Productivity and Efficiency are the two keywords that many industrial manufacturers are pursuing. Automated Dispensing System is designed to prove ways to improve efficiency for them. As Industry 4.0 begins to spread throughout global industries, workers can handle higher responsibility jobs, the production rate is increased, and the margin of human error in processes is removed.

Basically, automated dispensing utilizes highly specific desktop units or robots which can dispense fluids, such as adhesives, accurately, consistently, and in the exact proposition. Key advantages to automated dispensing systems are cost-effectiveness and time savings.

One of the most popular fluid materials to be used in automated dispensing systems is adhesive. This kind of material is variable in functionality and appearance. From electrically conductive interconnects to thermal interface materials to surface mounting to glob top coatings to die attachment. Dispensing System will help dispense repeatable, precise, small volumes of adhesives.

According to different applications and industries, the construction of Dispensing systems will be different. At the entry level, a standard single dispensing system is the combination of the following equipment:

Automated Dispensing Robot

High precision robotic fluid dispensers replace manual processing to increase throughput speed, improve product quality, and lower assembly costs. Used by the display, automotive, electronic, healthcare, aerospace/ defense, telecommunication manufacturing companies these user-friendly automated robotic dispensers offer a rapid ROI and can apply high, medium, and low viscosity liquid adhesives continuously in lines, dots, patterns. They are often employed for dispensing adhesives simultaneously on multiple parts/components and are easily adaptable to reach confined spaces even in hazardous work environments.

Depending on productivity and precision, there are three options for dispensing tasks using robots:

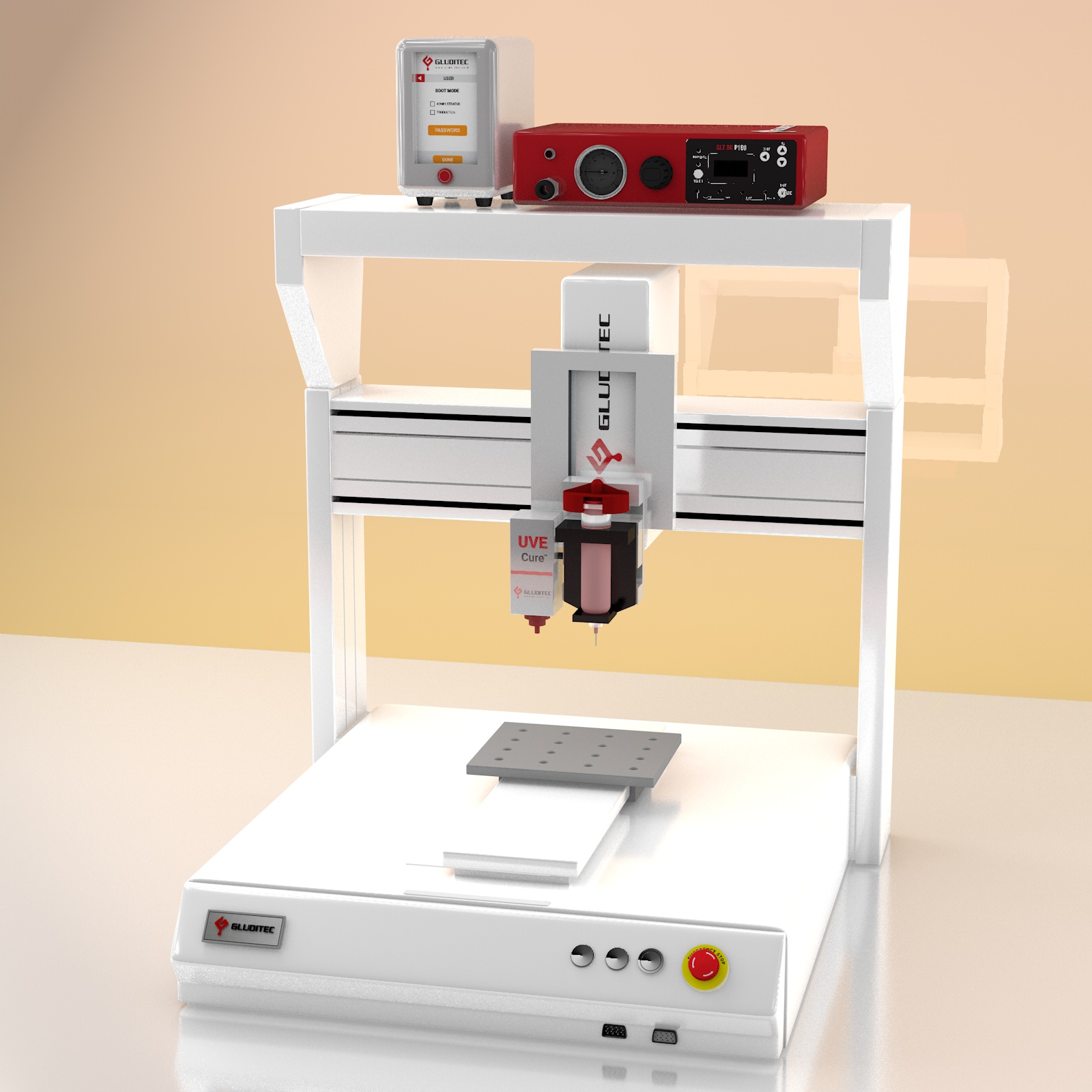

Desktop Dispensing Robot

Options: 3D – 6D Desktop Dispensing Robot, 2 Bed Dispensing Robot, Multiple Output Dispensing Robot, High Precision Dispensing Robot, Customizing Dispensing Robot.

Discovery further information here.

Arm Dispensing Robot

Compared to the desktop robot, the arm dispensing robot is more multi-functional and easily switch among these functions (such as output tools). This kind of robot is designed especially for high productivity in manufacturing.

Discovery further information here.

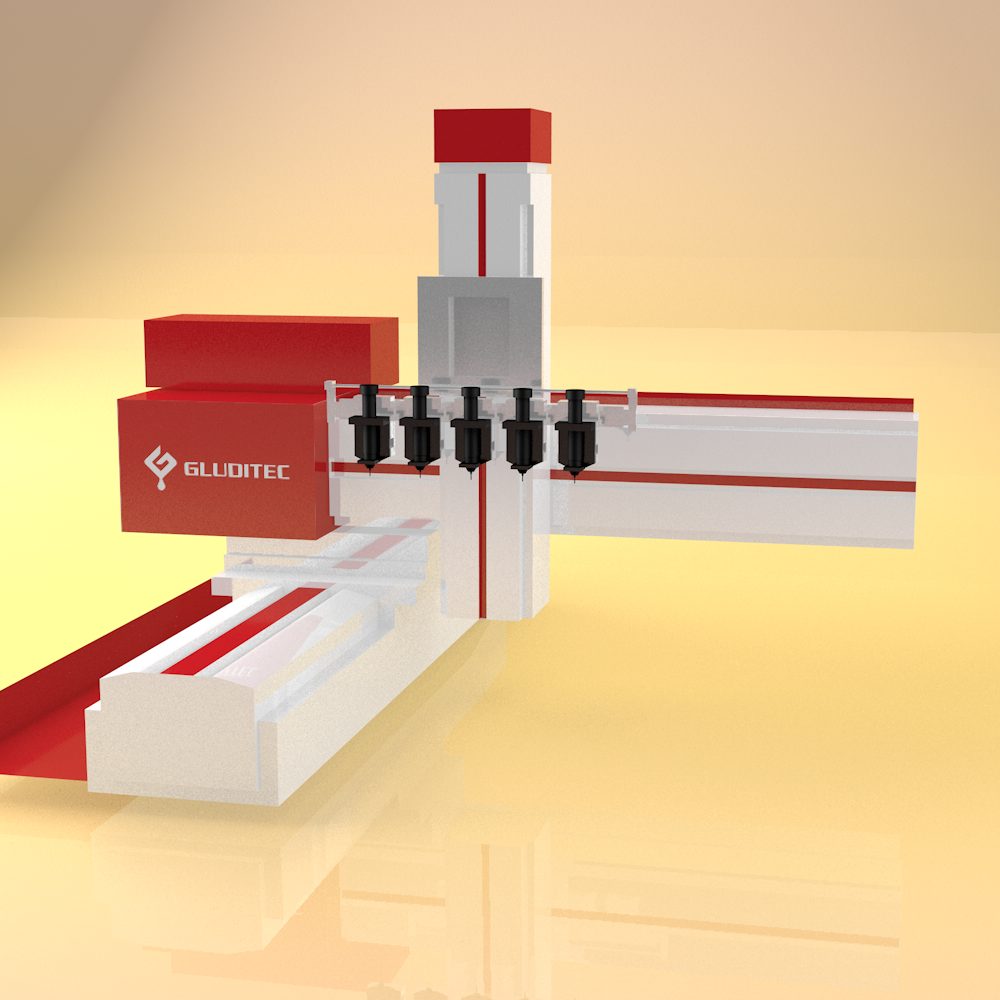

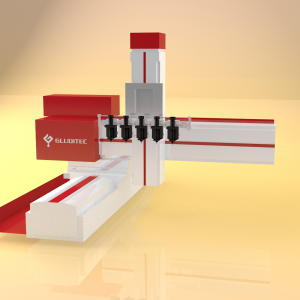

Gantry Dispensing Robot

Gantry robots can utilize an entire cubic work envelope of 96% of their space and size. A Cartesian robot has three axes. Like their namesake and more recognizable giant cousins, the gantry crane, they are commonly suspended from an X or X/Y axis beam on a rigid structure. Coordinates in three axes are usually defined as X, Y, and Z.

Like Arm Dispensing Robot, Gantry (and Cartesian) is used for large production lines and separate working areas.

Discovery further information here.

PROSTECH with strategy partner – GLUDITEC has various experience in automation and specialty material (as adhesive). As a result, we not only can provide customers with suitable solutions but also customize the whole system for their specific demands. Contact us for more information.

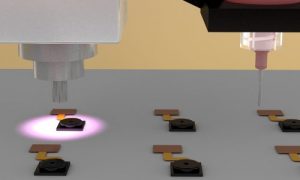

Dispensing Valve

Our valves are engineered to provide precise, repeatable, and reliable dispensing for a variety of dispensing tasks. For different purposes and applications, we must make decisions among different kinds of valves.

By determining your desired fluid viscosity, fluid content, and application type, we can identify the best dispensing valve for the job. We offer spool valves for high viscosity materials, poppet valves for smaller shots sizes, diaphragm valves for volatile fluids and UV resins, pinch-tube valves for volatiles, and cyanoacrylates, needle valves for dots, and auger valves are for high viscosity fluids such as solder paste applications.

Whatever the needs of your system or the materials you’re working with, you’re sure to find the right fit with our diverse selection of sealant and adhesive dispensing valves, including fluid control valves, piston valves, air-actuated valves, and epoxy dispensers. Our sealant valves are available for the management of low-to-high viscosity materials, abrasive materials, pourable or cohesive materials, and high-to-low flow materials. So, whether you’re looking for a valve with a fast shut-off, a valve designed for bead dispensing, or a no-drip valve for accuracy and efficiency, we have it.

See all our dispensing valves.

Dispensing Controller

Our dispensing controllers are designed to provide efficiency and convenience by ensuring accurate deposit size by keeping control close to the valve. Find the right controller for your dispensing valve.

See all our dispensing controllers.

To choose a suitable automated dispensing system, there are many different conditions that have been taken into consideration. Contact us for free consultant: