The latest, greatest phones now can survive a dip in the pool. We often call them waterproof phones. But while manufacturers have successfully increased the water-repelling nature of smartphones, they are still far from “waterproof”. Let’s discover all the techniques utilized for smartphone manufacturer to make your phone water resistant, provide ultimate water protection!

1/ What is water resistance?

First of all, understand that, technically, very few phones are 100 percent waterproof – most are simply water-resistant. Waterproof is not water-resistant. Many companies advertise their devices as waterproof, but in fact there’s no such thing as a waterproof phone. Waterproof means completely protected from water; whereas water-resistant means that it can usually resist water penetration to some extent.

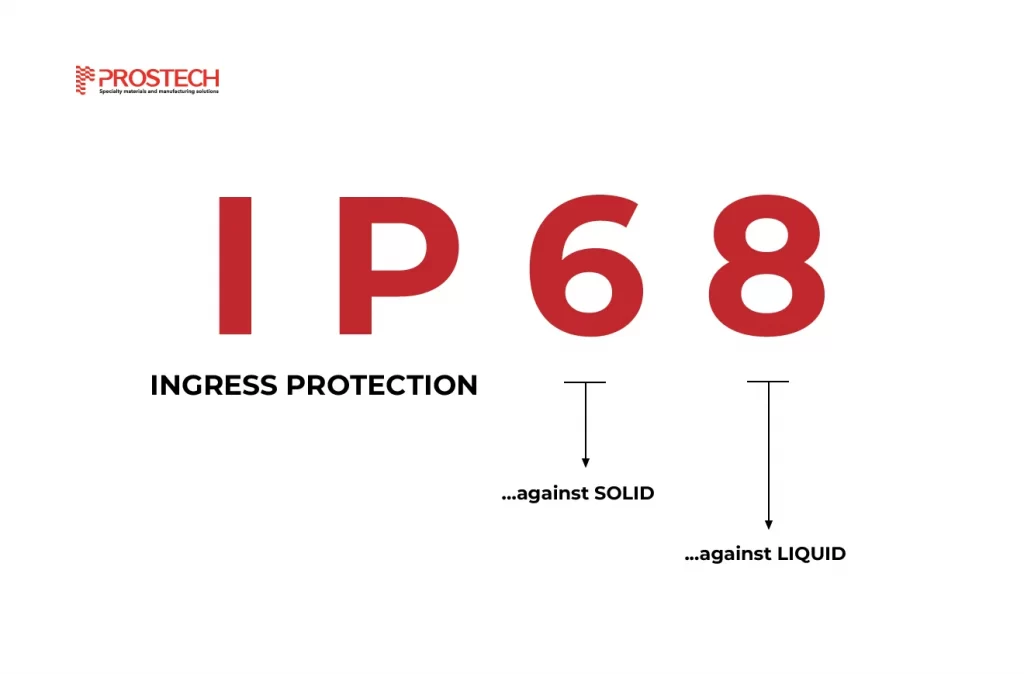

There’s a rating system used to measure devices’ resistance against solids (such as dust) and liquids (namely water). It’s called the IP (Ingress Protection) rating to let people know how resilient it is. It’s indicated by the letters “IP” followed by two numbers; for example, IP68. In a rating of IP68, the 6 refers to protection against solids on a scale of 0 (no protection) to 6 (high protection), and 8 refers to protection against water on a scale of 0 (no protection) to 9 (high protection).

2/ How are phones made water-resistant?

Phones aren’t the only devices that can be water-resistant; any parts of phone need to have an IP rating. Making a phone water-resistant requires several components and techniques. The first things we see about the phones are the giant gap between the rim of your phone and its glass screen of the rim and the backplate. The backplate of your phone is held tightly in place by strong adhesive strips. This creates a strong seal that keeps water from seeping through the seam.

It is worth noting that your phone doesn’t just have one or two gaps, it has many. Every single port, button and switches, the camera, flash, USB port, SIM card tray and speakers and microphone hole could be the weakest link that lets water into your handset. Some parts also can be covered and sealed by using glue, adhesive strips and tape.

Leverages expertise in manufacturing materials and a deep understanding of electronic-grade adhesives and water resistance standards, Prostech offers a comprehensive selection of tapes, adhesives, and materials specifically designed for water-resistant electronics. Contact Prostech today to find the perfect waterproof solution for your needs.

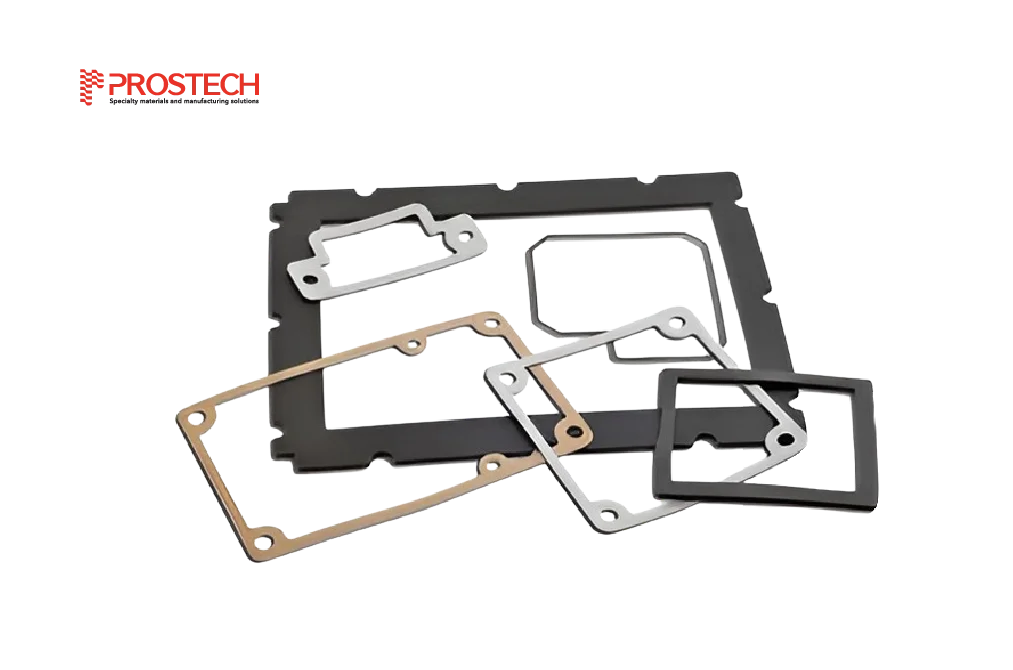

You can find that some parts in the smartphone won’t work with adhesive, like ports. Ports like the headphone jack, charging port, microphones, and sim/SD card tray use seal and gasket instead. This gasket is sandwiched between the port and the chassis of the phone to create a tight seal.

Sealing against dust and moisture is crucial for smart phone displays because it operates in diverse environments, from indoors to outdoors. Sealing help the phone to block light and resist water to protect against spills from cleaning fluids and drinks. In contrast, a handheld device gasket must be highly waterproof to function effectively win the rain.

The gasket evenly distributes pressure from the housing or bezel across the display, preventing pressure points that could cause image distortion or electrical faults. It also cushions the display when pressed forcefully, dispersing the pressure to protect against concentrated stress or localized damage.

If you want to know more about Sealing and Gasket Material, you can contact Prostech or read more articles here:

Overview of Sealing and Gasket

LCD Gasket: Which Gasket Material Can be Used for an LCD/ Touchscreen?

Prostech provides a full solutions of seal and gasket for waterproofing electronics.

You can find that some parts in the smartphone won’t work with adhesive, like ports. Ports like the headphone jack, charging port, microphones, and sim/SD card tray use seal and gasket instead. This gasket is sandwiched between the port and the chassis of the phone to create a tight seal.

Prostech provides a full solution of seal and gasket for waterproofing electronics.

For buttons, manufacturers may use a different technique: a little boot of silicone rubber that completely separates the physical part you push from the electrical contacts inside. After this, a layer of ultra-thin polymer nanocoating is applied to the phone’s circuit board to help repel water.

Prostech offers a wide range of conformal coating safeguards for your phone’s circuit board.

Speakers and microphones need air to enter and leave your phone because creating vibrations in the air is how they produce sound, so they use a water-resistant mesh material to repel liquids.

Speaker adhesion is also acommon challenge faced by phone and electronics manufacturers. Prostech offers a solution specifically designed to address this issue: Adhesive for Speaker Assembly- Frame/Basket Bonding

3/ Conclusion

In conclusion, as dependence on consumer phones grows, so do expectations for their functionality, longevity and resistance to just about everything from water to mechanical shock. Protecting against the damaging effects of external influences that can destroy a phone’s function is critical to a user’s satisfaction with their device.

With a focus on improving efficiency and improving the quality of life, Prostech’s water-resistant solutions will bring you great experiences when using our products.