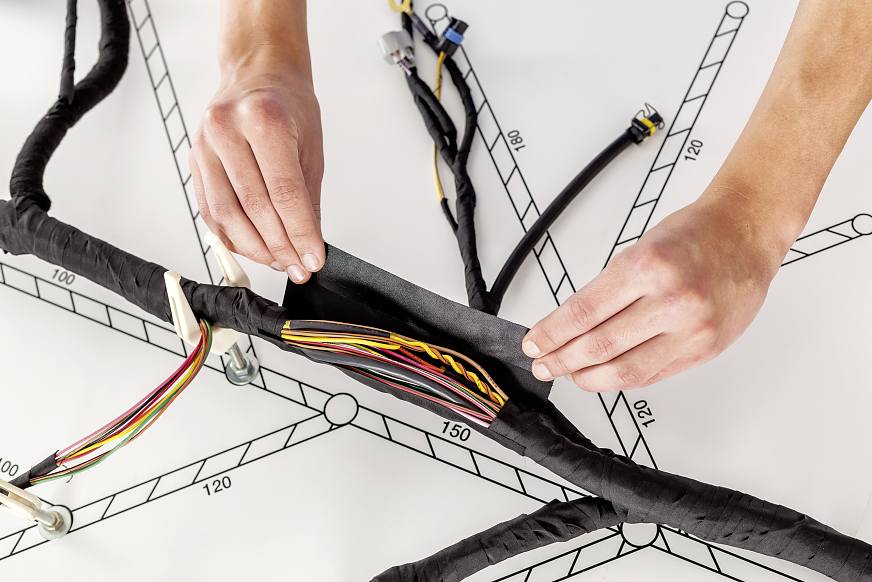

PROSTECH solutions help wire harnesses achieve high performance in challenging conditions

A wire harness, also commonly referred to as a wiring harness, is an exterior sheath used to cover some types of electronic wires. Generally, wiring harnesses are made of thermoplastic or thermoset materials that can help protect the cables from the environment. It is a low-cost, simple method for technicians to keep wires organized, protected, and easy to navigate. Although most wires come with their own exterior sleeves, those sleeves seldom are thick enough to protect the wires from dust, debris, and moisture. The thicker the wire is, the more risk there is of it sustaining damage due to a burned fuse.

Today’s wire harnesses face a variety of challenges including high temperatures, abrasion, and exposure to such elements as water, diesel, and crude oil. These evolving challenges require a partner that can provide technical support, a variety of solutions, and continuity of service. PROSTECH offers an impressive mix of products that protect wire harnesses in harsh environments and can help make the harness manufacturing process more efficient.

In the different applications, the tapes and adhesives used in Wire Harness Application will have various functions. For example, harness coverings need to securely bundle harnesses and withstand demanding temperatures and environmental conditions. Products for the engine compartment have to be highly resistant to abrasion, while in the passenger compartment, tapes are applied to reduce noises. In the sealing wiring harnesses, sealant adhesive will be used to seal harness housing to prevent moisture ingress into the electronics of the vehicle.

PROSTECH SOLUTION

The term “wire harness” is often used interchangeably with the term “cable assembly.” However, these are actually two different products. While both are exterior sheaths used to protect wires or cables, the cable assembly is made of a more durable material and is created to offer a higher level of protection in the most extreme conditions. Wiring harnesses and cable assemblies each have a distinct purpose in the electrical field. Selecting the right one is based on the application needed and is an important part of the success of your product.

Conductive & Insulating Tapes

|

Insulating and Conductive Tapes are made from a broad range of backings and adhesives for demanding applications. Main functions:

|

Vinyl Tape

|

Vinyl Electrical Tapes combine the flexibility of a PVC backing with excellent electrical insulating properties, high dielectric strength, and resistance to moisture, UV rays, abrasion, corrosion, alkalies, and acids. (Their rubber-based adhesive performs well over a range of temperatures). Fade-resistant vinyl comes in a range of colors for marking. For primary electrical insulation up to 600 volts, including wire harnessing, degaussing coils and high-voltage cables.

|

Sealing Adhesive

|

Sealing adhesives, used in wire harnesses, are a two-part (or adhesive with activator), 100% solid, the electrical-grade system with easy mixing ratios and a range of flexibility and viscosity. Main functions

Features

|

Each application has different requirements about wire harness material. Contact us for more consultants: