The future of mobility is being redefined with the paradigm shift from traditional internal combustion technology to steadily growing and continually evolving electric vehicle technology. As advancements in e-mobility are made, the intrinsic need for advanced materials is ever present and growing. Safety, reliability and performance continue to remain driving forces in the specification of polymers in e-mobility applications. Silicone’s unique properties enable Prostech’s materials, such as its LSR (Liquid Silicone Rubber) and HCR (High Consistency Rubber) based material technologies, to meet and exceed demanding performance requirements of electric vehicles in a wide breadth of e-mobility applications.

Some of our material characteristics that are key to addressing and solving such complex challenges include:

- High Thermal Stability

- Low compression set without post-cure

- Self-lubricating properties

- Low viscosity

- Fast cure

- Low modulus

- Increased crack resistance

- Outstanding resistance to aging

- Easy to color

- Self-bonding

- Thermal conductivity

- Excellent electrically insulating properties

- Dielectric strength

With those outstanding features, Prostech’s advanced material solutions play an essential role in the vehicles of today and tomorrow. From thermal management to battery solutions; from sensor coatings to adhesives and sealants. Here are some outstanding applications of E-mobility using our Silicone products.

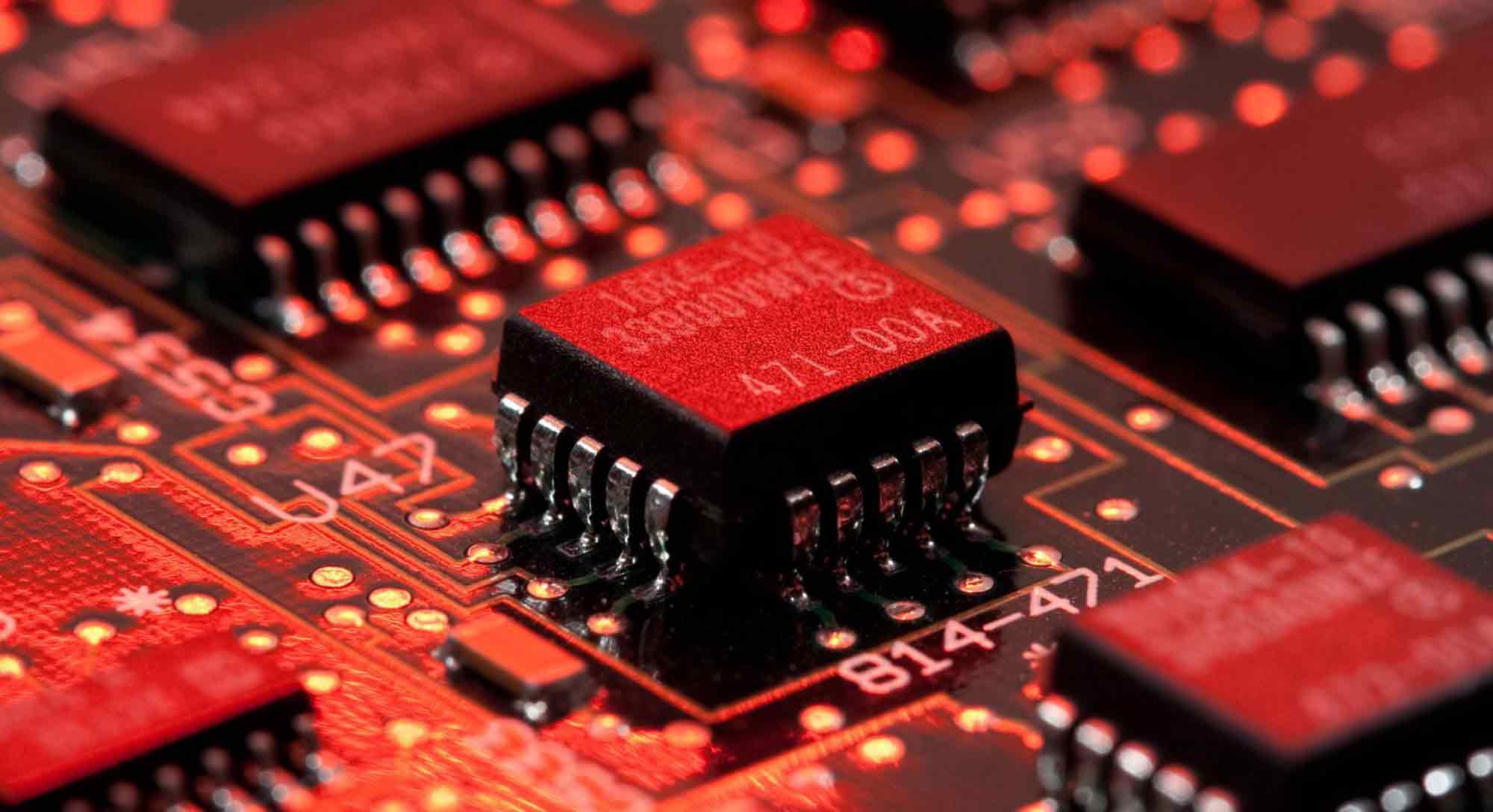

POWER ELECTRONICS

Vehicle power electronics process, control and distribute electric power to other vehicle systems, as well as control the speed and torque of the motor. Therefore, these parts must achieve absolute safety during use. Our silicone materials are possible to meet the needs of manufacturers. Prostech silicone solutions offer thermal management, encapsulation/potting, and sealing for power electronics, including inverter systems (and IGBT modules), DC/DC converters, and onboard chargers.

HIGH VOLTAGE BATTERY SYSTEM

Batteries are the technology in which manufacturers are racing to become the leader in the electric vehicle industry. Prostech has a full range of solutions for the most advanced electric car battery technologies, including thermal management (thermal gap fillers, adhesives), thermal potting/ encapsulation, and sealing adhesives.

For battery housing components, our silicone fluid is a non-halogenated flame retardant that enables excellent EV fire safety performance without compromising other important properties such as mechanical toughness or non corrosiveness.

EV THERMAL SOLUTIONS

Thermal management systems on electric cars include:

- Coolant Heaters improve battery performance by delivering consistent temperature distribution inside the battery pack and its cells.

- The Electric Coolant Pump regulates and provides coolant to the cooling system.

- PTC (Positive Temperature Coefficient) Air Heater heats the vehicle cabin using high-voltage electricity from the battery or hydrogen cell.

We provide total solutions for the above applications including protection, thermal management, insulation, sealing,… with materials have outstanding properties such as:

- Very low thermal resistance

- High reliability

- Adhesion to various substrates coupled with outstanding mechanical properties

- Outstanding protection to electronic components from dust, moisture, fluids and harmful environmental contaminants.

As a new era of e-mobility emerges, it’s accompanied by new manufacturing challenges that require new material solutions. Companies must innovate in order to meet these challenges. We are proud that we can solve any problem that customers require. Please contact us to get more product advice.