Cooling fluids are essential for managing temperatures, but many of these liquids are inherently corrosive to metal components. Over time, this corrosion can cause critical failures like pump breakdowns, clogged lines, and even heat loss, all of which can compromise the system’s efficiency and lead to costly repairs. Our solution to this problem lies in the use of advanced OAT-based coolants, which are specifically designed to prevent corrosion in cooling system, ensuring your system remains efficient, reliable, and free from costly repairs.

Corrosion Problems in cooling system

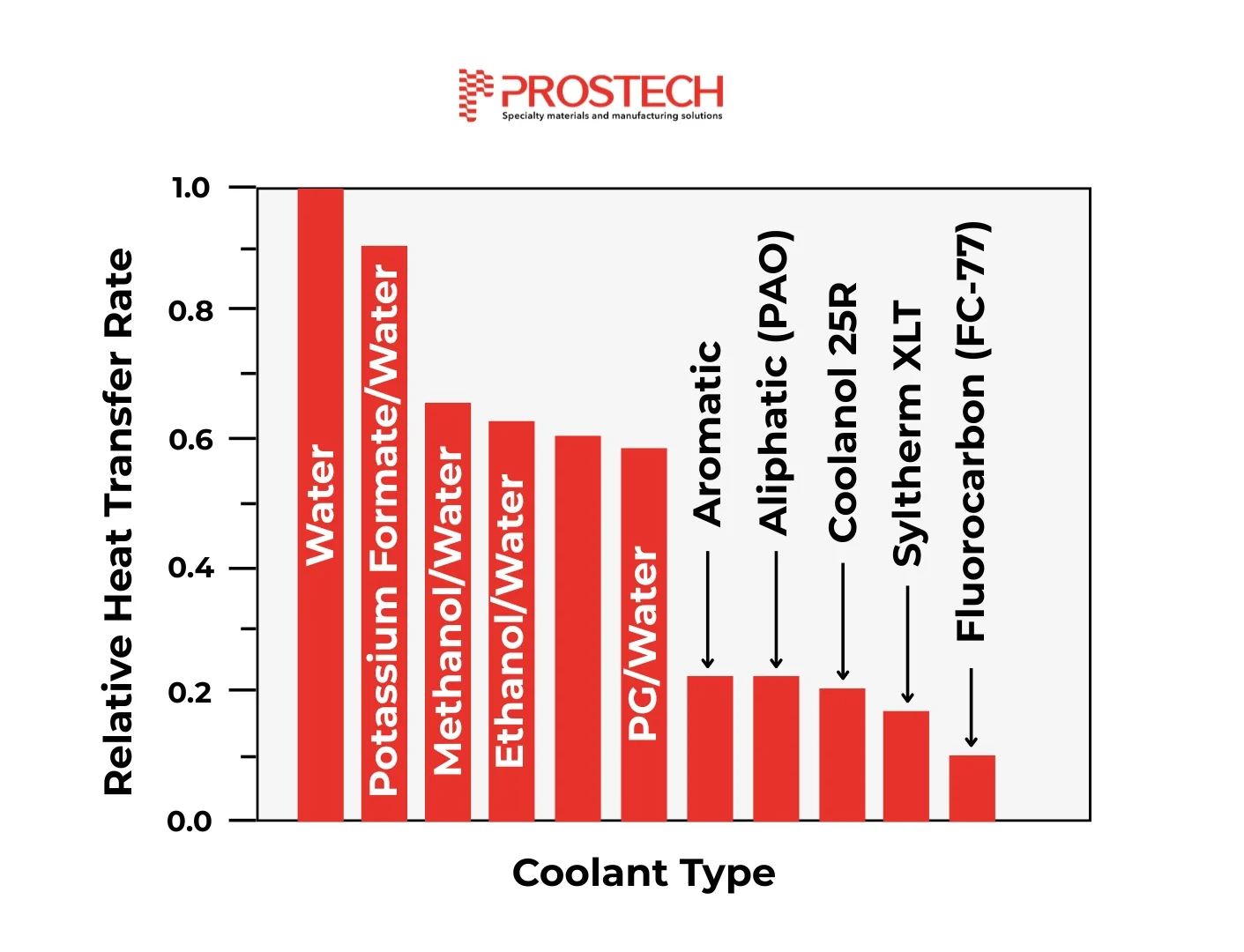

Heat Transfer Fluids (HTFs) are critical in cooling systems, as they effectively transfer heat and maintain optimal temperatures across various industrial applications.

Different coolant types have varying levels of heat transfer efficiency, but they also come with a major flaw: they cannot be used alone due to their highly corrosive nature.

