The issue of storage costs and adhesive quality are factors that manufacturers are concerned about when choosing industrial adhesives. One-component adhesives often require strict storage conditions and have high storage costs because their chemical properties will be affected if not stored properly.

Meanwhile, AB glue, also known as two-component adhesive, allows users to mix part A and part B directly before use. This can minimize the risk of glue decomposition without requiring strict storage conditions. Thanks to that, AB glue has become a popular choice in many industries. This article will provide an overview of AB glue, from its structure, operating mechanism to its practical applications and benefits.

What is AB glue?

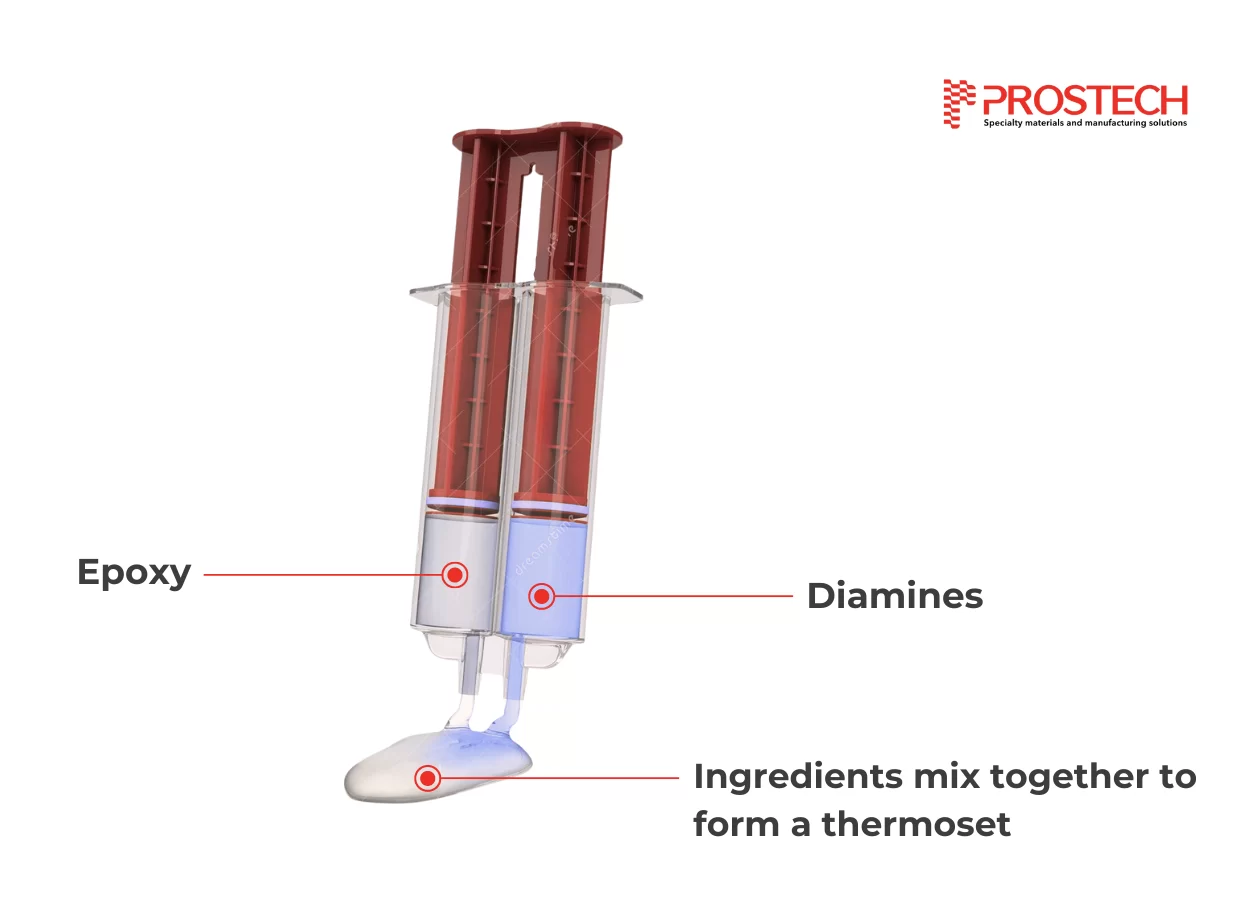

AB glue, also known as two-component adhesive, is a type of glue made up of two main parts: part A – the glue (usually epoxy, silicone,…) and part B – the hardener. When these two components are mixed together, a chemical reaction occurs, creating a strong glue that can adhere to many material surfaces.

AB glue is usually made from epoxy, acrylic and polyurethane which are thermosetting polymers with good mechanical strength and chemical resistance.

Structure and working mechanism of AB glue

AB glue consists of two main components:

Component A – glue: This is the component that determines the adhesive ability and mechanical properties of the glue. Usually from thermosetting polymers with good mechanical strength and chemical resistance such as:

Component B – hardener: The hardeners have a general role in helping to enable the hardening process of the glue. Each type of glue will have a suitable type of hardener:

- Epoxy curing agents are usually amines, amides, anhydrides or acids.

- PU curing agents are isocyanate compounds.

- Acrylic curing agents are usually peroxides, amines, azo compounds and quinones.

When these two components are mixed, a chemical reaction occurs, creating a strong polymer network. This process causes the adhesive to change from a liquid state to a solid state, creating a strong bond between the surfaces being bonded.

How to use AB glue?

Two-component adhesives have a special process for application. You can measure and mix the adhesive manually or by machine, or using AB adhesive tubes (also known twin syringe or 2-component adhesive tubes) is a very efficient technique. In these syringe, the two components of the adhesive are packaged separately, with a typical mixing ratio of 1:1, 2:1 or 10:1 by volume, depending on the specific formulation. The two components are then pumped through a static mixer (called a mixing tube) using a suitable dispensing gun, which can be manual or pneumatic. This adhesive mixture is then pumped onto the surface of the material to be bonded. As the adhesive cures, it bonds one material to another and holds the parts together.

Characteristics of AB glue

- Fast curing at room temperature: Some types of glue usually take only a few minutes to a few hours depending on the mixing formula, saving time during construction and production.

- High strength bonding: After hardening, the glue can withstand high tension and compression, ensuring that the joints do not break or separate under pressure.

- Resistance to chemicals and high temperatures: AB glue can resist chemicals such as acids, alkalis, solvents or mechanical abrasion and withstand high temperatures without losing properties, suitable for applications in harsh environments such as in industrial equipment or engines.

- Simple equipment: Simple mixing tools, easy to use and no need for high temperatures for curing, thereby reducing dependence on heating equipment, saving costs and energy.

However, during the application process, this type of glue has some limitations such as difficulty in rework, requiring precise mixing ratios or the existence of air bubbles, etc. To use AB glue effectively, manufacturers need to pay attention to some aspects when using in order to choose the appropriate type of adhesive and application process and optimize the production process. With many years of experience in the adhesive technology, Prostech is proud to provide customers with professional advice on AB adhesive suitable for each specific application. Please contact us for more details!

Applications of AB glue

AB adhesives (two-component adhesives) are among the first choice for applications requiring extremely high strength, typically used to bond materials such as bare, coated, painted or pre-treated metals, and composite materials such as glass-reinforced plastics (GRP + SMC) or carbon-fiber reinforced plastics (aramid, carbon, CFC). They are also suitable for bonding between other metals or composites, and solid materials such as ceramics or glass (transparent epoxy adhesives).

Two-component adhesive is suitable for some applications such as::

- Construction/transportation (automotives, railway vehicles, aircraft)

- Mechanical engineering, machinery, equipment and housing construction

- Medical Electronic Devices

- Electrical and electronic manufacturing

- Assembly linkage

- Engineered consumer goods (household appliances)

- Prefabricated building components

- Doors/gates

Popular AB glue brands on the market

- Permabond is a well-known adhesive brand with over 50 years of experience in the adhesives industry. They offer a wide range of epoxy adhesives with different properties, suitable for many applications.

Typical products: PERMABOND® ET530, PERMABOND® ET5147, PERMABOND® ET5003, PERMABOND® ET505 - Loctite is owned by the Henkel Group, one of the most famous adhesive brands in the world. Their products are used in many industries, from automotive to electronics

Typical products: LOCTITE® EA M-31CL™, LOCTITE® EA M-21HP™ - Gluditec is an adhesive brand specializing in industrial and construction adhesive solutions. Their products are known for their stable quality and reasonable prices.

Typical products: GLT A585-45, GLT C369-2, GLT A595-2 - Huntsman is a chemical corporation that provides a wide range of high quality epoxy adhesives for industrial applications.

Typical products: Araldite AV 138M-1 và Hardener HV 998, Araldite AW 139-1 / Hardener HW 5323, Araldite AW 4752 / Hardener HW 4753

Prostech is an authorized distributor of two-component adhesives from famous brands such as Permabond, Huntsman, Gluditec, etc. With many years of experience, Prostech has provided products to thousands of large and small manufacturers nationwide.

To optimize production efficiency and improve product quality, Prostech’s two-component adhesive solutions are committed to providing customers with superior experiences with its products and services. For free consultation on the type of AB glue suitable for your application, contact us now!