High green strength adhesive is rapidly gaining recognition across industries for their ability to deliver strong, reliable bonds almost instantly. In sectors like construction, automotive, and electronics, they have become indispensable for ensuring materials remain secure without delays. But what exactly is green strength, and why is it so important?

What is Green Strength?

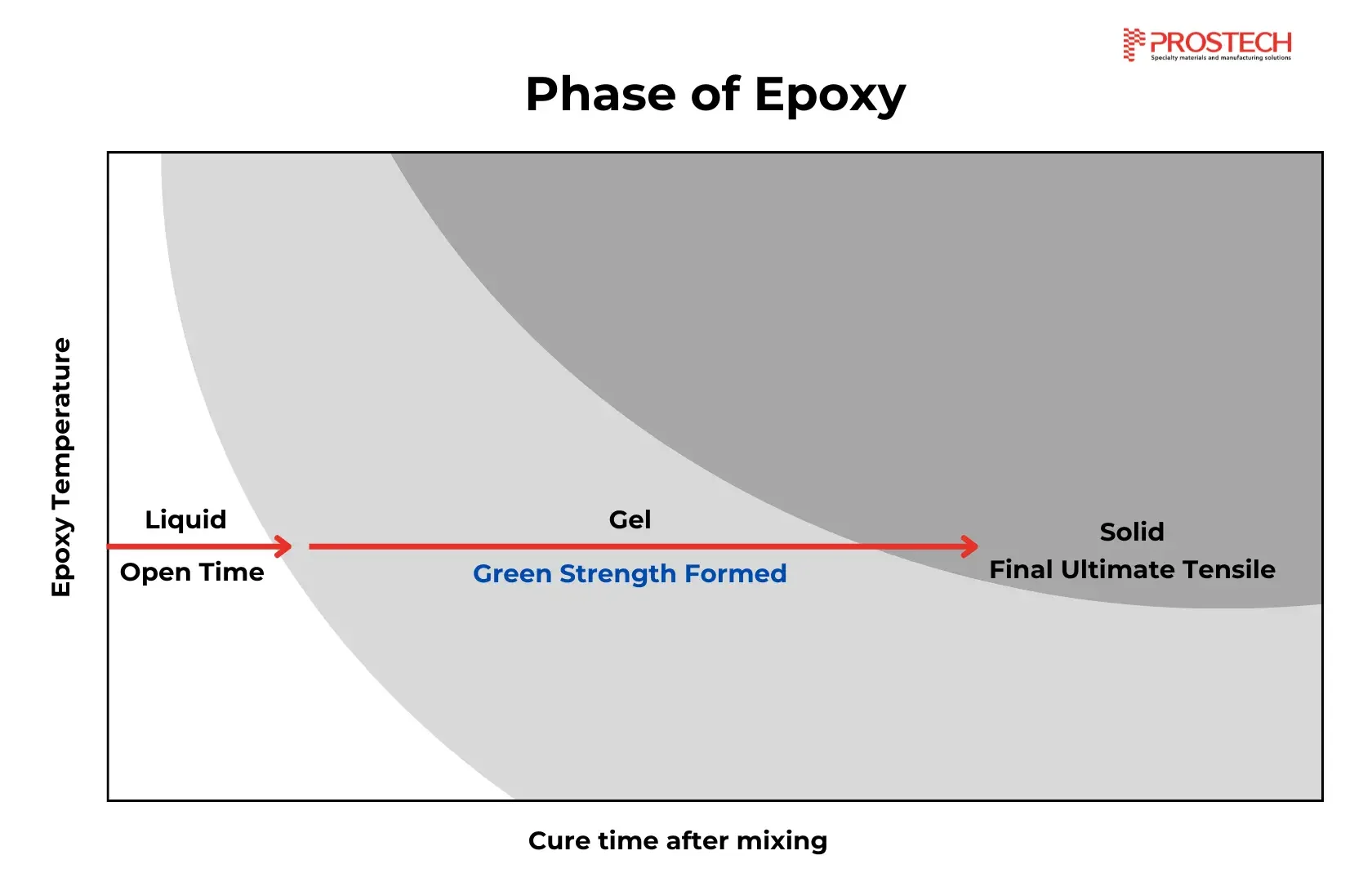

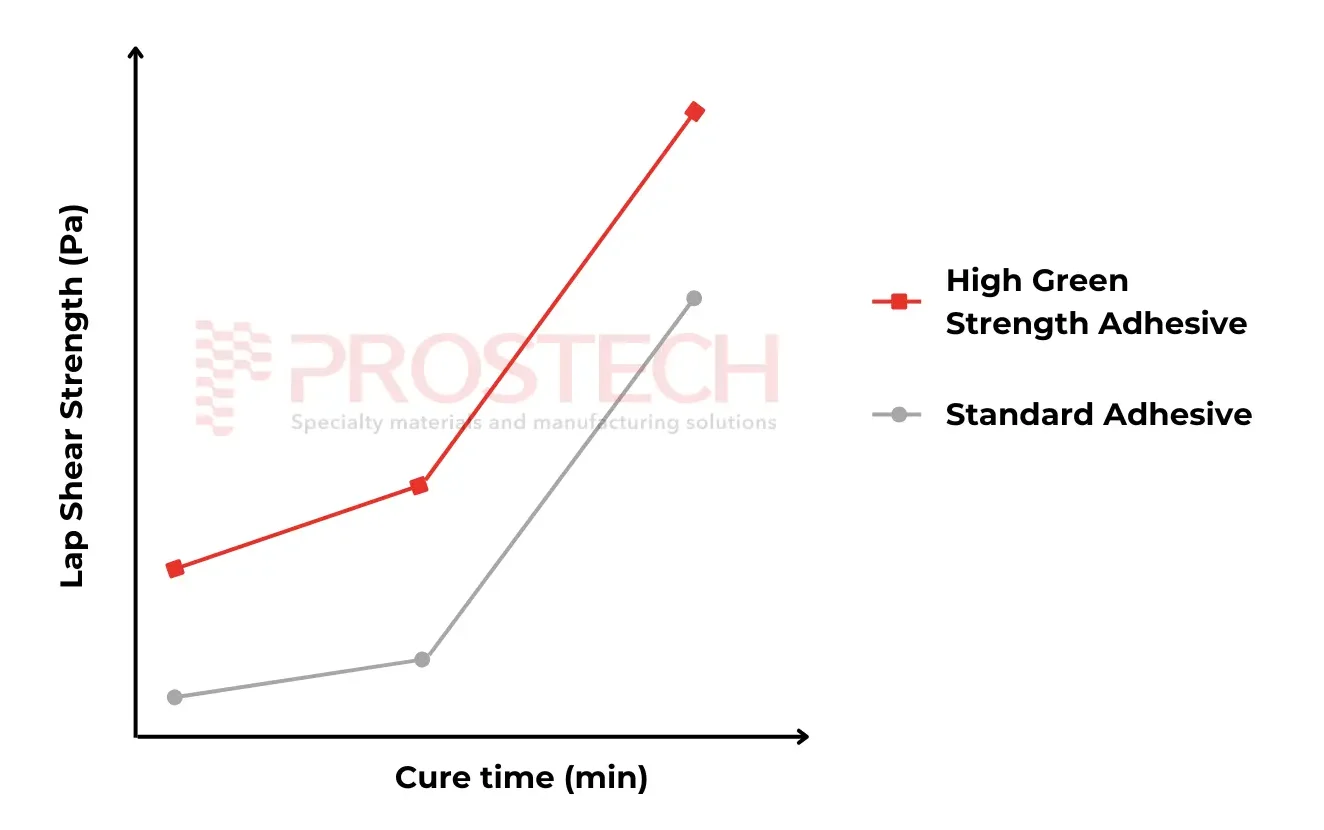

Green strength refers to the initial bond strength of an adhesive before it fully cures, typically much lower than the final tensile strength. It indicates that the adhesive bond is strong enough to handle materials shortly after they are joined, even before full curing is achieved.

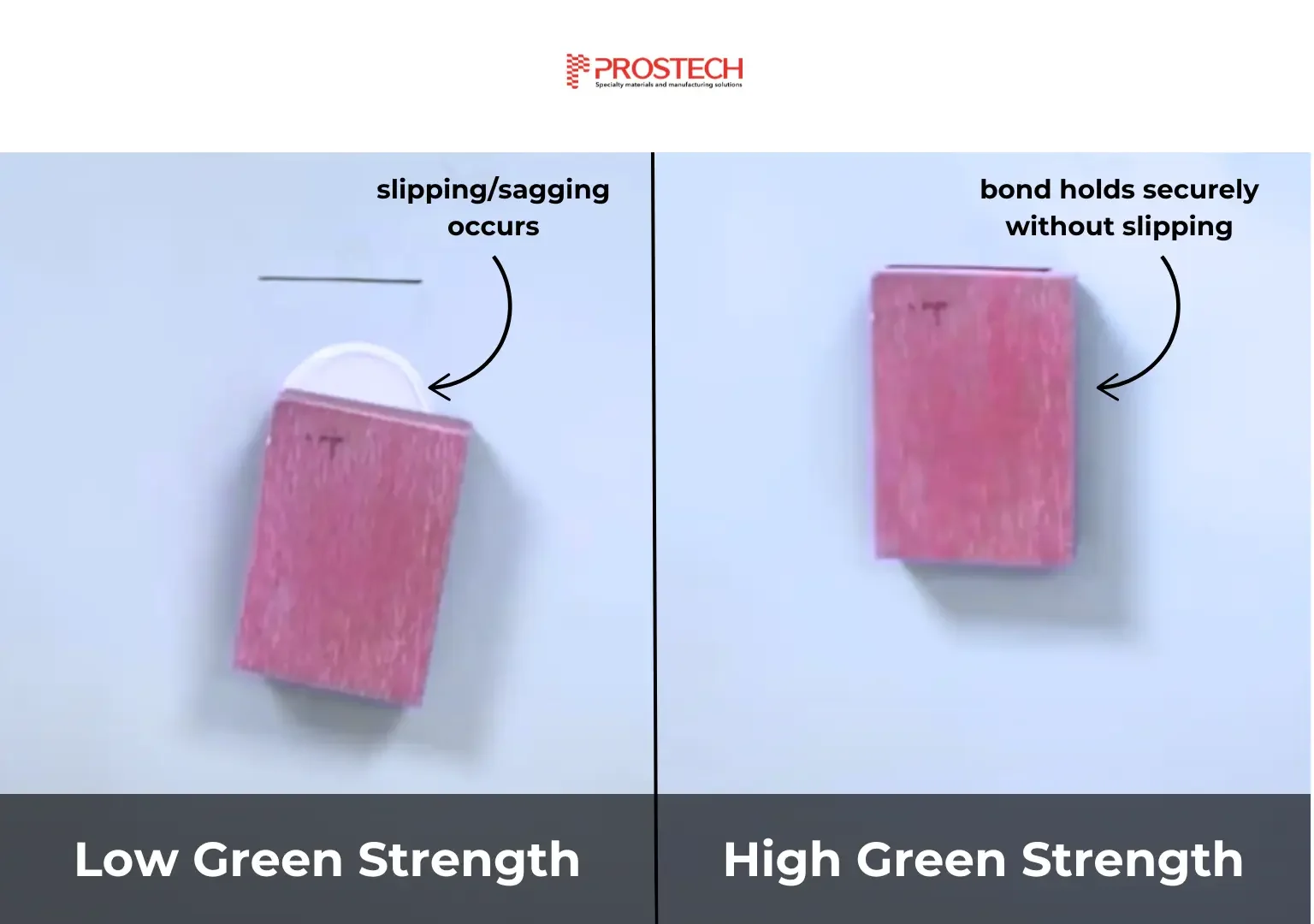

This property is crucial for ensuring bonded materials remain secure without slipping or shifting, especially in vertical applications or with heavy components. The required level of green strength can vary depending on the specific application. For some uses, the adhesive must be strong enough to hold components firmly in place, but not so strong that adjustments or repositioning become impossible. This balance is crucial in applications where precise alignment or temporary bonding is necessary before the adhesive fully cures.

Benefits of High Green Strength Adhesive

Faster assembly: High green strength adhesive allows production to proceed immediately after bonding, minimizing waiting times and reducing overall production time and complexity. This leads to significant cost savings and higher throughput, making them ideal for fast-paced assembly lines where minimizing downtime is essential for maintaining efficiency and meeting tight deadlines.

Versatility: These adhesives can bond a wide range of materials, including rigid PVC, polyurethane, composites, and lightweight substrates. Their adaptability makes them suitable for applications in various industries like automotive, construction, and electronics.

Better design flexibility: Adhesives offer unparalleled flexibility in design compared to mechanical fasteners. They enable engineers to bond lightweight materials and create unique part designs without compromising structural integrity. Unlike fasteners, adhesives don’t require additional space to be hidden, enhancing aesthetic appeal and consumer satisfaction.

Applications of Adhesives with Green Strength

High green strength adhesives are indispensable in industries where quick and reliable initial bonding is critical. Their versatility and performance make them suitable for a wide range of applications, including:

- Automotive Industry: High green strength adhesive provides immediate, secure bonds for components like body panels, interior trims, and lightweight materials, enabling faster and more efficient production processes. They eliminate the need for mechanical fasteners, reducing stress points and enabling more aerodynamic designs.

- Appliance Manufacturing: These adhesives work well with diverse materials such as plastics, metals, and composites, ensuring strong and durable bonds. Their quick bonding properties reduce production times, which is essential for high-volume manufacturing. By avoiding visible fasteners, adhesives contribute to the sleek design of modern appliances.

- Construction Industry: High green strength adhesive ensures that materials like tiles, drywall, and insulation panels stay securely in place, even on vertical surfaces. It is also ideal for bonding materials that require immediate load-bearing capacity, such as stone facades or glass panels.

- Electronics Assembly: These adhesives provide quick, reliable bonding for intricate and delicate parts, ensuring precision and reducing misalignment risks. This feature eliminates the need for heat, protecting sensitive electronic components and saving energy.

- Aerospace: High green strength adhesive is essential for bonding lightweight materials like composites and aluminum used in aircraft manufacturing. They provide temporary yet strong bonds during assembly, ensuring stability under demanding conditions.

Understanding Green Strength Variability

Green strength is influenced by more than just the adhesive’s formulation. It depends on several interrelated factors, such as:

- Surface Properties: The texture, porosity, and cleanliness of the bonded surface significantly affect the adhesive’s performance.

- Application Dynamics: Contact pressure, duration of contact, and separation rates all impact green strength results.

- Environmental Factors: Test conditions, including humidity and temperature, can alter adhesive behavior during the early bonding phase.

- Mechanical Stiffness: The rigidity or flexibility of the bonded materials also affects green strength outcomes.

These factors can lead to variations in performance under different test methods. For instance, loop and probe green strength tests may produce reversed rankings due to differing contact times, highlighting the complexity of green strength evaluation.

Selecting the right adhesive, especially one with high green strength, can be challenging due to the wide variety of materials, application conditions, and performance requirements involved. Factors like surface properties, environmental conditions, and specific bonding needs add complexity to the decision-making process. To ensure optimal results and avoid costly mistakes, it’s always best to consult with experts who can provide tailored recommendations based on your unique application. Their guidance can help you navigate the options and choose the adhesive that perfectly suits your needs. If you need consultation, feel free to contact us!

Product Recommendations

Prostech offers a variety of high green strength adhesives suitable for diverse applications. Notable products include:

|

|

This Silyl Modified Polymer (SMP)-based adhesive is designed for elastic construction joints requiring high strength. It is solvent-, isocyanate-, and PVC-free, offering high green strength and excellent workability. It adheres well to many substrates without the need for a primer and remains permanently elastic within temperatures from -40°F to 212°F (-40°C to 100°C). |

|

Polyurethane hot melt adhesives (PUR) Jowatherm-Reaktant 605.65 |

This adhesive is an “all-rounder” for processes involving thin thermoplastic foils, decor papers, or wrapping veneers with fleece-backing. It offers high green strength coupled with a short open time, making it suitable for general profile wrapping with high requirements |

|

|

This high-performance, two-part acrylic adhesive provides excellent shear, peel, and impact strength. It features a 10:1 mix ratio and offers a variety of open times, making it suitable for bonding metals, plastics, and composites |

Prostech provides a comprehensive range of adhesives with green strength to meet diverse application needs. Our expert technical advisors are here to assist you in selecting the most suitable adhesive for your specific requirements. For personalized technical guidance, please reach out by providing your information below.