- What Is a Progressive Cavity Pump?

- How Progressive Cavity Pumps Solve Industrial Dispensing Problems

- 1. High-Precision Volumetric Dispensing

- 2. Stable Output Regardless of Viscosity or Pressure

- 3. Low Shear Force: Protecting Adhesive Integrity

- 4. Built-in Reverse Suction: Clean Dispensing with No Drip

- 5. Robust Wear Resistance for Abrasive Materials

- 6. Solving Real Industrial Failures

- 7. Productivity, Cost Efficiency, and Flexibility

- Comparison with Other Pump Types

- Adhesives Compatibility

- Application Scenarios Across Industries

- Classification of Progressive Cavity Pumps for Adhesives

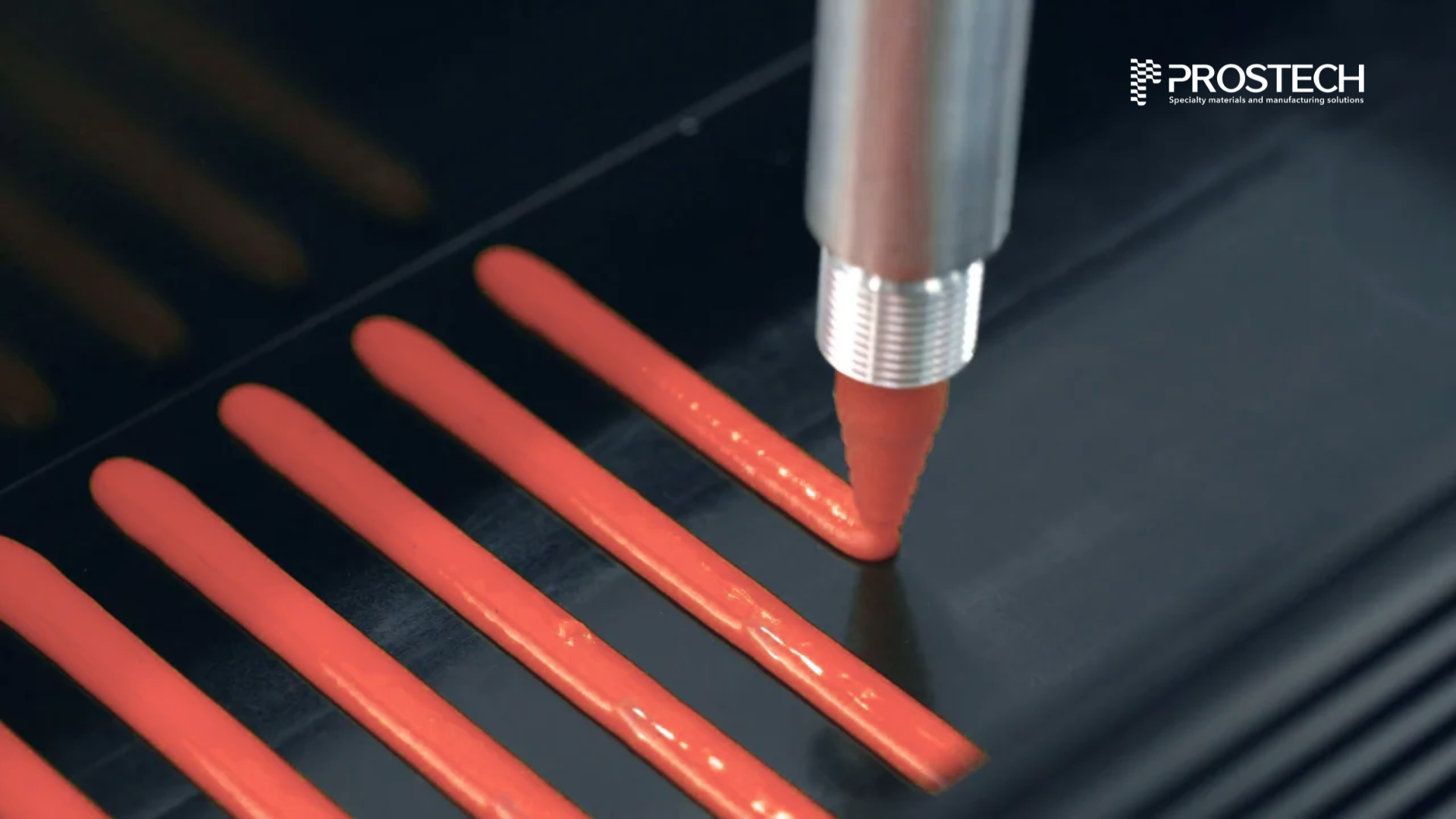

Progressive Cavity Pumps—also known as screw pumps—have become indispensable in today’s precision dispensing and automated manufacturing industries. Whether you’re working with high-viscosity adhesives, abrasive thermal gels, or sensitive medical sealants, these pumps offer unmatched control, accuracy, and reliability. Their unique ability to handle complex fluid properties with minimal shear and consistent output makes them a go-to choice for engineers and production teams seeking both performance and efficiency.

As modern industries evolve under the banner of Industry 4.0, the demand for smarter, more adaptable fluid dispensing solutions has skyrocketed. In this comprehensive guide, we’ll walk you through everything you need to know about Progressive Cavity Pumps—how they work, why they matter, where they’re used, and how they’re redefining standards in electronics, energy, medical, and aerospace sectors.

At Prostech, we specialize in delivering end-to-end manufacturing solutions—including Progressive Cavity Pumps (PCP) designed specifically for demanding dispensing tasks. Whether you’re dealing with challenging materials or complex application requirements, our deep expertise in both adhesives and precision dispensing systems ensures you get a solution that works flawlessly from material selection to final output.

