-

What is soldering in PCBs?

Soldering within PCBs is the way of joining components on PCBs surfaces by melting and putting a filler metal (solder) into the joint. Based on the substrate materials you are soldering; you must choose the solder with a lower melting point.

-

Methods of soldering on PCBs

1. Hand soldering

Hand soldering is done for through-hole electronic components using soldering iron or soldering station. Hand soldering is not meant for mass production. It is done for repairing and repairing rejected PCBs during mass production or for repairing faulty Printed Circuit Boards after using electronic products for a long time.

2. Automate soldering

Automated soldering is done for mass production. It can be done by using a Wave Soldering machine, Reflow machine or Automatic SMT Machine.

– Wave Soldering machine

Wave soldering is a large-scale soldering process by which electronic components are soldered to a printed circuit board (PCB) to form an electronic assembly. The name is derived from the use of waves of molten solder to attach metal components to PCBs.

A wave soldering machine consists of a Flux Applicator, a Pre-heat Tunnel, and a Pumped Wave of Solder.

The process is much faster and can create a higher quality product than manual soldering of components, suitable for mass production.

– Reflow machine

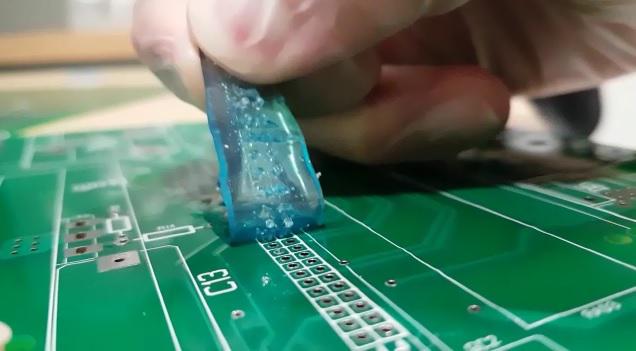

Reflow soldering is the most widely used method of attaching surface mount components to printed circuit boards (PCBs). The aim of the process is to form acceptable solder joints by first pre-heating the components/PCB/solder paste and then melting the solder without causing damage by overheating.

A reflow soldering machine consists of Pre-heat process, Thermal Soak process, Reflow and cooling process.

– SMT machine

SMT (surface mount technology) component placement systems, commonly called Pick-and-Place machines or P&Ps, are robotic machines which are used to place surface-mount devices (SMDs) onto a printed circuit board (PCB).

A SMT machine typically includes three steps: Solder Paste printing, Components placement and Reflow soldering.

-

Materials for soldering

|

1. Solder paste Solder paste develops in the direction of halogen-free, temperature stable. Find out more about solder paste: https://prostech.vn/products/application/soldering/solder-paste/ |

|

|

2. Solder wire Key benefits:

Find out more about Solder wires: |

|

|

3. Solder bar

|

|

|

4. Flux for Pre-soldering Key benefits:

Find out more about Solder flux: https://prostech.vn/products/by-market/general-industrial/

|

|

Need more information on solutions for your applications in Soldering? Contact us: