The phase-out of 3M Novec products has raised concerns across industries that rely on them for various applications, especially in cleaning and degreasing. With the discontinuation of these products, businesses need to explore reliable alternatives that meet their specific needs. In this blog, we’ll explore the key criteria for selecting 3M Novec replacements, ensuring your operations continue smoothly with minimal disruption.

3M Novec phase-out

Considering the increasingly stringent regulations on the use of PFAS compounds, 3M has announced that it will be phasing out its 3M Novec product line by the end of 2025. PFAS includes tens of thousands of different compounds that can be found in virtually every application around us. Among them, to mention the application we are discussing, PFAS is used in industrial cleaning solvents. While manufacturers, who are using Novec, have not yet faced worldwide restrictions on PFAS, they have been actively seeking 3M Novec replacement to minimize supply chain disruptions to their manufacturing operations before the discontinuation of 3M Novec solvent in 2025.

Read more at: Navigating PFAS Discontinuation: Solutions for 3M Novec Users

3M Novec Replacement Solution

The current market offers a variety of 3M Novec replacement solvents, which can be divided into two main categories:

- The first category consists of drop-in solvents that can be immediately replaced without the need for equipment changes or cleaning performance tests. These solvents have the same molecular formulation as 3M Novec.

- The second category includes solvents with different chemical formulas that do not contain PFAS. For this category, qualifying cleaning efficiency and compatibility with existing equipment and processes is required.

Read the article for more detail: 3M Novec replacements: Drop-in and long-term solution

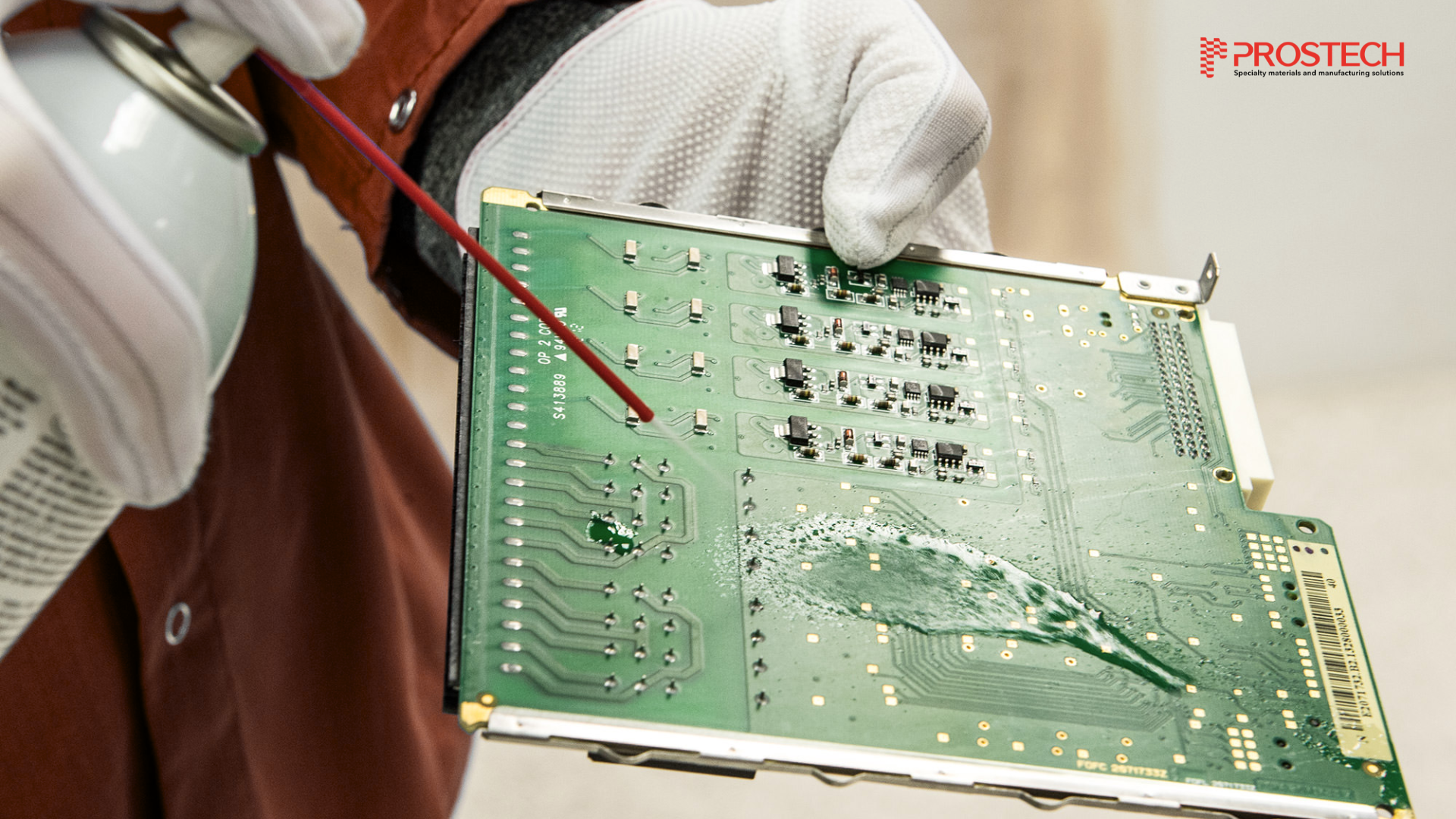

It is understandable for those who use Novec to have concerns about the effectiveness of alternative solvents and the potential need for equipment changes when selecting a long-term replacement. Novec has been a reliable and successful line of cleaning solvents for many years, serving as a substitute for chlorinated solvents like TCE and nPB. Additionally, the cost of cleaning equipment is high, making it difficult to switch to new equipment that is compatible with a different solvent.

A long-term alternative will inevitably need to be found if you have a sustainable development orientation. Therefore, it is crucial to start assessing the replacement options of 3M Novec early to guarantee a smooth transition.

Key criteria for qualifying 3M Novec replacement

1. Cleaning performance

The effectiveness and performance of the 3M Novec replacement fluid are critical factors to consider. Does it offer comparable or superior performance to 3M Novec? Consider factors such as solvency power, boiling point, heat transfer capabilities, and stability over time.

| 3M Novec Product Series |

Key Performance Criteria |

| Cooling Liquids |

|

| Cleaners |

|

| Coatings |

|

| Fire Suppressants |

|

| Lubricants |

|

The cleaning performance is subject to the soil and process; therefore, it is imperative to conduct a design of experiment (DOE) that closely resembles your process to accurately assess the replacement’s effectiveness. Do not get too deep into the chemistries but define your cleanliness requirement. Establishing the definition of cleanliness is a prerequisite for devising a testing procedure as well as evaluating the cleaning effect of solvents.

2. Compatibility

Compatibility with existing materials and equipment is an essential criterion when qualifying a 3M Novec replacement. Assess whether the substitute can be used with the same materials, components, and substrates without causing any adverse effects. To achieve compatibility, manufacturers must conduct thorough testing on their products to ensure they meet industry standards and requirements.

3. Regulatory Compliance

Regulatory compliance is another crucial criterion for qualifying a 3M Novec replacement. Ensure that the substitute meets relevant industry regulations, such as those about hazardous substances, workplace safety, and environmental protection. 3M Novec replacement may comply with regulations relating to PFAS restrictions, but there is still some risk of some other regulatory noncompliance. Consider local, national, and international regulations to avoid any legal or compliance issues.

- GWP and ODP: Ensure low or zero Global Warming Potential (GWP) and Ozone Depletion Potential (ODP)

- Industry Standards (e.g., UL, IEC, RoHS)

4. Availability and Cost

When it comes to evaluating the availability and cost of a replacement fluid, one must consider several factors. Firstly, it is important to determine whether the substance is readily accessible. This means assessing how easy it is for suppliers to obtain the product and whether any logistical challenges could hinder its distribution. For example, if the 3M Novec replacement fluid is only found in certain regions or countries, this could affect its availability and potentially increase costs due to transportation fees.

Secondly, an evaluation of cost should be conducted to ensure that the price of the 3M Novec replacement fluid is reasonable and affordable for both consumers and suppliers. This also includes considering any potential fluctuations in pricing that may occur due to market conditions or supply chain disruptions. It is crucial to have a consistent supply chain in place when sourcing replacement fluids so that businesses can maintain production schedules without delays or interruptions.

5. Health and Safety

When assessing a potential 3M Novec replacement, it is crucial to consider its impact on human health and safety. This involves evaluating factors such as toxicity, exposure limits, and the likelihood of causing skin or eye irritation. It’s important to prioritize alternatives that have undergone thorough testing and have established health and safety profiles. Additionally, it’s essential to take into account any applicable regulations and compliance requirements to ensure that the 3M Novec replacement meets the required standards and compliance requirements to ensure the replacement meets the necessary standards.

Thankfully, according to the Global Harmonized System (GHS), vapor degreaser solvents are typically nonflammable. This makes them less likely to cause fires or explosions than other solvent types. However, solvents like n-propyl bromide (nPB), trichloroethylene (TCE), and perchloroethylene (perc) that were once commonly used for vapor degreasing are now discouraged due to their negative health effects. These solvents have been linked to various health issues including lung cancer, renal failure, cognitive impairment, and reproductive problems. Therefore, it is recommended to avoid these substances and consider the costs associated with ensuring adequate ventilation and personal protective equipment to ensure a safe work environment.

6. Vendor Reliability

Lastly, the reliability of the vendor supplying the replacement product is a key factor. It’s important to choose a supplier with a proven track record of quality and consistency. Establishing a long-term partnership with a reliable supplier will help ensure that your operations remain smooth and uninterrupted. Here are the key aspects to consider:

- Supply Chain Security: A reliable supply chain reduces the risk of disruptions, such as delays or shortages, which can impact your production schedules. Choose a vendor with robust supply chain management practices to guarantee continuous availability of the replacement product.

- Customer Support: Your chosen vendor should offer comprehensive support, including assistance with product selection, integration into your processes, and troubleshooting any issues that arise.

By thoroughly evaluating these criteria and engaging with manufacturers and suppliers, you can identify a reliable and sustainable alternative. They are candidates that meet your specific needs while minimizing environmental impact and ensuring the well-being of workers and the community.

A quick look at the great properties of 3M Novec replacement

COVEN NP2103 is an ideal 3M Novec 72DE, 71DE & 73DE alternative without PFAS in the formulation. It is designed for heavy-duty vapor degreasing, immersion cleaning, or lubricant deposition; featuring high solvency, low surface tension, non-flammability, and fluid stability. This innovative solvent is much safer than the four most common industrial solvents: TCE, nPB, Perc, and Methylene Chloride.

For a detailed overview of options for 3M Novec replacements, check out our blog: 3M Novec replacements – Drop-in and long-term solution

Download our 3M Novec and Fluorinert replacement guideline to find out how our innovative solutions can help you adapt to the phase-out seamlessly:

Prostech understands the technical issues related to industrial materials. We offer a complete range of solutions, including consulting, materials, and automation equipment. We have a nationwide network of storage facilities and provide support for logistics procedures. Positioned as a comprehensive supplier, Prostech is committed to becoming a trusted partner for manufacturers in the international market. Please contact us by leaving your information below: