Exploring the world of Electric Vehicles (EVs) involves understanding the sophisticated array of sensors that power these innovative machines. EV sensors play a pivotal role in monitoring, controlling, and optimizing various aspects of electric vehicles’ performance and safety. From measuring battery health to regulating motor torque, each sensor brings unique functionalities to the table. There are several parameters about measurement principles to consider in the sensor system of electric vehicles, such as position, current, voltage, and temperature. In this comprehensive post, we will explore various types of EV sensors corresponding to the mentioned parameters and their standout features, shedding light on the technology driving the future of automotive engineering.

1/ Position

|

Sensor types |

Location |

Features |

|

Motor control position |

Estimates the traction motor position using a resolver to control brushless DC operation. |

Gathering the mechanical motion data from the traction motors to guarantee that the system runs in harmony. After the angular position data is recorded, a motor controller or motor control unit (MCU) converts it into electric impulses to start the feedback loop. |

|

Motor control angle |

Estimates the traction motor angle using a resolver to control brushless DC operation. |

|

|

Motor control speed |

Estimates the traction motor speed using a resolver to control brushless DC operation. |

‘Click on this article to explore a comprehensive and detailed source of information about silicone material solutions for components in electric vehicles researched and provided by Prostech.’

2/ Current

|

Sensor types |

Location |

Features |

|

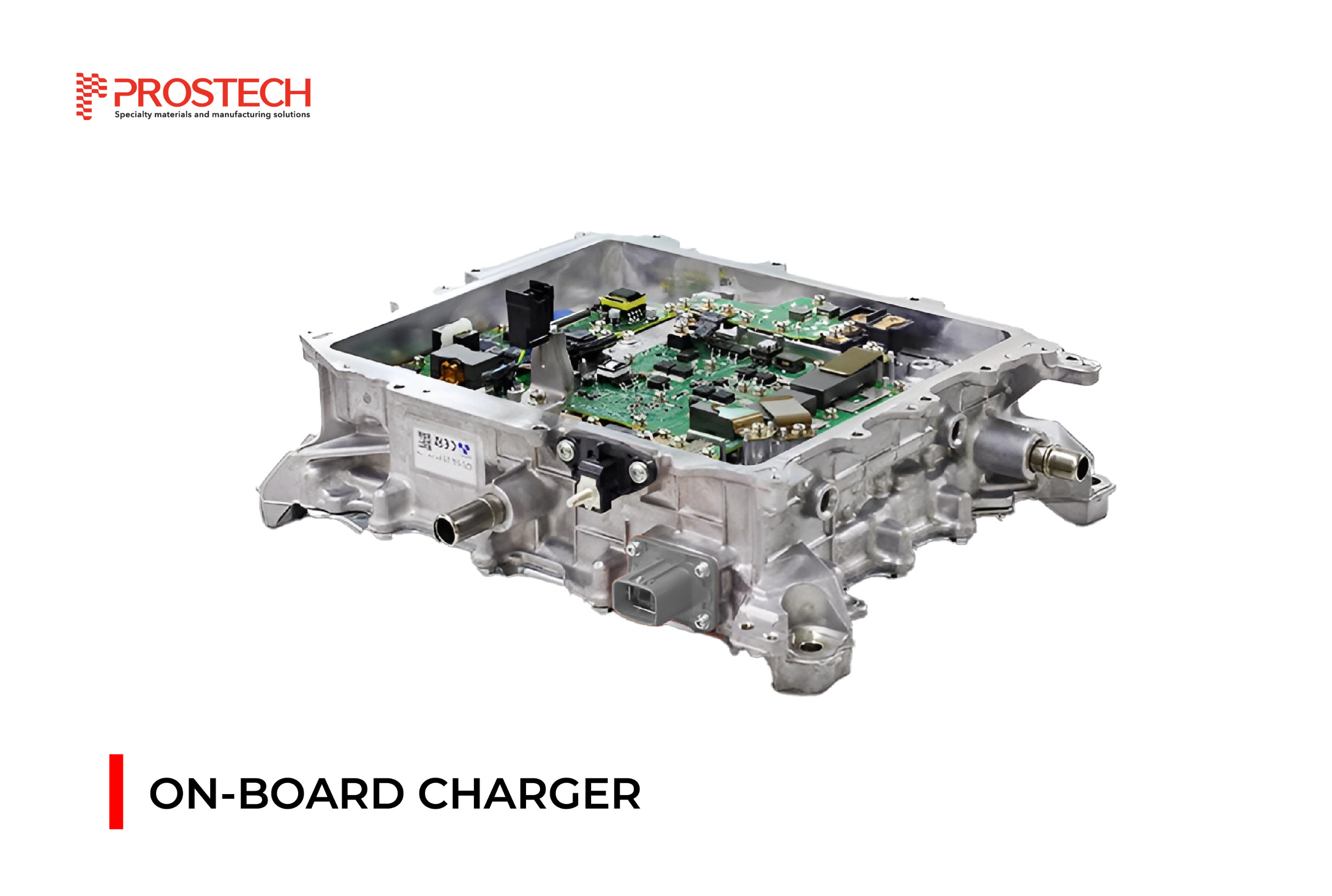

Onboard charger current sensor |

Located on the primary as well as the secondary side for control-loop operations and protection from overcurrent faults. Current sensing in power factor correction schemes improves the ON/OFF sequences. |

Showing us how much energy, we used and avoiding the overcurrent. In BMS, it provides charging and discharging cycle information by reporting the status of battery SOH. |

|

DC/DC current sensor |

Located mainly on the primary side as well as the secondary side for protection purposes on the primary side and for control-loop operations on the secondary side. |

|

|

Battery-management current sensor |

Stand-alone and onboard current sensors are required in battery management systems for state-of-charge and state-of-health calculations. |

|

|

Traction motor current sensor |

Located on the hot side for protection purposes and on the low side or in phase of the field-effect transistors for motor drive operations. |

|

|

Motor current sensor |

For various kinds of motors in the vehicle, current sensors on the low side are used for motor diagnostics and control loop operations. |

|

|

Transmission current sensor |

Proportional solenoids use current sensing to accurately monitor current and send the information to the microcontroller, where the PWM duty cycle percentage is adjusted to make the solenoid drive more efficient. |

‘Through successful experimentation and collaborative efforts within electric vehicle projects, Prostech has acquired specialized material solutions aimed at improving different facets of electric vehicles. This invaluable information is easily accessible to you with just a click within this article.’

3/ Voltage

|

Sensor types |

Location |

Features |

|

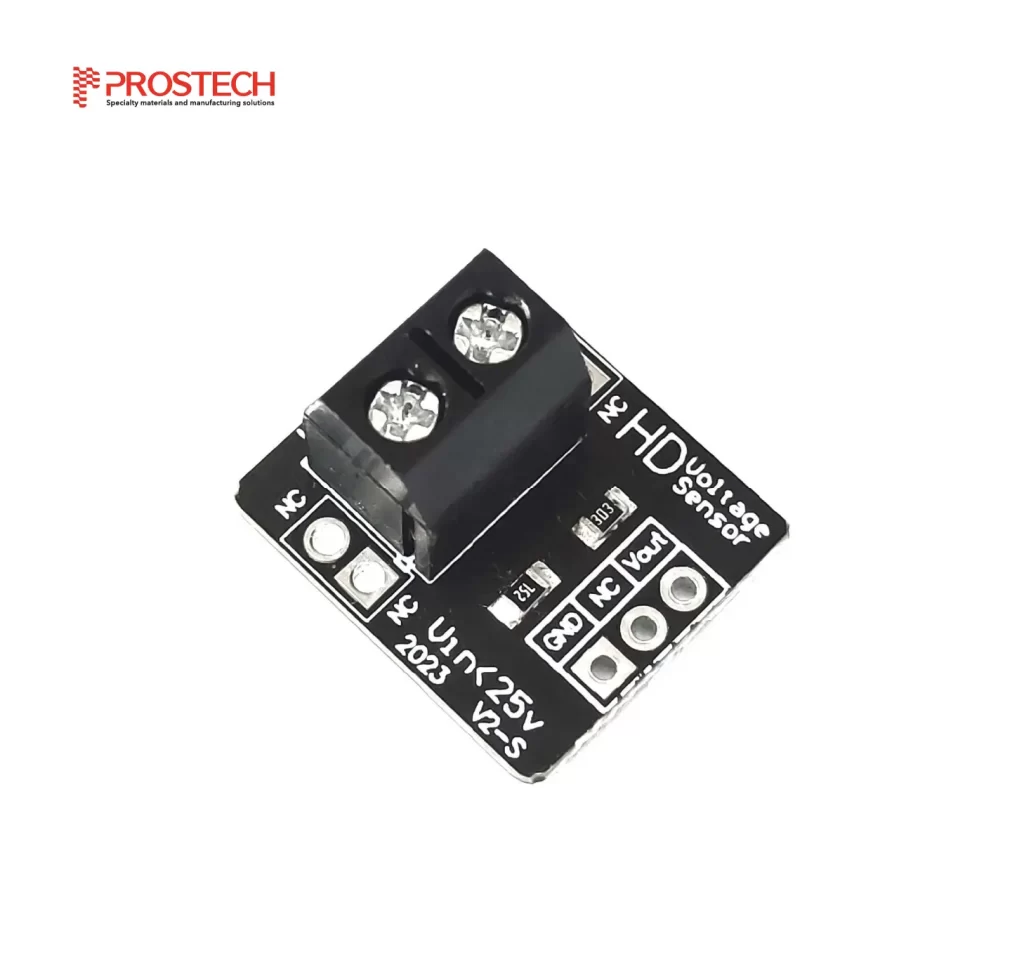

Onboard charger voltage sensor |

The voltage sense monitors the voltage magnitude of the DC/DC input/ output. A resistive divider is normally used to divide the high voltage. Galvanic isolation is normally needed to prevent electric hazards from the high voltage. |

Measure the voltage in various ways, from measuring high voltages to detecting low current levels, which ensures no insulation damage in the battery pack and each cell. |

|

DC/DC voltage sensor |

The voltage sensor on the primary side monitors the voltage magnitude of the high-voltage battery. A resistive divider is normally used to divide the high voltage. |

|

|

Battery-management voltage sensor |

Battery monitoring ICs measure cell voltages along with current and temperature and perform cell balancing to monitor and protect the cells. |

4/ Temperature

‘The temperature sensor plays an incredibly important role in electric vehicles, helping individuals have better and safer experiences throughout their journeys. Our Prostech team has researched and tested to develop a comprehensive solution for temperature sensors in electric vehicles. If interested, please click on this post to receive more information.’

|

Sensor types |

Location |

Features |

|

Onboard charger temperature sensor |

Temperature monitoring circuitry maintains the health of the power transistors during their active operation by checking the case or internal temperature depending on where the sensor is positioned. It immediately shuts down the system once the temperature is above the threshold. |

In a battery system, it is installed directly into the battery cells, giving accurate temperature measurements and regulating the heating and cooling processes to keep each cell operating within a safe range. In the case of overheating, continuous monitoring can initiate safety steps, such as disconnecting the battery or lowering charging rates, and enable the assessment of battery health.

In an e-motor, it is used to measure the temperature of the motor windings (sensors with shrink tube insulation), the temperature in the bearings, and other parts of the motor. They also ensure the motor’s dependability and ensure that there are no defects relating to torque production, control, or efficiency. |

|

DC/DC temperature sensor |

Temperature monitoring circuitry maintains the health of the power transistors during their active operation by checking the case or internal temperature depending on where the sensor is positioned. It immediately shuts down the system once the temperature is above the threshold. |

|

|

Battery-management temperature sensor |

Battery monitoring ICs measure temperature and perform cell balancing to monitor and protect the cells. |

|

|

Traction motor temperature sensor |

IGBT’s temperature is monitored to protect the system from overtemperature faults. |

‘In addition to providing extensive and top-notch material solutions, Prostech also offers design and component solutions to tackle the existing issues encountered by electric vehicles. If you are genuinely interested, feel free to get in touch with to us explore solutions tailored to your electric vehicle needs.’

CONCLUSION

In conclusion, the diverse array of Electric Vehicle (EV) sensors showcased a remarkable spectrum of capabilities, each designed to enhance performance, safety, and efficiency in the realm of electric mobility. From precision monitoring of battery health to real-time environmental data collection, these sensors serve as the backbone of EV technology, propelling the industry toward a sustainable future. Understanding the nuanced features of each sensor type empowers manufacturers, engineers, and consumers alike to harness the full potential of electric vehicles, driving innovation and advancement in automotive engineering. Reach out to Prostech for more detailed information regarding electric vehicle-related issues.