CPAP Machines Background

Sleep apnea is a serious health condition where a person’s breathing repeatedly stops and starts during sleep. This can happen 30 or more times an hour, leading to significant medical complications. Continuous Positive Airway Pressure (CPAP) machines are a critical treatment, providing a steady flow of air pressure to keep the user’s airway open. The reliability of these machines is paramount, and Prostech recently played a key role in helping a major CPAP machine manufacturer overcome a critical production challenge.

The Challenge: Inconsistent Potting Compound

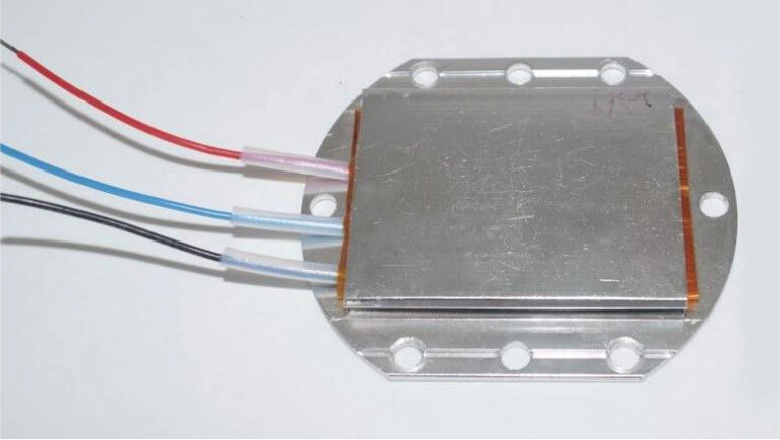

A leading manufacturer of CPAP machines uses a potting compound to coat and protect the ceramic disk heating elements from the water they heat. As the company began to increase its production, it encountered significant quality and manufacturing issues. The source of the problem was the potting compound from their existing supplier, which had major variations in viscosity. This inconsistency hindered their ability to scale up production effectively and ensure the long-term reliability of their devices.

The Comprehensive Solution: Potting Materials for CPAP Machines and Automated 2K Potting Systems

Potting Materials for CPAP Machine – Insulcast 116 FR

The manufacturer turned to Prostech for a solution. After analyzing the production line and the issues caused by the inconsistent viscosity, Prostech recommended Insulcast 116 FR, a high-performance potting and casting compound from our partner, ITW Performance Polymers.

INSULCAST 116 FR-FC Epoxy Potting | ITW

Insulcast 116 FR was the ideal solution for several reasons:

- Optimized for Manufacturing: It is a general-purpose compound designed for easy use in manufacturing applications. Its 1:1 mix ratio is perfect for production line mixing and automated dispensing, allowing for increased throughput without compromising quality.

- Superior Protection and Adhesion: The compound provides excellent adhesion and cures to form a low-transition vapor barrier, effectively protecting the sensitive heating elements.

- Enhanced Safety: Insulcast 116 FR is one of the safest epoxy compounds available. It significantly lowers the risk of skin, eye, and respiratory issues often associated with epoxy use, creating a safer environment for production staff.

Insulcast 116 FR Technical Specifications: TDS

| Property | Value |

| Dielectric Constant (KHz) | 4.4 |

| Dielectric Strength (Volt/Mil) | 420 |

| Coefficient of Thermal Expansion (°C) | 30×10⁻⁶ |

| UL Flammability Rating | 94V-0 |

By implementing Prostech’s recommendation of Potting Materials for CPAP Machines, the manufacturer successfully resolved the production and quality issues. The stable viscosity and automated dispensing-friendly nature of the new potting material allowed them to ramp up production confidently. The result was greater manufacturing throughput and a more reliable, high-quality product for sleep apnea patients who depend on it nightly.

As a leader in specialty materials solutions, Prostech provides materials for the Medical Industry that hold comprehensive medical certifications and meet rigorous international standards.

Automated 2K Potting Materials for CPAP Machines

To complement our high-performance potting materials, Prostech provides advanced 2K (two-component) potting meter, mixing, and dispensing systems.

Engineered for large-volume manufacturing, these systems deliver precise mix ratios and consistent, high-speed dispensing. This allows you to automate and optimize your production line for maximum efficiency and quality.

2K Meter, Mixing and Dispensing Systems

See how our system streamlines the process in this video.

Partner with Prostech to optimize every aspect of your production. Beyond providing specialty materials, we are a full-service solutions provider dedicated to solving your unique challenges.

Contact us today to leverage our expert support, including:

-

- Laboratory Testing Support

- Formulation Customization

- Package & Label Customization

- Production Automation & Optimization

- Global Shipping

Let’s build a custom solution for your success. Reach out to the Prostech team now!