- Thermal Interface Materials (TIMs) for data center infrastructure

- Lens active alignment materials for data center infrastructure

- Epoxy and acrylic adhesives for structural bonding

- Module sealants for data center infrastructure

- Conformal coatings for electronic component

- Potting and encapsulation to protect PCB

- EMI shielding materials for data center infrastructure

- FPC reinforcement materials for data center infrastructure

- Underfills for sensitive component

Data center demands robust assembly and protecting solutions to ensure the reliability and efficiency of critical infrastructure like servers, storage systems, switches, and routers. These solutions provide durability, protect against environmental stressors like dust and moisture, and optimize performance in demanding operational environments. In this article, we explore the critical assembly and protection solutions that data centers rely on.

Thermal Interface Materials (TIMs) for data center infrastructure

TIMs are applied between heat-generating components and cooling solutions to enhance heat transfer by filling microscopic gaps that can trap air, which acts as a thermal insulator. In servers, TIMs like thermal pads, thermal grease or thermal gels are placed between CPUs or GPUs and heat sinks to dissipate heat efficiently and maintain consistent performance without thermal throttling. In switches and routers, TIMs ensure heat dissipation for ASICs and power modules, maintaining optimal performance under heavy data traffic loads.

For detailed TIMs solution, refer to the article: Thermal Interface Materials (TIMs) Solutions for High-Performance Data Centers

Lens active alignment materials for data center infrastructure

High-precision bonding materials are used to align lenses in optical modules, ensuring accurate data transmission. UV-curable adhesives are used in pluggable optical modules (POMs) to ensure alignment of optical lenses, critical for high-speed data transmission.

Read more at: Adhesive materials for Active Alignment application in Camera Modules

Epoxy and acrylic adhesives for structural bonding

Structural adhesives, such as epoxy and acrylic adhesives (e.g., MMA), offer high strength and durability, making them ideal for demanding applications. These adhesives are widely used to assemble components in industries where load-bearing and long-term reliability are critical. They are used to assemble server racks, router enclosures, and storage system mounts:

- Server Racks: Acrylic adhesives secure frames and panels, reducing vibrations and ensuring stability under heavy loads.

- Enclosures: Epoxy adhesives are used for assembling protective housings, ensuring stability and protecting sensitive components like switches and routers from shocks and environmental exposure.

Related article: Uses of Structural Adhesive in Industrial Manufacturing

Module sealants for data center infrastructure

Silicone or polyurethane sealants protect enclosures and connectors from moisture, dust, and environmental contaminants. Routers and switches deployed in humid environments benefit from these sealants to maintain functionality and durability.

Conformal coatings for electronic component

Conformal coatings are essential for protecting printed circuit boards (PCBs) in servers, switches, and other critical electronic components. These coatings shield sensitive circuitry from environmental factors such as humidity, dust, and chemical exposure, ensuring reliable operation in demanding conditions.

Silicone, polyurethane, acrylic and some modified acrylic coatings are applied to PCBs in servers and switches to protect against humidity and chemical exposure.

Potting and encapsulation to protect PCB

Sensitive components, such as power modules in routers or storage controllers in storage systems, are protected from vibrations and dust using epoxy & silicone potting compounds:

- Epoxy potting compounds: Epoxy provides excellent mechanical strength, commonly used for potting power modules in routers and storage controllers in storage systems where stability and long-term protection are critical.

- Silicone potting compounds: Silicone potting compounds excel in high-temperature environments, Ideal for components subjected to thermal cycling or where flexibility is required, such as in power electronics and modules exposed to frequent temperature changes.

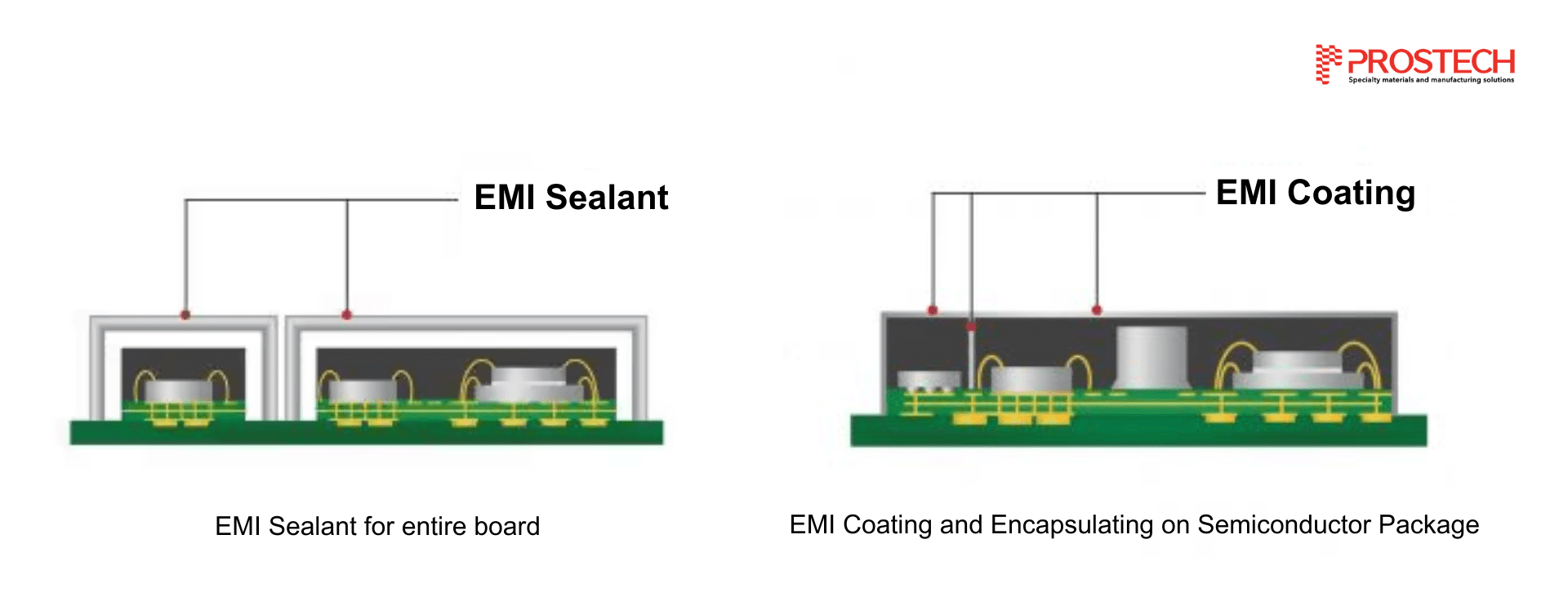

EMI shielding materials for data center infrastructure

EMI shielding materials provide electrical conductivity while shielding sensitive electronics, such as processors in servers or networking chips in routers, from electromagnetic interference.

