The camera cover plays a crucial role in protecting internal components from dust, moisture, and impact while ensuring optical clarity for high-quality imaging. It also contributes to the overall structural integrity and design aesthetics of the device. High-performance adhesives are essential for securing camera cover in place, providing both strong bonding and environmental resistance.

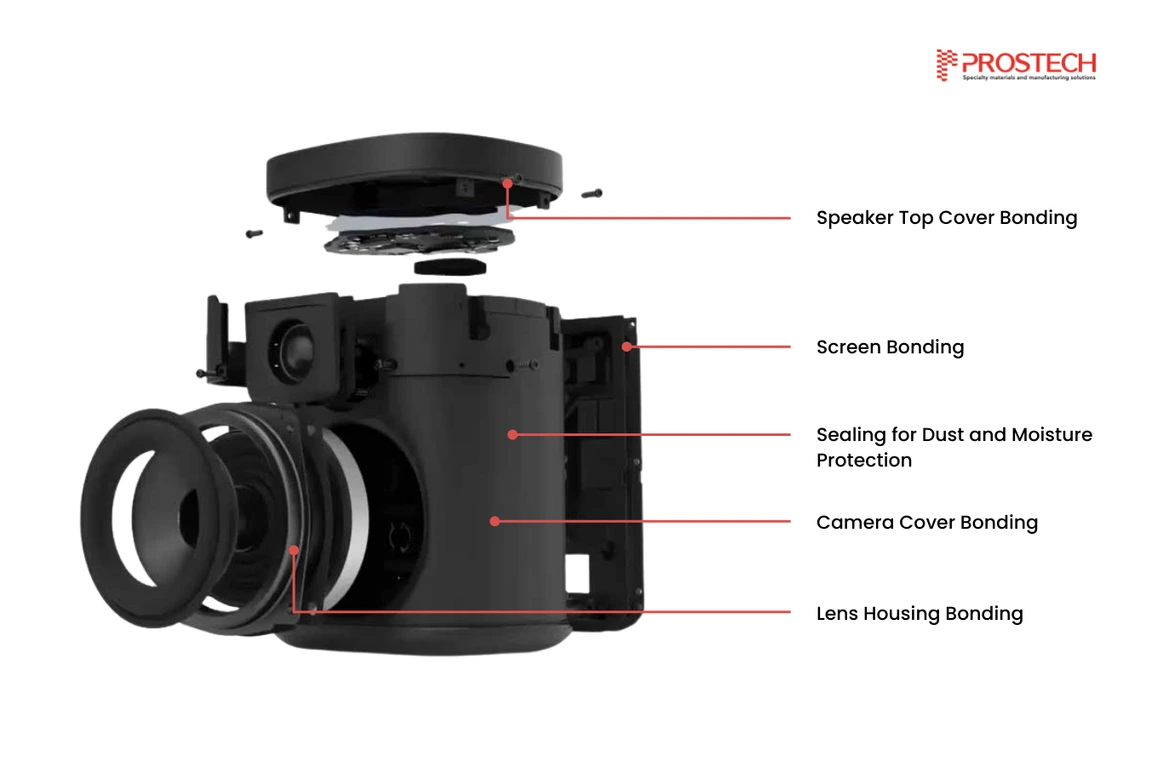

Key Bonding Parts in Camera Cover Assembly

- Camera Cover Bonding: Securing the protective cover over the camera lens to prevent dust and external damage.

- Speaker Top Cover Bonding: Attaching the top cover of the speaker assembly to ensure sound integrity and structural stability.

- Lens Housing Bonding: Fixing lens components in place for precise alignment and durability.

- Screen Bonding: Attaching the screen panel securely to the device housing, ensuring durability, impact resistance, and optimal touch functionality.

- Sealing for Dust and Moisture Protection: Creating a protective barrier around critical internal parts.

For information on other camera components, please refer to the following articles:

- Bonding & Sealing Solutions for Security Camera Assembly

- Adhesive materials for Lens to Barrels bonding in Camera Modules

- Camera Modules Manufacturing Applications

Adhesive Requirements for Camera Cover, Speaker, and Screen Bonding

To meet the stringent demands of electronic device manufacturing, adhesives used for bonding must fulfill the following criteria:

- Strong Structural Bonding: Must provide high adhesion to materials such as plastic, glass, and metal.

- Optical Clarity (if required): Should not interfere with camera performance or light transmission.

- Resistance to Environmental Factors: Must withstand temperature fluctuations, humidity, and exposure to UV light.

- Vibration and Shock Absorption: Helps prevent component displacement due to drops or impact.

- Compatibility with Automated Assembly: Should be suitable for high-precision dispensing and fast curing processes.

- Flexible and Stress-Resistant for Screens: Ensures that the screen maintains durability while handling minor flexing and pressure.

Adhesives for Camera Cover Bonding

Prostech’s bonding solutions ensure the secure installation of camera cover by:

- Ensuring a long-lasting bond for camera covers, speakers, and screens

- Protecting against humidity, dust, and thermal expansion

- Optimizing for automated manufacturing, reducing production time.

- Working effectively with plastic, metal, and glass materials

- Preventing contamination that could affect optical and electronic performance.

Here are some of our top-performing adhesives and tapes designed to enhance durability, efficiency, and aesthetics in camera cover assembly:

Devcon® HA0810:

- Strong adhesion to PC/ABS substrates

- Good flexibility, allowing for slight material movements without cracking

- Simple reworkability at 60°C, allowing for easy disassembly and adjustments.

- Ensures airtight sealing and waterproof protection

- Fast curing, reducing assembly time

- Superior resistance to extreme temperature variations

Plexus® MA310:

- Capable of bonding a wide range of materials, including thermoplastics, metals, and composites

- Provides robust adhesion.

- Achieves fixture strength in 30-35 minutes at room temperature

- Offers a working time of 15-18 minutes, allowing adequate time for precise positioning

- The thixotropic nature prevents sagging during application

Devcon® Tru-Bond LOCA 5000 UV Cure Adhesive:

- Designed to eliminate air gaps between cover lenses, ensuring clear visibility for camera covers.

- Cures rapidly upon exposure to UV light

- Provides a durable bond with ultra-low hardness, suitable for sensitive components in camera modules.

Can’t find the right product? Let our experts help! Contact us today for a free consultation and discover the best adhesive solution for your camera assembly needs.