When it comes to medical device manufacturing, adhesive technologies play a pivotal role in the efficient assembly and functionality of various devices. One of the most advanced solutions available is UV-Curable Cyanoacrylate Adhesives (UVCA), which combine the traditional moisture-curing capabilities of cyanoacrylates with the precision and speed of UV light curing. This dual-cure feature makes UVCA ideal for medical applications where performance, reliability, and process efficiency are critical. In this blog, we explore why UV-curable cyanoacrylate adhesives have become an ideal solution for medical device applications, delve into some typical applications and provide some recommendations of UVCA for medical devices to help you make the best choice.

What Are UV-Curable Cyanoacrylate Adhesives?

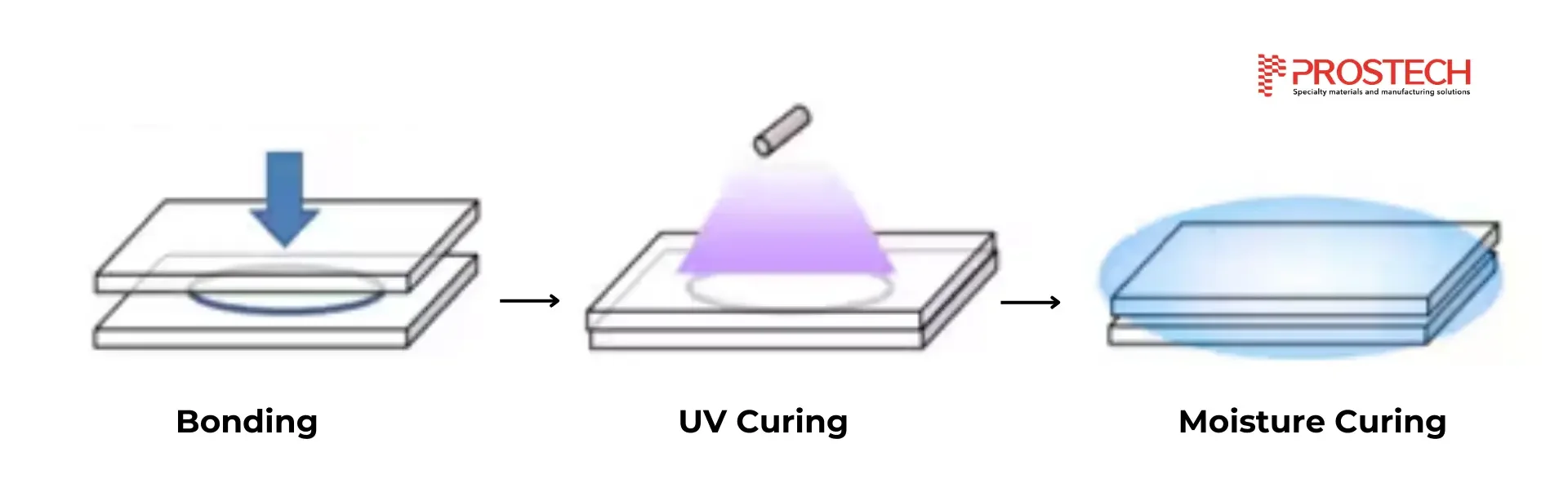

UV-Curable Cyanoacrylate (UVCA) adhesives have a dual-cure formulation, which combines the conventional moisture-curing mechanism of cyanoacrylates with an accelerated UV light cure.

When using UVCA adhesives, moisture in the air enables surface curing, which takes up to 60 seconds fixture time. For areas exposed to UV light, the curing process can be accelerated to under 5 seconds, even with low-power visible or long-wave UV light. This dual-cure mechanism allows engineers to bond parts quickly and with greater control, especially when working with transparent materials or areas outside of the bond line, where traditional cyanoacrylates face challenges.

For more detail about UV Adhesive, refer to the article: UV Adhesive – A Comprehensive Overview

Key Advantages of UVCA for Medical Devices Applications

Dual Cure for Precision and Control

The unique dual-cure capability of UVCA adhesives provides unmatched control in assembly processes. Engineers can adjust and align parts before curing, using UV light to expedite the process where needed, while the moisture-curing mechanism ensures thorough bonding even in areas where UV light cannot reach. This flexibility makes it ideal for complex medical assemblies with both visible and non-visible bond lines.

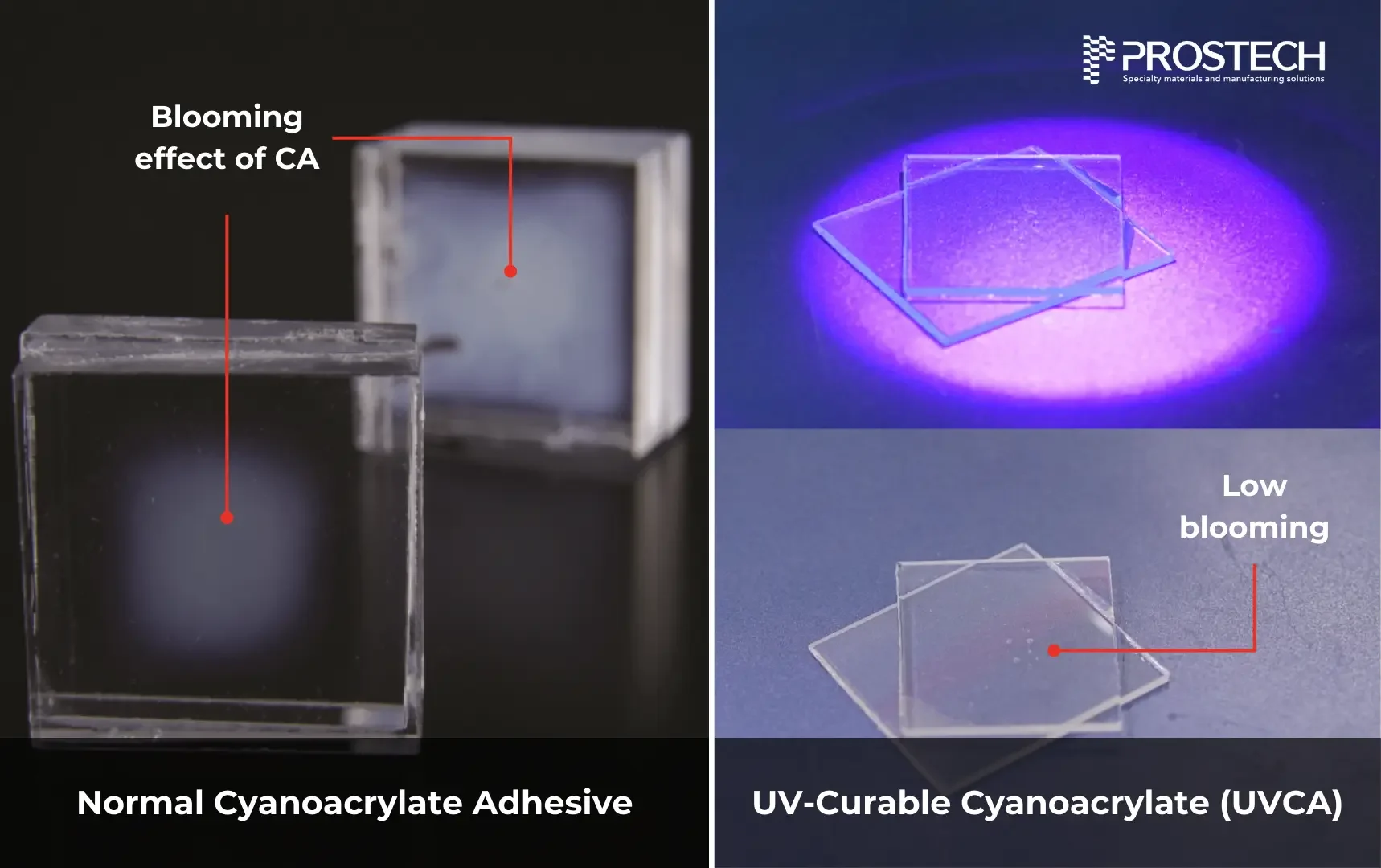

Reduction of Blooming

A common issue with traditional cyanoacrylates is blooming—a whitening effect caused by the release of fumes during curing. With UVCA adhesives, blooming can be minimized or eliminated by using UV light to cure exposed filets or areas. The light-activated cure ensures a cleaner, more aesthetically pleasing bond, which is especially important in medical devices where clarity and appearance are critical.

Biocompatibility

UVCA for medical devices meet stringent biocompatibility standards such as ISO 10993 and USP Class VI, making them safe for use in medical devices that come into contact with the human body. These adhesives form strong, biocompatible bonds, suitable for various medical applications like catheters, syringes, and diagnostic devices.

Read this article for more information about adhesive standards in the medical industry: Is Your Adhesive Biocompatible?

Fast Curing for Increased Efficiency

The ability to cure in under 5 seconds with UV light significantly increases manufacturing throughput, making UVCA adhesives a time-saving solution for high-volume production environments. Even without UV light, the moisture-curing process provides fixture times of around 60 seconds, ensuring strong bonds and quick assembly.

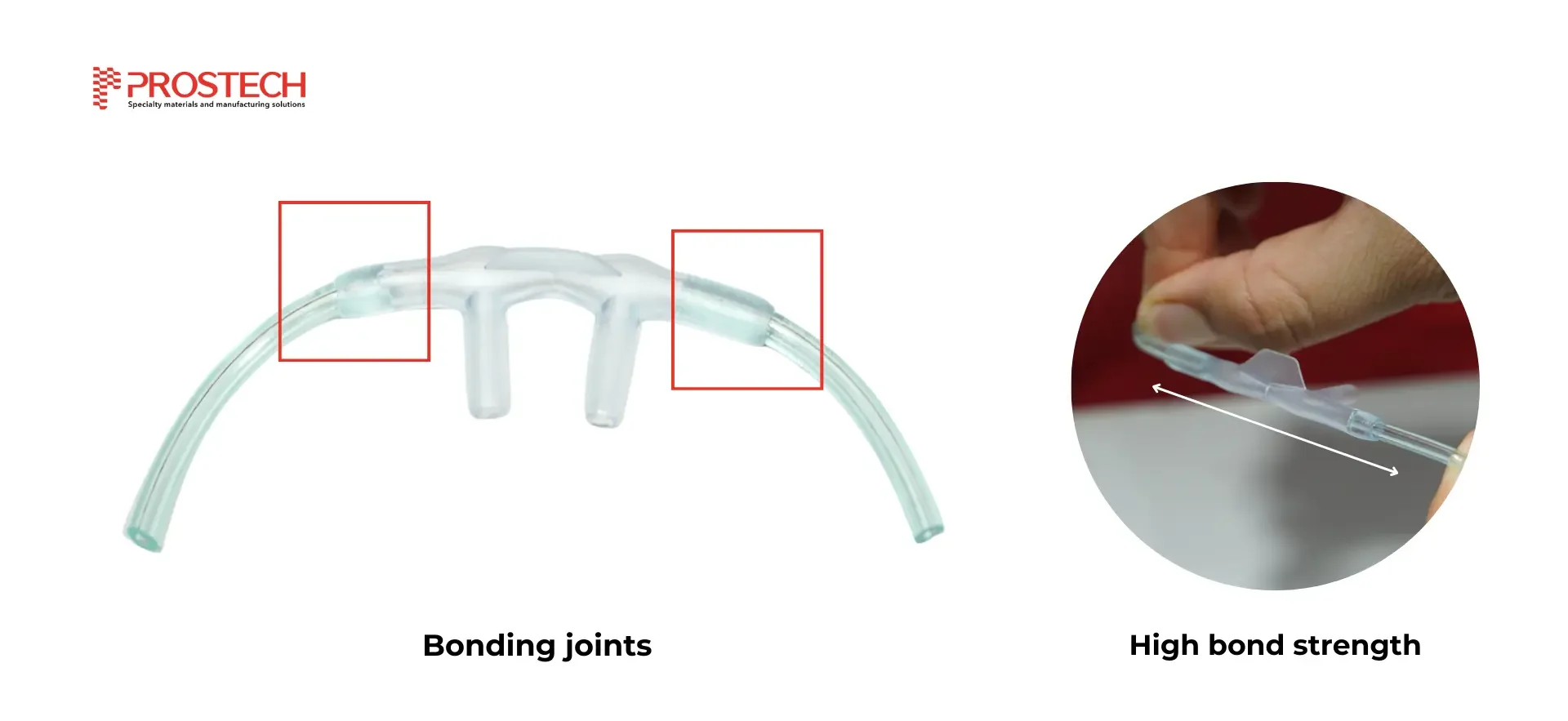

Strong Bonds and Durability

UVCA for medical devices offer high bond strength across a variety of substrates, including plastics, metals, and glass. They also exhibit excellent durability, maintaining performance through sterilization processes like autoclaving, gamma radiation, and ethylene oxide.

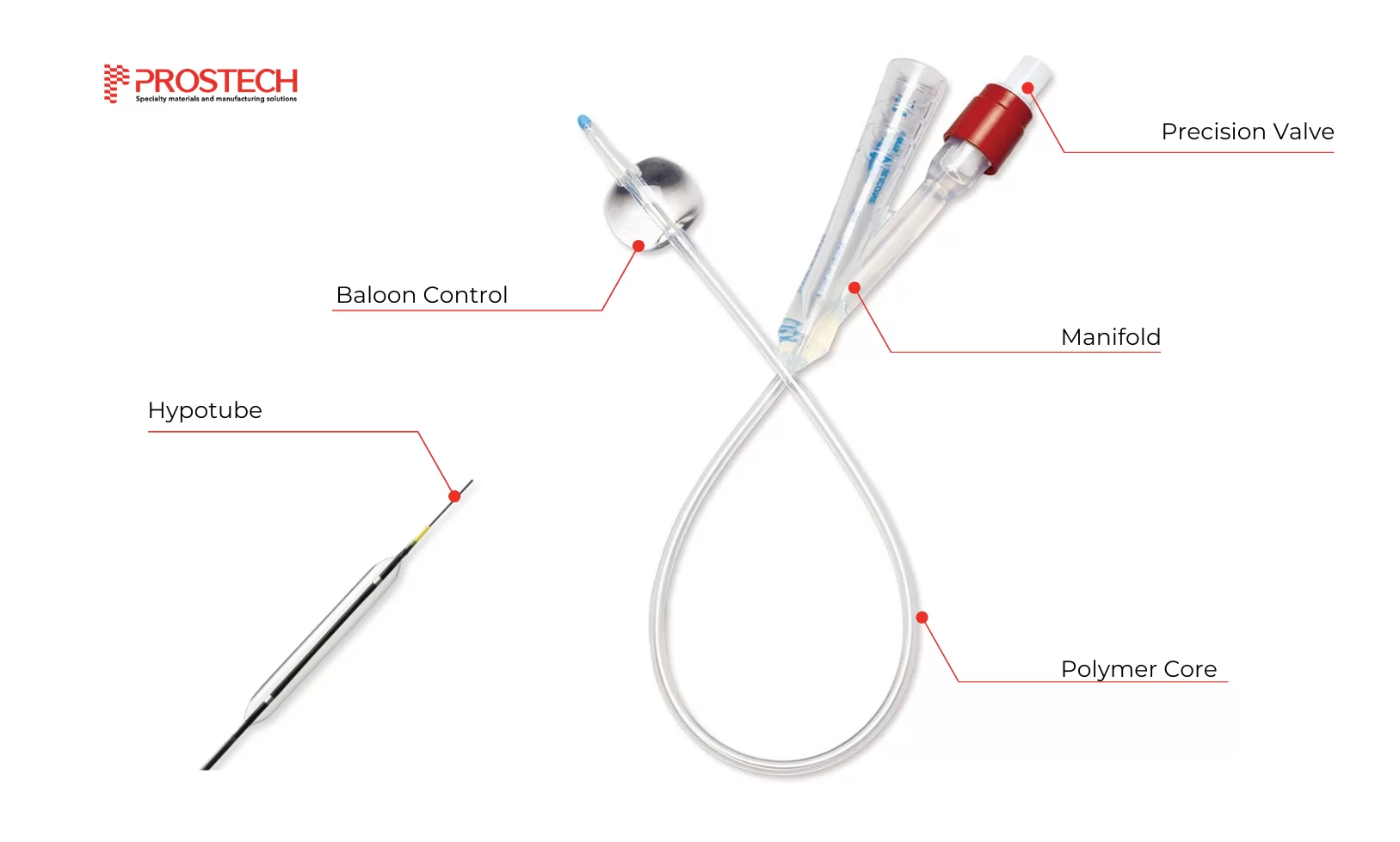

Applications of UVCA for Medical Devices

UVCA adhesives are versatile and can be used in a wide range of medical device applications. Their dual-cure feature makes them suitable for assembling intricate and precision-driven components. Key applications include:

Catheters and Tubing Assemblies: using UVCA to adapt with fast process and flexible bonding.

Read this article for more information: Catheter Assembly: Choosing the Right Medical Adhesive Grade

Needles and Syringes: UVCA could offer quick curing, reducing production time while maintaining high safety and bond integrity

Medical Electronic Devices: hearing aid, blood gas analysis, infusion pump. UVCA can be compatible with hard to bond substate such as Nylon 12, PEBA,.. while still providing an excellent flexibility and durable bonding strength.

Wearable Medical Devices: Bonds formed are biocompatible and flexible, ensuring comfort for the wearer and adherence to skin without causing irritation such as Wearable Blood Pressure Monitors.

Benefits of UVCA over traditional Cyanoacrylates in Medical applications

While traditional cyanoacrylates remain a staple in medical device manufacturing, UVCA for medical devices offer several clear advantages over their single-cure counterparts:

- Dual Cure Flexibility: UVCA adhesives offer the flexibility of using UV light for rapid curing in visible areas while relying on moisture curing in regions where UV light cannot penetrate. This solves the challenge of incomplete curing outside the bond line, a limitation of traditional cyanoacrylates.

- Improved Aesthetics: The reduction of blooming with UVCA adhesives results in cleaner, clearer bonds, making them ideal for transparent or aesthetically sensitive medical devices. The option to use UV light ensures bonds are cured quickly and without the unsightly whitening effect associated with standard cyanoacrylates.

- Enhanced Sterilization Resistance: Medical devices are often exposed to harsh sterilization methods. The durable bonds formed by UVCA adhesives can withstand high-temperature autoclaving, gamma radiation, and ethylene oxide sterilization, ensuring long-term reliability and safety.

Top UVCA Product Picks for Medical Applications

Top products on the market are designed to have exceptional bonding performance and meet stringent medical standards, ensuring both reliability and durability under various sterilization methods. Below are typical products on the market for UV-curable cyanoacrylate (UVCA) adhesives in medical applications:

|

|

MXBON 22401M

|

|

MXBON 22455M

|

|

MXBON 21446M

|

|

|

Permabond 130UV

|

The choice of the appropriate UVCA in medical device bonding depends on the specific requirements of the application and environmental conditions. Each type of adhesive offers its own advantages and is suited to different demands during the manufacturing and usage processes. With many years of experience in the industrial material, Prostech is ready to assist customers in selecting the right material and providing integrated solutions for production lines to optimize manufacturing efficiency. Contact us for free consultation.