Read more at: EMI Shielding Materials and Mechanisms

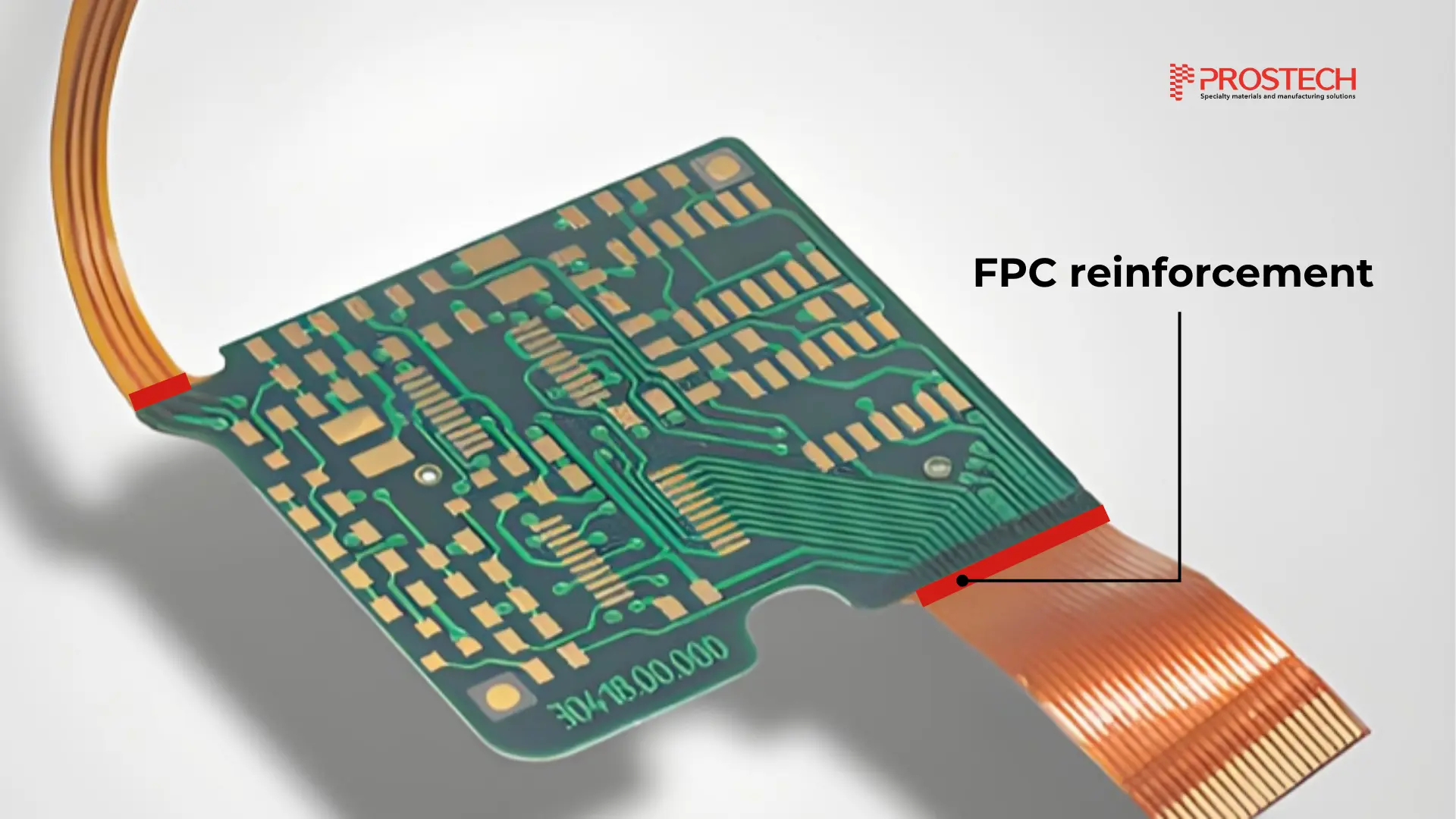

FPC reinforcement materials for data center infrastructure

Reinforce flexible printed circuits (FPCs), reducing the risk of tearing and ensuring durability in high-vibration environments. Provide mechanical stability for connectors and bonding pads in storage devices and routers.

Related article: How to choose the right materials for FBC reinforcement in camera modules

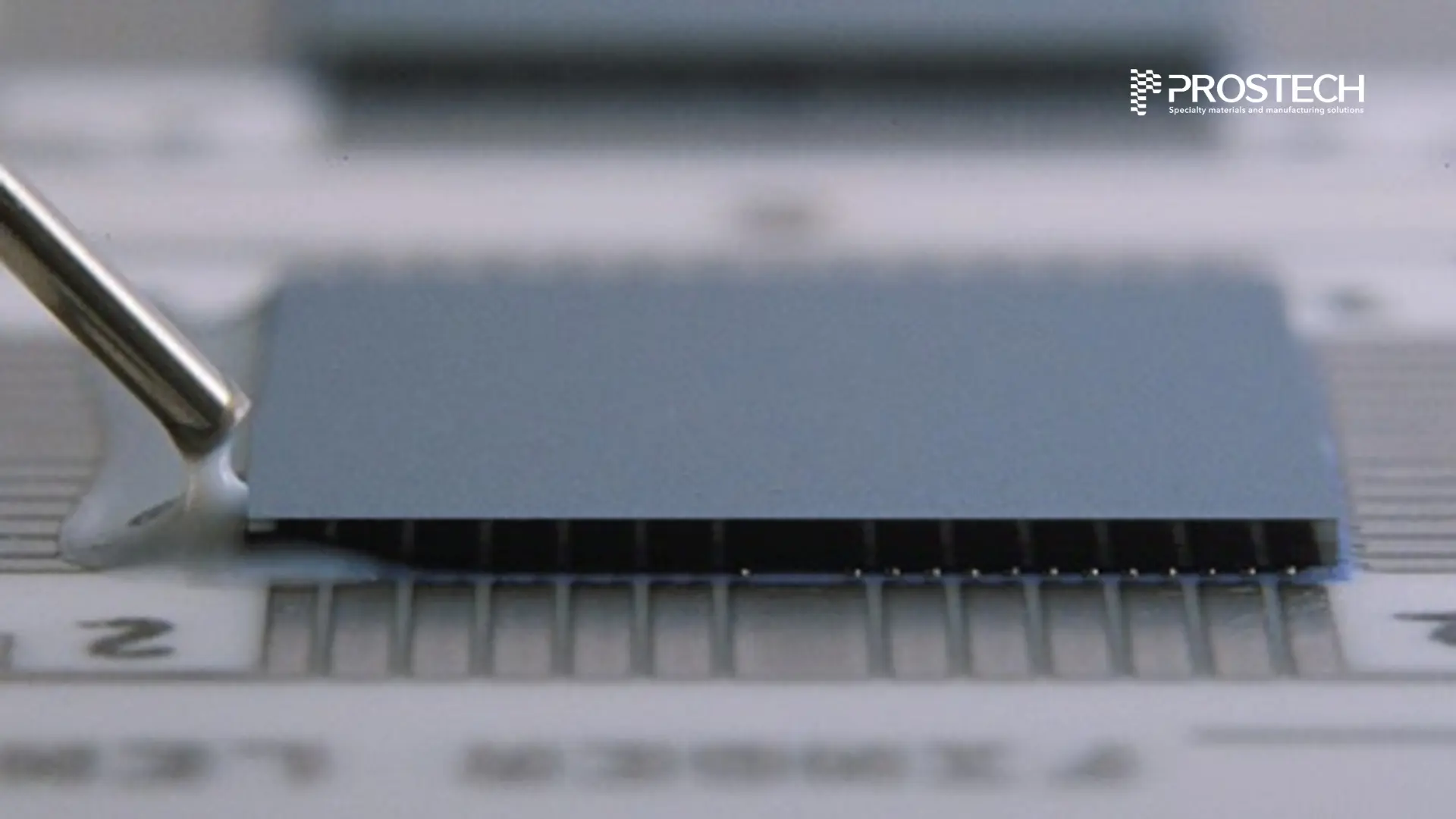

Underfills for sensitive component

Underfills enhance mechanical integrity and protect fine-pitch array components or ICs from thermal and mechanical stress. Available in reworkable and non-reworkable formulations, underfills effectively protect component interconnects with low bump heights. In storage systems, underfills ensure durability for delicate connections in high-density circuits.

Read more at: Underfills for reinforcing Components on PCBs

Prostech understands the technical issues related to circuit boards and electronic devices and other data center applications. We offer comprehensive solutions, including consulting, materials, and automated adhesive application equipment. We have a global warehousing network to assist customers with logistics procedures. Positioned as a comprehensive supplier, Prostech is constantly striving to become a trusted partner for manufacturers around the world. Contact us by leaving your information below: