Some manufacturers these days primarily rely on traditional cleaning and surface treatment methods such as water blasting, sandblasting, the use of strong alkaline chemicals like NaOH, HCl, as well as ultrasonic waves and laser technology. However, these solutions still have several limitations in terms of cost, efficiency, and environmental impact. A new solution that can overcome these drawbacks is plasma surface treatment technology. What is the main mechanism behind plasma surface cleaning? Why should manufacturers choose this technology? What are the standout applications of plasma technology? All will be answered in this article!

Read more: What is Plasma Surface Treatment and how does it work on the surface?

Mechanism of Plasma Surface Cleaning

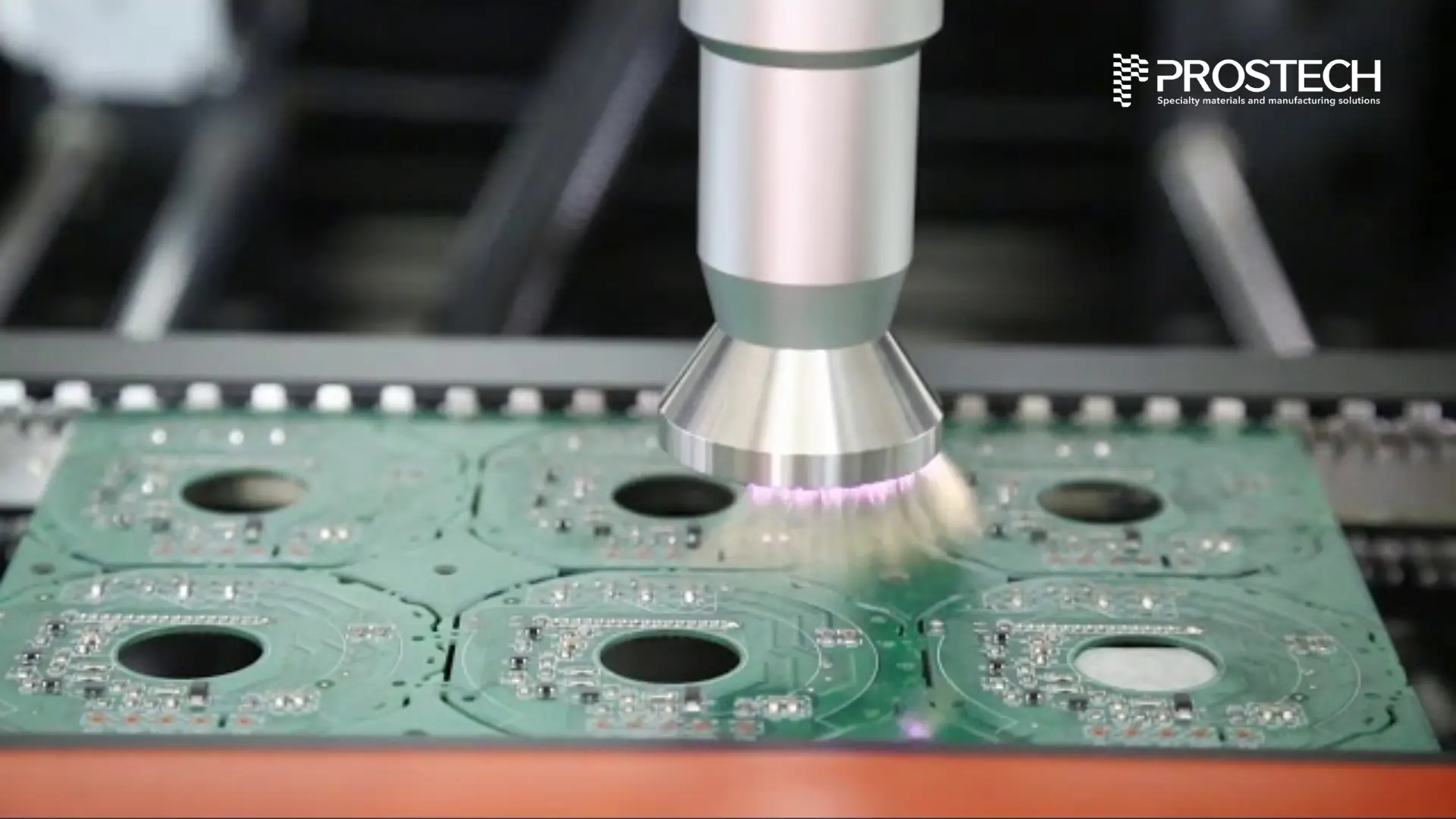

Plasma is generated by ionizing a gas (commonly argon, oxygen, nitrogen, or a mixture of other gases) in a vacuum chamber using high-frequency or microwave power. When the gas is ionized, it produces charged particles (ions, electrons) and high-energy neutral particles (free radicals, excited molecules). These particles facilitate the surface treatment process through three main mechanisms:

