Product Description of Polytec PU 1000

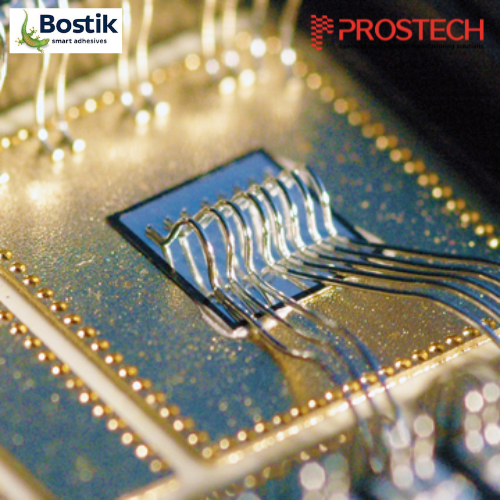

Polytec PU 1000 is a one-component, room temperature curing, highly flexible polyurethan eadhesive with excellent electrical conductivity. It has been specifically developed for contacting chip modules on dual interface smart cards. It is used in micro electronics, hybrid and electronic applications. Polytec PU 1000 cures at room temperature or accelerated with heat. It stands out due to its high flexibility combined with mechanical strength. It is also suitable for electrical contacting of copper surfaces The material can be applied by dispensing, jet dispensing or manually.

Application &Process of Polytec PU 1000

- Application: It is used in micro electronics, hybrid and electronic applications.

- Process:

-

It can be dispensed directly from the syringe.

-

For optimum storage stability we recommend storage in a fridge at 5-8°C. However, the product needs to be prevented from freezing, prolonged storage above 25 °C should be avoided.

-

Plastic needles are preferred for dispensing, since steel needles are prone to clogging. • Surfaces should be clean, thus free of dirt, grease, oil, dust or process chemicals.

-

For Safety information please refer to the respective Material Safety Data Sheet.

-

About Polytec

Bostik acquires Polytec PT GmbH, thereby strengthening its product offering for the fast-growing battery and electronics markets. Bostik is a multinational manufacturer of specialty adhesives and part of the listed specialty materials manufacturer Arkema, headquartered in Colombes near Paris, France.

Prostech is proud to be an authorized distributor of Bostik.

See all Bostik Product here

About Prostech

Prostech offers specialty materials (adhesives, tapes, thermal interface materials, insulating materials, sealants, PCB protection materials, …) along with manufacturing solutions. We proudly serve a wide range of industries and are an authorized distributor for leading global manufacturers of industrial materials and equipment. Our product range is designed to deliver customized solutions that address each customer’s unique needs.

With years of experience and a successful project history, we are confident in our ability to provide comprehensive material solutions. These solutions effectively tackle the challenges manufacturers face. To explore our full product catalog, simply click here. Our dedicated team is ready to assist with:

- Provide quotation, sample, TDS/MSDS, and technical consultation

- Testing sample quality and verifying product compatibility in our laboratory

- Customizing material formulas for special applications

- Adapting product sizes, quantities, and packaging to meet specific needs

- Offering expert advice on suitable equipment and automation processes

- Delivering technical training and on-site support for optimal product use

Moreover, Prostech ensures the safe and accurate global delivery of all materials, including “dangerous goods”, in compliance with legal regulations. For personalized technical support or to receive a quotation, please contact us today.

Properties in Uncured State

| Property | Method | Unit | Technical Data |

|---|---|---|---|

| Chemical Basis | – | – | Polyurethane Dispersion |

| Number of Components | – | – | 1 |

| Mixing Ratio (Weight) | – | – | – |

| Mixing Ratio (Volume) | – | – | – |

| Pot Life at 23°C | TM 702 | h | – |

| Storage Stability at 6-8°C | TM 701 | Months | 6 |

| Consistency | TM 101 | – | Creamy Paste |

| Density (Mix) | TM 201.2 | g/cm³ | 1.72 |

| Density (A-Part) | TM 201.2 | g/cm³ | – |

| Density (B-Part) | TM 201.2 | g/cm³ | – |

| Type of Filler | – | – | Silver |

| Maximum Particle Size | – | µm | <30 |

| Viscosity (Mix) 84 s⁻¹ at 23°C | TM 202.1 | mPa·s | 12,000 |

| Viscosity (A-Part) 84 s⁻¹ at 23°C | TM 202.1 | mPa·s | – |

| Viscosity (B-Part) 84 s⁻¹ at 23°C | TM 202.1 | mPa·s | – |