in next-gen vehicles. Contact PROSTECH today for expert consultation and selection of the most suitable epoxy solution for your vehicle and mobility device production—from EV batteries and ECUs to composite body parts. Or explore our dedicated solutions for the Vehicle & EV industry here:

Read more:

Potting for Battery Cells in EVs

End Cap Bonding and Potting in Filters

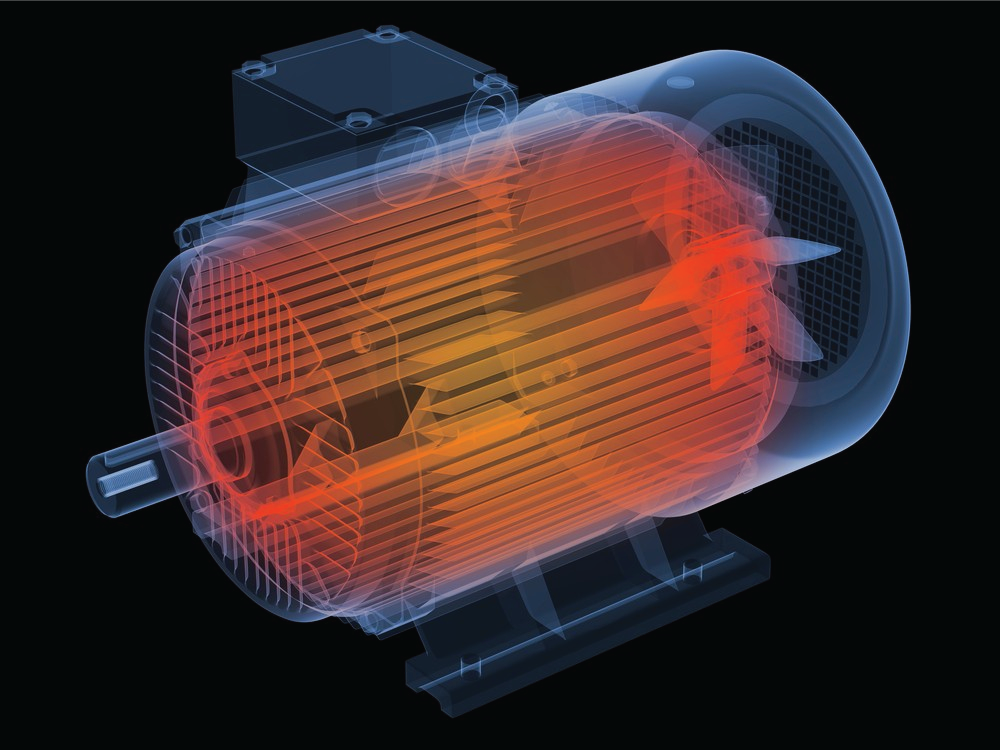

E-motor Potting – Optimal Thermal Management for EV Motor Systems

Food and Medical Equipment Industry

Some lines of food-grade epoxy adhesives have been certified by the FDA, meeting stringent requirements for use in:

- Manufacturing of industrial kitchen equipment and food conveyors

- Bonding and sealing of medical devices and diagnostic equipment

- Assembly in clean environments requiring odorless and non-toxic materials

These epoxy types are typically odorless, antibacterial, and resistant to harsh cleaners, making them ideal for devices that come into indirect contact with food or pharmaceuticals.

Not all adhesives comply with strict food safety and hygiene standards. If you are manufacturing industrial kitchen equipment, processing machines, or food packaging machines, selecting the right FDA-compliant, odorless, chemical-resistant epoxy is crucial.

Some food-safe epoxy products distributed by PROSTECH include:

- Permabond ET5147

- Permabond ET5164

- 3M™ Scotch-Weld™ Epoxy Adhesive DP100NS

- Permabond ET5365

Related articles:

