At Prostech, we distribute leading brands of thermal interface materials, including T-global, Jonestech, AOK, Momentive, Henkel, and Lipoly. Not only offer high-quality thermal interface materials but also advanced machinery solutions such as pick & place thermal pad and thermal conductive fluid dispensing systems.

We understand our customers’ challenges and are committed to providing the qualifed and most effective solutions for specific applications.

WHAT ARE THERMAL INTERFACE MATERIALS?

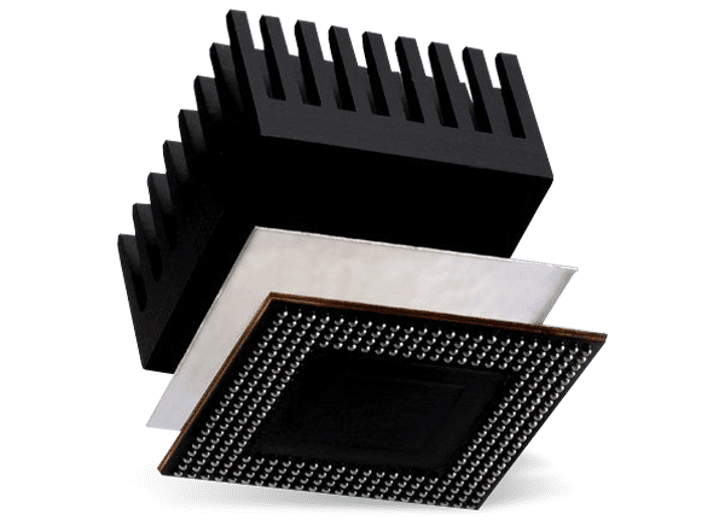

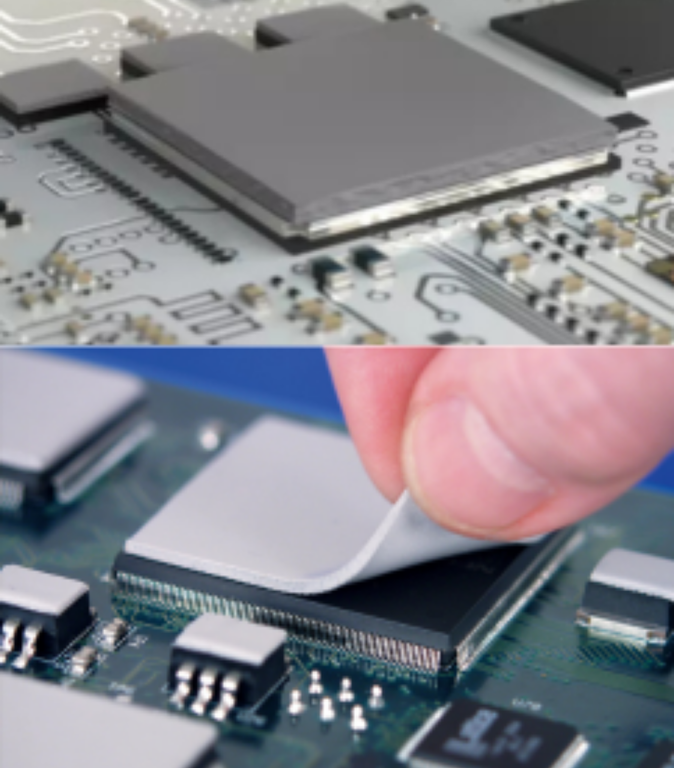

A thermal interface material (TIMs) describes any material that is inserted between two parts in order to enhance the thermal coupling between these two components. A majority of applications are related to the heat dissipation of the system. The TIM is inserted between the heat producing device (the heat source) and the heat dissipation device (heat sink).

Challenges manufacturers face include:

- Numerous types of TIMs

- A wide variety of products within each type

- Limited technical knowledge to select the right solution

- Difficulty finding a reliable supplier

THERMAL INTERFACE MATERIALS THEORY

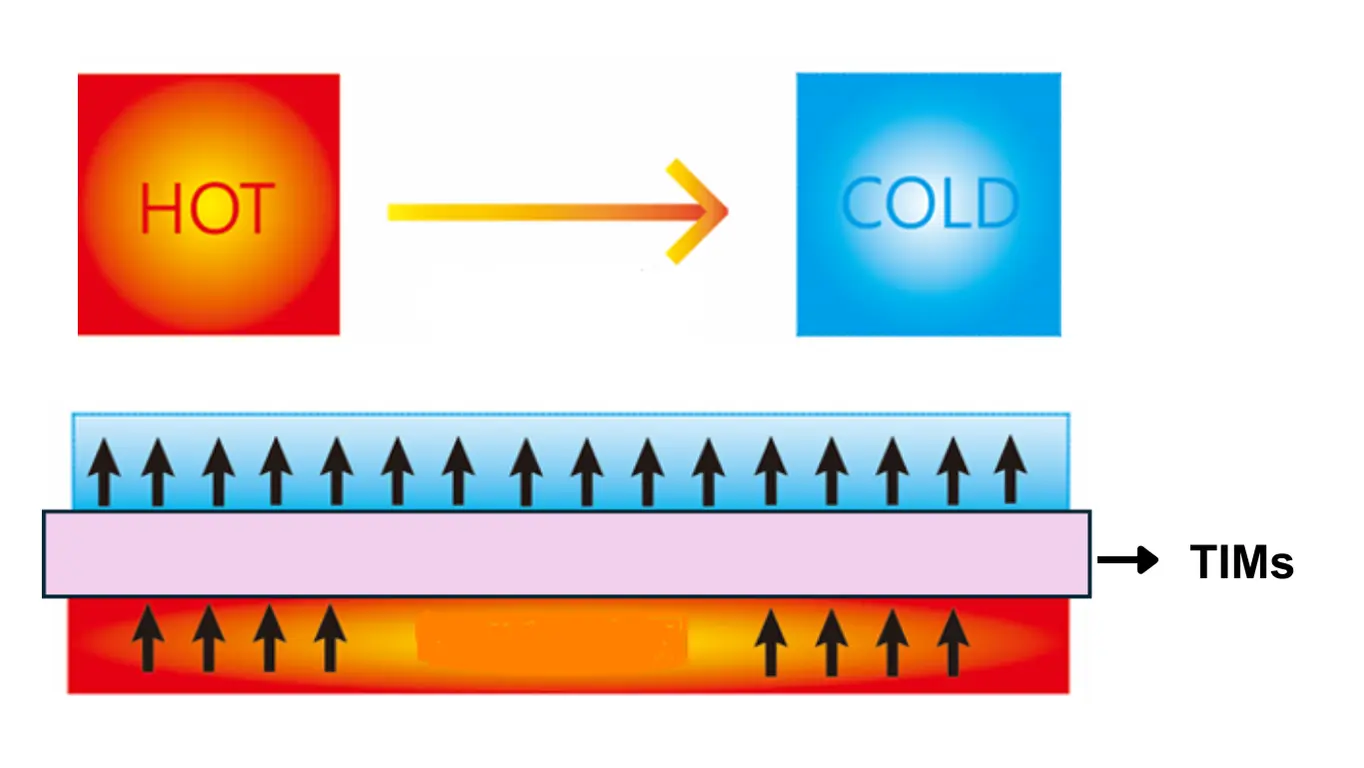

Heat will always be transferred from a hot medium to a cold medium:

WHY DO WE NEED TIMS?

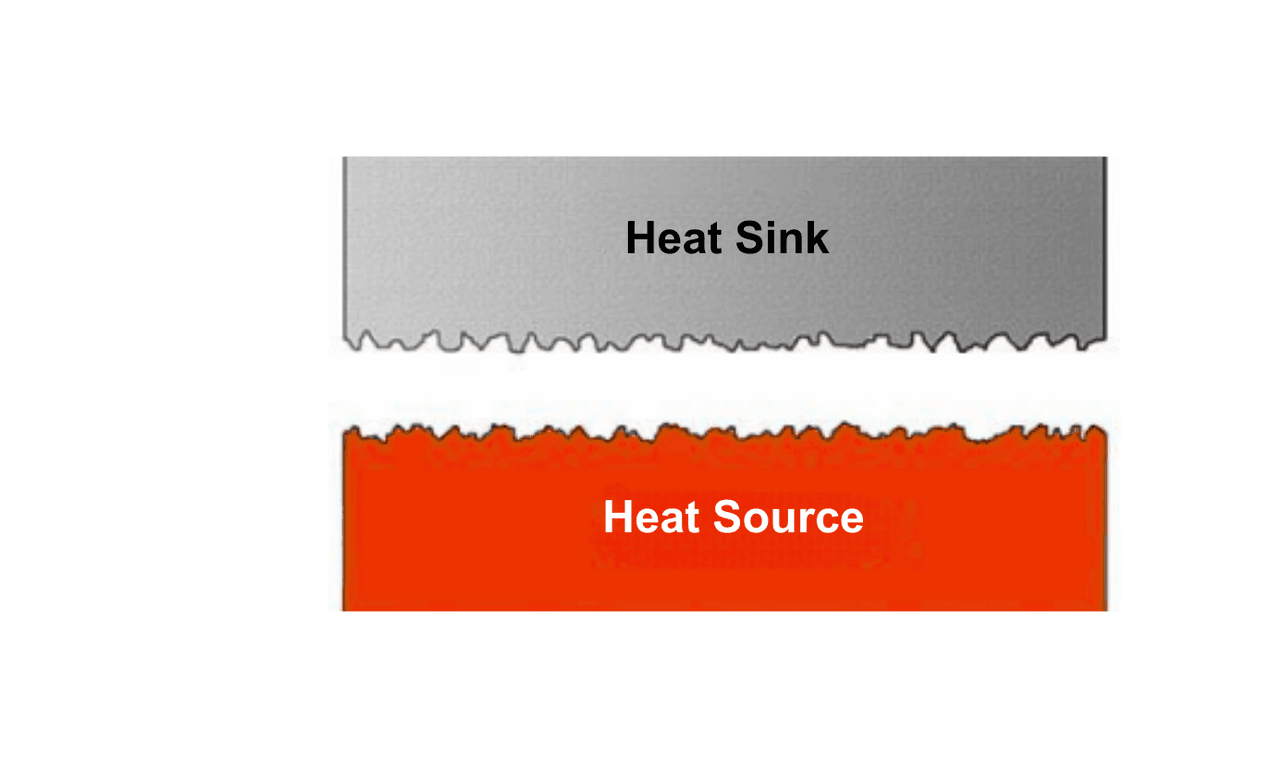

The rough machined surfaces of a heat sink and heat source result in limited contact points.

Bringing the rough surfaces closer creates insulating air gaps, causing contact resistance and thermal barriers.

A thermal interface material (TIM) fills voids, replaces air with a higher conductivity material, and improves surface contact for better heat transfer.

BENEFITS OF THERMAL INTERFACE MATERIALS

Reduce thermal impedance across gaps

Replace air with more thermally conductive materials

Conform to surface irregularities

Electrical isolation

Attachment

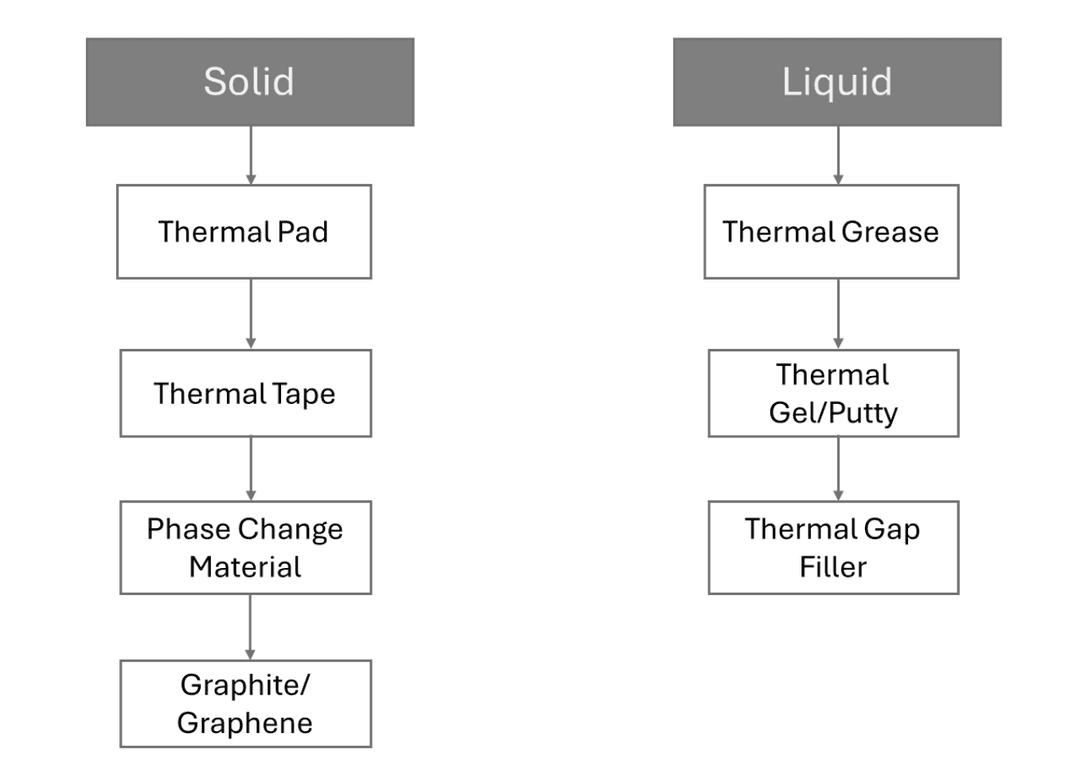

TYPES OF THERMAL INTERFACE MATERIALS

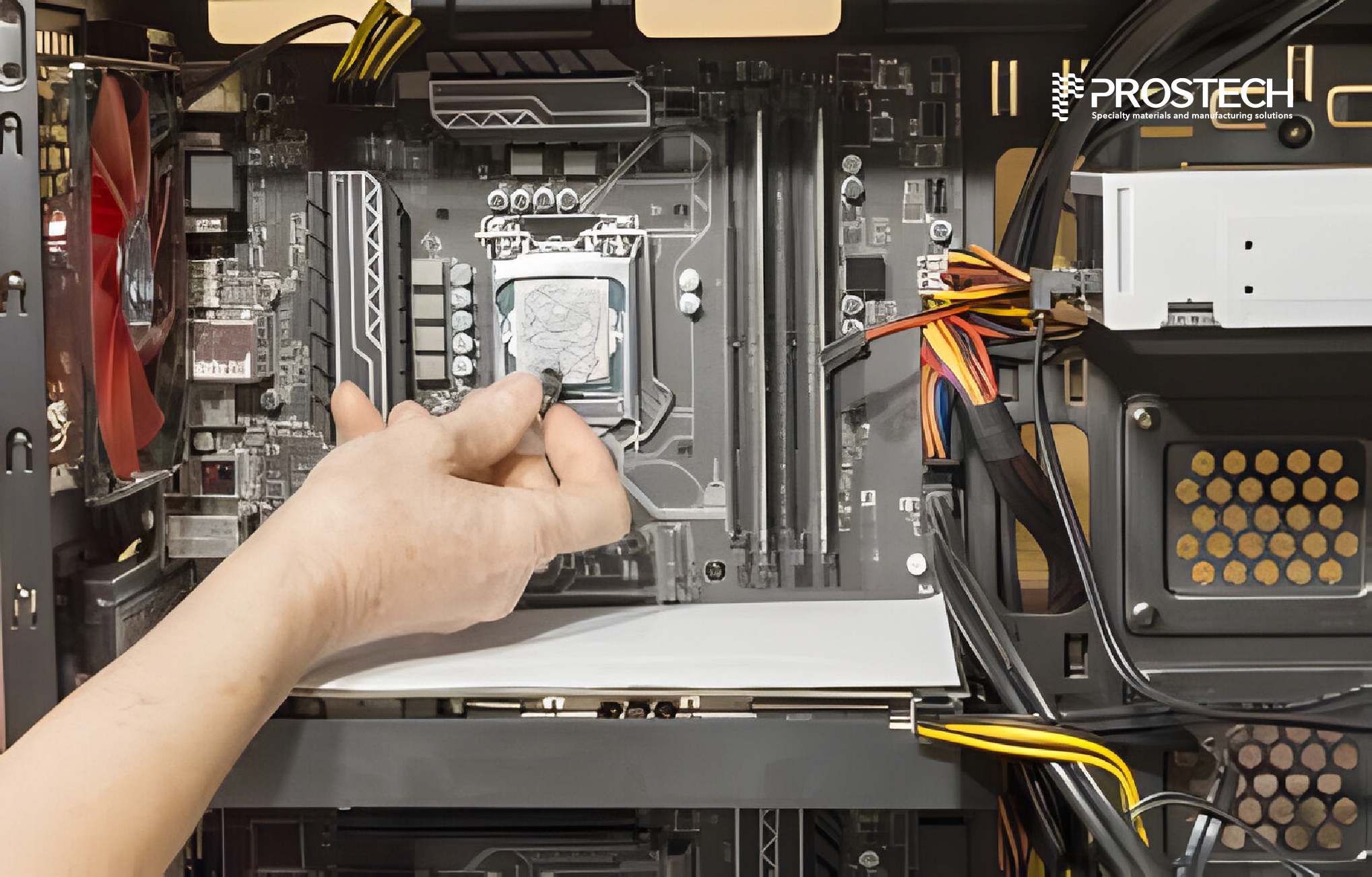

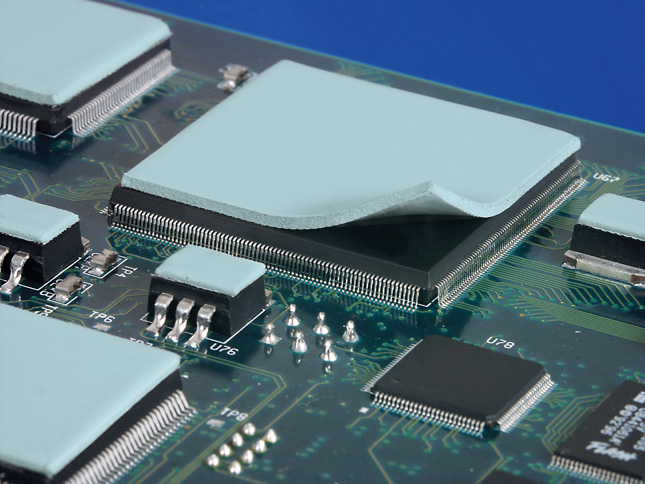

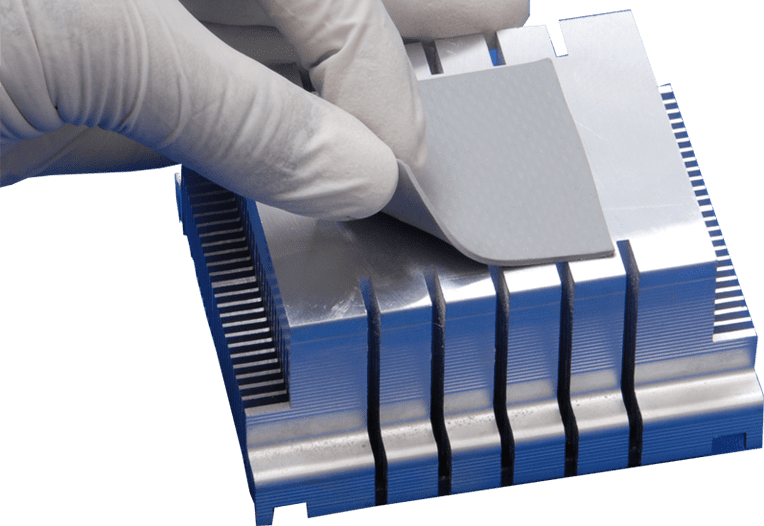

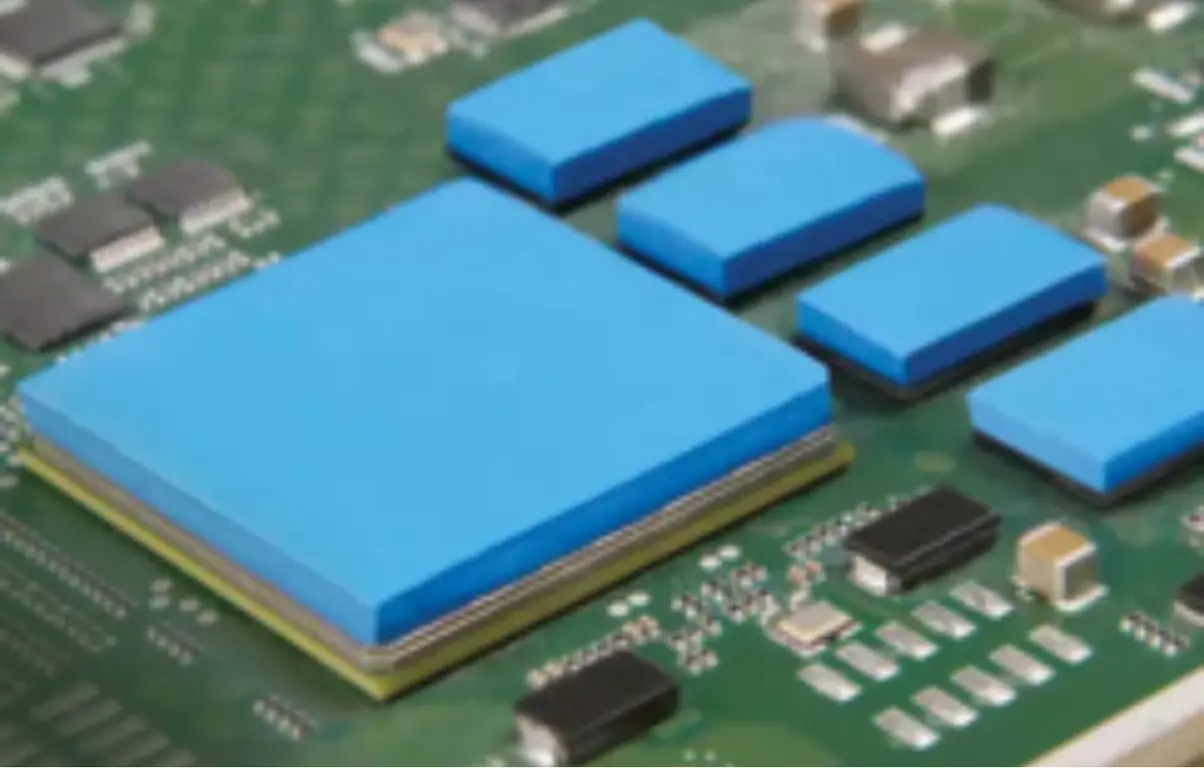

What is thermal pad?

Thermal Pads (also called thermally conductive pads) are a preformed square or rectangle of solid material (often silicone-based) commonly used on the underside of the heatsink to aid the conduction of heat away from the component being cooled (such as CPU or another chip) and into the heatsink.

FEATURES

- 0.5 – 24 W/mK thermal conductivity

- 0.2 – 12 mm thickness

- 2 – 10 kV/mm breakdown voltage

- Silicone or Silicone free

BENEFITS

- Soft & conformable to fit uneven & rough surface area

- Providing low stress on components during assembly while providing shock-dampening abilities

- Providing easier handling abilities for simple application & automated assembly

- Offering puncture, shear & tear resistance for added device resilience

- Cut to the desired size and shape

FEATURES

- Typically composed of a carrier material, such as polymer, embedded with thermally conductive fillers like ceramic or metal particlesThermal conductivities of around 1-2 W/mK

- Thin material

BENEFITS

- Electrically insulating

- Good adhesion is perfect for fastening mechanical components

- Low thermal impedance

- Easy to apply

- Cut to the desired size and shape

What is Phase Change Material?

Phase change material (PCM) refers to a substance that changes the state of a substance and provides latent heat without changing the temperature. The process of transforming physical properties is called a phase change process. At this time, the phase change material will absorb or release a large amount of latent heat.

FEATURES

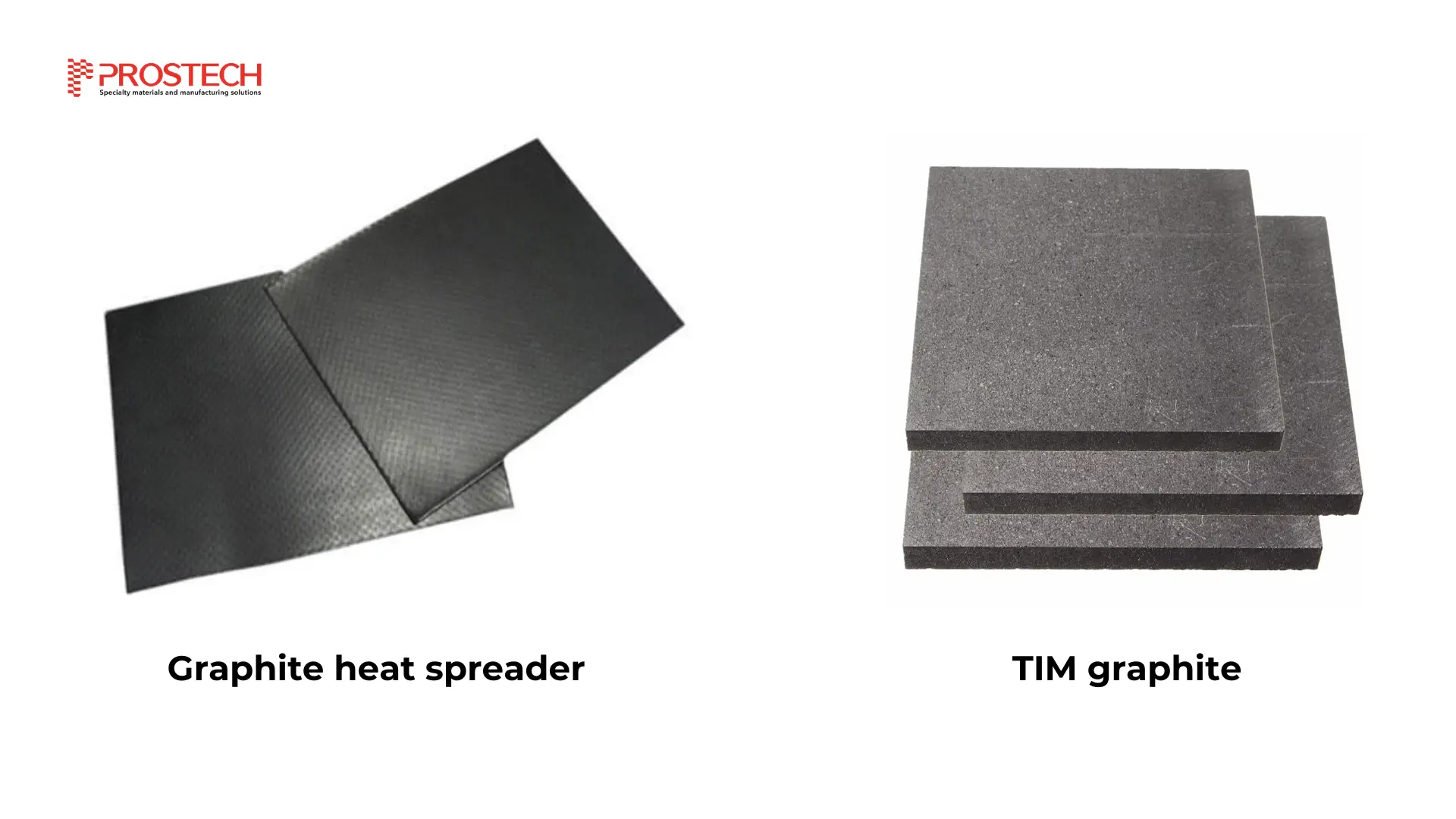

- Typically made from natural or synthetic graphite

- Excellent thermal conductivity in the horizontal XY-plane (up to 1800 W/m-K)

- Can be laminated with adhesive layer

- Cut to desired size & shape

BENEFITS

- Can handle high temperatures and thermal cycling, this makes them suitable for use in high-power applications

- Highly flexible and conformable

- Simply process

What is Graphite/Graphene sheet?

Thermally Conductive Graphite is a TIM with high thermal conductivity and a thin graphite film structure (thickness measured in microns). Graphite is formed of a layered structure with strong covalent bonds within the layers, and weak van der Vaals bonds connecting the layers.

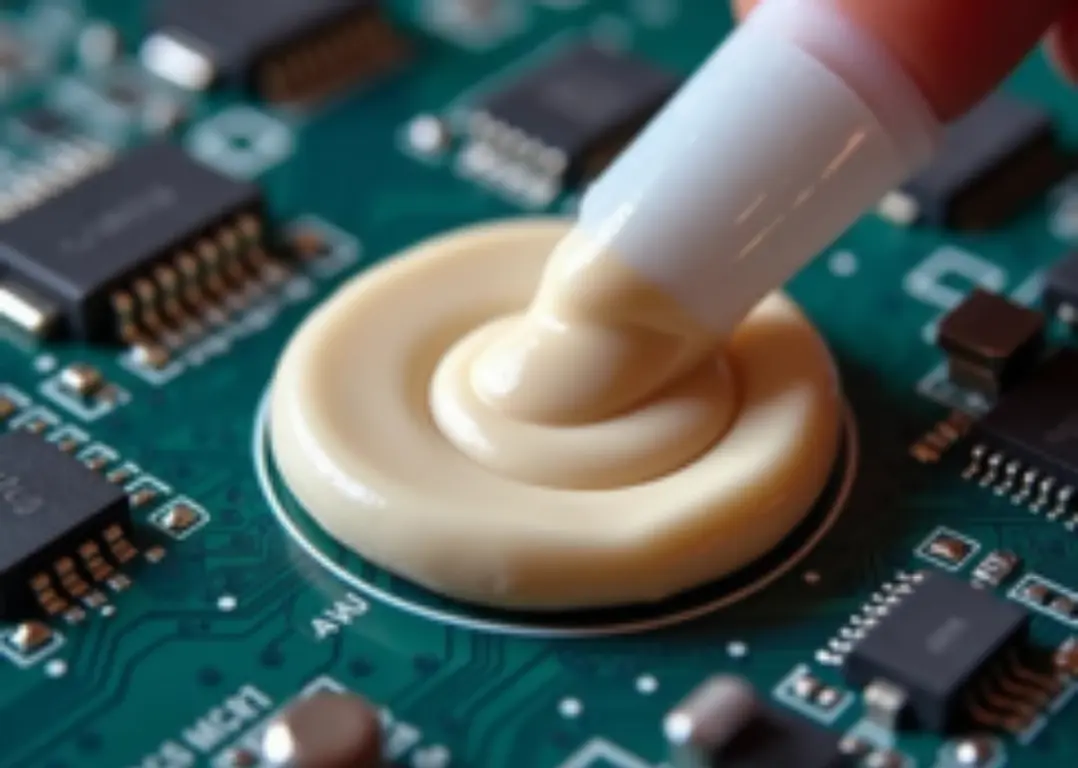

What is Thermal Grease?

Thermal grease is a type of material that is used to improve heat transfer between two surfaces that are in contact with each other. Thermal grease is typically made up of a mixture of thermally conductive fillers, such as aluminium oxide, silicon dioxide, and boron nitride, suspended in a carrier fluid, such as a silicone oil or water. The fillers are chosen to maximize thermal conductivity while minimizing electrical conductivity to avoid shorting out the electronics.

FEATURES

- Either silicone or non-silicone based

- Non-silicone putties tend to have good stability and longevity compared to silicone formulas and are advisable in silicone sensitive applications

- It can be messier to apply and more difficult to remove

BENEFITS

- A soft, mouldable material that is used to fill gaps and uneven surfaces

- Strong thermal conductivity and electrical insulation properties

- Offers good resistance to thermal cycling and maintains strong levels of thermal conductivity

- Suited for high volume application

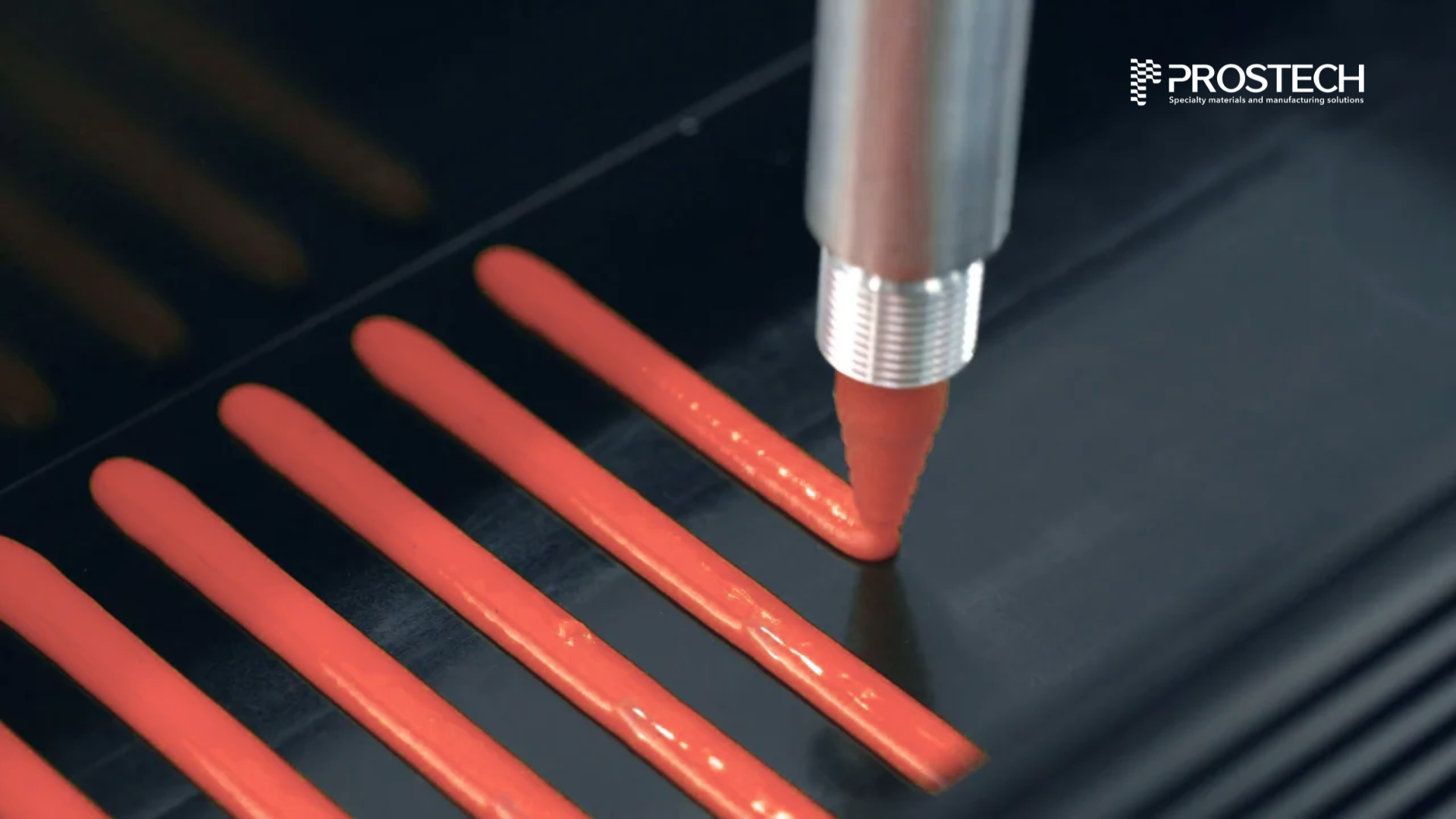

What is Thermal Gap Filler?

Gap fillers are thermally conductive gap filling liquid materials designed to enhance thermal performance and enable easier dispensing application for your high-volume manufacturing operations.

FEATURES

- Two-part material

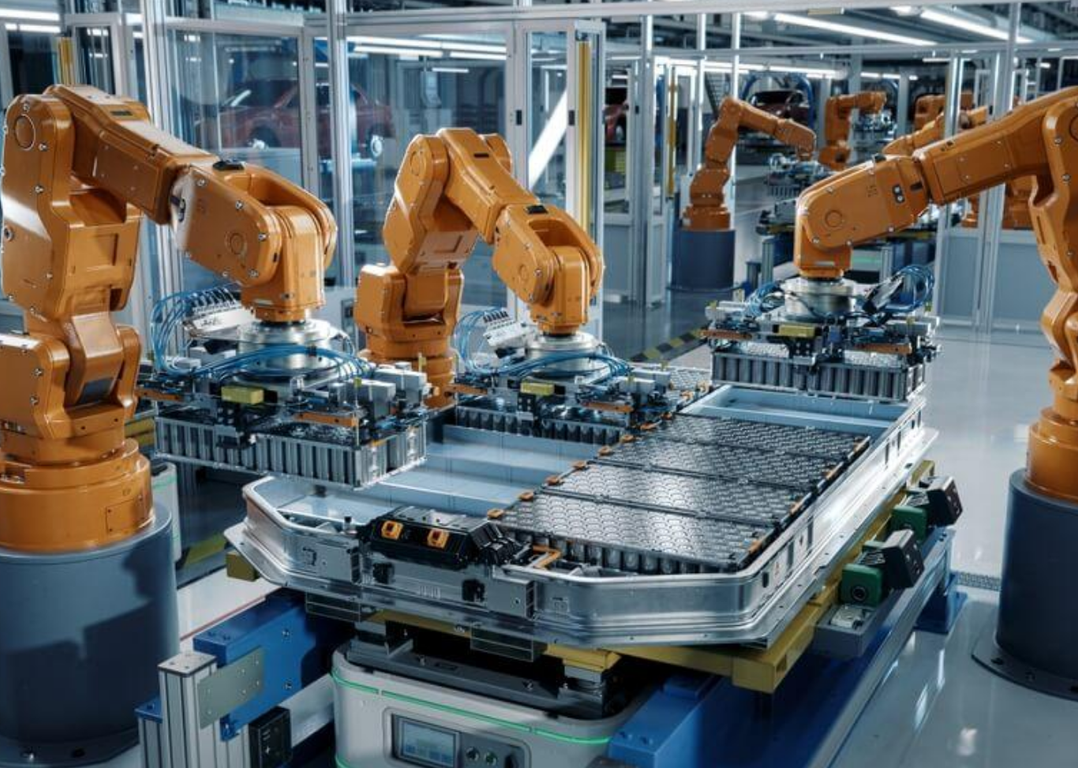

- Are frequently utilized in markets such as automotive, where high reliability is required

BENEFITS

- Ultra-low modules for minimal stress during assembly

- Excellent conformability to intricate geometries

- Single solution for multiple applications

- Efficient material usage

- Customizable flow characteristics

INDUSTRIES

Automotive ADAS

Automotive E-mobility

Datacom

Power Conversion

5G Telecom Infrastructure

Aerospace

LED Lighting

Consumer Electronics

Industrial Automation

PROSTECH’s TIMS OPTIONS

Comprehensive range of thermal interface materials tailored to meet diverse application needs

Advanced materials ensure optimal thermal management, enhancing performance and reliability for your products

The product is certificated to RoHS, Reach standard

Our engineers offer expertise in selecting the best thermal interface materials for specific applications

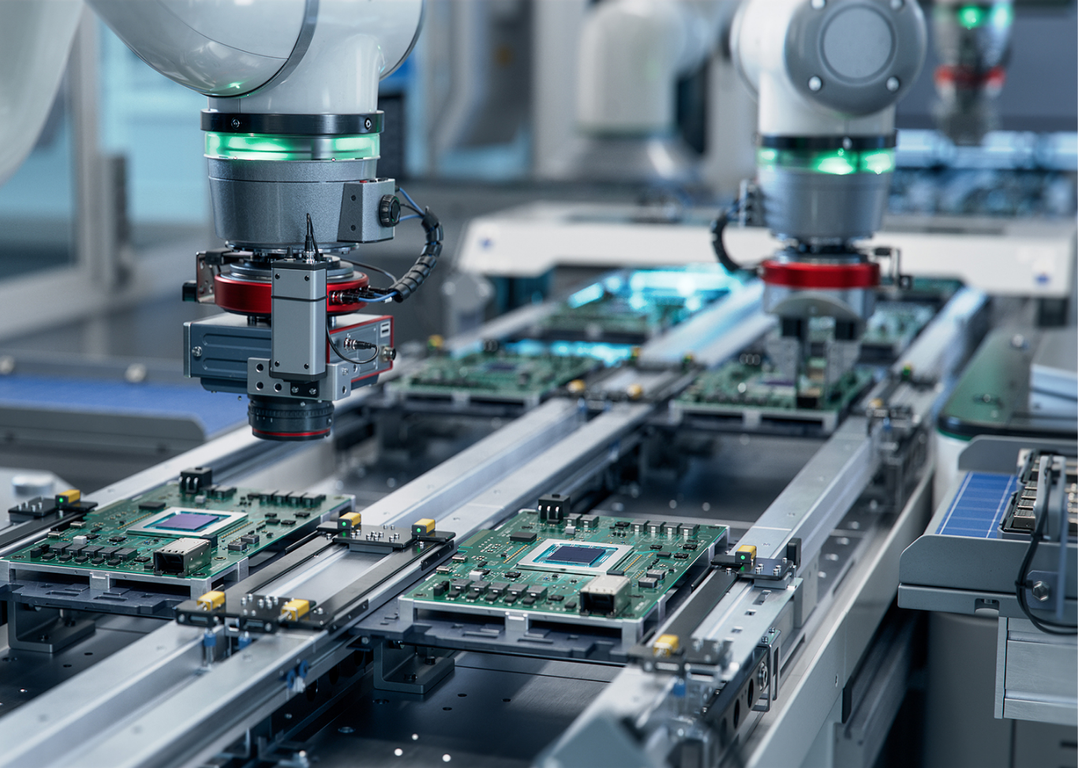

Advanced machinery solutions such as pick & place thermal pad and dispensing systems

Global delivery service for customer

CHOOSING THERMAL INTERFACE MATERIALS

Prostech’s thermal interface materials are engineered to suit a variety of applications. However, the specific interface material you require will vary based on your manufacturing needs. Choosing the appropriate thermal management solution is crucial for:

- Optimizing heat dissipation

- Extending the life of components

- Upholding performance of devices

- Eliminating the risk of failure and performance drops

Selecting the right thermal interface material for your application depends on several factors, including:

- Heat dissipation requirements

- Adhesive qualities needed in assembly

- Whether a solid or liquid is more applicable

- The size of the gap that needs to be filled

- Gap topography and surface

- Component stress level requirements

- Physics, including application temperature and structure

TIMs basic guideline and their efficiency for PCB thermal management

FEATURED COLLABORATIONS

We take pride in providing thermal interface material from some of the world’s most renowned brands, including t-Global, Gluditec, Vietape, AOK, Everwide,… We are dedicated to understanding your needs, recommending the most suitable products, ensuring a seamless supply chain, and delivering prompt support.

Discover our selection of world-class material brands here, or reach out to us to find the ideal solution for your application.

AUTOMATED DISPENSING SOLUTION

Prostech has established a strong equipment partnership with Gluditec, a leading provider of advanced industrial machinery. Through this collaboration, Prostech offers cutting-edge equipment solutions, including dispensing machines and pick & place thermal pad systems, ensuring efficient and precise application of materials.

Pick & Place System

The Pick and Place Machine is an advanced solution designed to automate and streamline the installation process of heat dissipation silicone pads.

Useful Information

Thermal Interface Material (TIMs) Solutions for Data Centers

Data centers, filled with densely packed servers running resource-intensive processes, face significant heat-related challenges. Excessive heat can throttle server performance

Differences between Silicone-based and Non-silicone Thermal Interface Materials (TIMs)?

In recent years, the risk of overheating, which can lead to reduced performance or even fire and explosion of electronic

Thermal Interface Materials- TIMs basic guideline and their efficiency for PCB thermal management

Why is Thermal Management so crucial in Electronic packaging? Up to 55% of failures on electronic circuit boards are caused

Uncured Properties of Thermally Conductive Gap Filler (TGF) and Selection Guide

How to choose the TGFs with the right Uncured Properties for industrial applications? In the last topic, PROSTECH generally talks

Thermally Conductive Gap Filler (TGF) Selection Guide

How to choose the right Thermally Conductive Gap Filler in the various options? Nowadays, the demands and use of thermal

Thermally Conductive Gap Filler (TGF) Solutions

Easy to dispense and maintain TIMs, beyond good thermal conductivity and reducing trouble air gaps features. What are Thermally Conductive

Common Types of Thermal Interface Materials TIMs

Thermal interface materials or TIMs are any material that is applied between the interfaces of two components to enhance the

A Comprehensive Guide of Graphite Sheet

Thermal management graphite materials are becoming increasingly popular due to their high thermal conductivity, lightweight nature, and flexibility. However, choosing

Thermal Pad – All About The Thermal Interface Pad

In the process of manufacturing and assembling electronic devices, thermal management is always one of the issues that manufacturers are

WHY THERMAL MANAGEMENT IS NECESSARY?

Up to 55% of failures on electronic circuit boards are caused by heat Most electronics such as power transistors, CPUs