The loosening of threaded joints in machinery or equipment not only affect the machine’s performance but can also lead to serious failures, even posing a danger to humans. Vibration, high temperatures, or prolonged mechanical impacts cause screws or bolts to gradually loosen. To thoroughly address this issue, threadlockers have been applied to secure joints, preventing rotation and loosening over time. This article will introduce the uses of threadlockers and guide you in selecting the appropriate threadlocker!

What is threadlocker? Uses of threadlockers

Threadlockers, also known as bolt adhesive or screw adhesive, are single-component adhesives used to prevent common issues during machine operation such as looseness, fluid leakage, or corrosion in rivets, nuts, screws, and bolts with threaded parts.

This type of adhesive not only prevents screws from loosening or rotating but also protects metal components from the effects of vibration, impact, and abnormal machine temperatures.

Benefits of threadlockers:

- Prevent Loosening: Threadlockers secure rivets, nuts, screws, and bolts with threads, preventing gradual loosening due to impact and thermal shock during operation.

- Prevent Leakage and Corrosion: They help prevent fluid leakage and corrosion of machinery.

- Lubricant: Threadlockers also act as lubricants, aiding in controlling the applied force during the assembly process.

- Easy Disassembly and Repair: They prevent sticking or seizing due to leaks or metal corrosion, making it easier to disassemble and repair when necessary.

Related article: How to properly tighten screws?

How to choose the suitable threadlocker

To select the appropriate threadlocker, users typically need to consider three main factors:

-

Threadlocking Strength: Threadlocking strength refers to the adhesive’s ability to secure joints and prevent loosening due to vibration or load. Depending on the specific application, users need to determine the required strength (low, medium, or high) to choose the right adhesive. For example, purple threadlockers with low strength are suitable for small screws, while red threadlockers with high strength are ideal for high-load applications.

-

Screw Thread Size: The size of the thread affects the connection and the holding force of the adhesive. Users should consider the specific size of the screw and select a threadlocker that matches the size. For screws from < ¼” (6 mm) and above, different threadlockers are used based on the size.

-

Timing of Application: The timing of threadlocker application is crucial to ensure maximum effectiveness. Most threadlockers are designed to be applied during the assembly process. However, some threadlockers are formulated for use after the machine has already been assembled.

Distinguishing between purple, blue, green, and red threadlockers

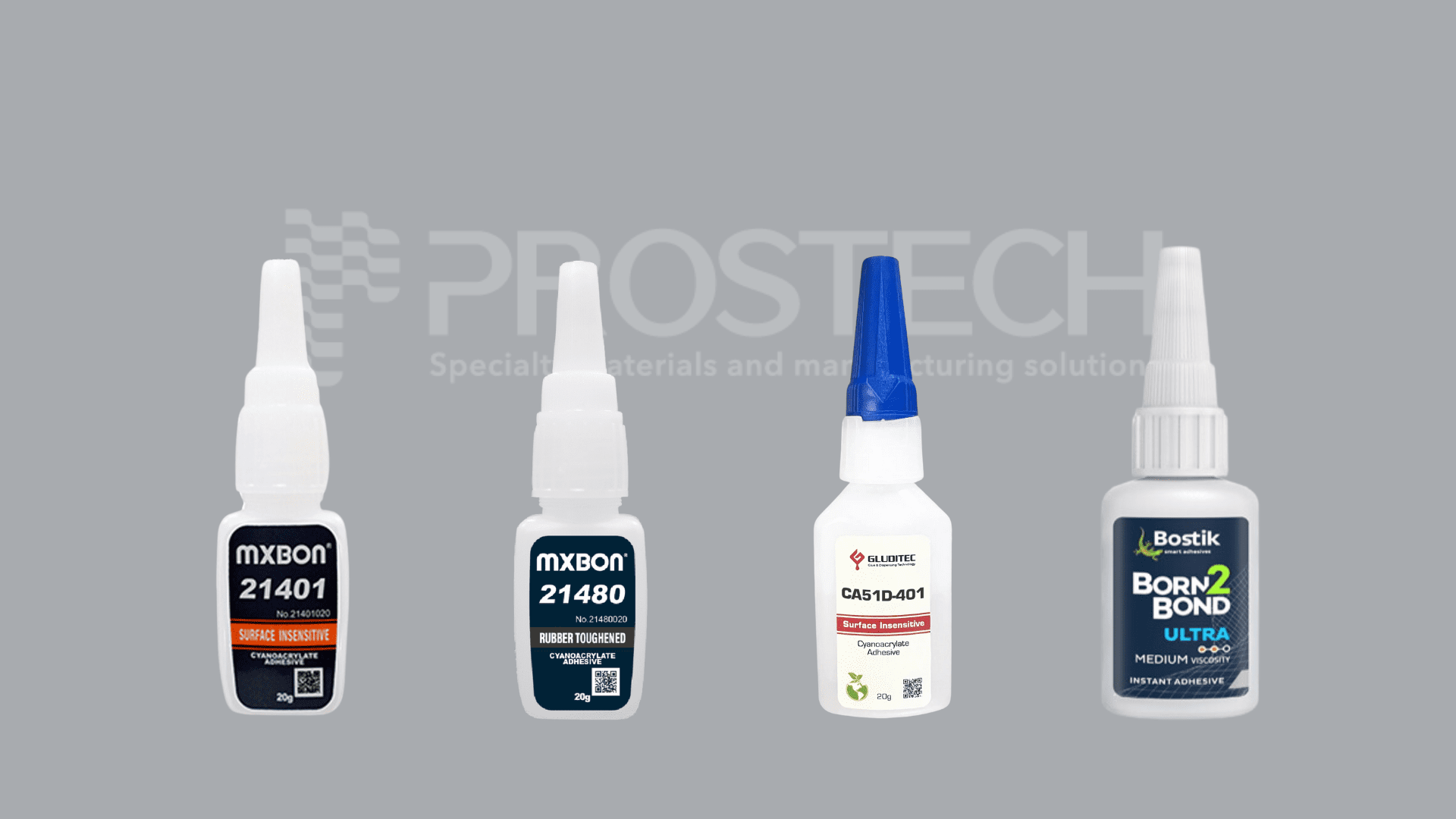

Common threadlockers products

|

|

|

| Blue Threadlocker MXLOC 11242 | Blue Threadlocker MXLOC 11243 | Red Threadlocker MXLOC 11262 |

|

|

|

| Blue Threadlocker LOCTITE 243 | Red Threadlocker LOCTITE 263 | Green Threadlocker LOCTITE 290 |

The choice of the appropriate threadlockers depends on the specific requirements of the application and environmental conditions. Each type of adhesives offers its own advantages and is suited to different demands during the manufacturing and usage processes. With many years of experience in the industrial material, Prostech is ready to assist customers in selecting the right potting compound and providing integrated solutions for production lines to optimize manufacturing efficiency. Contact us for free consultation.