Food safe epoxy adhesives for food & drink applications

Potting Materials for CPAP Machines – Prostech Case Study

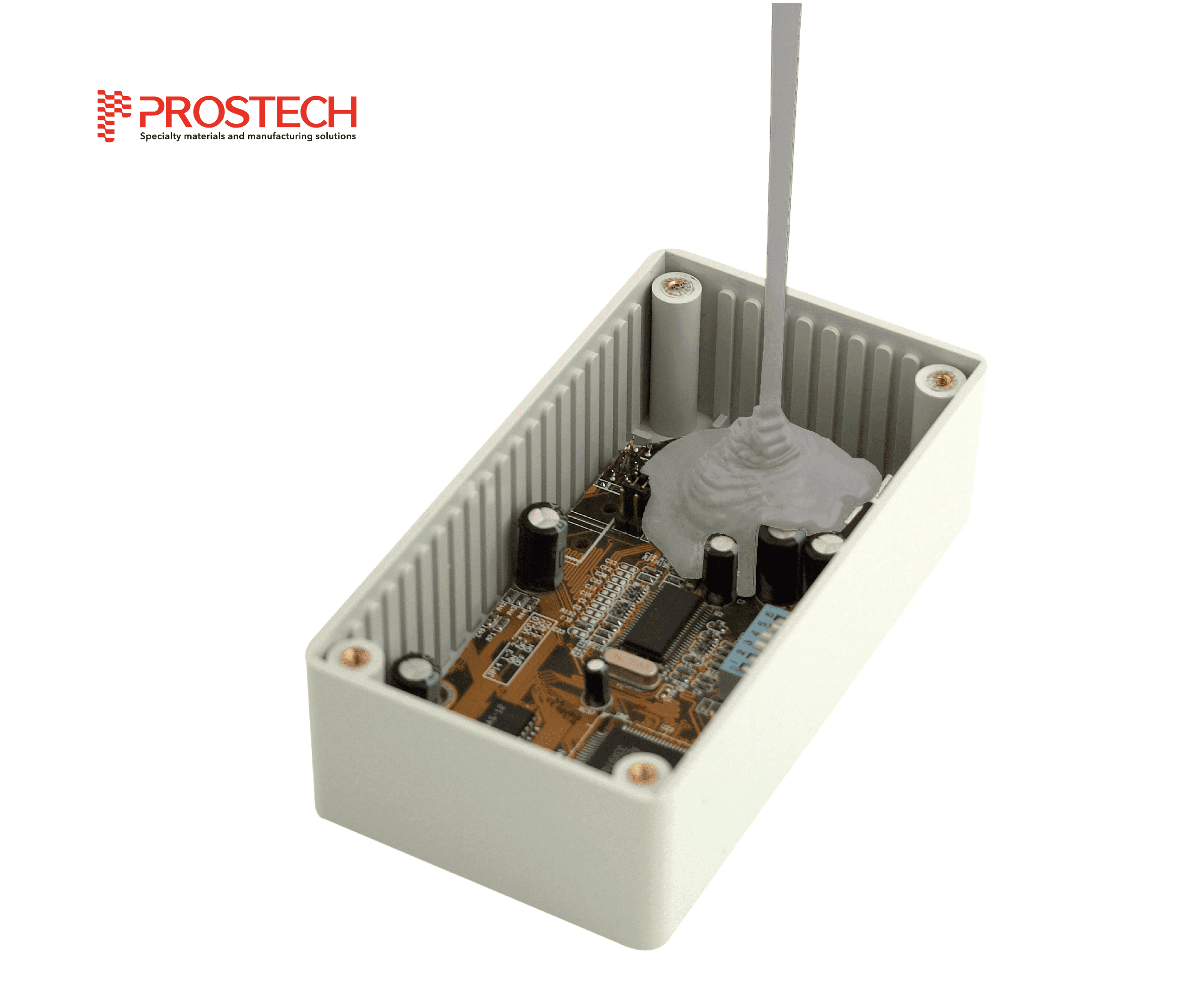

Electronics & LED Industry

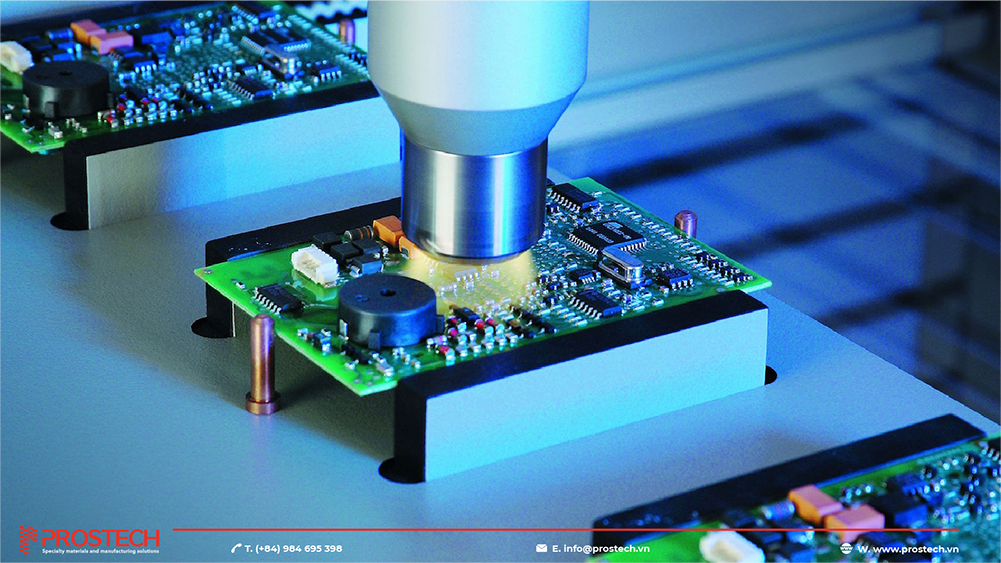

Industrial epoxy is a top choice for potting and encapsulation applications in electronics, used to protect PCB boards, sensors, ICs, and LED components from moisture, dust, chemicals, and mechanical shock.

Key applications include:

- Electrical insulation for PCBs, capacitors, inductors

- Waterproof LED encapsulation

- Potting in relays, sensors, power modules, etc.

With excellent insulation and high moisture resistance, epoxy helps extend component lifespan and ensures electrical safety.

PROSTECH offers a diverse range of epoxy materials for potting and encapsulation featuring:

- High dielectric strength, moisture and heat resistance

- Adjustable viscosity for molding or automated dispensing

- Room or heat curing options

- Thermal conductivity options for high-power applications

Explore our full potting product lineup—from DIY to industrial production lines:

Related articles:

Potting – The Ultimate Protective Layer For Electronics

Clear Potting Solutions for Smart Rings

Mechanical Engineering – Mold Making – Equipment Manufacturing

In precision engineering, epoxy is widely used to:

- Bond and fix metal parts

- Cold welding to replace traditional welding

- Fill cracks and restore worn components

- Align and assemble hard-to-machine mechanical parts

With high strength and dimensional stability, epoxy offers a flexible and quick solution for equipment and mold repair.

Construction – Interior – Civil Applications

Construction-grade epoxy is widely used for:

- Bonding granite, wall tiles, aluminum facades

- Waterproofing concrete floor cracks and joints

- Anchoring chemical bolts and rebar

- Gloss sealing, dustproofing, hardening concrete floors

Especially in liquid form, epoxy can be poured into small cracks without demolition, helping save both time and cost.

Classification of High-Performance Epoxy Adhesives on the Market

1. Classification by Number of Components

Industrial epoxy adhesives are categorized into two main groups based on the curing mechanism: one-component epoxy (1K) and two-component epoxy (2K or AB). Each type has its own advantages and suitable applications in manufacturing.

One-Component Epoxy Adhesive (1K Epoxy)

This is a type of pre-mixed adhesive from the manufacturer, which remains inactive until heat is applied to reach the activation temperature (typically 100–150°C). Suitable for mass production processes with heating systems or curing ovens.

Advantages:

-

No mixing required → simplified operation, eliminates ratio error

-

High stability, easy storage before activation

-

Fast processing on lines equipped with heat curing systems

Limitation:

- Requires heat for curing → unsuitable for on-site use or heat-sensitive substrates.

Typical Applications:

-

Bonding electronic modules, SMD components, encapsulation

-

Structural bonding in automation component production

Representative Products:

- 3M™ Scotch-Weld™ One-Part Epoxy 6102

- Gluditec GLT322 One-Part Epoxy Adhesive

- H.B. Fuller Tonsan®1321FS Epoxy Adhesive

- Elantas Elan-glue® EP 5610 1K Epoxy

- PERMABOND® ES579 One-Part Heat Cure Epoxy

PROSTECH is the official distributor of one-component epoxy adhesives (1K Epoxy) from leading brands such as 3M™, ITW, Permabond, elantas, Weltone, Everwide and other reputable international manufacturers. We offer a diverse product portfolio for applications including structural bonding, electronics, potting, encapsulation and more. With our team of expert materials engineers, PROSTECH is ready to:

-

Provide adhesive selection based on process and substrate

-

Support sample testing at our laboratory

-

Optimize working time – cure speed – bond strength

Explore PROSTECH’s portfolio of 1K epoxy adhesives here:

Two-Component Epoxy Adhesives (2K Epoxy / AB Adhesive)

This type of adhesive consists of two separate components (resin + hardener), which are mixed together immediately before application. It is the most commonly used epoxy type on the market, widely adopted in industrial manufacturing and civil construction.

Advantages:

-

Easier to transport and store

-

Can cure at room temperature

-

Wide variety of options for different substrates and application conditions

Limitation:

- Requires precise ratio and thorough mixing (if done manually), and may produce air bubbles if handled improperly.

Typical Applications:

-

Bonding metal–composite structures in automotive, machinery, and equipment

-

Potting and encapsulating LED modules, sensors, and PCB assemblies

-

Stone bonding, concrete crack repair, epoxy floor coating

Representative Products:

- Devcon® 5 Minute® Epoxy I-FR 14272 – High Performance Fire Retardant Epoxy

- 3M™ Scotch-Weld™ 2-Part Epoxy DP460NS

- PERMABOND® ET5147 Two-Part Epoxy Adhesive

- Cyberbond Cyberpoxy 5895

- Araldite 2014-1 Two-Part Epoxy Adhesive

- Bostik Clear Epoxy Adhesive 7575 – 2oz Tube

- GLT EB-6315 High Strength Structural Two-Part Epoxy

PROSTECH offers a complete solution for two-component epoxy (AB epoxy) tailored for all industrial needs—from structural bonding, component potting and encapsulation, to PCB protection coatings, and automated adhesive dispensing systems for high-volume production.

In addition to distributing high-quality AB adhesives from leading brands, we also supply:

- Manual Tools: AB cartridge guns, static mixing nozzles, various cartridges

- Automated Meter-Mix-Dispense Systems: suitable for industrial assembly lines, offering high precision and reduced material waste

Explore PROSTECH’s two-component epoxy adhesive portfolio here:

2. Classification by Application and Material Surface

With its flexible formula adjustment capability, Epoxy adhesive can be optimized for each specific material surface and unique technical requirement. Below are common groups of epoxy adhesives based on practical applications:

Epoxy Adhesive for Steel

Designed for structural bonding of metals such as iron, black steel, and carbon steel. Requires high adhesion, tensile-compressive strength, and corrosion resistance.

Recommended steel adhesives:

|

|

| PERMABOND® ES569 One-Component Epoxy, Heat-Cured |

- 3M™ Scotch-Weld™ DP125 Two-component Epoxy Adhesive

- 3M™ Scotch-Weld™ DP190 – Gray 2K Epoxy for Steel

- Devcon® 5 Minute® Epoxy I-FR 14272 – High-Performance Fire-Retardant Epoxy Adhesive

- ELANTAS EASYPOXY® K-22 Epoxy Adhesive

Epoxy Adhesive for Stainless Steel

Stainless steel has an inert and smooth surface, requiring epoxy adhesive with excellent wetting ability, high metal adhesion, and resistance to aging and galvanic corrosion.

Recommended Stainless Steel Adhesives:

Epoxy Adhesive for Wood

Suitable for joinery, bonding natural wood, veneer, or engineered wood. Requires good gap-filling properties and no shrinkage.

Recommended Wood Epoxy Products:

- Devcon® 5 Minute® Epoxy DA051 400ml Epoxy Adhesive

- PERMABOND® ET5147 Two-Component Epoxy Adhesive

- 3M™ Scotch-Weld™ 2216 Epoxy Adhesive

- 3M™ Scotch-Weld™ DP125 Two-component Epoxy Adhesive

- ELANTAS EASYPOXY® K-22 Epoxy Adhesive

- H.B Fuller Tonsan TS832

Epoxy Adhesive for Plastics

Compatible with ABS, PC, PVC, Nylon… Requires adhesion to low-surface-energy materials, with flexibility or elasticity to prevent cracking.

Recommended Products:

Epoxy Adhesive for Rubber

Rubber is elastic and prone to deformation, requiring flexible epoxy that doesn’t become brittle, with adhesion to difficult-to-bond surfaces.

Recommended Rubber Epoxy Products:

- 3M™ Scotch-Weld™ DP100 Plus Clear Two-Component Epoxy Adhesive

- ELANTAS EASYPOXY® K-22 Epoxy Adhesive

- 3M™ Scotch-Weld™ 2216 Epoxy Adhesive

High-Temperature Resistant Epoxy

Used in applications requiring continuous operation at 120–300°C, such as motors, heaters, and heat-transfer metal components.

Recommended Products:

- PERMABOND® ET5392 Two-Component Epoxy

- PERMABOND® ET 5424

- DEVCON HR SUPER 3000

Prostech is the official distributor of the above products. Contact PROSTECH today for product consultation and quick detailed quotations.

Insulating Epoxy for Electronics

Used for circuit board encapsulation (potting) or conformal coating. Requires high resistivity, no moisture absorption, and non-conductivity.

Recommended Insulating Epoxy Products:

Optically Clear Epoxy

Designed for bonding glass, acrylic, crafts, LED protection, or coating. Requires optical clarity and no yellowing.

Related article: LED Lighting Bonding Solutions – Enhance Durability & Performance

Recommended Clear Epoxy Products:

- Scotch-Weld Epoxy DP190 Translucent,

- 3M™ Scotch-Weld™ DP125 Clear Two-Component Epoxy

- Everwide JD342,

- Everwide JB 267-6,

- Permabond ET500 – Clear Two-Component Epoxy

Contact Prostech for product consultation and customized quotations for your specific applications!

Multi-Purpose Epoxy – Consumer Grade

Ideal for general repairs and bonding in civil construction and small mechanical applications. Requires user-friendly products that cure at room temperature.

Recommended Multi-Purpose Epoxy Products:

- Devcon® 5 Minute® Epoxy Gel

- Araldite Rapid,

- GLT A595-2 High Performance Epoxy Adhesive

- PERMABOND® ET5143 Two-Component Epoxy

- 3M DP 100NS,

- PERMABOND® ET503,

- Fast-curing epoxy adhesive GLT A585-4

Flexible Epoxy – Vibration Resistant

Designed for impact-resistant bonds, vibration damping, or material expansion applications. Features high elasticity while maintaining excellent adhesion.

Recommended Products:

- PERMABOND® ET515 Two-Component Epoxy

- 3M™ Scotch-Weld™ 2216 Epoxy

- 3M™ Scotch-Weld™ DP125 Two-Component Epoxy

- 3M™ Scotch-Weld™ DP190 – Gray 2K Epoxy

Fast-Curing Epoxy

Engineered to minimize curing time – from minutes to under 1 hour – improving production line efficiency and supporting applications requiring rapid fixture.

Ideal for:

-

Fast assembly in mass production

-

Bonding components requiring early positioning (fixture fast)

-

On-site repairs without long waiting periods

-

Temporary bonding before mechanical processing

These adhesives typically have short pot life after mixing (3-15 minutes), after which the product begins curing and achieves load-bearing strength within 15-60 minutes post-application.

Prostech exclusively distributes 60-second fast-curing epoxy products, with only 45 seconds for mixing and application, maximizing process efficiency while maintaining the strong bonding performance of two-component epoxy. Contact us to find products matching your adhesion requirements, processing time, and budget. Prostech is ready to assist:

Recommended Products:

- Devcon® 1 Minute® Epoxy – Fast-Curing Epoxy

-

Devcon® 5 Minute® Epoxy 14630 9LB Fast-Curing Epoxy Adhesive

-

Devcon® 10 Minute Epoxy 14255 BLACK Ultra-Fast Curing Adhesive/Packaging Sealant

-

PERMABOND® ET503,

Each epoxy formulation has unique chemical properties and technical specifications. To select the right product matching your materials, working conditions, and processing.

AB Epoxy Adhesive Application Guide

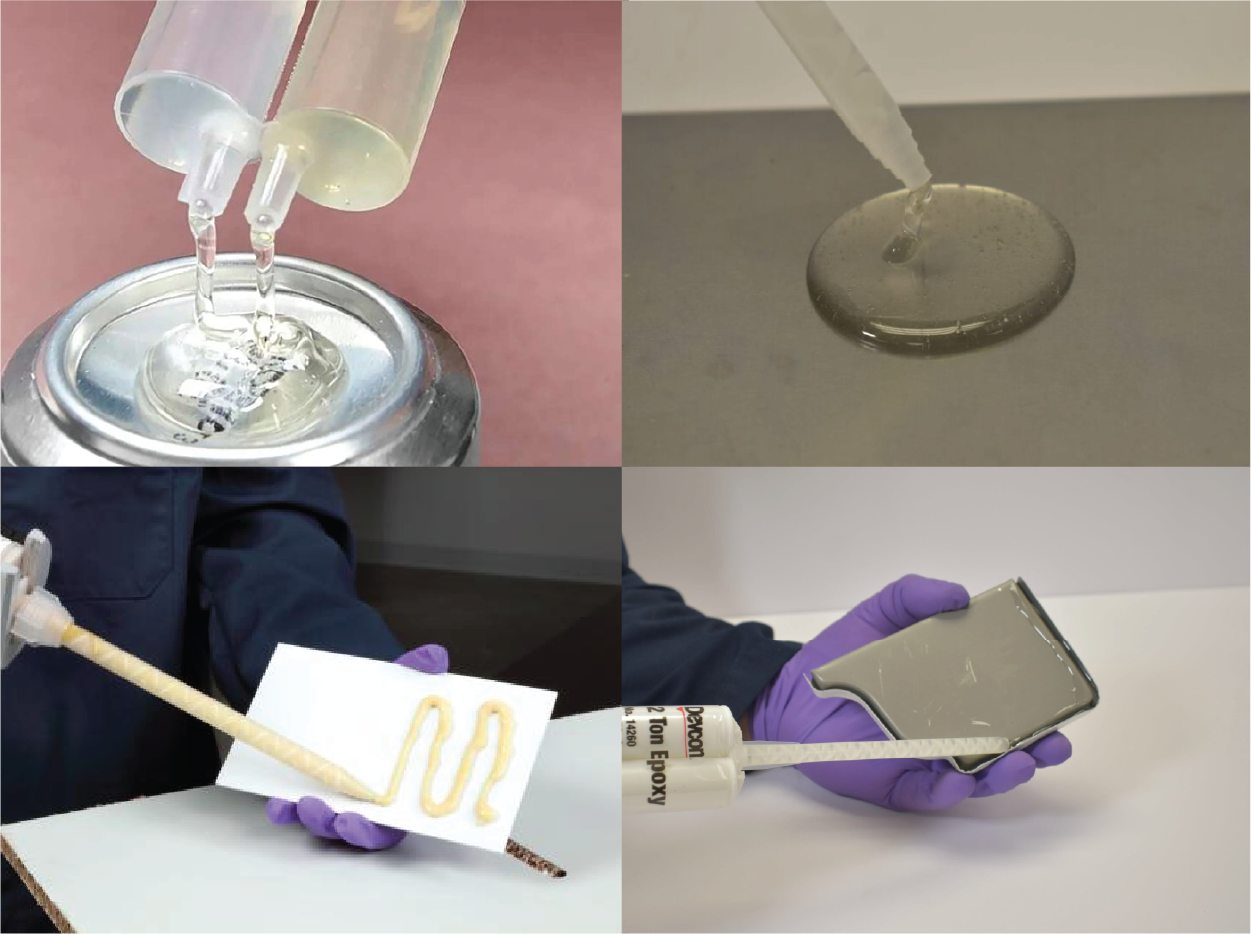

1. Manual Mixing of AB Epoxy

Manual AB epoxy mixing is suitable for:

-

Individual users: field engineers or small repair units

- Small-scale or single-piece production: where flexibility is prioritized

-

R&D sample testing: in laboratories or pre-production

-

Civil applications: without specialized equipment

Benefits of Manual Mixing

-

Flexible & adaptable: Can mix exact required amounts, minimizing waste

-

No expensive equipment investment needed

-

Ideal for small, variable applications

Tools Required:

-

Precision digital scale or measuring cups (depending on adhesive requirements)

-

Wooden or plastic mixing sticks

-

Disposable plastic mixing cups

-

Nitrile gloves/PPE equipment

Manual AB Epoxy Mixing Procedure:

-

Surface preparation: Thoroughly clean bonding surfaces

-

Precisely measure A:B ratio per product instructions (e.g. 1:1, 2:1, 10:1) by weight or volume

-

Mix thoroughly with stirring stick using circular motions – scrape sides and bottom to ensure complete reaction

-

Apply adhesive to surfaces – spread evenly or bead as required

-

Allow proper curing time:

-

Pot life (working time): 3-60 minutes depending on product

-

Fixture time: several hours

-

Full cure: 24-72 hours

-

Limitations of Manual Mixing

-

Ratio inaccuracies may affect bond strength and cure time

-

Difficult to mix thoroughly with components of differing viscosities

-

May introduce air bubbles if stirred too vigorously

-

Not suitable for large-scale production requiring consistency

To overcome these limitations, Prostech recommends the following two alternative methods.

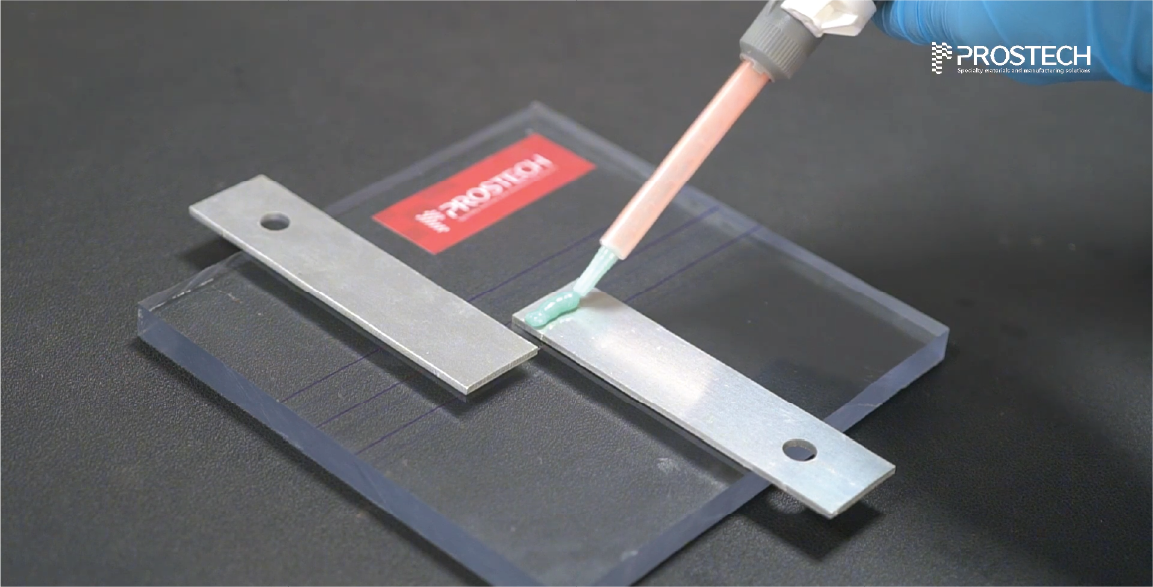

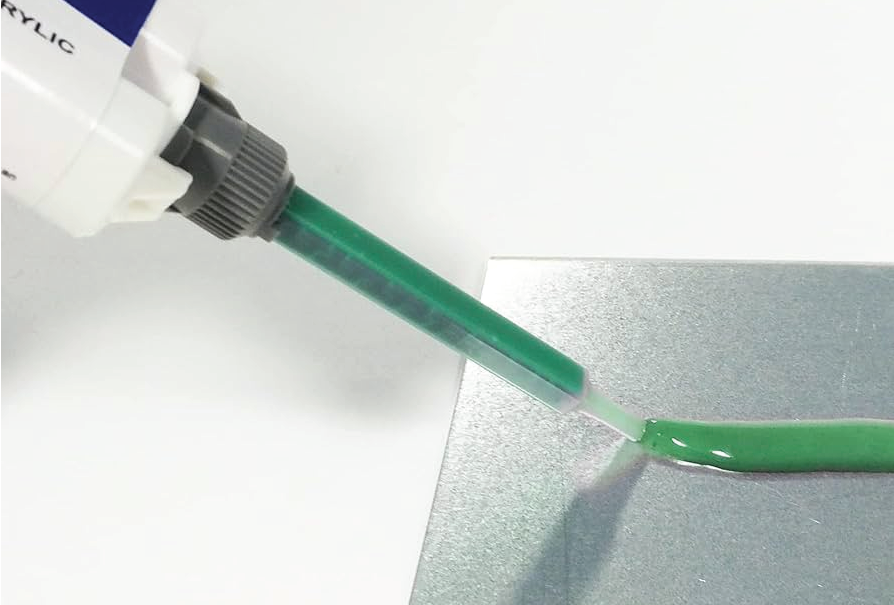

2. AB Epoxy Application Using Dispensing Guns and Static Mixing Nozzles

Equipment:

