Product Introduction

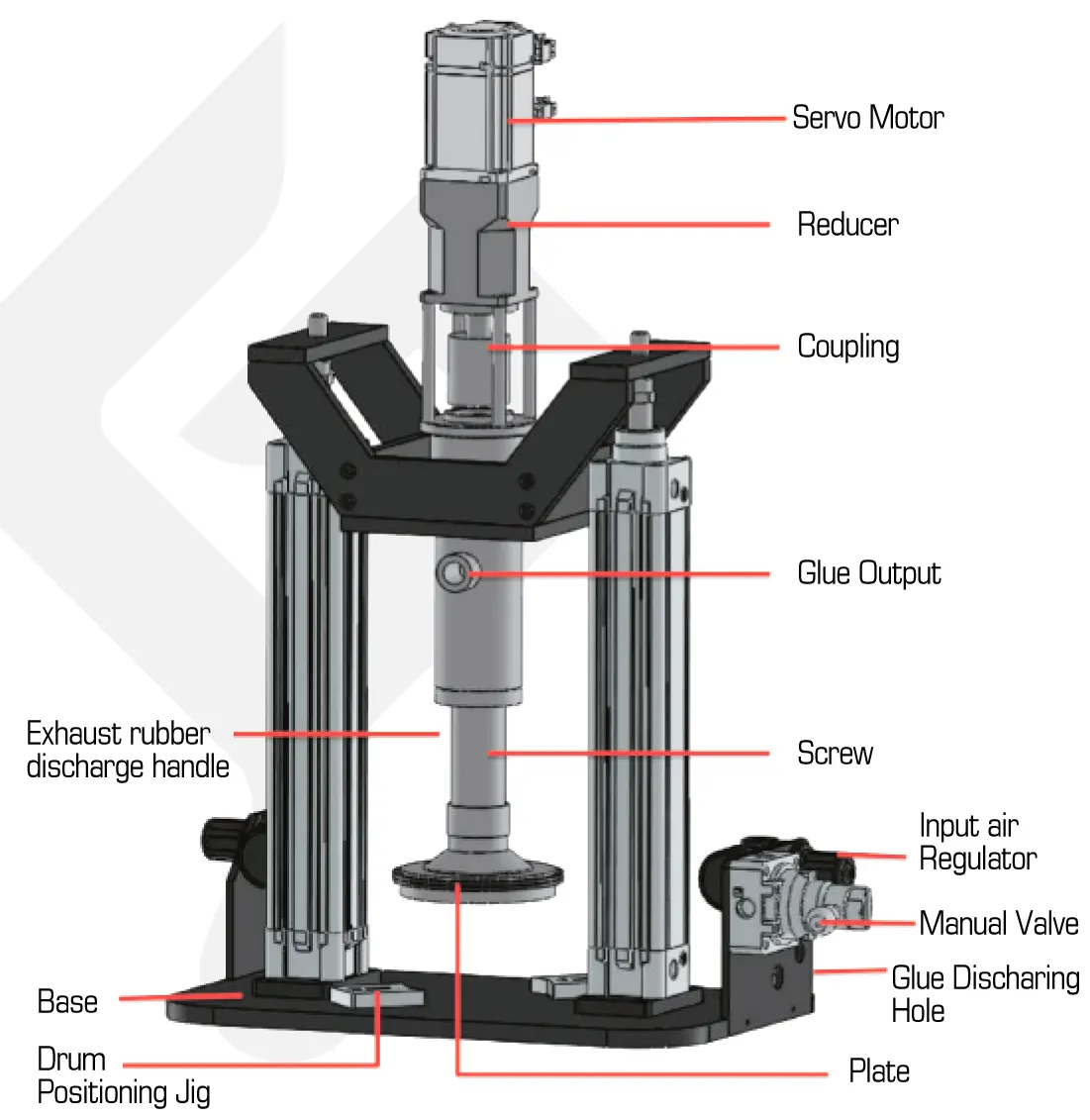

GSP-135 is a glue supply system pushing 1KG, 3KG, 5KG packaging drums and screw pump self-suction through the pressure of the cylinder, and the pressure is constant to maintain the material flow rate, combined with the precise time control of the on-off valve to ensure the dispensing amount and dispensing speed.

GSP-135 Features

- Direct Drum Usage: Directly use 1KG, 3KG, 5KG silica gel sleeve packaging method to achieve quantitative dispensing.

- High-Viscosity Compatibility: Suitable for high viscosity glue with viscosity of 10,000–1,000,000.

- Accurate Mechanical Extrusion: In view of the high viscosity of silica gel, the glue is dispensed by mechanical extrusion, and the glue output is more accurate. Different from the pneumatic pressure conveying method, the residue of gas in the silica gel is eliminated.

- Compact Design: Small appearance and easy operation. The external element ultra-precision dispensing valve realizes precision dispensing and greatly improves the production capacity and dispensing quality.

- Low-Level Alarm: The pump head comes with a glue low level alarm switch.

- Customizable Pressure Plate: The pressure plate can be customized according to the diameter of the barrel and is suitable for straight-through/cone barrel.

GSP-135 Applications

- Dispensing from 1KG–5KG silica gel packaging drums

- Industrial glue dispensing for high-viscosity adhesives

- Mechanical extrusion dispensing to improve accuracy and reduce gas residue

- Precision-controlled glue dosing in automated production lines

About Prostech

Prostech offers specialty materials (adhesives, tapes, thermal interface materials, insulating materials, sealants, PCB protection materials, …) along with manufacturing solutions. We proudly serve a wide range of industries and are an authorized distributor for leading global manufacturers of industrial materials and equipment. Our product range is designed to deliver customized solutions that address each customer’s unique needs.

With years of experience and a successful project history, we are confident in our ability to provide comprehensive material solutions. These solutions effectively tackle the challenges manufacturers face. To explore our full product catalog, simply click here. Our dedicated team is ready to assist with:

- Provide quotation, sample, TDS/MSDS, and technical consultation

- Testing sample quality and verifying product compatibility in our laboratory

- Customizing material formulas for special applications

- Adapting product sizes, quantities, and packaging to meet specific needs

- Offering expert advice on suitable equipment and automation processes

- Delivering technical training and on-site support for optimal product use

Moreover, Prostech ensures the safe and accurate global delivery of all materials, including “dangerous goods”, in compliance with legal regulations. For personalized technical support or to receive a quotation, please contact us today.

GPP-135

| Properties | GPP-135 |

|---|---|

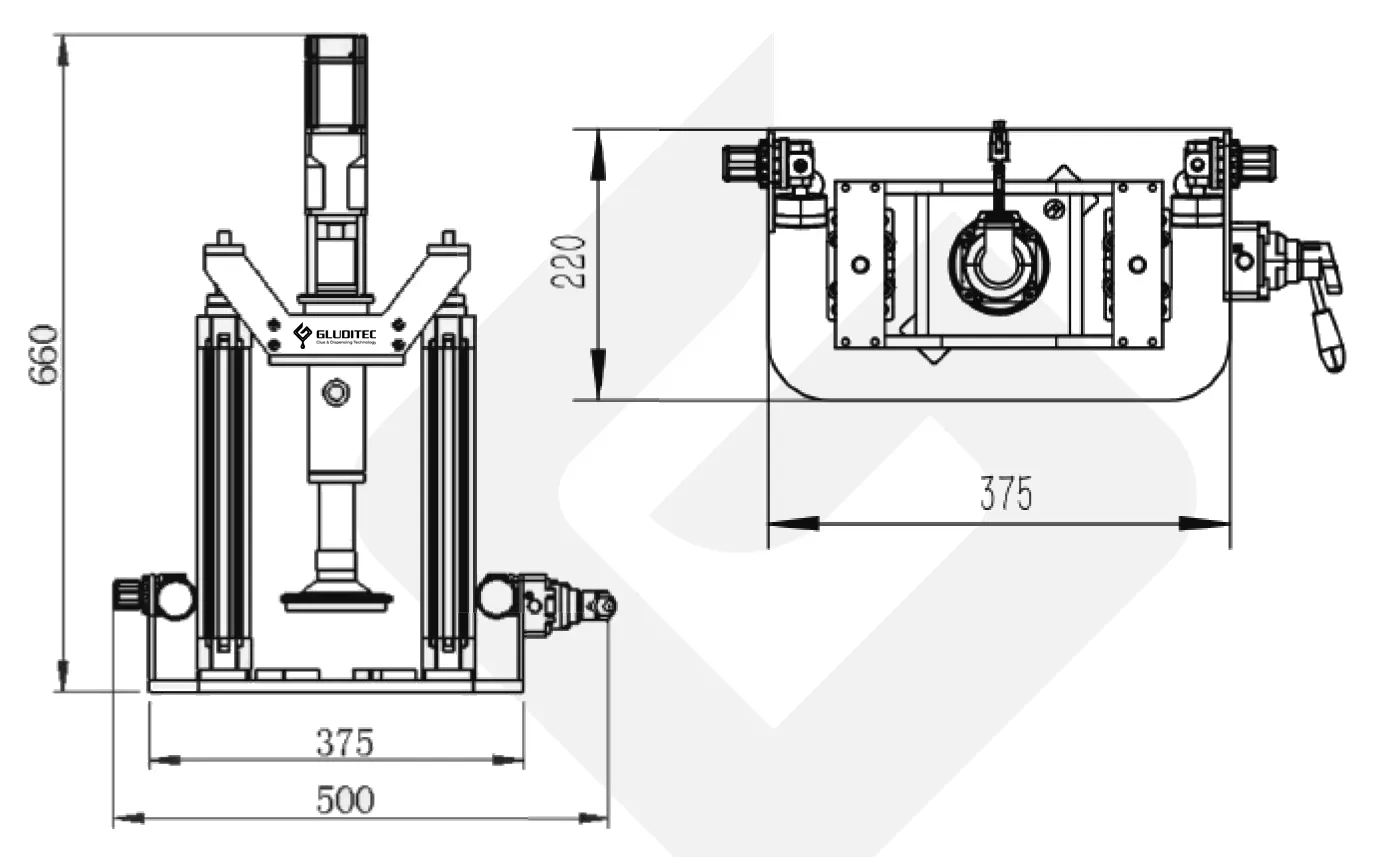

| External dimensions | L500 x W220 x H660 mm |

| Power | 400W |

| Air Input | 0.5 ~ 0.7 MPa |

| Cylinder thrust | 50kg (at air pressure 0.5Mpa) |

| Track length | 1500mm, customizable |

| Pumping method | Cylinder push + progressive cavity pump self-priming |

| Glue packaging | 1KG, 3KG, 5KG packing |

| Sealant material | PEEK/TEFLON/ Special rubber |

| Structural part material | Aluminum alloy anode/stainless steel |

| Applicable material viscosity | <1,500,000 cps |

| Hardness of applicable material | <60HRC |

| Control mode | PLC control |

| Monitoring method | Closed-loop control of pressure sensors |

| Alarm alert | Lack of material alarm, abnormal pressure alarm |

CONFIGURATION

DRAWING