Product Introduction

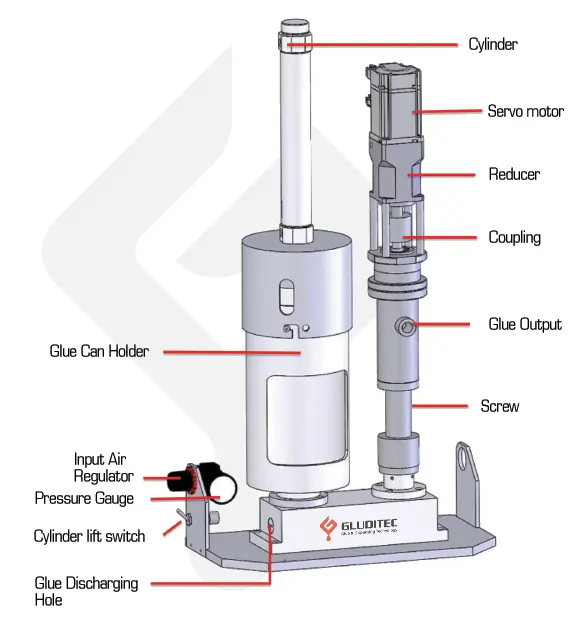

GSP-2600 glue supply system pushes the 2600cc packaging rubber drum and screw pump self-suction through the cylinder pressure, and the material flow rate is maintained at a constant pressure, combined with the precise time control of the on-off valve to ensure the dispensing volume and dispensing speed.

GSP-2600 Features

- Packaging Compatibility: Compatible with 2600cc silicone sleeves and sausage glue packaging, enabling fixed-weight dispensing.

- High-Viscosity Performance: Ideal for high-viscosity adhesives ranging from 10,000 to 1,000,000 cps.

- Pulsation-Free Dispensing: Effectively addresses glue breakage, volume instability, and uneven lines commonly caused by traditional pneumatic pressure pump pulsing.

- User-Friendly Interface: User-friendly design featuring a dedicated controller with a touchscreen, a low liquid level alarm, and adjustable glue volume via the controller’s speed setting.

- High Accuracy: High dispensing accuracy within ±3%, with a minimum dispensing amount of 0.03g and a maximum of 5g/s.

- Long Lifespan: Durable, cost-effective design with minimal part replacements required, ensuring a long service life.

- Compact and Integrable: Compact and easy to install, optimized for integration with automated systems.

GSP-2600 Applications

- Automated dispensing with 2600cc silicone or sausage-type glue packs

- High-viscosity glue applications in precision manufacturing

- Production lines requiring consistent, non-pulsing adhesive delivery

- Industries needing ±3% precision in controlled glue volume output

About Prostech

Prostech offers specialty materials (adhesives, tapes, thermal interface materials, insulating materials, sealants, PCB protection materials, …) along with manufacturing solutions. We proudly serve a wide range of industries and are an authorized distributor for leading global manufacturers of industrial materials and equipment. Our product range is designed to deliver customized solutions that address each customer’s unique needs.

With years of experience and a successful project history, we are confident in our ability to provide comprehensive material solutions. These solutions effectively tackle the challenges manufacturers face. To explore our full product catalog, simply click here. Our dedicated team is ready to assist with:

- Provide quotation, sample, TDS/MSDS, and technical consultation

- Testing sample quality and verifying product compatibility in our laboratory

- Customizing material formulas for special applications

- Adapting product sizes, quantities, and packaging to meet specific needs

- Offering expert advice on suitable equipment and automation processes

- Delivering technical training and on-site support for optimal product use

Moreover, Prostech ensures the safe and accurate global delivery of all materials, including “dangerous goods”, in compliance with legal regulations. For personalized technical support or to receive a quotation, please contact us today.

GSP-2600

| Properties | GSP-2600 |

|---|---|

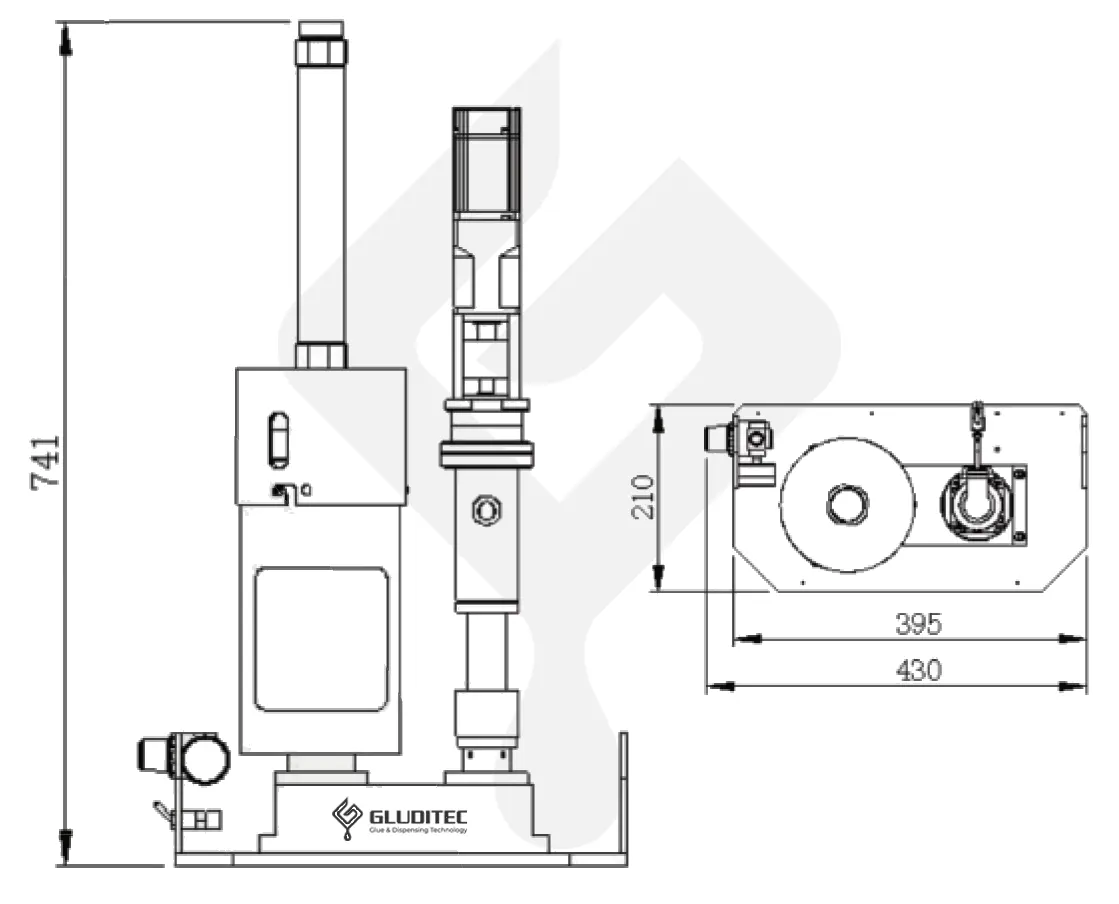

| External dimensions | L430 x W210 x H741 mm |

| Power | 400W |

| Air Input | 0.5 ~ 0.7 MPa |

| Cylinder thrust | 50kg (at air pressure 0.5Mpa) |

| Track length | 1500mm, customizable |

| Pumping method | Cylinder push + progressive cavity pump self-priming |

| Glue packaging | 2600cc |

| Output Volume Options | 1.5cc/ 6cc/ 9cc |

| Rotor material | Stainless steel |

| Stator material | Stainless steel + Extra wear-resistant rubber |

| Sealant material | PEEK/TEFLON/ Special rubber |

| Structural part material | Aluminum alloy anode/ stainless steel |

| Applicable material viscosity | <1,500,000 cps |

| Hardness of applicable material | <60HRC |

| Control mode | PLC control |

| Monitoring method | Closed-loop control of pressure sensors |

| Alarm alert | Lack of material alarm, abnormal pressure alarm |

CONFIGURATION

DRAWING