-

AB epoxy cartridges (1:1, 2:1, or 10:1 ratio)

-

Manual or pneumatic dispensing guns compatible with cartridges

-

Static mixing nozzles matching cartridge specifications

-

Gloves, masks, wipes, and cleaning tools

AB Epoxy Dispensing Procedure Using Static Mixing Nozzles:

-

-

Load cartridge into gun:

Align cartridge properly with both pistons engaging components A and B -

Prime before attaching mixer:

Dispense small amount (~2-5g) to ensure air removal and stable A:B ratio -

Attach static mixer:

Securely screw on mixing nozzle – internal helical design ensures thorough mixing -

Dispense adhesive:

Apply even pressure to dispense uniformly mixed adhesive directly onto surfaces -

Curing:

Secure bonded parts during pot life, allow full cure per product specifications

-

Dispensing Gun and Static Mixer Tutorial

Usage Tips

-

Always use new mixing nozzles to prevent clogging from cured adhesive

-

Replace nozzle if paused for 2-3 minutes as internal curing begins

-

Maintain nozzle contact during dispensing to prevent air bubbles

Advantages of This Method

-

Precise mixing ratios versus manual methods

-

Fast, clean application process

3. Automated 2K Meter-Mixing & Dispensing Systems

Read detailed article: How 2-Component Adhesive Metering Systems Work?

Ideal for:

-

Medium-to-large scale manufacturing requiring continuous, precise adhesive application

-

EV components, medical devices, electronics where ratio control is critical

-

High-volume potting, encapsulation, coating or structural bonding

System Components:

-

Material Supply System

-

Pumps from drums or manual loading into pressure pots

-

Follower Plate Pumps for high-viscosity materials

-

Pressure Regulators for consistent material delivery

-

Metering Module

-

Precise A:B ratio measurement (e.g. 1:1, 2:1, 10:1) via volumetric pumps

-

Flow adjustment matching robot speed or application requirements

-

-

Mixing & Dispensing Module

-

2K dispensing valves for precise component metering

-

Static or dynamic mixers:

▸ Static: convenient, disposable, easy maintenance

▸ Dynamic: motor-driven for high-viscosity or disparate ratio materials

-

-

Motion Control System

-

Desktop robots or Z-axis manipulators for automated dispensing paths

-

Optional defect inspection integration for quality assurance

-

-

Central Control Panel

-

- Ratio, flow rate, pump speed, and mixing cycle programming

- PLC or factory MES system integration

System Advantages:

-

Absolute mixing precision – eliminates manual errors

-

Increased production speed and reduced cycle times

-

Consistent quality independent of operator skill

-

Reduced waste: closed mixing system minimizes environmental exposure

-

Customizable for specific products, materials or production cycles

-

Safer, cleaner operation with reduced direct chemical contact

PROSTECH – Complete Automated AB Epoxy Solutions

As Vietnam and Asia’s pioneer, PROSTECH provides turnkey automated 2K systems including:

-

2K metering-mixing machines

-

Specialized static/dynamic mixers

-

Application-specific robotic dispensing systems

-

Custom system design, integration, installation and commissioning

Contact PROSTECH today for system consultation and demonstrations!

Conclusion

Industrial epoxy adhesives are more than simple bonding agents – they represent comprehensive material solutions for demanding applications requiring durability, precision and extreme condition resistance. With exceptional adaptability, epoxies bond metals, plastics, rubber, wood and concrete, performing reliably in high-temperature, vibration, chemical or high-voltage environments. This makes them indispensable in EV, electronics, machinery, construction, medical and food industries.

In modern manufacturing where quality and speed are equally vital, selecting the right epoxy and application system determines productivity and effectiveness.

PROSTECH – Your Complete Industrial Epoxy Solutions Partner

PROSTECH proudly serves as Vietnam and Asia’s premier industrial material solutions provider, offering comprehensive capabilities:

-

Complete range of 1K and 2K epoxies for bonding, potting, encapsulation and circuit coating

-

Manual to fully automated dispensing systems

-

Technical consulting, lab testing and on-site support services

Contact PROSTECH today for expert guidance selecting the optimal epoxy solutions for your production and technical requirements!