Product Introduction

The GSP-300H hot melt glue precision screw valve is powered by a customized brushless servo motor, offering high torque and efficient transmission ratio. It features a precision-grade tungsten steel spiral assembly that ensures accurate dispensing. Maintenance is easy, with quick disassembly and assembly of the screw assembly. This product finds applications in industries such as STM, optoelectronics, 3C digital products, connectors, and more. Compatible fluids include hot melt, PUR hot melt adhesive, PUH hot melt adhesive, and other high-temperature sol fluids.

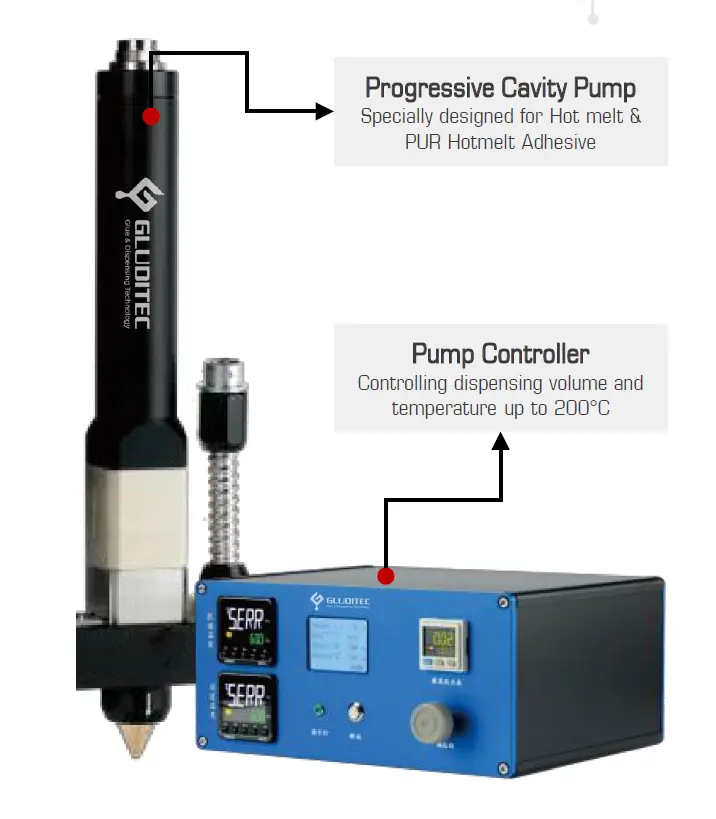

GSP-300H Features

- Motor Drive: Utilization of advanced precision brushless servo motor technology.

- Quick Setup: Streamlined assembly process with tungsten carbide screws and modern modular design.

- Enhanced Productivity: Implementation of an efficient screw conveying system to boost production rates effectively.

- Extended Lifespan: Utilization of replaceable cemented carbide screw assembly for prolonged durability.

- Increased Flow Capacity: Offering a range of pitch options for efficient fluid transport with large pitch feeding capability.

- Simple Upkeep: Easy disassembly and assembly with a modular tungsten carbide screw setup for maintenance convenience.

- Cost-effective Operation: Unique patented design structure that minimizes consumables, reducing maintenance expenses during production.

- Consistency: Long-lasting stability in dispensing operations achieved through the use of spiral fluid conveying method.

GSP-300H Applications

- Surface-mount technology (STM) processes

- Optoelectronics manufacturing

- 3C digital product assembly

- Connector production lines

- Dispensing of hot melt, PUR, PUH, and other high-temperature adhesives

About Prostech

Prostech offers specialty materials (adhesives, tapes, thermal interface materials, insulating materials, sealants, PCB protection materials, …) along with manufacturing solutions. We proudly serve a wide range of industries and are an authorized distributor for leading global manufacturers of industrial materials and equipment. Our product range is designed to deliver customized solutions that address each customer’s unique needs.

With years of experience and a successful project history, we are confident in our ability to provide comprehensive material solutions. These solutions effectively tackle the challenges manufacturers face. To explore our full product catalog, simply click here. Our dedicated team is ready to assist with:

- Provide quotation, sample, TDS/MSDS, and technical consultation

- Testing sample quality and verifying product compatibility in our laboratory

- Customizing material formulas for special applications

- Adapting product sizes, quantities, and packaging to meet specific needs

- Offering expert advice on suitable equipment and automation processes

- Delivering technical training and on-site support for optimal product use

Moreover, Prostech ensures the safe and accurate global delivery of all materials, including “dangerous goods”, in compliance with legal regulations. For personalized technical support or to receive a quotation, please contact us today.

GSP300H

| Model | GSP-300H |

|---|---|

| Dispensing method | Contact dispensing mode |

| Suitable for liquid types | PUR, PUH, hot melt adhesive high temperature dissolved fluid, etc |

| Applicable liquid viscosity | 10,000–2,000,000 cps |

| Operating frequency | Max: 400 rpm |

| Applicable needle type | Steel needles, custom-made needles |

| Glue supply air pressure | Body Max: 200°C Rubber Pail Max: 150°C |

| Valve Weight | 1000g |

| Dimensions (W x L x H) | 75 × 75 × 335 mm |

GSP-300H Controller

| Model | GSP-300H Controller |

|---|---|

| Control mode | Microcontroller embedded system |

| Dispensing time control | Digital Circuitry/ Parameterization |

| Power | AC220V/50Hz*120W |

| Weight | 2kg |

| Dimensions | L280mm * W240mm * H120mm |