- What is EMI?

- Causes of Electromagnetic Interference (EMI)

- The Impact of Electromagnetic Interference (EMI) on Electronic Devices

- What is EMI Shielding?

- The Importance of EMI Shielding

- EMI Shielding Mechanisms

- EMI Shielding Materials: Reflection and Absorption Methods

- Challenges and Solutions in EMI Shielding

In the modern world, electronic devices play an extremely important role in all aspects of life, from work to entertainment. However, one of the biggest technical problems we face is electromagnetic interference, also known as EMI (Electromagnetic Interference). This article will explain what EMI is, its causes, and why EMI Shielding is important in protecting electronic devices from the negative effects of electromagnetic interference.

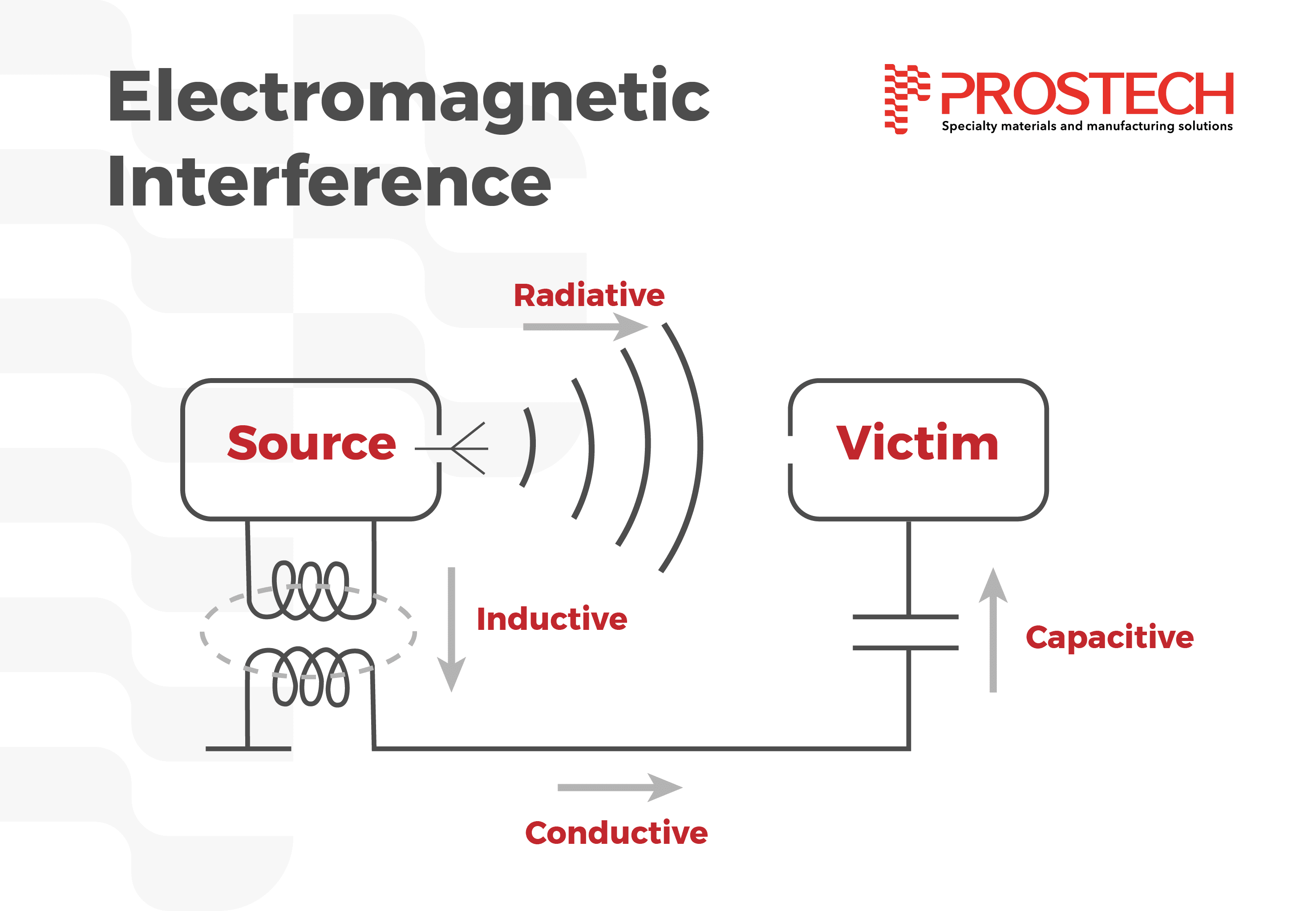

What is EMI?

EMI, short for Electromagnetic Interference is a disturbance caused by an external source that affects an electronic circuit through methods such as electromagnetic induction, electrostatic coupling, or conduction. When interference occurs in the radio frequency range, it is also known as radio frequency interference (RFI). This phenomenon affects the operation of electronic circuits and devices through the electromagnetic induction and capacitive coupling environment.

Causes of Electromagnetic Interference (EMI)

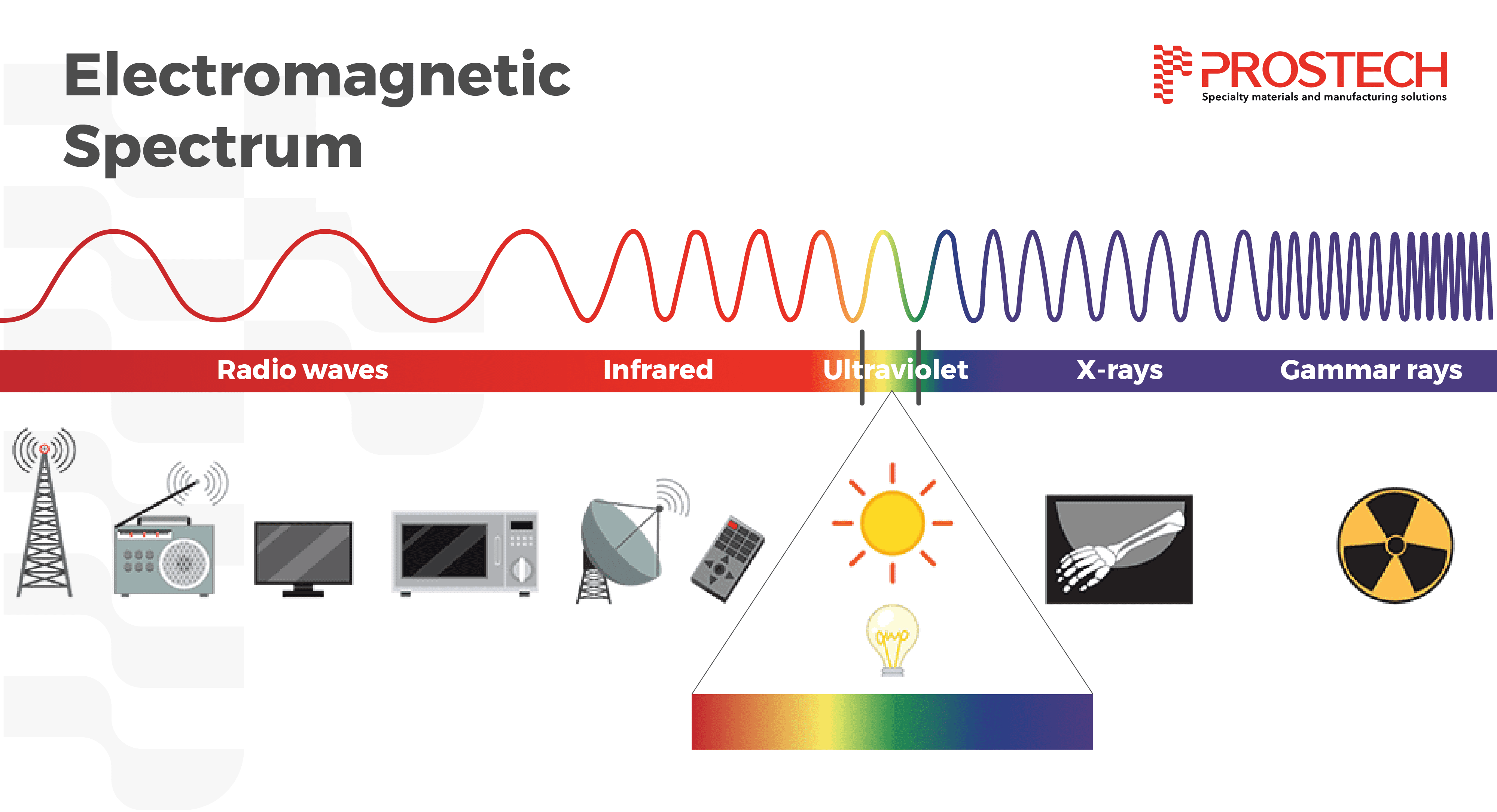

Electromagnetic interference (EMI) can affect electronic devices from a variety of sources, which can be broadly classified into two categories: natural and man-made.

Natural Sources:

-

Sunlight: Ultraviolet radiation and solar flares can cause EMI.

-

Lightning: Lightning strikes generate powerful electromagnetic pulses that can affect electronic devices within a wide range.

-

Aurora: Auroras, also known as the Northern Lights, can produce electromagnetic interference.

Man-made Sources:

-

Radio waves: Signals from mobile phones can interfere with other electronic devices.

-

Microwaves: Microwave ovens and other microwave-emitting devices can be sources of interference.

-

Other electronic devices: Computers, televisions, and other household electronics can also generate EMI.

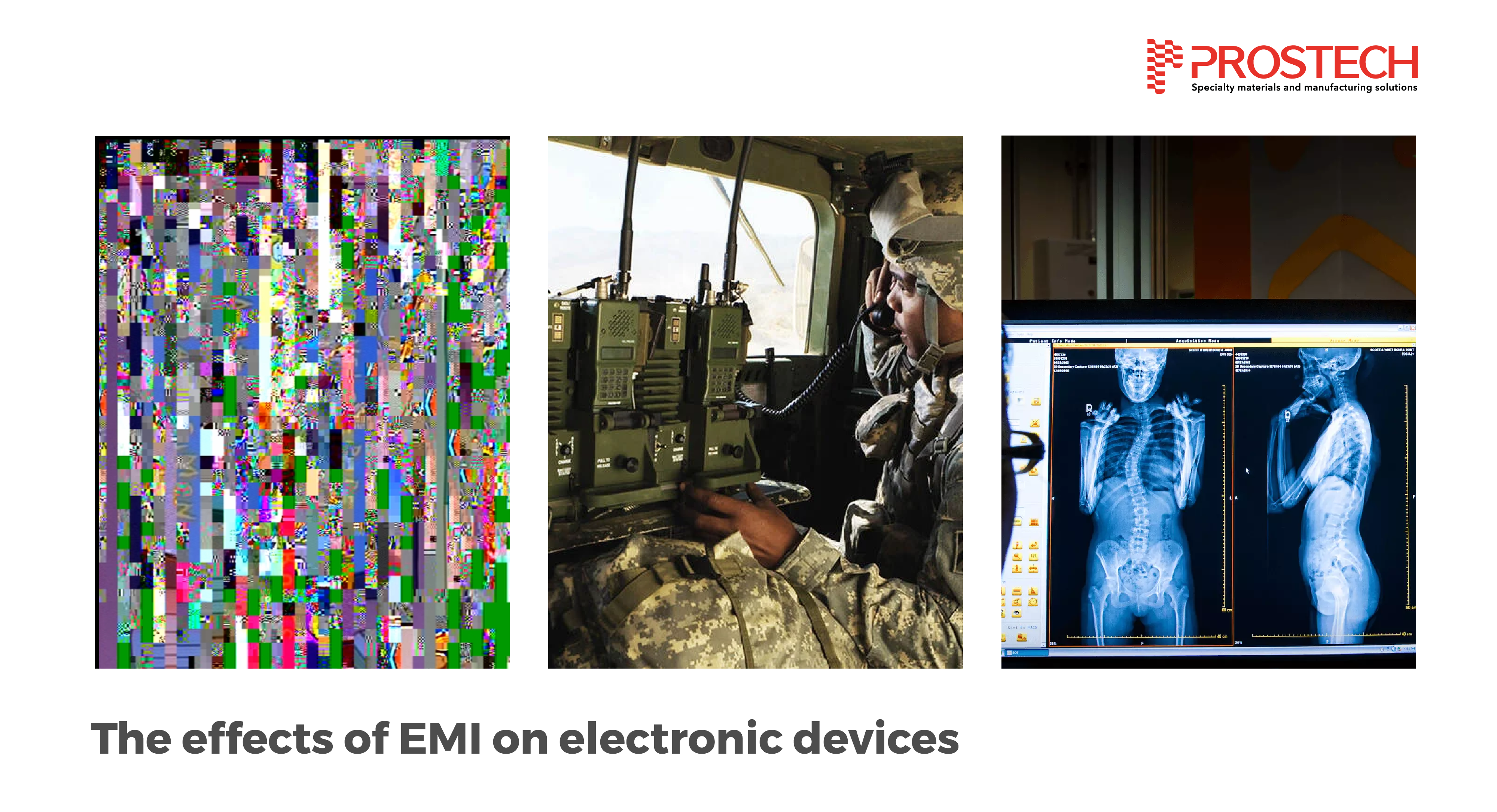

The Impact of Electromagnetic Interference (EMI) on Electronic Devices

Electromagnetic interference (EMI) can severely impact the operation of electronic devices. Examples of EMI-induced malfunctions include:

-

Reduced performance: EMI can degrade the performance of devices, causing them to operate erratically.

-

Device damage: In severe cases, strong interference can damage the hardware of electronic devices.

-

Disrupted operations: Critical devices such as aircraft, medical equipment, and communication systems can experience disrupted operations, leading to significant risks and losses.

To address these EMI-related issues, EMI Shielding solutions have emerged. Continue reading this article to learn about Prostech’s EMI Shielding solutions.

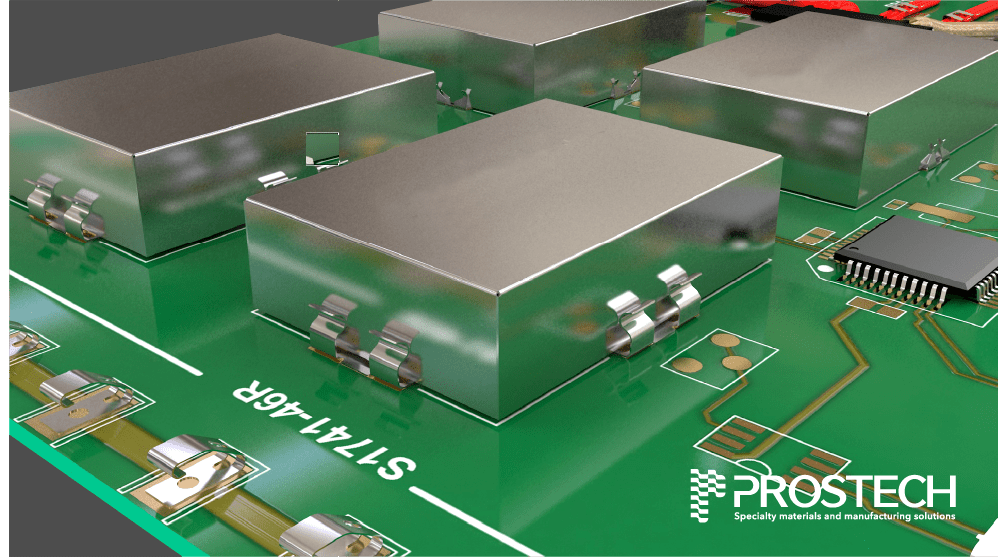

What is EMI Shielding?

EMI Shielding, also known as electromagnetic shielding, is a technique that utilizes conductive or magnetic materials to attenuate or redirect electromagnetic fields (EMFs) in order to safeguard electronic devices from external electromagnetic interference and prevent the device from causing interference to surrounding components. This is a crucial measure to ensure that electronic devices operate reliably and efficiently.

The Importance of EMI Shielding

EMI Shielding has wide-ranging applications for electronic devices in many fields, including:

- Medical: Protect sensitive medical devices from interference, ensuring they operate accurately.

- Military: Protect information systems and weapons from electromagnetic interference to maintain high performance.

- Telecommunications: Ensure signal quality and minimize disruptions in communication systems.

To supplement information on EMI Shielding Electromagnetic Interference Solutions for the Electronics Industry, please read this article for detailed information: EMI Shielding solution in Electronic Devices

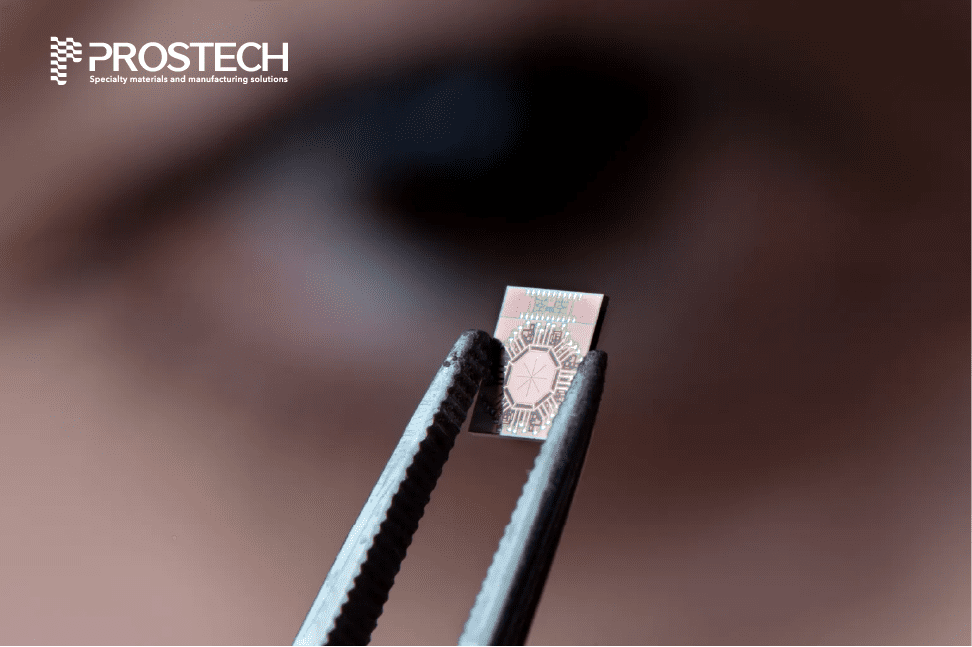

As technology continues to develop and become an indispensable part of our daily lives, electromagnetic interference/signal interference phenomena are also becoming more diverse. These invisible signals emitted from various sources negatively affect weak, sensitive components within the device itself and surrounding devices. This leads to various problems in the operation of electronic devices to varying degrees.

Handling interfering electromagnetic waves will be more difficult for small components with fast processing speeds. In this case, the manufacturer needs to choose a material with high performance but still suitable for the small size of the device.

Prostech provides EMI shielding solutions, especially high-quality specialized materials, small size, high shielding efficiency. Please contact Prostech for detailed advice on the type suitable for your application.

EMI Shielding Mechanisms

To combat EMI, the main techniques focus on preventing or minimizing the intrusion of electromagnetic waves into electronic devices. Three main methods are used:

- Reflection: Using conductive materials such as metals (copper, aluminum, steel) to create a barrier, reflecting electromagnetic waves away, preventing them from entering the device.

- Absorption: Absorbing materials (ferrite, conductive rubber) “consume” the energy of electromagnetic waves, converting it into heat, minimizing the impact on the device.

- Elimination: Eliminating the source of interference or moving the sensitive device away from the source of interference is the optimal solution but not always feasible.

We have explained the EMI Shielding mechanism in more detail in this article, you can refer to it for more information.

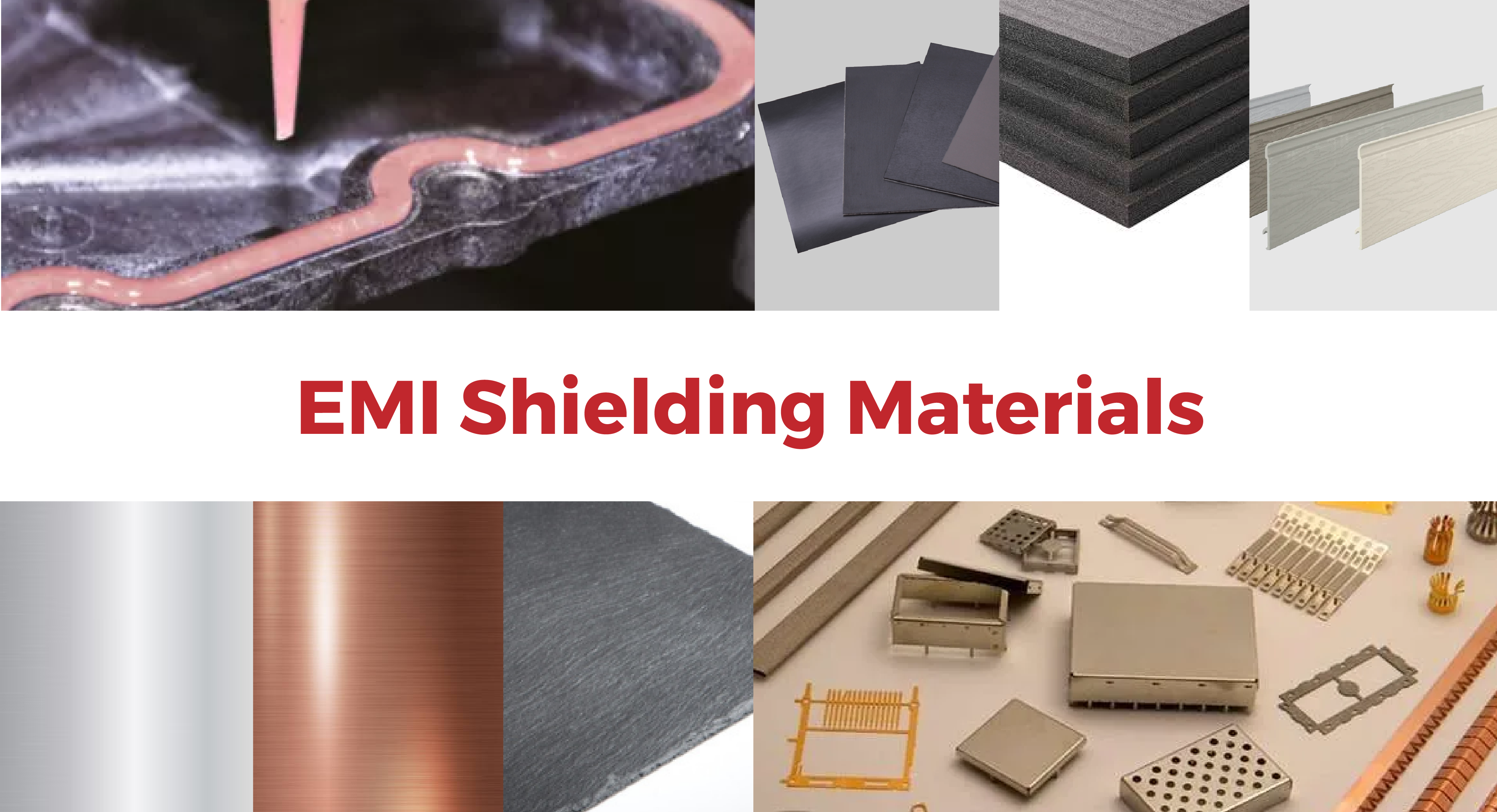

EMI Shielding Materials: Reflection and Absorption Methods

Reflection and absorption methods are commonly used for electromagnetic interference (EMI) shielding. This means that conductive materials and electromagnetic wave absorbing materials are highly recommended for shielding electronic components from external electromagnetic waves. The selection of the appropriate material depends on various factors. Some commonly used solutions include:

EMI Shielding & Grounding Coatings

-

Conductive and Thermally Conductive Adhesive Tapes: 3M™ Electrically Conductive Double-Sided Tape 9711S Series

-

Aluminum and Fabric Tapes: 3M™ EMI 1170 Aluminum Tape

-

Conductive and Thermally Conductive Foam Tapes: tesa® 60246, Tglobal – TGJ3C Electrically Conductive Cushion Tape

-

EMI Shielding Graphite: VieTape GP2801, Vietape GP4200

EMI Absorption Tape and Gasketing Liquid

- Silicone Materials absorb EMI: Gluditec EMI6425, BERGQUIST GAP PAD TGP EMI4000, LOCTITE SI 5421, Momentive SnapSil CXE16-0226B

- Flexible, Elastic Materials block noise and absorb EMI: 3M™ EMI Absorber AB6000, AB6000S, and AB6000G Series, VieTape EMI70 Series

Flux Field Directional Material (FFDM) for Optimal Performance in NFC, RFID, and WPC Devices

NFC (Near Field Communication), RFID (Radio Frequency Identification), and WPC (Wireless Power Consortium) devices frequently encounter electromagnetic interference (EMI) issues and require the use of FFDM (Flux Field Direction Material) to optimize performance.

NFC (Near Field Communication), RFID (Radio Frequency Identification), and WPC (Wireless Power Consortium) devices frequently encounter electromagnetic interference (EMI) issues and require the use of FFDM (Flux Field Direction Material) to optimize performance.

FFDM materials can enhance the performance of wireless charging devices, near-field communication, and the frequency range that RFID readers need to cover. FFDM can also be used in magnetic field environments to shield sensitive and vulnerable electronic devices.

3M™ Flux Field Directional Material (FFDM) EM25TP

NFC (Near Field Communication), RFID (Radio Frequency Identification), and WPC (Wireless Power Consortium) devices frequently encounter electromagnetic interference (EMI) issues and require the use of FFDM (Flux Field Direction Material) to optimize performance.

Challenges and Solutions in EMI Shielding

Addressing EMI interference is particularly challenging for small, high-speed electronic components. Therefore, selecting the appropriate shielding materials is crucial. Effective solutions include:

-

Employing high-quality materials: Ensure that the shielding materials used possess excellent attenuation and absorption capabilities.

-

Implementing sound design principles: Design circuits and enclosures to optimize EMI shielding performance.

EMI is a complex phenomenon that can cause severe problems for electronic devices. Understanding EMI and implementing effective EMI shielding measures is paramount to protecting devices and ensuring their reliable operation.

Prostech recognizes the technical challenges associated with EMI shielding faced by PCB and electronics manufacturers. We offer comprehensive solutions, encompassing consulting, materials, automated glue dispensing equipment, and tape application systems. Our nationwide warehousing network and logistical support facilitate seamless customer service. As a full-service provider, Prostech is committed to becoming a trusted partner for manufacturers in Vietnam and the international market. Contact us today to discuss your specific needs.