MARKET CHALLENGES

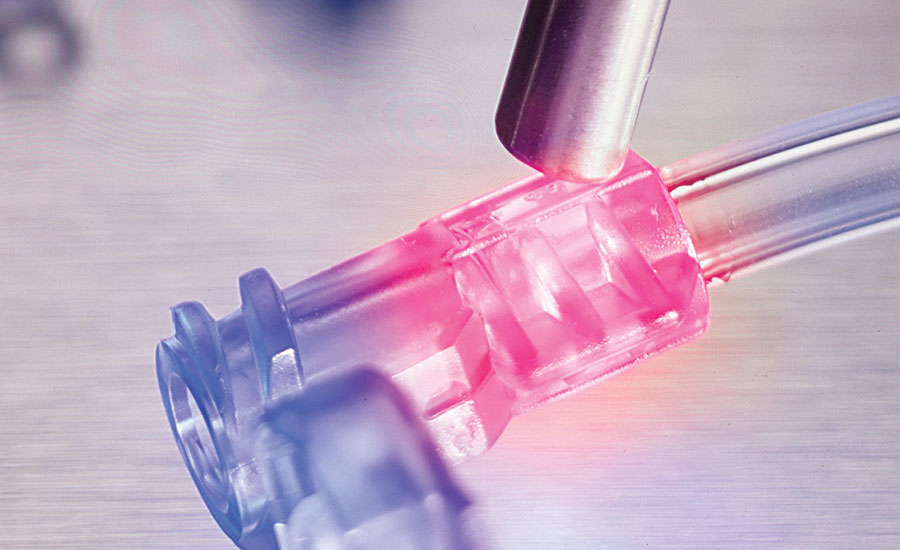

Hard To Bond Substrates Nylon, Coc/cop And Peba

Biocompatibility Testing

Medical-grade Standards Requirement

The Impact Of Sterilization Processes On Bonding Joint

PROSTECH’S SOLUTIONS

In conjunction with the development of Medical Technology, Medical Devices are increasingly diverse. They range in scope from a Q-tip to an X-ray machine and the manufacturing process involves uncountable applications. PROSTECH is confident to keep pace with medical technology development and provide customers with the utmost medical adhesive solutions.

Firstly, our range of adhesives for medical devices is equally as diverse and has been carefully selected to demonstrate our capabilities. There are a few key features of the popular products. However, the effectiveness we mentioned will be reflected in our customizing product line which can be formulated to best suit your requirements.

Furthermore, we do not promise to provide the best adhesive Adequate Adhesive Solution. Some medical device adhesive applications require adhesives formulated to pass biocompatibility testing (not all medical devices), others require structural bonding of equipment. It is more important to select the right adhesive rather than the best one.

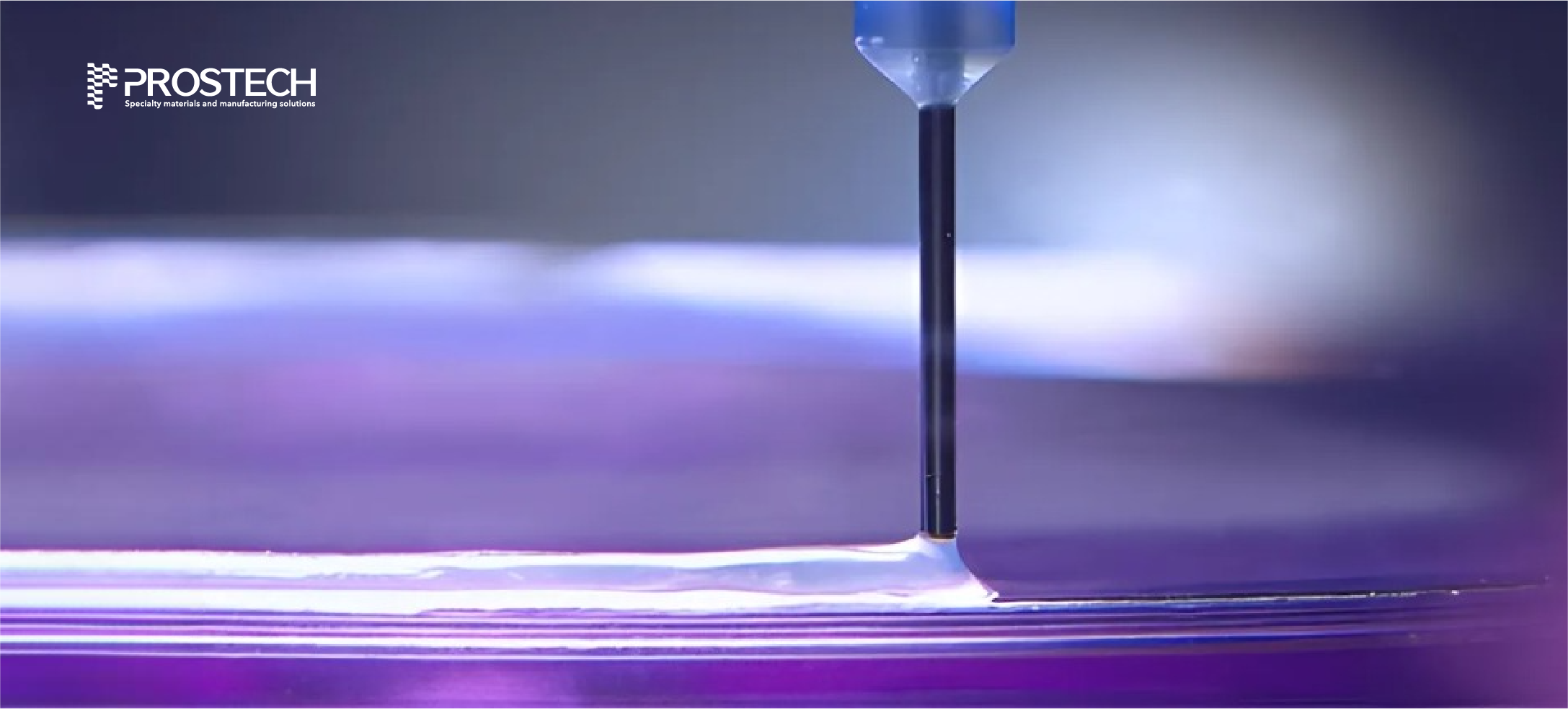

In Medical Devices Manufacturing Industry, whether you are seeking a unique UV curable adhesive to bond a state-of-the-art oxygenator or a structural bond of an MRI housing we are here to help.

Bonding solutions for hard to bond substrates (Nylon, COC/COP and PEBA)

Biocompatibility adhesives

Medical-grade standards adhesives

Sterilization Resistant Adhesives

MEDICAL-GRADE STANDARDS

ISO 10993 biocompatibility standards (ISO 10993-5,-10,-11,-4,-6)

Depending on the application requiring an adhesive solution, many of our products also have passed ISO 10993 testing for skin sensitization and irritation as well.

ISO 13485 Medical Devices Quality Management

Ensuring that our products are made consistently and that they will conform to Medical Device Quality Management Standards.

USP Class VI Bio-compatibility of Materials

set by the US Pharma Convention (USP) with a focus on medications, healthcare technologies, food ingredients, and materials used in medical devices.

FDA Approval for Medical Devices

Since the user must submit his part for final testing and FDA certification, an adhesive’s qualification to ISO 10993 or USP Class VI is viewed as sufficient to allow a user to determine “probable” device acceptance.

WHY CHOOSE PROSTECH

Customer Sample Testing Support

Global Delivery

Medical-grade Adhesives Available For Shipping

Automate And Optimize Production Process

MEDICAL-GRADE ADHESIVE PRODUCTS

Detailed Application

Useful Information

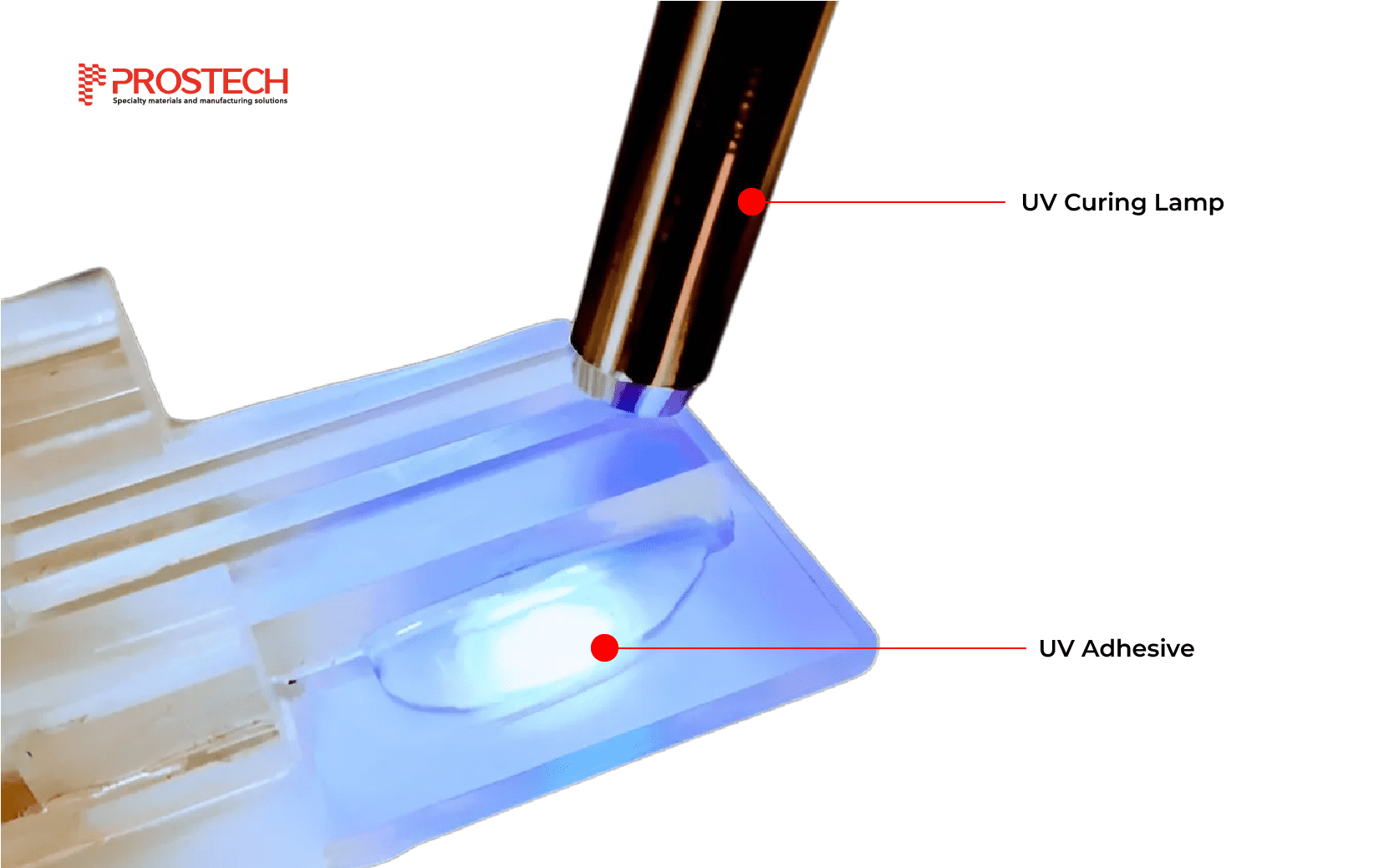

UV-curable cyanoacrylate adhesives (UVCA) for medical devices

When it comes to medical device manufacturing, adhesive technologies play a pivotal role in the efficient assembly and functionality of

7 Reasons why Light-Curable Adhesives are Ideal for Medical Device Assembly

As in-home patient care becomes more common, material regulations tighten, and the demand for safer, less invasive devices increases, selecting

How to bond Hard-to-bond Substrates (Nylon, COC/COP and PEBA) in Medical Devices Assembly?

In medical device assembly, substrates such as Nylon, COC/COP (cyclic olefin copolymer/polymer), and PEBA (polyether block amide) are favored for

Solvent Welding and Ultrasonic Welding Alternatives in Medical Assembly

When assembling medical devices, ultrasonic welding and solvent welding are popular joining methods for plastic parts. Although they offer fast processing and strong

What is UV Adhesive? Applications of UV Adhesive in Medical Industry

Choosing the right adhesive can be a complex decision that requires balancing the demands of production processes with the performance

UV Adhesive: A guide to overcome all the challenges for optimizing its benefits

UV adhesive is a common type of adhesive in use today, employed across various manufacturing industries due to its superior

What are the advantages of using UV Adhesive?

UV adhesives have a fascinating history that dates back to the 1960s when traditional adhesives often required a very long

How to prevent blooming issue of Instant Adhesive or Cyanoacrylate Adhesive

The cause and the nature of blooming in CA adhesive Cyanoacrylates (CAs) are commonly known as instant adhesive or super

The 9 Myths about Cyanoacrylate Adhesives

Cyanoacrylate adhesives (CA adhesives) — also called “super glues” or instant adhesives — are popular in many industrial and domestic

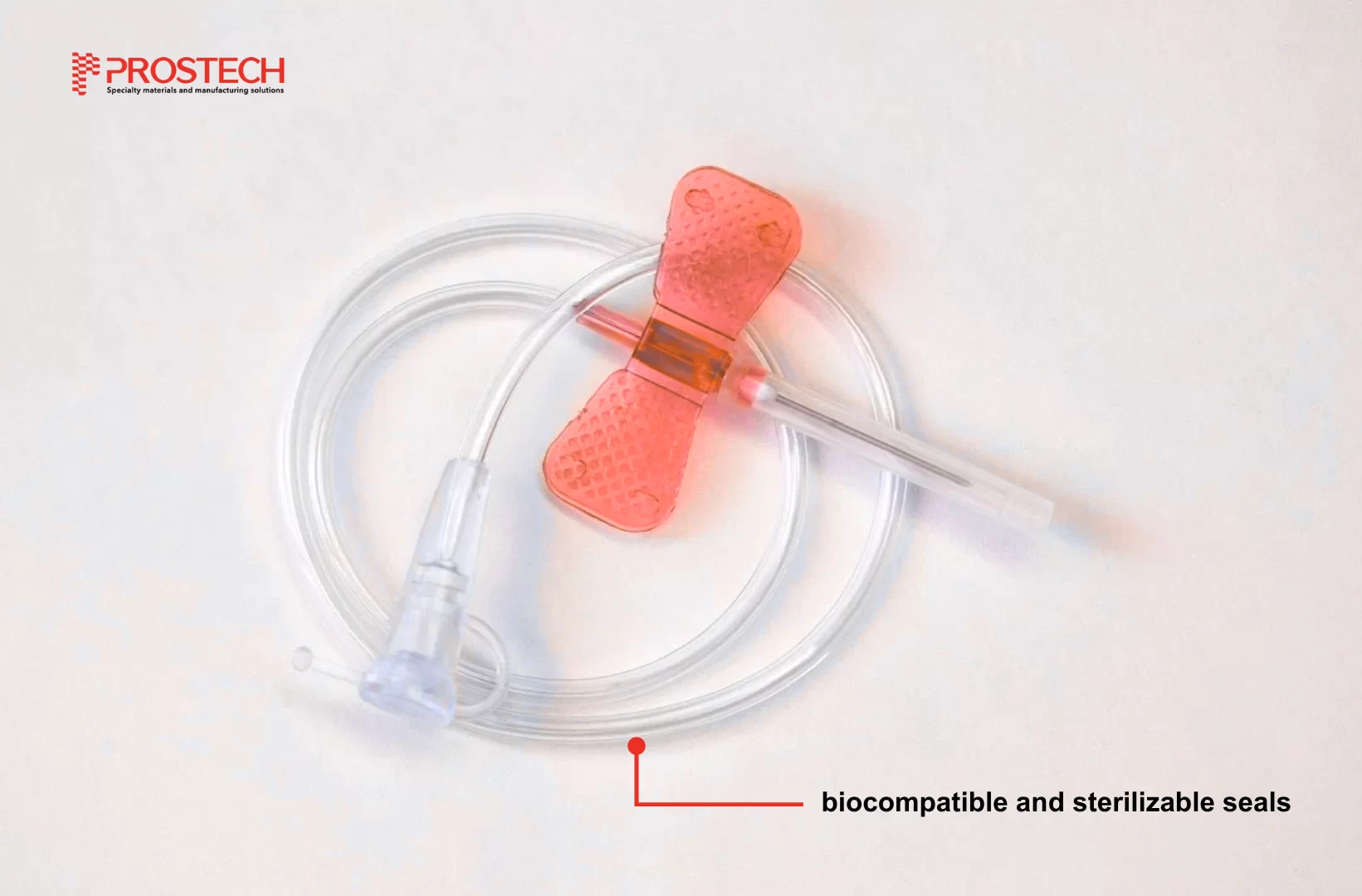

Guideline to disposable medical devices adhesives

Disposable medical device assemblies require adhesives with strong, reliable, biocompatible medical liquid and sterilization-resistant properties. Adhesives for any application should

ACRYLIC ADHESIVES USES IN INDUSTRIAL MANUFACTURING

Structural Acrylic Adhesives are characterized by their high bond strength and wide range of material compatibility. Their applications are in

Is Your Adhesive Biocompatible?

A biocompatible adhesive is designed for safe use in medical applications involving contact with biological tissues or fluids. These adhesives