Cyanoacrylate (CA) adhesives, commonly known as fast-curing glue or super glue, have long been a popular choice due to their ability to bond quickly and strongly to various substrates such as plastic, metal, wood, and rubber. However, one of the drawbacks of traditional CA is its odor and the blooming effect during use. What causes this issue and how can we overcome it? Let’s find out in this article.

You may be also interested in: The 9 Myths about Cyanoacrylate Adhesives

Two Common Issues with Traditional Cyanoacrylate Adhesives

Strong odor: When cyanoacrylate (CA) adhesive cures, it often emits a strong, pungent odor that can be unpleasant for users. This is particularly problematic in enclosed work environments, where the smell can negatively impact the user experience. As a result, many people are hesitant to choose CA glue for long-term use or in professional settings.

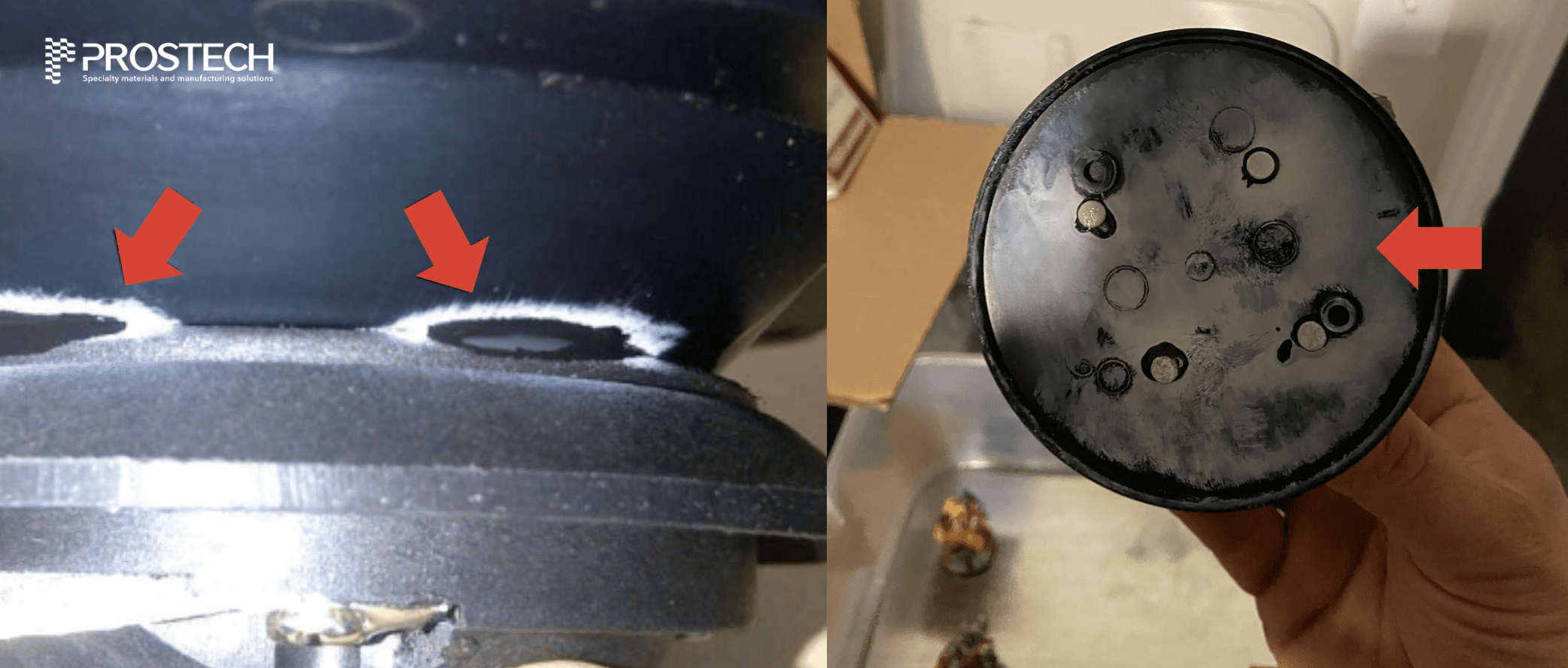

Blooming effect: This is the appearance of a foggy or smoky haze, where unwanted white residue appear on the surface of the material after the CA adhesive cures. This phenomenon not only reduces the aesthetic quality of the product but can also diminish the bonding performance.

Causes of Strong Odor and Blooming Effect

The two common issues with traditional cyanoacrylate adhesive (strong odor and blooming effect) both originate from the adhesive’s chemical reaction with moisture in the air. When the adhesive comes into contact with moisture, volatile compounds are released, producing an unpleasant odor. Simultaneously, during the polymerization process, small molecules form a white film on the surface, leading to the blooming effect, which impacts aesthetics and reduces bonding quality.

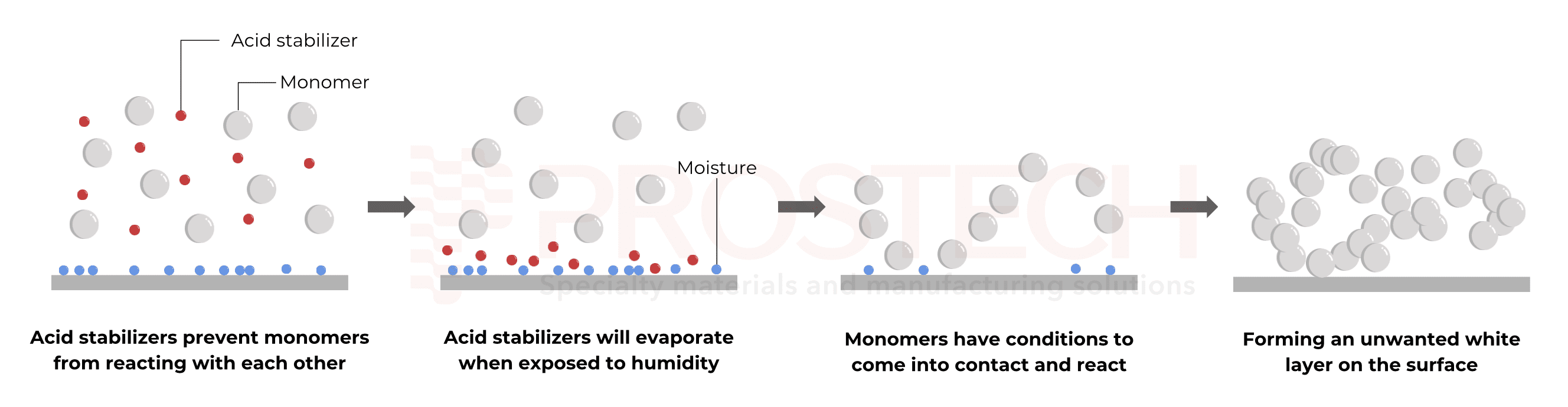

Chemical Mechanism Behind the Blooming Effect:

Cyanoacrylate adhesive contains two main components: monomers and acid stabilizers. The acid stabilizer prevents the monomers from reacting too early. When exposed to moisture in the air, the acid stabilizer evaporates, allowing the monomers to react and form an unwanted white film on the surface.

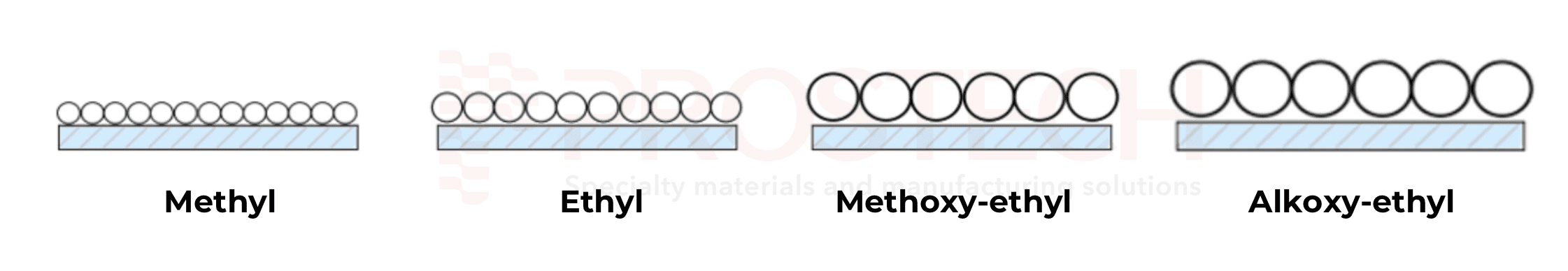

In particular, smaller monomers such as Methyl and Ethyl are more easily carried along by the acid stabilizer, resulting in a higher occurrence of blooming. In contrast, larger monomers like Alkoxy-ethyl and Methoxy-ethyl are less affected and do not easily cause blooming. This is the key factor that helps improve this issue.

Solutions to Overcome Odor and Blooming Effect

To address the drawbacks of traditional cyanoacrylate adhesives, low-odor and low-blooming adhesive lines have been developed using Alkoxy-ethyl and Methoxy-ethyl cyanoacrylate technology. This technology significantly reduces the amount of volatile compounds, minimizing the pungent odor and blooming effect, providing a more comfortable user experience while maintaining strong bonding performance.

Some methods to mitigate blooming:

1. Avoid Adhesive Spillage to reduce blooming effect

When adhesive spills outside the area intended for bonding, it can create unwanted white streaks on the surrounding surface. To minimize this issue, users should adjust the amount of adhesive appropriately, ensuring that it is only applied to the necessary contact surfaces. Using the precision fluid dispensing systems can help better control this process, reducing the risk of adhesive overflow.

2. Control Humidity

Cyanoacrylate adhesives react with moisture in the air, leading to the precipitation of compounds that create white streaks on the surface. Therefore, using dehumidifiers or controlling room temperature can help maintain low humidity levels, providing optimal working conditions for the adhesive.

3. Use Accelerators

Accelerators are used to speed up the curing process of the adhesive, reducing exposure time to moisture in the air. However, it is important to use accelerators according to the instructions to ensure bonding quality and avoid negatively impacting the material surface.

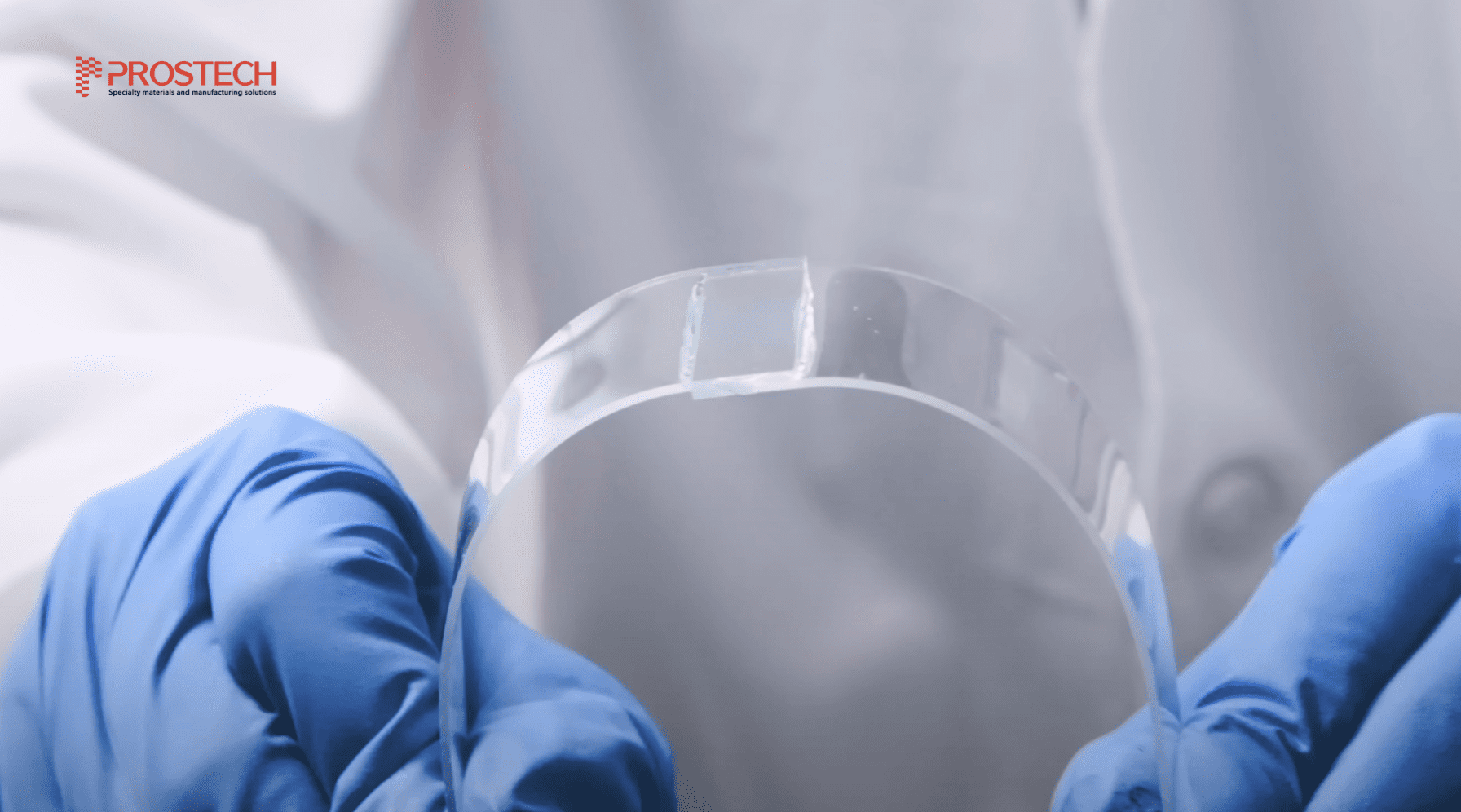

4. Use UV-Curable CA Adhesives

The UVCA adhesive technology allows for more precise control over the curing process while minimizing blooming by reducing dependence on moisture in the air. UV adhesives also provide a clear, aesthetically pleasing bonding surface and a better finish.

Although low-odor and low-blooming cyanoacrylate adhesive products are more expensive than traditional types, their aesthetic effectiveness and long-lasting durability in applications are well worth the investment.

Read more: How to prevent blooming issue of Instant Adhesive or Cyanoacrylate Adhesive

Applications of Low-Odor, Low-Blooming Cyanoacrylate Adhesives

With the ability to minimize odor and blooming effects, this adhesive line is suitable for various applications that demand high aesthetic and performance standards in industries such as:

-

Electronics: Bonding sensitive components without affecting performance.

-

Toys and Models: Safe and easy to use in enclosed spaces without causing discomfort.

-

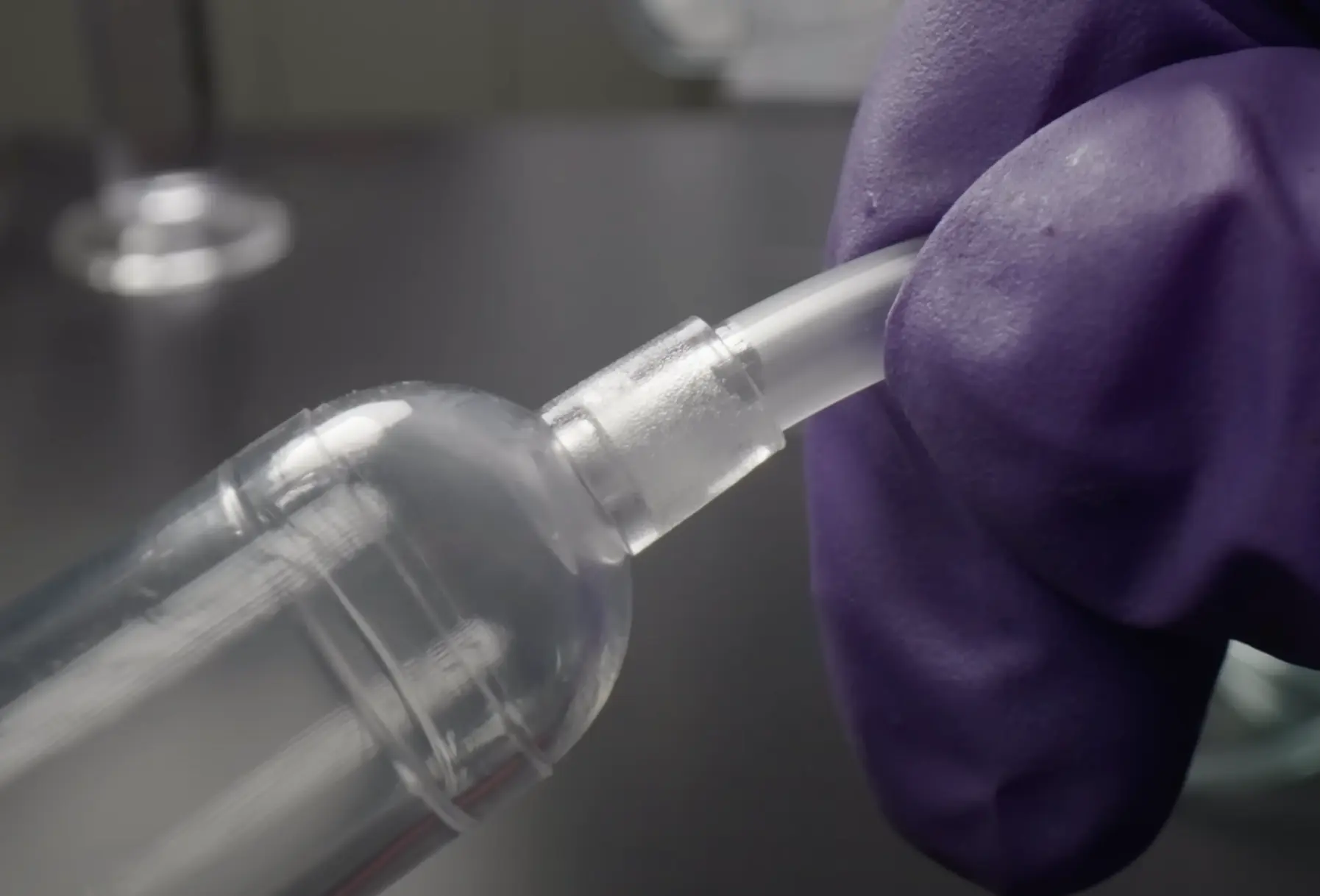

Medical Devices: Meeting high standards for cleanliness and safety.

-

Manufacturing of Speakers, Headphones, and Automotive Parts: Ensuring high aesthetics while maintaining bonding performance.

|

|

|

|

| Bonding camera lens | Bonding speaker | Bonding medical goggles | Bonding medical tubes |

Read more about the applications of UVCA adhesive in the production of medical devices in the article: UV-curable cyanoacrylate adhesives (UVCA) for medical devices

Recommended Cyanoacrylate Adhesive Products

Series MXBON 224XX (22401, 22403, 22460…)

MXBON 22401 Medical Grade CA for Insensitive Surface

MXBON 22403 Low Odor Low Blooming Cyanoacrylate

MXBON 22408 Low Viscosity Low Odor Low Blooming CA

MXBON 22460 Low Odor Low Blooming CA

Series Permabond 94X (940, 941, 943…)

|

|

|

| PERMABOND 940 Low Odor Cyanoacrylate Adhesive | PERMABOND 941 Cyanoacrylate Multi-purpose Adhesive | PERMABOND® 943 Cyanoacrylate |

Bostik Born2Bond (Ultra LV/MV/HV..)

|

|

|

| Bostik Born2bond Ultra LV low-odor, low-blooming, instant adhesive | Bostik Born2bond Ultra MV low-odor, low-blooming, instant adhesive | Born2Bond™ Ultra HV Instant Adhesive |

The choice of the appropriate cyanoacrylate depends on the specific requirements of the application and environmental conditions. Each type of material offers its own advantages and is suited to different demands during the manufacturing and usage processes. With many years of experience in the industrial material, Prostech is ready to assist customers in selecting the right potting compound and providing integrated solutions for production lines to optimize manufacturing efficiency. Contact us for free consultation.