Easy to dispense and maintain TIMs, beyond good thermal conductivity and reducing trouble air gaps features.

What are Thermally Conductive Gap Fillers?

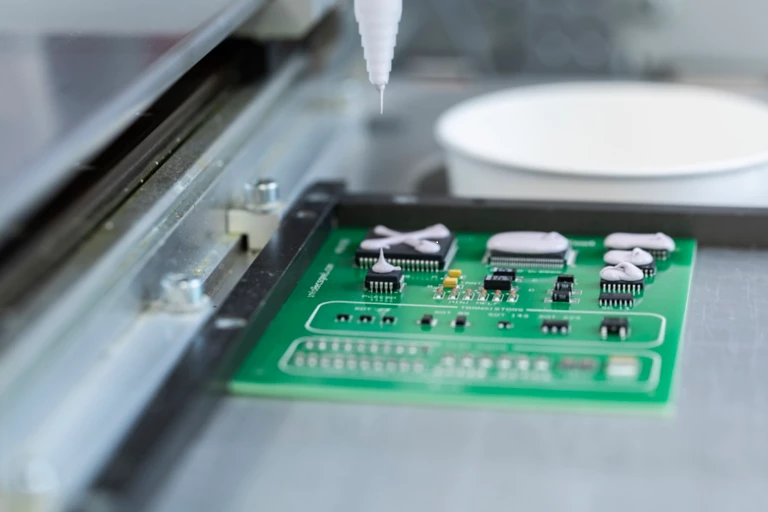

In general, Thermally Conductive Gap Fillers is a liquid material type of TIMs that is designed to enhance the thermal performance in variable industries: mobile, electronics, medical, and so on. Different from the traditional thermally conductive method, Thermally Conductive Gap Fillers are easy to use (through advanced dispensing technology) and ideal for high-volume manufacturing operations.

These materials provide unrivaled thermal and mechanical performance while inducing virtually zero stress on electronic components during assembly, helping manufacturers improve performance and reliability across your device assemblies.

In some applications, these TIMs are formed as an easy-to-remove liquid which facilitates significantly the repairing and maintaining process. Especially in the Electric Mobile industry which has a vast heat source – Battery System.

Because they’re liquid mediums, thermally conductive gap filler materials can conform to highly intricate topographies and multi-level surfaces. This allows them to deliver better wet-out for optimized thermal resistance, generally lower than more solid pad-based mediums.

|

|

Application volume and pattern are completely adaptable to suit a wide range of applications.

Benefits of Gap Fillers – Why us?

PROSTECH gap filler solutions are designed with an understanding of the intricacies of balancing filler content with thermal conductivity requirements and product integrity. Our optimized liquid gap filling materials can be deposited in extremely high volume for industries like automotive, where large systems require maximum heat dissipation.

Furthermore, we are dispensing system providers. This means we can customize our gap-filling solutions for your dynamic applications and enable the various dispensing technologies you require.

Let’s review some significant benefits of TGF

- Improved reliability in harsh temperatures

They withstand peak exposure at 200°C and perform reliably at operating temperatures ranging up to 150°C.

- Easy processing

These advanced thermally conductive materials dispense easily from their original packaging with minimal to no additional process preparation, making them well-suited for automated application using standard meter mix equipment.

- Effective assembly

Avoid slumping on vertical surfaces during assembly. After cure, they maintain their vertical stability even after long use. Select formulations incorporate glass beads to control bond line thickness during assembly.

- Cost-effective, fast cure

The platinum cure system enables fast, controlled cure at room temperature, although cure times can be accelerated further with heat to reduce manufacturing cycle times. No post-cure steps are required.

- UL 94 V-0 recognition

Received recognition under Underwriters Laboratories UL 94 standard, which evaluates the flammability of plastic and silicone materials intended for parts in devices and appliances. Recognition under UL 94 is a step towards applying the UL label on your final product.

- Repairability

A property to enhance sustainability over the lifecycle of a battery pack and other devices including end of service life. PROSTECH gap filler solutions offer good repairability without compromising performance.

Thermally Conductively Gap Filler Applications

Gap fillers are used in many applications, thanks to their diversity and flexible dispensation. In the modern world of electronics, gap fillers can be used in many electronic components, including:

- Battery Pack Lower Case Thermal Management

- Printed circuit boards (PCBs)

- Power supply cooling

- High volume applications where automatic dispensing can be used

- Where pad configurations are not suitable

- Where grease and potting compounds can be used

- Across varied topographies and surfaces

- In gaps higher than 0.5mm, to eliminate voids

Find more information about Thermally Conductively Gap Filler Here

How to choose the right Thermally Conductive Gap Fillers?

When to use Gap Fillers vs. Thermal Gel?

Compare Gap Fillers and Gap Pad?

Successful and Recommended Applications which make use of Gap Fillers

To meet the specific requirements, there are various types of Thermally Conductive Gap Filler. Please contact us for free consultant.