-

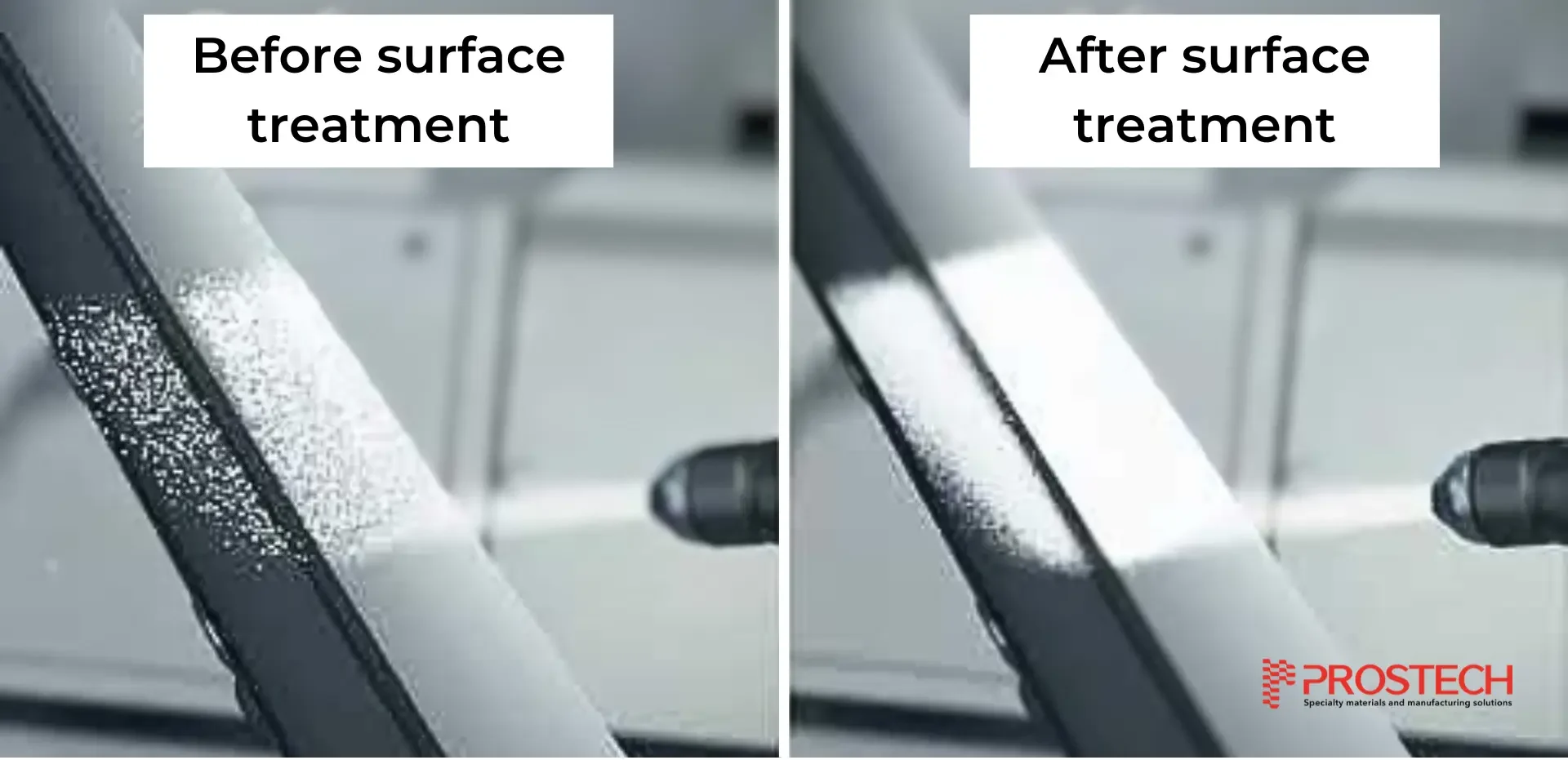

Surface Cleaning: The high-energy particles in the plasma are capable of removing impurities, oils, grease, and even the tiniest oxide layers from the surface of materials. This ensures a clean surface and improves the adhesion of coatings or bonding materials.

-

Surface Activation: Free radicals and ions in the plasma can attach new functional chemical groups (such as hydroxyl, carboxyl, or amino groups) to the surface of the material, altering its surface properties to enhance hydrophilicity or hydrophobicity.

-

Micro-etching: Plasma can erode and create microscopic structures on the material’s surface, increasing the surface area and improving mechanical adhesion.

Why Choose Plasma Technology for Cleaning Processes?

So, why has plasma technology become the top choice for surface cleaning in manufacturing? Below are some key benefits:

- Thorough Cleaning Without Residue: The high-energy ions and electrons in plasma are highly reactive. They have the ability to break down chemical bonds of contaminants on material surfaces. Ionized gas particles strongly impact the surface, effectively removing impurities like oil, grease, dirt, and oxides.

-

No Material Deformation, Preserving Mechanical Properties: Plasma cleaning is highly compatible with a wide range of surfaces, as it does not rely on harmful chemicals or solvents. This prevents abrasive or chemical-induced damage to the surface, especially for materials like plastics, ensuring the material retains its original physical and mechanical properties.

-

Comprehensive Treatment for Both Flat and Uneven Surfaces, from Plastics, Metals, Glass to Aluminum: Plasma systems not only clean but also activate surface molecules, increasing the surface energy of the material. This improves the adhesion of subsequent coatings, ensuring product quality and durability. Plasma can also treat uneven surfaces, ensuring strong adhesion for future coatings. This is especially crucial in industries like automotive, mobile phone manufacturing, and electronics, where high durability and quality are required.

-

Easy Integration into Production Systems, Increasing Efficiency and Reducing Operating Costs: Plasma technology eliminates the waiting time for chemical or cleaning solution drying, accelerating production speed. Additionally, this system can be easily integrated into modern production lines, saving space and reducing operating costs.

-

Environmentally Friendly, No Hazardous Waste Generation: The primary materials used are dry gases (oxygen, nitrogen) or inert gases (argon). This makes it a green solution that is friendly to the environment and helps reduce waste disposal costs.

Read more: Benefits of using Plasma in Surface Treatment Process

Applications of Plasma Surface Cleaning Technology in Various Industries

Automotive Manufacturing: Plasma surface cleaning technology effectively removes contaminants such as oil, grease, and dirt. This improves the adhesion of paint, enhancing the durability and quality of the coating.

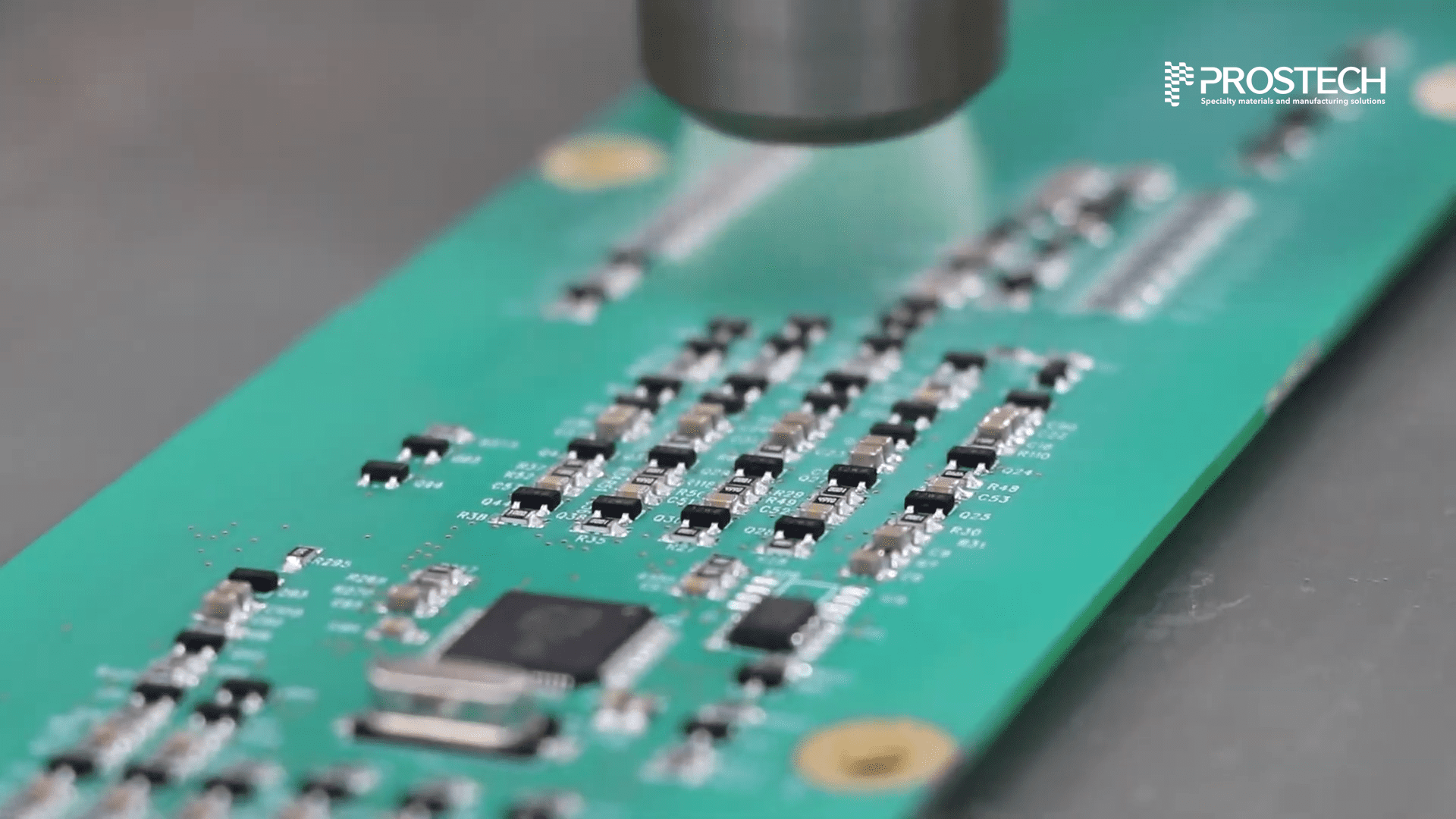

Mobile Phone and Smartphone Manufacturing: Ensures that the surfaces of electronic components are completely clean, enhancing the effectiveness of coating and bonding processes.

Electronics Manufacturing and Optical Components: Removes contaminants and dust from the surfaces of components such as lenses, mirrors, and sensors, ensuring that the surfaces are entirely clean and do not affect the image quality or optical performance of the devices.

Thus, plasma surface cleaning technology provides a comprehensive solution for surface treatment, not only enhancing adhesion and improving product quality but also contributing to increased production efficiency and environmental protection. If you are looking for high-quality plasma products and solutions, you can find detailed information at:

Plasma Surface Treatment Products

Some Products Offered by Prostech:

Plasma Machines

|

|

|

| AEPT Flame Plasma AFP-250S | AEPT VACUUM PLASMA AVP-125G-2-T | Eco-friendly surface tension test ink |

Automation System

|

Cobot |

|

|

Prostech understands the technical issues related to plasma surface cleaning technology. We offer comprehensive solutions, including consulting, integration into production lines, and maintenance of plasma systems. With a nationwide network, we provide prompt support to our customers. Positioned as a comprehensive supplier, Prostech is continuously strives to become a trusted partner for manufacturers around the world. Contact us by leaving your information below: