As the industry moves towards more sustainable and compliant manufacturing solutions, many companies are seeking alternatives for 3M Novec products, which have been widely used in cleaning, cooling, and heat transfer applications. While some short-term replacements have emerged in the market, many of these alternatives provide only temporary fixes, leaving companies at risk of facing the same problems again in the near future. Whether due to regulatory changes, supply chain challenges, or environmental concerns, transitioning to long-term alternatives is now a critical step for many businesses.

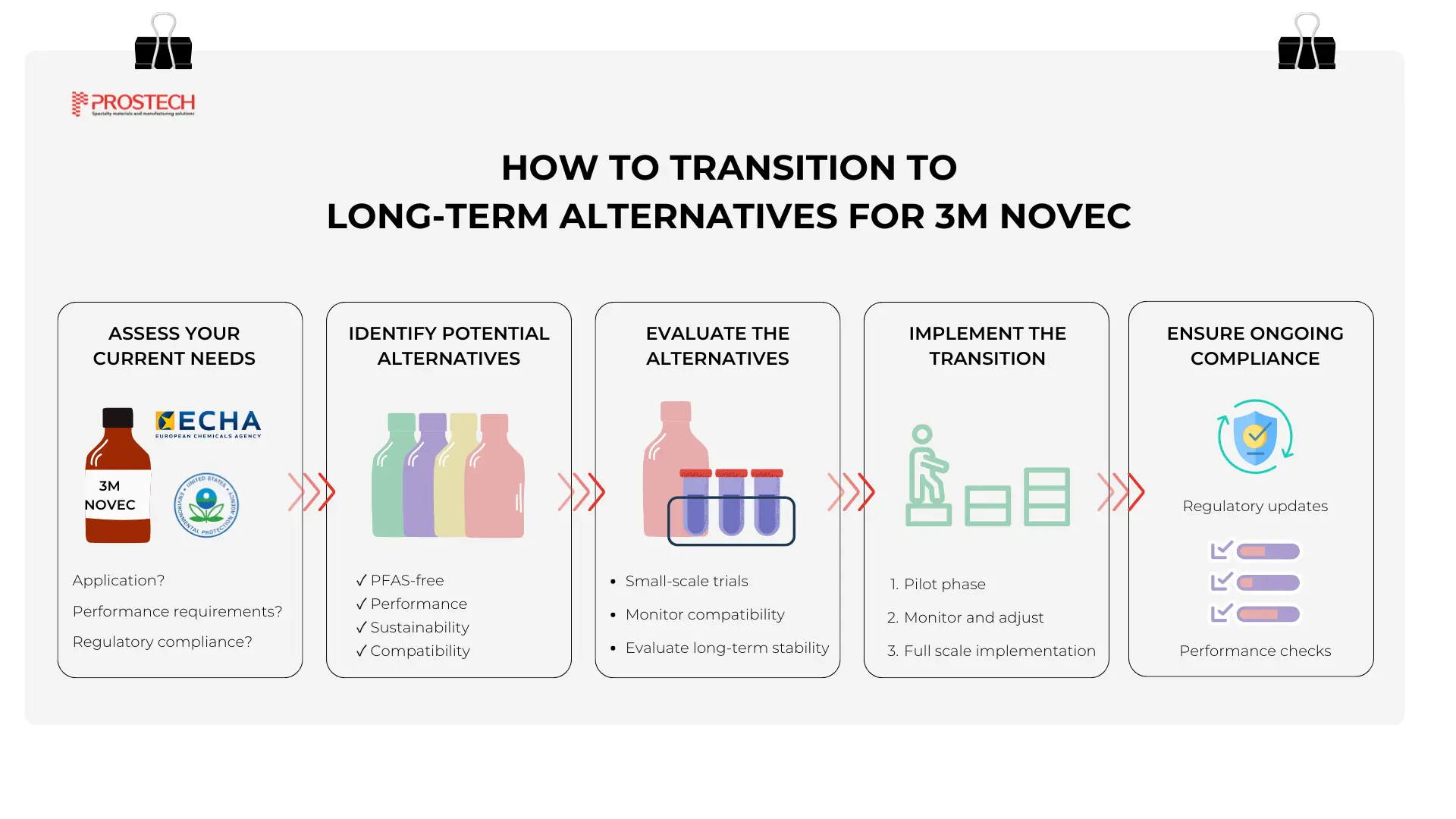

In this guide, we outline a practical, step-by-step approach to help engineers and manufacturers find, test, and implement suitable long-term alternatives for 3M Novec.

3M Novec Replacement Solutions

1. Assess Your Current Needs

Before you begin testing potential alternatives, it’s crucial to evaluate your current usage of 3M Novec products and clearly define the specific requirements you need from a replacement. Consider factors such as:

- Application: What is the primary function of the Novec product in your manufacturing process? (e.g., cleaning, heat transfer, precision drying)

- Performance Requirements: What are the essential characteristics you need in a replacement? Consider factors like thermal stability, evaporation rate, nonflammability, and dielectric properties, cleaning function, medical grade,…

- Regulatory Compliance: Avoid future compliance issue by ensure the replacement should follow specific regulations (e.g., EPA and ECHA restrictions)

By understanding your needs, you’ll be able to focus on finding long-term alternatives for 3M Novec that truly fit your manufacturing processes.

2. Identify Potential long-term alternatives for 3M Novec

Once your needs are mapped out, the next step is to identify alternative products that meet those requirements. Look for products that offer:

- PFAS-free certifications: Ensure compliance with EPA and ECHA standards by selecting replacements that are certified as free of restricted PFAS compounds.

- Equivalent or superior performance: Research potential alternatives that not only match but exceed the performance of 3M Novec in areas such as cleaning power, cooling efficiency, or heat transfer capability.

- Sustainability: Opt for alternatives that are environmentally friendly and align with your company’s sustainability goals.

- Compatibility with existing equipment and processes: It’s essential that the alternative product can be seamlessly integrated into your current manufacturing setup without requiring major adjustments to equipment, machinery, or processes. This minimizes downtime and reduces transition costs.

At Prostech, we provide a comprehensive selection of 3M Novec replacements, catering to various applications including precision cleaning, heat transfer fluids, fire extinguishing agents, and nano-coating materials.

|

Precision-V 3900 Solvent is a 100% U.S.-manufactured alternative to the 3M Novec 7100, 7200, and 7300 series, and is certified by the U.S. EPA. |

|

PWR-4 Solvent 3910 is a 100% U.S.-manufactured alternative to the 3M 71DA, 71IPA, 72DA/DE, 73DA/DE, and is certified by the U.S. EPA. |

Read the article for more information: “Government-Certified” PFAS-Free Replacements for 3M Novec

3. Evaluate The long-term alternatives for 3M Novec

Transitioning to a new product is not just about matching specifications—it’s essential to thoroughly test how the replacement performs in your specific manufacturing environment. During the testing phase, it would better to:

- Start with small-scale trials: Test the alternative in controlled conditions to ensure it behaves as expected. Evaluate factors like performance, safety, and efficiency.

- Monitor compatibility: Check for material compatibility, especially when working with sensitive components such as electronics or plastics. Ensure that the new solution doesn’t cause unwanted reactions like corrosion or material degradation.

- Evaluate long-term stability: Since some alternatives may have different lifespans compared to 3M Novec, conducting reliability test is necessary.

Read more: Key Criterias for choosing 3M Novec Replacements

4. Implement the Transition Gradually

A phased approach to implementation helps reduce risks and allows you to finetune the new solution. Some steps for your consideration:

- Pilot phase: Start by introducing the alternative into a specific part of your production line or for a single application.

- Monitor and adjust: Track performance metrics and make necessary adjustments, such as optimizing process conditions (e.g., temperature or pressure) to fully leverage the new product.

- Full scale implementation: Once the alternative has been validated in smaller trials, scale up its use across your entire manufacturing process.

5. Ensure Ongoing Compliance and Optimization

Finally, make sure that your new solution remains compliant with evolving regulations and continues to perform optimally in your production environment. Regularly review:

- Regulatory updates: Both the EPA and ECHA frequently update their guidelines for PFAS and other chemicals, so staying informed will help ensure long term compliance.

- Performance checks: Periodic evaluations of the replacement product’s performance will help you identify any issues early and keep your process running smoothly.

Indeed, transitioning from 3M Novec to long-term alternatives might seem challenging, but following this roadmap will help you discover high-performing, sustainable solutions that ensure your production process stays efficient and compliant. Prostech offers a comprehensive range of 3M alternatives that meet the most stringent industry standards. Download our 3M Novec and Fluorinert replacement guideline to find out how our innovative solutions can help you adapt to the phase-out seamlessly:

Prostech understands the complex technical challenges faced in the manufacturing of circuit boards and electronic devices. We offer complete solutions, including expert consulting, high-quality materials, and advanced automation equipment, supported by a global logistics network. As a comprehensive solutions provider, Prostech is dedicated to becoming a trusted partner for manufacturers worldwide. Contact us by leaving your information below: