Abrasives are indispensable materials in modern manufacturing, playing a critical role in shaping, finishing, and cleaning surfaces across a wide range of industries. Abrasives not only facilitate efficient material removal and surface finishing but also help enhance the quality and longevity of industrial components. In this blog post, we’ll explore the different types of abrasives, how they are classified, and their extensive applications in industrial settings.

What are abrasives?

Abrasives are materials with a hardness greater than the workpiece they are designed to act upon. They are used to remove surface imperfections, smooth out surfaces, and create precise shapes through processes like grinding, cutting, and polishing. The friction generated during abrasive processes can be harnessed to achieve various surface textures and finishes.

Types of Abrasives

Types of abrasives by material composition

This method categorizes abrasives based on their origin, whether they occur naturally or are manufactured synthetically.

1. Natural abrasives

Natural abrasives are sourced from the earth and have been used for centuries due to their availability and effective performance. Key examples include: Diamond, corundum, garnet, quartz, sand,…

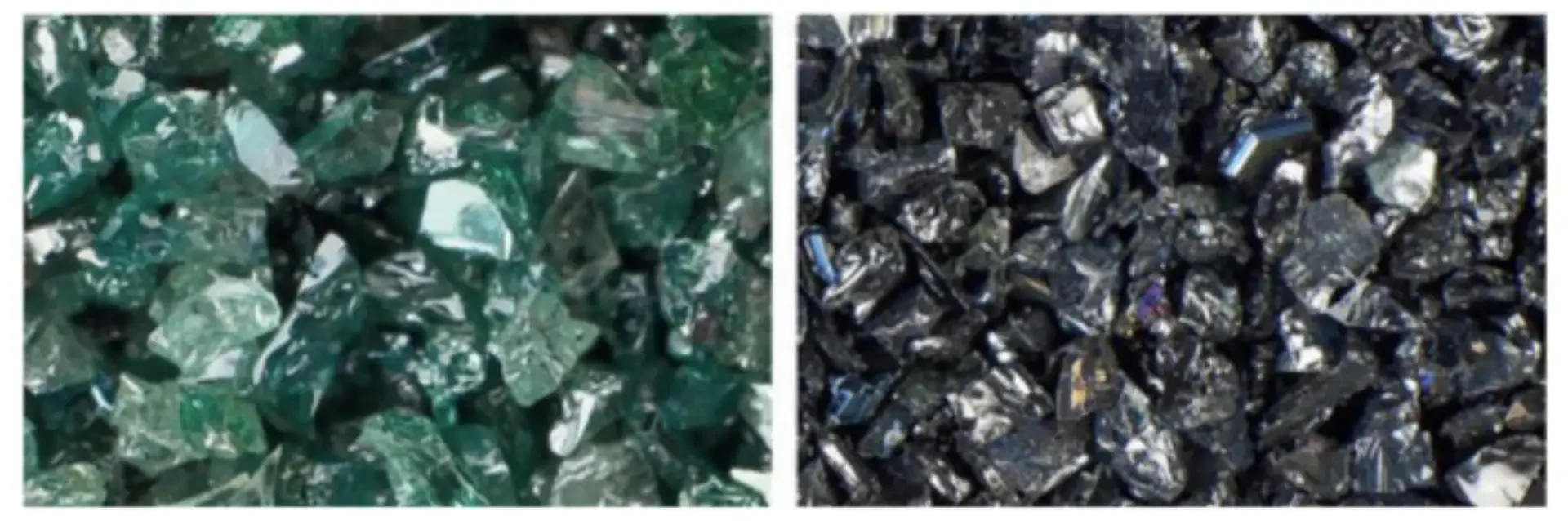

2. Synthetic abrasives

Synthetic abrasives are manufactured to provide uniformity in particle size and performance characteristics. Synthetic materials have mostly replaced natural abrasives due to the need for consistent properties in almost all industrial applications. Notable synthetic abrasives include:

- Aluminum Oxide: Aluminum oxide is one of the most common entry-level abrasives available today. It is characterized by its low cost and versatility. It is commonly used in grinding wheels and sandpapers, aluminum oxide is suitable for both ferrous and non-ferrous materials.

- Zirconium Abrasives: Zirconium abrasives are essentially a blend of aluminum oxide and zirconium, engineered to deliver a higher metal removal rate compared to pure aluminum oxide.

- Silicon Carbide: Silicon carbide abrasives offer a high metal removal rate and are tailored for more application-specific tasks. Known for their longevity and efficiency, they are widely used in settings where precision is critical. Silicon carbide is ideal for high-speed machining and cutting applications.

- Ceramic Abrasives: Ceramic abrasives combine strength, durability, and a self-sharpening ability that keeps them performing at peak efficiency for longer periods. It is used in applications where finish quality are critical and minimal abrasive wear is desired.

Types of abrasives by form and application

The abrasives and abrasive tools used in abrasive machining processes are of three primary types, namely, bonded, coated, and loose.

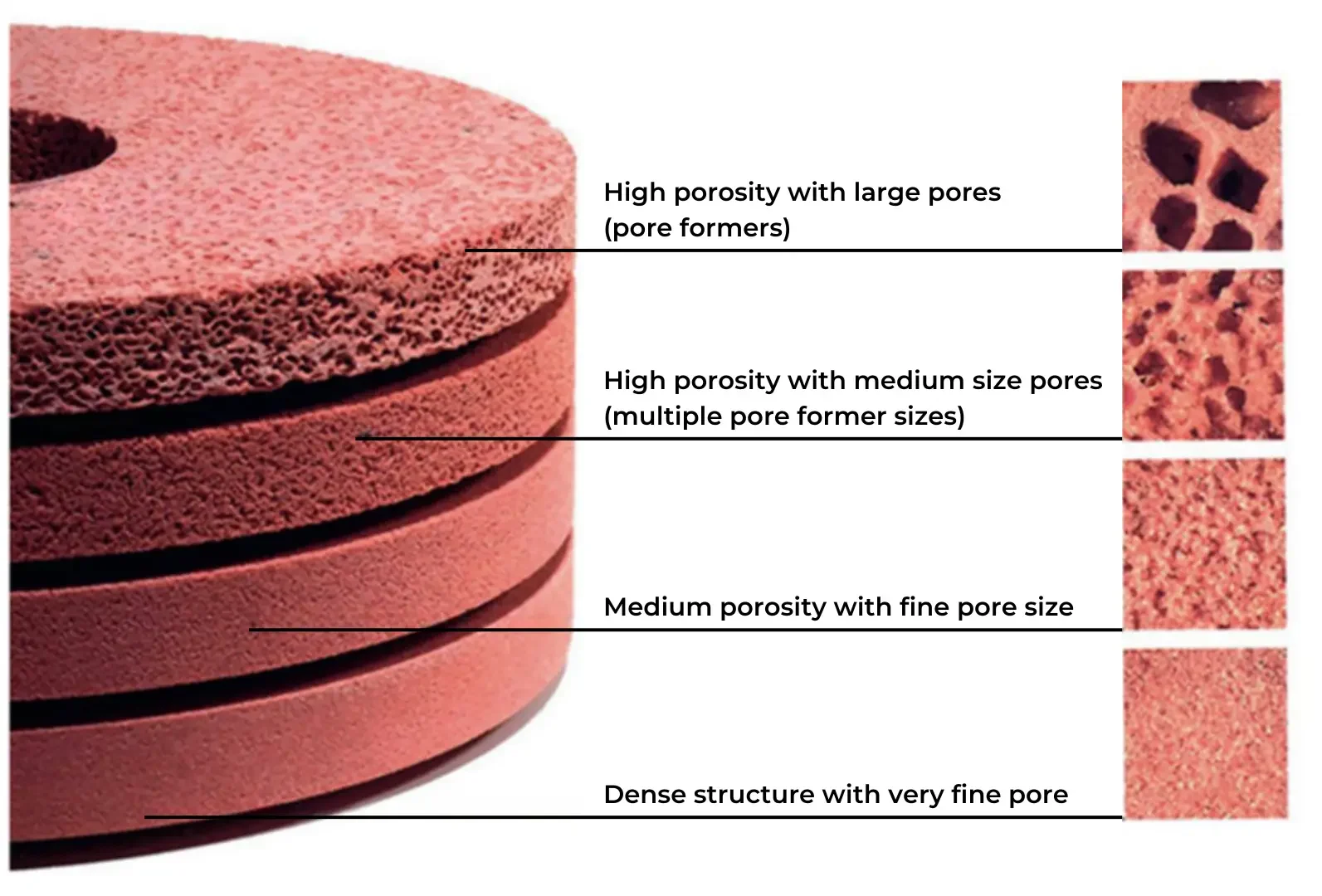

- Bonded abrasives: Abrasive grains are held together by bonding agents such as resin, metal, or vitrified materials. They are mainly used in grinding, honing, and superfinishing processes.

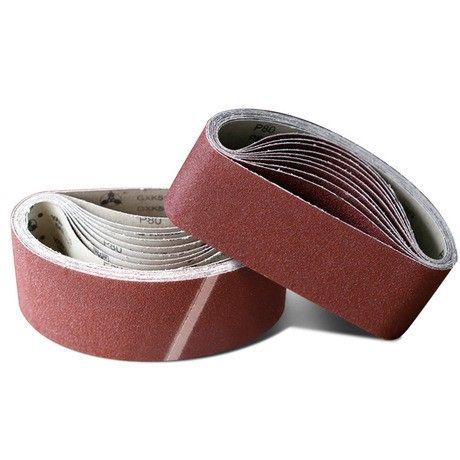

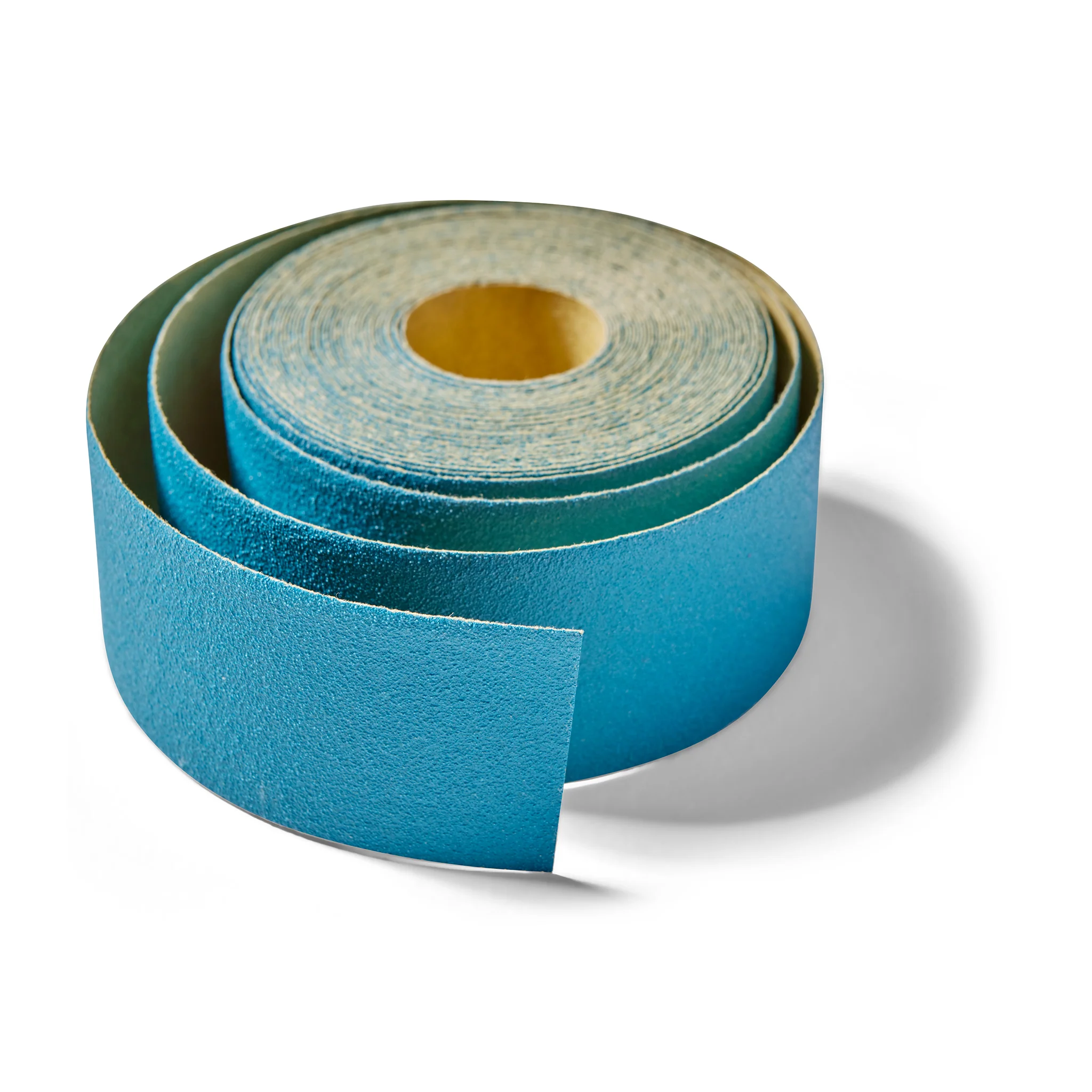

E.g. Grinding wheels, Cutting discs, Mounted points,… - Coated abrasives: Abrasive grains are attached to a flexible backing material such as paper, cloth, or fiber. They are mostly employed in grinding, deburring, superfinishing, and polishing processes.

E.g. Sandpaper, Abrasive belts, Abrasive rolls,… - Loose abrasives: These abrasives are free grains or mixed with a carrier fluid for lapping, polishing, or cleaning.

E.g. Diamond paste, Polishing compounds, Slurries used in semiconductor manufacturing,…

Abrasive tools and their applications

Abrasives are incorporated into a variety of tools and equipment, each designed for a specific range of tasks. Understanding the relationship between abrasive type and tool design is crucial for achieving optimal performance in industrial applications.

Grinding Wheels

Grinding wheels consist of abrasive grains bonded together. They are used extensively in metalworking for operations such as:

- Grinding and sharpening: To produce a smooth finish on metal surfaces and to sharpen tools.

- Deburring: To remove unwanted material and sharp edges from machined parts.

- Surface preparation: For cleaning and preparing surfaces prior to coating or assembly.

Sandpapers and Belts

Sandpapers and abrasive belts are sheets or strips of abrasive material bonded to a flexible backing, typically made of paper, cloth, or film. This versatile tool is widely used for:

- Surface finishing: To remove scratches, polish surfaces, and provide a uniform texture on wood, metal, and plastic.

- Material removal: For stripping paint or smoothing out irregular surfaces in automotive and furniture manufacturing.

Cutting wheels and discs

These tools incorporate abrasives into thin, flat forms that can cut through materials with precision. Common applications include:

- Metal cutting: Using thin, high-performance discs to slice through metal components in construction and fabrication.

- Tile and stone cutting: Employed in both construction and art to achieve precise cuts on hard materials.

Sanding Screens

Sanding screens are mesh-like abrasives that combine the durability of screens with the precision of fine grits. Their applications include:

- Surface blending: Achieving a uniform finish by evenly abrading surfaces and blending transitions.

- Material removal: Removing coatings or smoothing out surface imperfections with a controlled, less aggressive approach.

- Versatile finishing: Often used as an alternative to traditional sandpaper for large areas or curved surfaces, offering longevity and consistent performance.

Abrasive Brushes

Abrasive brushes are designed with bristles embedded with abrasive particles. They are especially useful for:

- Cleaning and rust removal: Effectively removing rust, scale, and contaminants from metal surfaces.

- Deburring and surface preparation: Providing a controlled method for cleaning parts before further processing or coating.

- Edge blending: Softening sharp edges or transitions without the need for more aggressive grinding or sanding.

Handheld Abrasives

Handheld abrasives include various manual tools such as hand pads, abrasive cloth, and sanding sponges. These tools offer precision control, versatility and ease of use.

|

Task |

Best Tool/s |

Alternative Tool/s (where applicable) |

|

Cutting – metal |

Cutting discs |

Diamond discs or burrs |

|

Cutting – non-metal |

Diamond discs |

n/a |

|

Grinding |

Grinding discs or wheels |

n/a |

|

Stock removal |

Flap discs or wheels |

n/a |

|

Deburring |

Burrs or flap wheels |

Sanding discs, hand pads, or abrasive cloth |

|

Hand sanding |

Hand pads or abrasive cloth |

n/a |

|

Surface preparation, stripping, or cleaning |

Sanding discs or belts, flap discs, or fibre discs |

Flap wheels, hand pads, or abrasive cloth |

|

Surface blending and conditioning |

Sanding discs or flap discs |

Hand pads or abrasive cloth |

Industrial applications of abrasives

Abrasives are a cornerstone in many industrial processes. Here’s a look at how different industries utilize these materials:

Metalworking and Manufacturing

- Precision grinding: Abrasives are essential in metal fabrication where tight tolerances are required. Grinding wheels and belts are used to produce flat, smooth surfaces on precision components.

- Tool sharpening: Regular maintenance of cutting tools through grinding and honing ensures that industrial machines operate efficiently.

- Deburring: Abrasives help remove burrs and sharp edges from metal parts, ensuring safety and functionality in assembly lines.

Construction and Stone Processing

- Surface preparation: In construction, abrasives are used for preparing surfaces for painting, coating, or bonding by removing rust, old paint, and other surface contaminants.

- Stone cutting and finishing: From countertops to building facades, diamond and silicon carbide abrasives allow for precise cutting and finishing of natural and engineered stone.

- Sandblasting: Abrasives like garnet and sand are deployed in sandblasting processes to clean and etch surfaces, enhancing adhesion for subsequent coatings.

Automotive and Aerospace Industries

- Residual material removal: In these sectors, abrasives are employed to eliminate residual materials and imperfections from machined components, ensuring precision and safety.

- Surface preparation: Abrasives are also used to prepare surfaces prior to painting, removing contaminants and enhancing coating adhesion for a high-quality finish.

Electronics and Semiconductor Manufacturing

- Wafer polishing: In the electronics industry, achieving extremely smooth surfaces is crucial for semiconductor wafer production. Polishing compounds with ultra-fine abrasives are used to achieve the required surface finish.

- Precision machining: Abrasive processes ensure that components meet the rigorous standards necessary for high-performance electronics.

Factors Influencing Abrasive Selection

Selecting the right types of abrasives is a balance of several factors, including:

- Material hardness: The abrasive must be harder than the workpiece to be effective.

- Grit size: Finer grits yield smoother finishes, while coarser grits are more effective for rapid material removal.

- Bond type: The choice of bond material (resin, vitrified, metal) affects the wear rate and cutting action of the abrasive tool.

- Operating conditions: Temperature, speed, and the presence of coolant or lubricant can impact abrasive performance.

These considerations ensure that the types of abrasives not only meets the immediate operational needs but also enhances the longevity and efficiency of the process.

|

Specification |

Aluminum Oxide |

Zirconium |

Silicon Carbide |

Ceramic |

|

|

|

||

|

Hardness (Mohs Scale) |

8 – 9 |

8 – 9 |

9 – 9.5 |

9+ |

|

Durability |

Moderate |

High |

High |

Very High |

|

Cutting Speed |

Moderate |

High |

Very High |

Extremely High |

|

Self-Sharpening |

No |

No |

Limited |

Yes |

|

Recyclability |

High |

High |

High |

High |

|

Cost Efficiency |

Low (Budget-friendly) |

Medium |

Medium-High |

High (Premium quality) |

Relying solely on the initial price when selecting an abrasive is a common error. Instead, you should evaluate the specific application, cost per unit, durability of the material, and scrap rates to determine the best types of abrasives for the task. With many years of experience in the industrial material, Prostech is ready to assist customers in selecting the right abrasive materials and providing integrated solutions for production lines to optimize manufacturing efficiency. Contact us for free consultation!