The formation of corrosion in cooling system

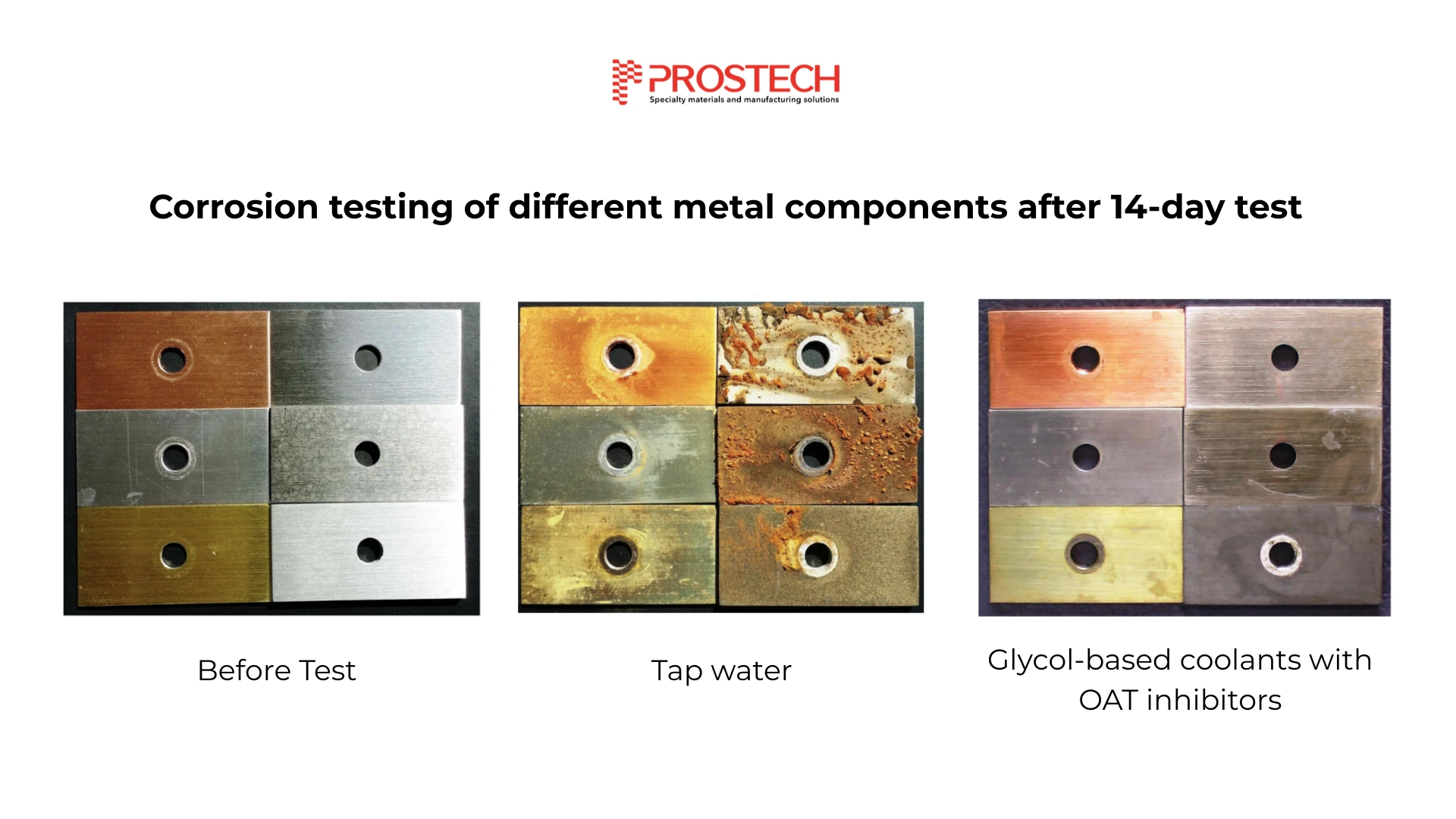

Corrosion occurs when water, metal, and oxygen come into contact, forming rust. In a cooling system, this happens when the metal parts (like the pipes and channels) come into prolonged contact with water. Over time, the water begins to oxidize, causing the metal to corrode. This is particularly evident in the coolant channels of plastic injection molds, data center cooling systems, where rust can accumulate, causing poor heat transfer and, as a result, affecting the finish quality of molded plastic bottles.

Each fluid has to be combined with corrosion inhibitors to prevent metal damage. If the right type of inhibitor is not used, or if the fluid is not replaced regularly, the system will eventually fail due to the buildup of rust and corrosion.

Read more: Solving Common Problems in Fluid Cooling System

Solution: Corrosion-Resistant Coolants

The solution to this problem lies in the use of advanced coolants like OAT-based coolant, which is specifically designed to prevent corrosion. Unlike traditional coolants that are prone to causing metal damage, OAT-based coolant offers up to 10 years of protection against corrosion under proper conditions.

Mechanism of Corrosion Protection of Inorganic Technology:

- Fluid Flow: The cooling fluid flows through the system, coming into contact with various metal surfaces such as aluminum, cast iron, steel, copper, and others (e.g., zinc/tin). This is the initial phase where the fluid is introduced to the metal components.

- Molecule Alignment: The OAT molecules, unlike traditional inhibitors, are directional in nature and align towards the metal surface. These molecules form a thin but effective protective layer on the surface. This layer is much thinner compared to traditional inorganic inhibitors, typically only around 2 micrometers in thickness.

- Formation of Protective Layer: Once the OAT molecules are aligned, they bond with the metal surface, creating an impermeable layer that prevents the further interaction between metal, water, and oxygen — the main contributors to corrosion. This layer works similarly to traditional inhibitors but is thinner and more efficient in maintaining the protection.

- Extended Life Protection: If some of the OAT molecules break away due to intense fluid movement or environmental factors, they can reattach to the metal surface and continue to protect the material. The fluid does not become depleted as easily as traditional inhibitors, ensuring long-lasting corrosion protection.

Corrosion Protection Result:

After a 14-day test using Reco-Flow X, the metal surfaces show minimal corrosion, indicating the effectiveness of Reco-Flow X coolant in protecting the metal from rust. The metal surfaces remain much cleaner and more intact, illustrating the protective layer formed by the coolant that prevents corrosion and ensures the longevity of cooling system components.

While standard coolants can be highly corrosive, selecting a corrosion-resistant coolant like Recochem’s OAT-based solution provides long-term protection. By preventing corrosion, these coolants help ensure the longevity and efficiency of your cooling system, protecting your equipment from expensive repairs and maintaining optimal performance.

Contact Prostech today for a customized quotation and expert consultation tailored to your specific cooling requirements.