Product Description

Epoxylite® 578EB is a Class 180° C epoxy resin system designed for the Impregnation of both random and form wound machines, and is suitable for use on windings rated up to and including 3.3 kV.

For 6.6kV machines, specific insulation structures should be used to optimise impregnation. Epoxylite® 578EB has excellent tank stability and a relatively short cure cycle. The resin’s ability to give both good penetration and high film build means that excellent environmental and chemical protection can be obtained with a single application. This makes the resin ideally suited for both OEM and Electrical Repair Shop use.

Applications of Epoxylite® 578EB

Epoxylite® 578EB is designed to be applied by a Vacuum Pressure Impregnation process

Processing of Epoxylite® 578EB

Various VPI (Vacuum Pressure Impregnation) processes can be performed using Epoxylite® 578EB. Below are some examples:

-

Random Wound Machines: A dry vacuum level of at least 1-2 mbar is recommended for about 15-30 minutes before introducing the resin into the vacuum vessel. Afterward, maintain the same “wet” vacuum level for 10-15 minutes before applying a pressure of 60-70 psi for an additional 15-30 minutes.

-

Form Wound Stators and Armatures (up to 3.3 kV): A vacuum level of 0.5 mbar or better should be maintained for a minimum of 60 minutes before introducing the resin into the vacuum vessel.

See all Elantas Product Here

About Prostech

Prostech offers specialty materials (adhesives, tapes, thermal interface materials, insulating materials, sealants, PCB protection materials, …) along with manufacturing solutions. We proudly serve a wide range of industries and are an authorized distributor for leading global manufacturers of industrial materials and equipment. Our product range is designed to deliver customized solutions that address each customer’s unique needs.

With years of experience and a successful project history, we are confident in our ability to provide comprehensive material solutions. These solutions effectively tackle the challenges manufacturers face. To explore our full product catalog, simply click here. Our dedicated team is ready to assist with:

- Provide quotation, sample, TDS/MSDS, and technical consultation

- Testing sample quality and verifying product compatibility in our laboratory

- Customizing material formulas for special applications

- Adapting product sizes, quantities, and packaging to meet specific needs

- Offering expert advice on suitable equipment and automation processes

- Delivering technical training and on-site support for optimal product use

Moreover, Prostech ensures the safe and accurate global delivery of all materials, including “dangerous goods”, in compliance with legal regulations. For personalized technical support or to receive a quotation, please contact us today.

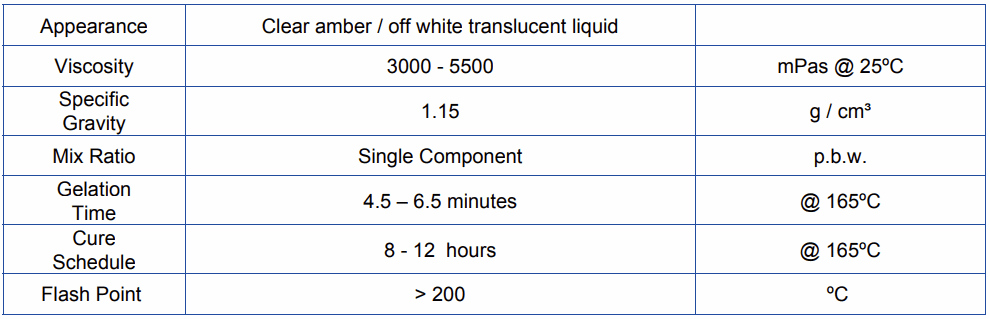

Typical properties