Contact us today for expert consultation and let us help optimize your process with the right technology and technical support.

What Is a Progressive Cavity Pump?

A Progressive Cavity Pump (PCP)—often referred to as a screw dispensing pump, glue pump, or screw valve—is a type of positive displacement pump that offers precise, consistent, and pulsation-free fluid delivery. It has become a cornerstone in the field of precision adhesive dispensing, especially for high-performance manufacturing sectors such as electronics, automotive, and medical devices.

Structure and Working Principle of a Progressive Cavity Pump

A Progressive Cavity Pump (PCP) operates based on a simple yet highly effective rotor–stator mechanism. Its core components include:

-

Rotor: A single-helix metal shaft—typically crafted from hardened steel, tungsten carbide, or advanced ceramics—machined with high precision.

-

Stator: A double-helix elastomer sleeve that tightly envelops the rotor, forming a sequence of sealed cavities.

As the rotor turns inside the stator, these cavities progressively move forward, transporting the fluid from the inlet to the outlet in a smooth, continuous manner. This rotational extrusion mechanism ensures accurate, pulse-free flow, with each rotor revolution delivering a fixed volume—making it ideal for applications requiring high dosing precision.

Thanks to this design, PCPs outperform piston and diaphragm pumps in handling:

-

High-viscosity materials (e.g., >500,000 cps)

-

Thermal interface materials with solid fillers (e.g., aluminum oxide)

-

Thixotropic and shear-sensitive fluids

-

Chemically aggressive or reactive adhesives

This capability makes PCPs a reliable choice for industries demanding both precision and adaptability in fluid dispensing.

Key Design Components and Engineering Materials

To perform reliably across such diverse materials and environments, every part of the PCP is engineered for durability, chemical resistance, and precision control.

Rotor Materials

The rotor must withstand high torque, abrasive contact, and corrosive exposure. Common materials include:

-

Tungsten Carbide: Extremely hard, ideal for filled adhesives; significantly extends pump life.

-

Zirconium Oxide (ZrO₂): A corrosion-resistant ceramic used in chemically aggressive applications.

-

WC-Co (Tungsten Carbide-Cobalt): Balances hardness with mechanical toughness for long-term stability.

Stator Elastomers

The stator’s internal lining must flex with the rotor while resisting chemical swelling or fatigue:

-

EPDM: Suited for polar adhesives and general-purpose use.

-

PU (Polyurethane): Offers wear resistance but limited chemical resilience.

-

FFKM (Perfluoroelastomer): Industry-leading chemical resistance with minimal swelling—ideal for solvents or acids. Leakage rates drop to near-zero compared to standard rubbersInfluence mechanism and….

Motor and Control Systems

A PCP’s flow accuracy is directly linked to its motor and feedback system:

-

Swiss Maxon Servo Motors: Compact, responsive, and engineered for micro-volume control with sub-millisecond precision.

-

Closed-Loop Control: Real-time monitoring of speed, torque, and position enables ultra-stable dosing for both single- and two-component adhesives.

Common Synonyms and Industry Terms

Over time, various industries have adopted different names for the Progressive Cavity Pump depending on their specific application. You may encounter terms such as:

-

Screw dispensing pump – emphasizing its use in adhesive and fluid dispensing systems

-

Glue pump – emphasize the using of glue/ adhesive pump

-

Screw valve – highlighting its role in modular valve-based dispensing setups

No matter the name, all refer to the same reliable and versatile technology that continues to power next-generation production lines with unmatched accuracy and durability.

Historical Origin: René Moineau’s Invention

The origin of the progressive cavity pump dates back to 1930, when René Moineau, a French engineer and aviation enthusiast, patented the design. Moineau was inspired by his work on compressors and fluid mechanics, eventually leading him to develop a new type of pump capable of delivering a consistent flow regardless of pressure fluctuations. His invention laid the foundation for what we now call the Moineau pump, which remains the basis of all modern progressive cavity technologies.

How Progressive Cavity Pumps Solve Industrial Dispensing Problems

Progressive Cavity Pumps (PCPs)—also known as screw pumps—are increasingly becoming the gold standard in industrial adhesive dispensing. Their unique engineering allows them to tackle the toughest challenges in high-viscosity, abrasive, and sensitive material applications. From maintaining micro-level precision to resisting harsh wear conditions, PCPs bring a combination of performance, consistency, and adaptability that traditional dispensing technologies can’t match.

1. High-Precision Volumetric Dispensing

PCPs operate on a fixed-volume delivery principle—each rotor revolution dispenses an exact, repeatable quantity of material. This volumetric precision is crucial for high-value applications such as electronics, medical devices, and chip packaging, where CV (coefficient of variation) values below 1% are often required. It ensures consistent glue weight, accurate mixing ratios (for AB systems), and minimal waste.

2. Stable Output Regardless of Viscosity or Pressure

Unlike piston or diaphragm pumps that rely on air or pressure feedback, PCPs maintain independent, stable flow regardless of adhesive viscosity or backpressure in the system. Whether working with low-viscosity primers or ultra-high-viscosity thermal pastes (>500,000 cps), screw pumps keep the dispensing rate smooth and uninterrupted—ideal for non-stop 24/7 production lines.

3. Low Shear Force: Protecting Adhesive Integrity

PCPs are gentle on fluids. Their slow, progressive movement avoids the high-shear effects that can degrade shear-sensitive adhesives like UV-cured glues, cyanoacrylates, and thermally conductive gels. This makes them ideal for materials that would otherwise foam, separate, or lose performance during high-speed extrusion.

In real-world tests, the low-shear design also eliminated common issues like:

-

Bubble formation from aeration

-

Glue agglomeration or crystallization in hoses

-

Oil separation in two-component materials

4. Built-in Reverse Suction: Clean Dispensing with No Drip

PCPs are equipped with self-sealing capabilities and reverse suction. When the rotor reverses briefly after dispensing, it pulls back excess material at the nozzle tip—preventing glue trailing, stringing, or dripping. This function reduces the need for wipe-off mechanisms and keeps the production environment clean and consistent.

5. Robust Wear Resistance for Abrasive Materials

In industries dispensing filled adhesives like thermal gels or silver paste, equipment wear is a major concern. Screw pumps overcome this using:

-

Si₃N₄ (silicon nitride) rotors with Mohs hardness 9.4

-

NBR or FFKM stators for chemical resistance

-

Coated pump bodies to resist internal abrasion

Tests confirmed extended pump life even with highly abrasive, solid-filled adhesives. No pipe clogging or material buildup was recorded after 16 days of continuous operation.

6. Solving Real Industrial Failures

In practice, customers using conventional pumps experienced:

-

Frequent clogging and downtime

-

Bubble generation during thermal gel dispensing

-

Agglomeration and leakage in AB systems

After switching to PCP-based systems, they saw:

-

Stable output weight (CPK A+)

-

No signs of oil leakage or separation

-

Clean, clog-free pipelines even with 4.5-meter-long transfer hoses

These outcomes demonstrate how PCPs solve not just theoretical issues—but real production bottlenecks that directly impact yield and cost.

7. Productivity, Cost Efficiency, and Flexibility

By reducing:

-

Equipment downtime

-

Material waste

-

Cleaning and maintenance

-

Changeover times

PCPs enhance OEE (Overall Equipment Effectiveness) and lower total cost of ownership. Their modular design supports quick tool changes, while their compatibility with automation systems makes them ideal for Industry 4.0 environments.

In conclusion, Progressive Cavity Pumps aren’t just an upgrade—they’re a strategic solution for industries looking to dispense advanced adhesives more precisely, efficiently, and reliably. From thermal gel dispensing to semiconductor packaging and battery potting, PCPs are redefining what’s possible in high-performance fluid control.

Comparison with Other Pump Types

Choosing the right adhesive dispensing technology is critical for ensuring production efficiency, precision, and long-term equipment reliability. Here’s a comprehensive comparison of the three most common dispensing technologies: Gear Pump, Piston Pump, and Progressive Cavity Pump (PCP)—the technology behind Prostech’s high-performance dispensing solution.

| Performance Indicator | Gear Pump | Piston Pump | Progressive Cavity Pump (PCP) |

|---|---|---|---|

| Cartridge Compatibility | ✓ | ✓ | ✓ |

| Precision Volume Output | Medium | Medium | High |

| Two-Component (AB) Dispensing | Suitable | Suitable | Suitable |

| Continuous Line Dispensing | ✓ | ✗ | ✓ |

| Drip Control at Nozzle | ✓ | ✗ | ✓ (Built-in reverse suction) |

| Viscosity Range | Medium–High | Low–High (0–500,000 cps) | Low–High (0–500,000 cps) |

| Dispensing Accuracy | High | Medium | High |

| Tolerance for Complex Fluid Paths | Low | Medium | Medium |

| Sensitivity to Fluid Pressure/Shear | High | High | None |

| Bubble Generation Tendency | High | Low | Low |

| Shear Force on Fluid | High | Low | Low |

| Pulsation Level | High | Moderate | None |

-

Gear Pumps are simple and economical but fall short in material compatibility, and process control. They are not ideal for filled or shear-sensitive adhesives.

-

Piston Pumps offer high precision and are suitable for a wide viscosity range, but they can introduce pulsation, have slower response to dynamic control, and may suffer wear issues when dispensing abrasive or highly viscous fluids.

-

Progressive Cavity Pumps (PCP)—used in Prostech’s solution—combine pulse-free dispensing, low shear, and broad material compatibility with built-in reverse suction and excellent control across all flow conditions. They are especially effective for thermal gels, potting compounds, and high-precision applications that demand consistency and durability.

Prostech offers a full range of pump technologies tailored to your specific materials and application needs. Whether you’re working with high-viscosity adhesives, filled compounds, or require ultra-precise dosing, we’ll help you select the most suitable solution. Contact Prostech today for expert guidance and a customized recommendation.

Adhesives Compatibility

One of the standout strengths of Progressive Cavity Pumps is their exceptional versatility in handling a wide range of adhesive types and viscosities. From low-viscosity fluids to ultra-high viscosity adhesives exceeding 500,000 cps, these pumps maintain stable, consistent flow without pressure fluctuations or loss of precision.

Compatible with Challenging Adhesive Types:

Progressive Cavity Pumps are engineered to reliably dispense:

-

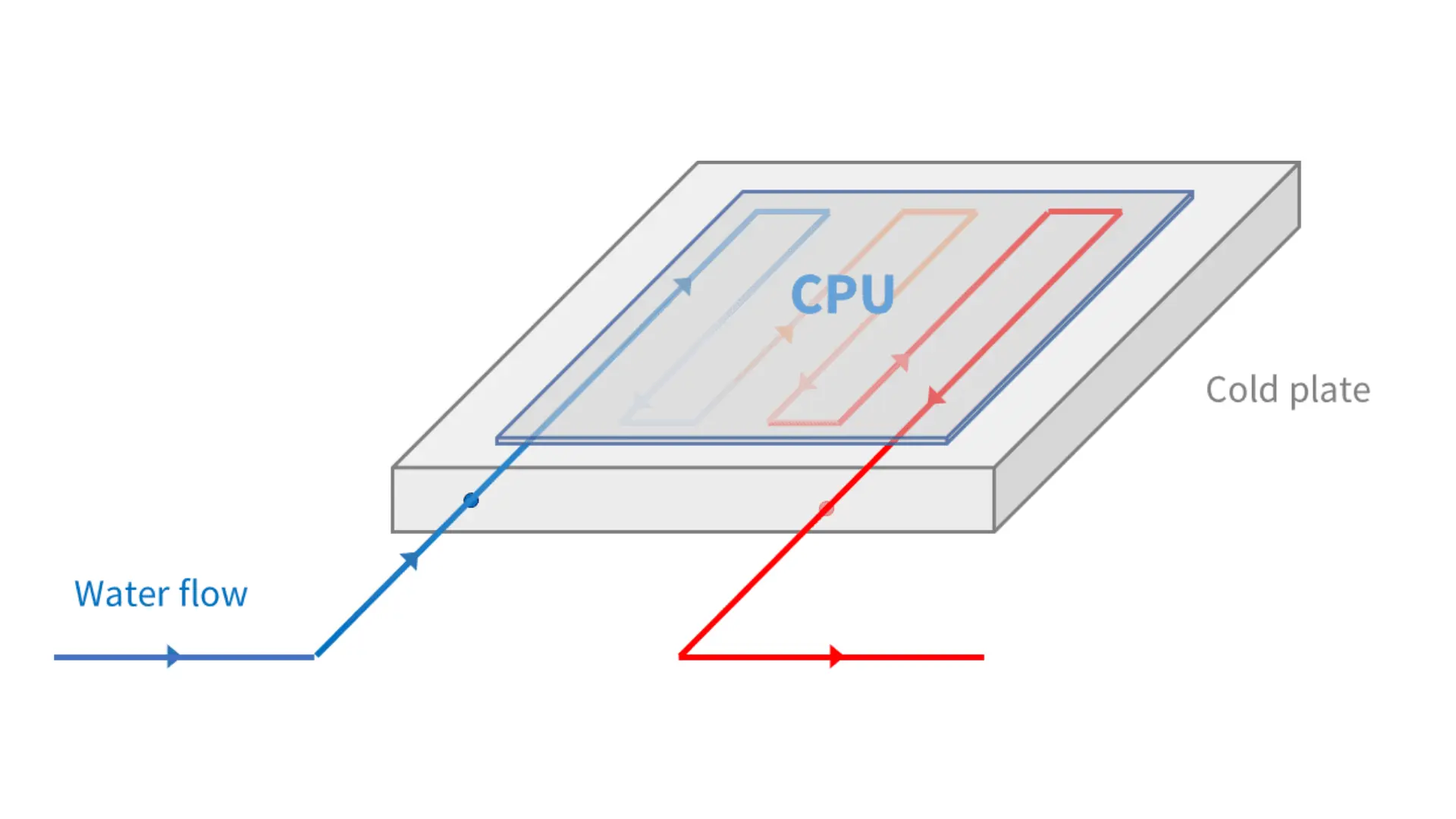

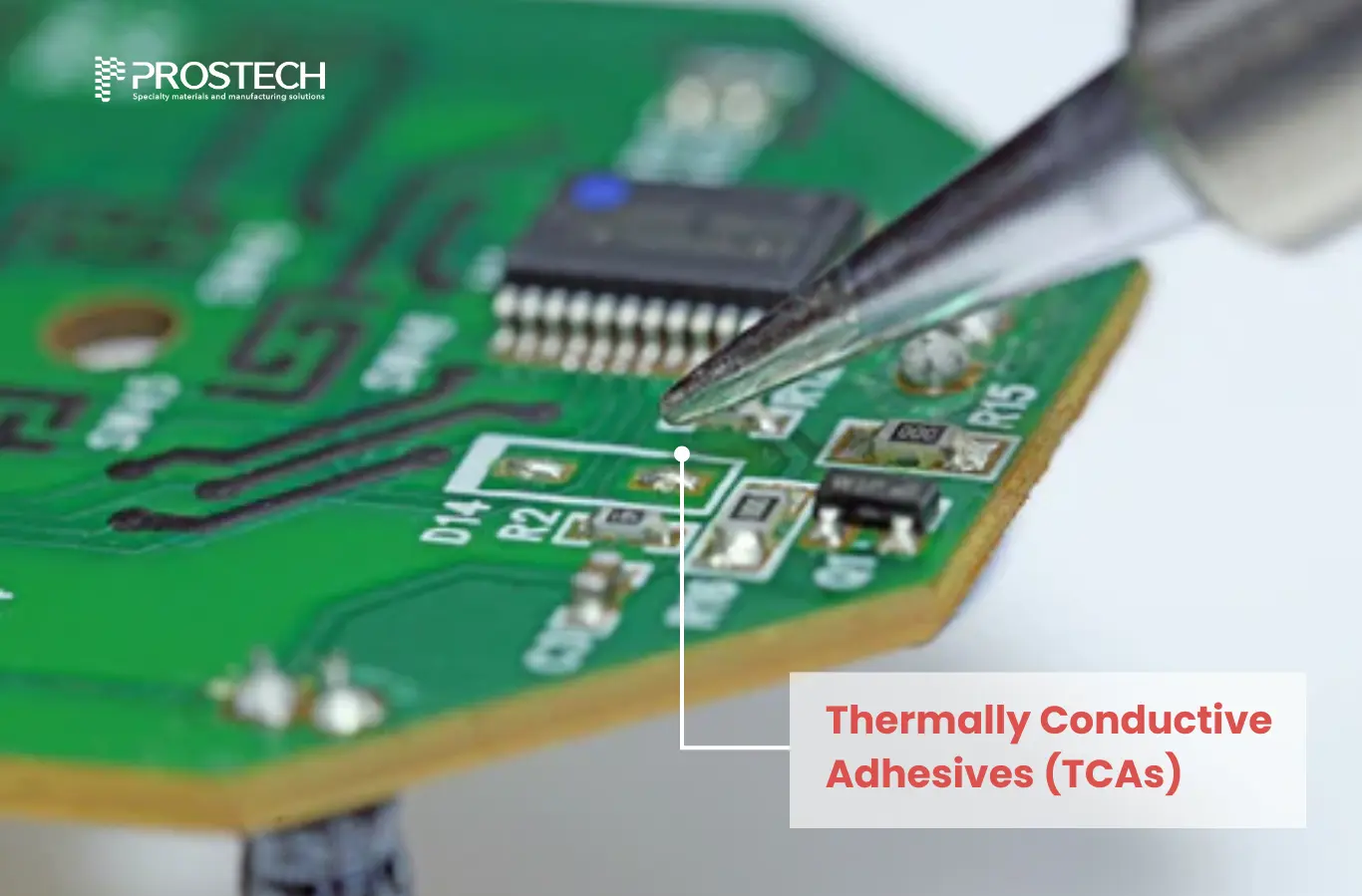

High-filler adhesives such as thermal interface gels and silver-filled pastes, which often contain abrasive particles that can damage traditional pump systems.

-

Chemically sensitive materials, including UV-cured glues and cyanoacrylates, which require low shear and minimal exposure to air or heat during dispensing.

-

Reactive two-component adhesives (AB glue) that demand precise ratio control and uniform mixing without introducing bubbles or separation.

These materials are essential in a wide range of critical dispensing applications, such as:

-

Bonding: structural, optical, and electronic component bonding

-

Sealing: housing, connectors, and gaskets for water, air, or dust protection

-

Potting and encapsulation: for power modules, PCBs, and transformers

-

Coating: protective layers for circuit boards or sensor surfaces

-

Dam & fill: used in LED packaging, underfill processes, and chip assembly

Whether you’re working in electronics, automotive, medical, or new energy industries, PCPs ensure that these adhesives are dispensed with high accuracy, low shear, and minimal waste.

At Prostech, we provide not only a complete range of advanced adhesives and thermal interface materials, but also the equipment and dispensing systems required to apply them—including high-performance Progressive Cavity Pumps.

Contact us today to get expert consultation on selecting the right material and dispensing solution tailored to your application needs.

Application Scenarios Across Industries

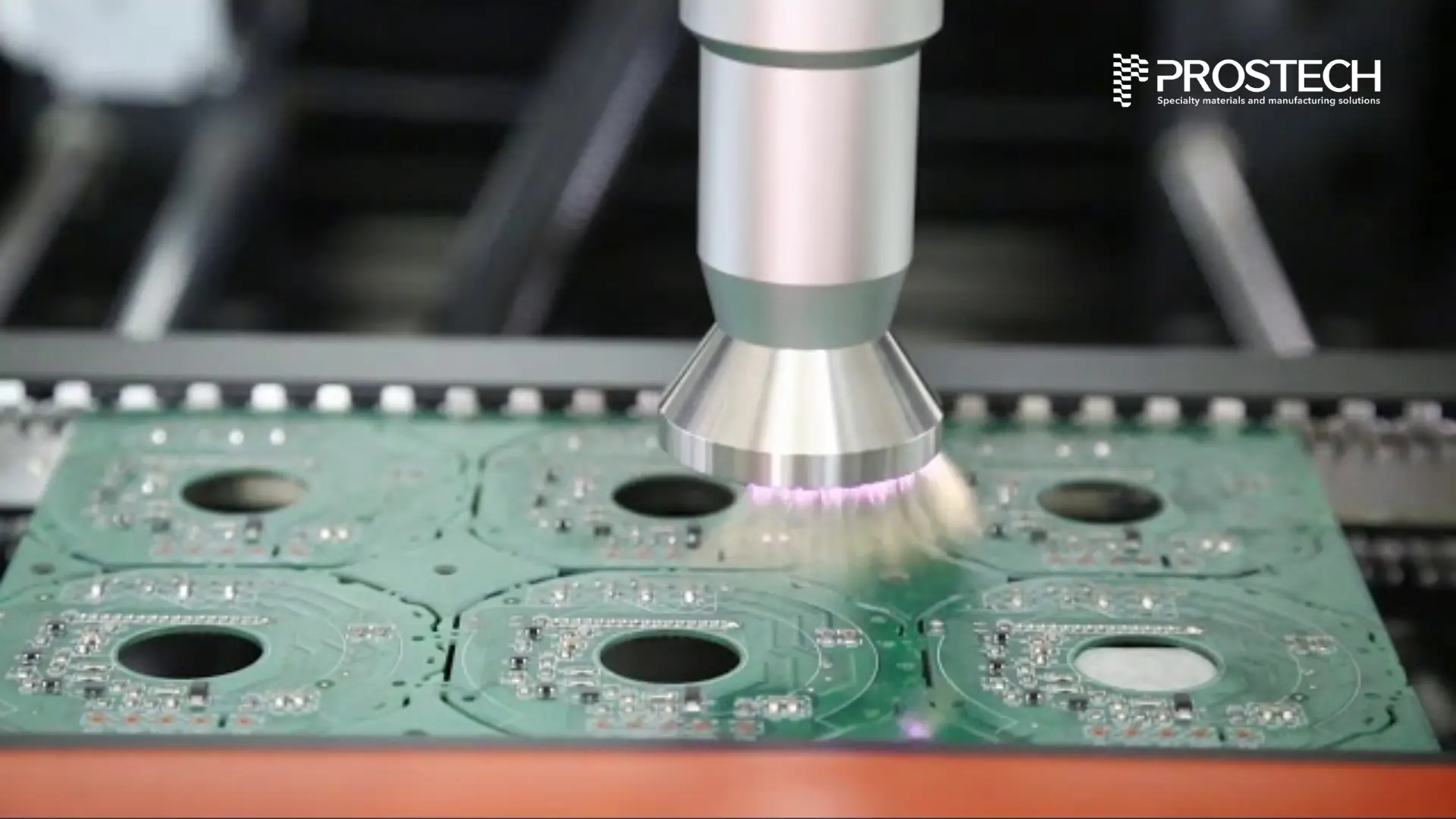

Progressive Cavity Pumps (PCPs) are trusted across a wide range of industries due to their ability to handle complex fluids with high precision and reliability. Here are some typical applications:

-

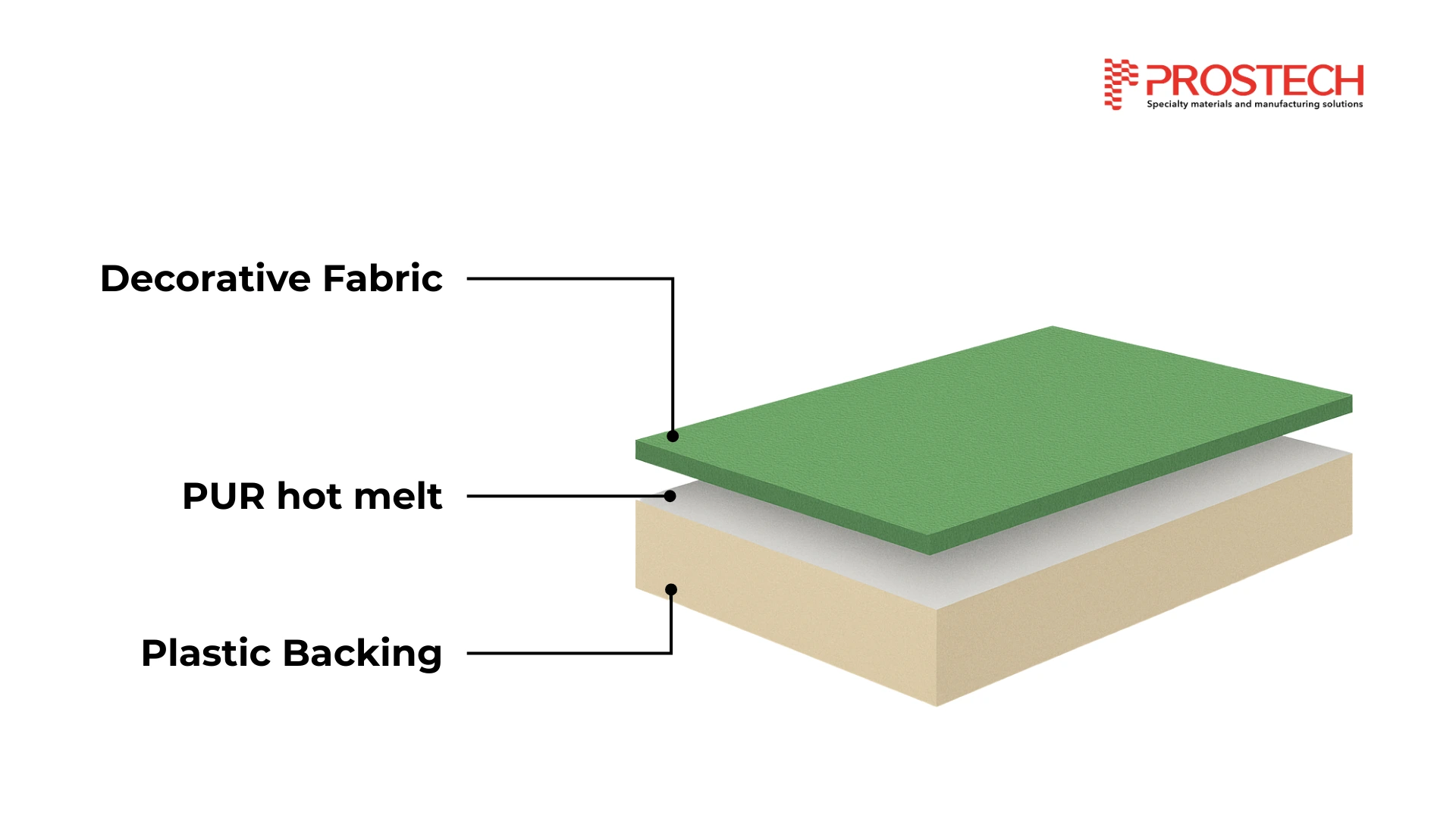

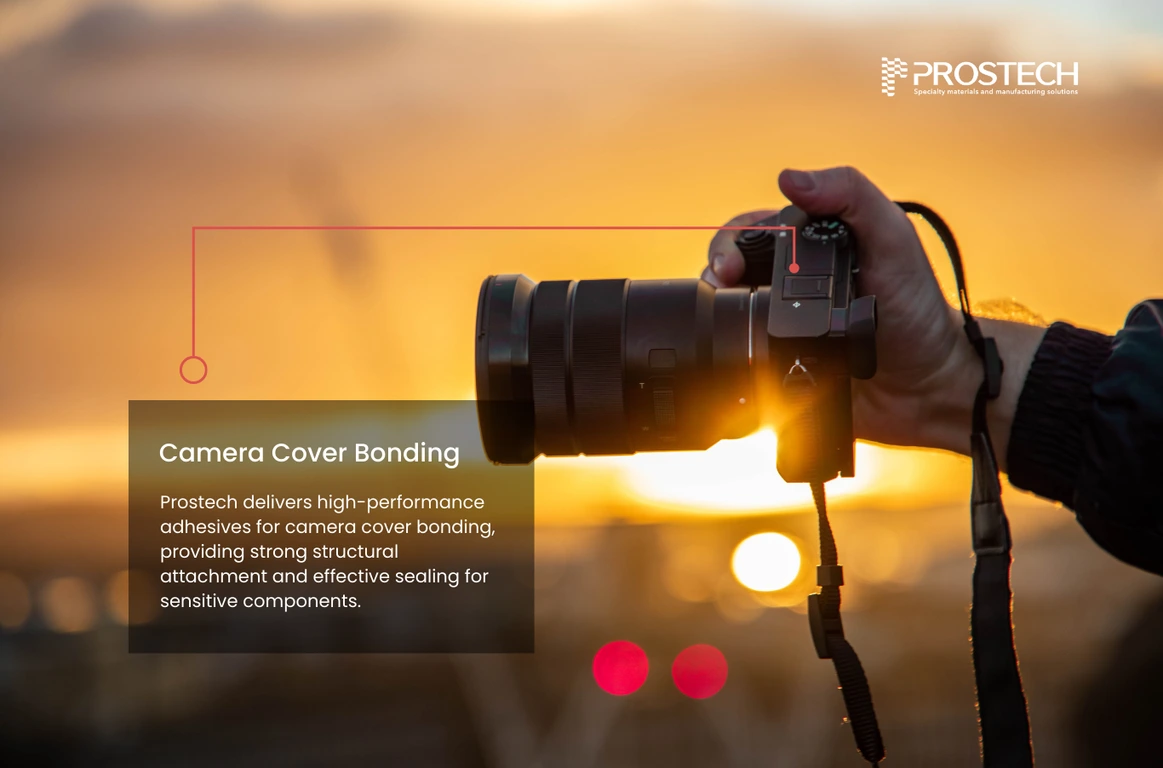

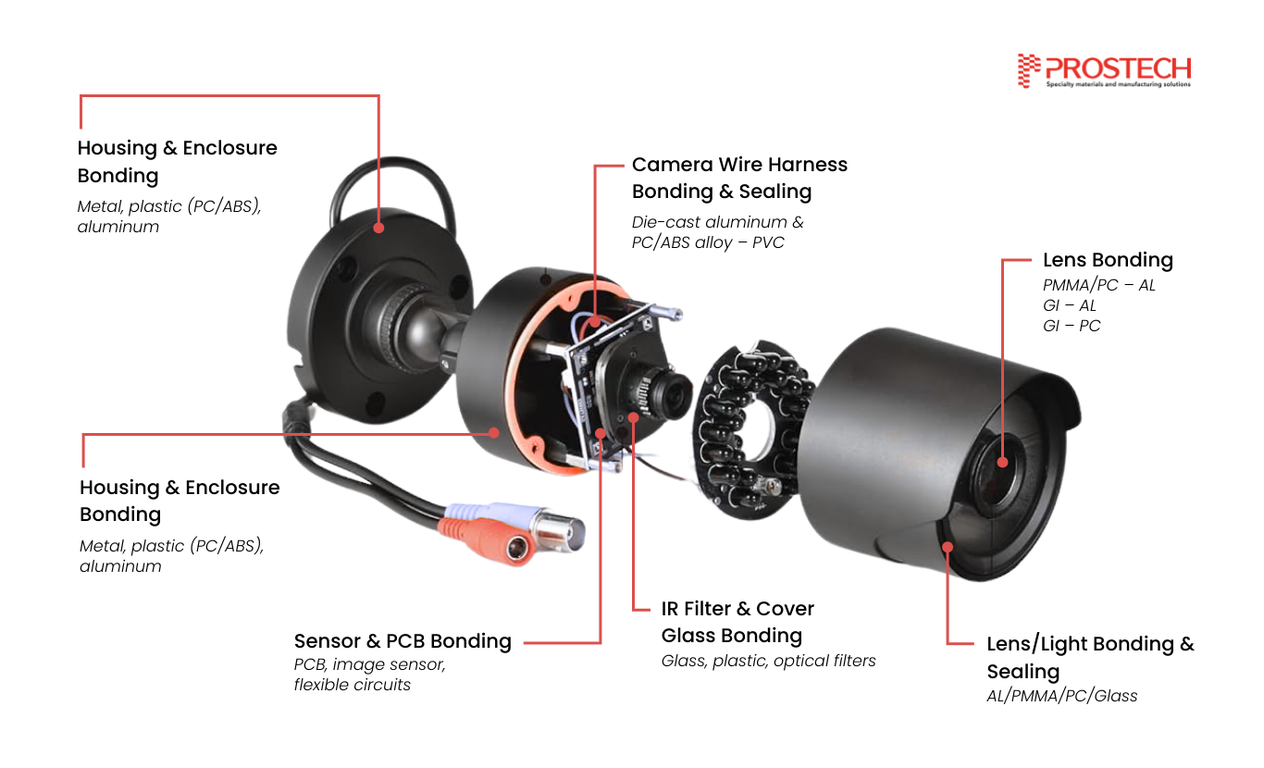

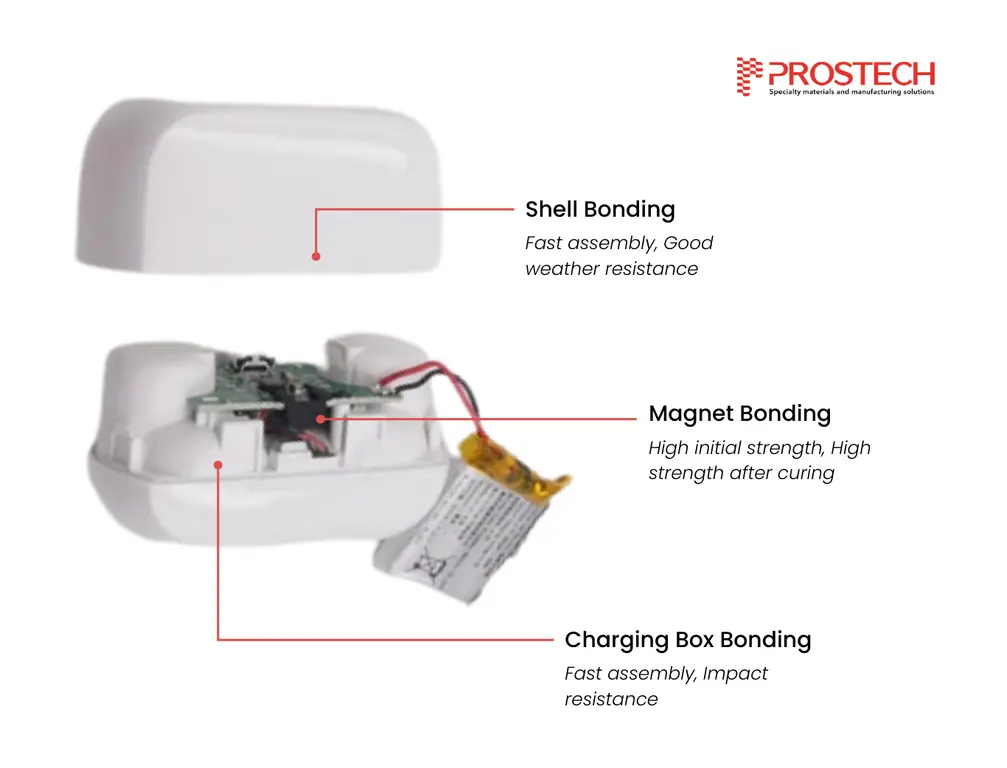

Electronics: Used for micro-dispensing in chip underfill, camera module bonding, and LED packaging. PCPs ensure precise volumes without bubbles—critical for high-density circuit reliability.

-

Automotive & New Energy: Ideal for potting battery modules, applying thermal interface materials, and sealing components. Their ability to dispense abrasive, high-viscosity adhesives with stable output makes them superior to piston pumps.

-

Medical Devices: Employed in assembling syringes, catheters, and insulin pens. Low-shear and drip-free dispensing prevents contamination and ensures compliance with strict quality standards.

-

Semiconductors: Perfect for dam & fill and capillary underfill processes, where ultra-fine control and clean flow are essential for protecting delicate chip structures.

Industries choose PCPs over traditional pumps because of their volumetric accuracy, non-pulsating flow, abrasion resistance, and compatibility with shear-sensitive or filled materials—making them indispensable for today’s precision manufacturing needs.

Classification of Progressive Cavity Pumps for Adhesives

Progressive Cavity Pumps (PCPs) are typically categorized based on their function in the adhesive dosing process. At Prostech, we provide PCP solutions tailored to specific application stages in adhesive dispensing workflows:

I. Bulk Unloader Progressive Cavity Pump – Feeding Adhesives to the System

-

Function: Transfers adhesive from its original container to the metering or dispensing system.

-

Compatible with Package Sizes:

-

330 ml cartridges

-

2600 ml sausage packs

-

1 kg / 3 kg / 5 kg pails

-

5-gallon drums

-

55-gallon drums

-

-

Application: Ideal for high-volume production lines where continuous material feeding is required without manual handling or interruption.

Check out recommended Prostech bulk unloader PCP products:

II. Volumetric Dispensing Progressive Cavity Pump – Dispensing Adhesives to the Substrate

-

Function: Precisely dispenses adhesive onto parts or substrates with controlled volume and flow rate.

-

Types Based on Adhesive System:

1. Single-Component (1K) Adhesive PCP

-

Designed for materials like silicones, polyurethanes, and epoxies

-

Consistent, pulse-free dispensing for bonding, sealing, or coating

Explore Prostech solutions for 1K adhesive PCPs:

2. Two-Component (2K) Adhesive PCP

-

Meter-mix-dispense compatible

-

Accurate ratio control for reactive systems (e.g., 1:1, 2:1, 10:1)

-

Ideal for potting, structural bonding, and encapsulation

Browse our 2K adhesive PCP options at Prostech: