The term “PFAS restriction” has gained increasing attention worldwide as concerns over the environmental and health impacts of these chemicals grow. PFAS, valued for their thermal stability and water/grease repellency, are widely used across industries. However, long-chain PFAS have been linked to serious health risks, including cancer, liver damage, and reproductive issues, as well as their persistent presence in the environment. This has led manufacturers to seek safer alternatives, although concerns remain about the environmental impact of some replacements. To address these risks, companies must follow strict regulations set by authorities such as ECHA, EPA, both of which have established detailed guidelines for what qualifies as “PFAS-free”. In this blog, we will explore these regulatory frameworks and our certified PFAS-free solutions.

ECHA and PFAS Regulation in Europe

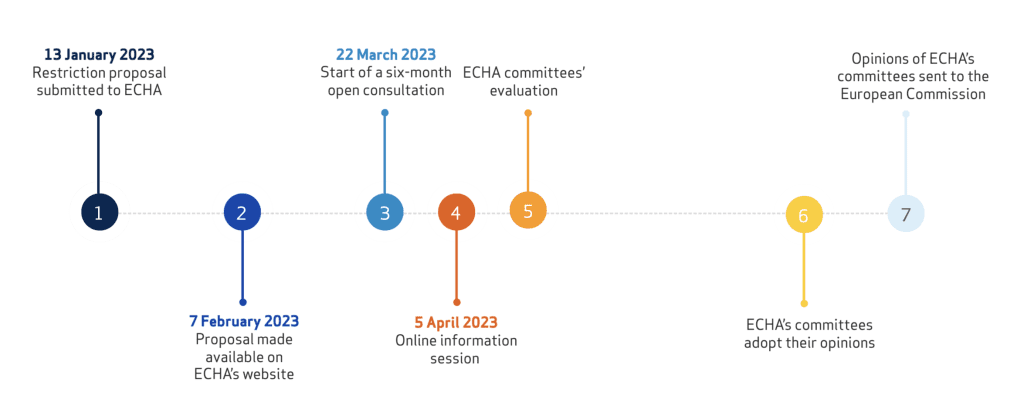

On February 7, 2023, the European Chemicals Agency (ECHA) announced its proposed restrictions on per- and polyfluoroalkyl substances (PFASs), a unique family of approximately 10,000 substances which are very persistent in the environment. The proposal, prepared by Denmark, Germany, the Netherlands, Norway, and Sweden, seeks to protect human health and the environment by limiting the manufacture, marketing, and use of PFAS under the REACH regulation.

The ECHA defines PFAS broadly, covering substances that contain at least one fully fluorinated methyl (CF3-) or methylene (-CF2-) carbon atom, without any H/Cl/Br/I attached to it. This broad definition extends to future substances with similar structures, aligning with the July 2021 Organization for Economic Cooperation and Development (July 2021 OECD) definition.

The proposed restrictions aim to ban the production, import, and sale of PFAS-containing products above specific concentrations, forcing manufacturers to ensure their products are certified as PFAS-free through third-party testing. However, since REACH regulations are frequently updated, manufacturers must continually update their testing protocols to remain compliant.

In response to growing regulatory pressure and environmental concerns, 3M announced its decision to phase out its entire 3M Novec solvent line, which contains PFAS, by the end of 2025, signaling the growing demand for certified PFAS-free alternatives.

Read more: 3M Novec replacements: Drop-in and long-term solution

EPA Regulations in the United States

On October 11, 2023, the U.S. EPA issued its final rule under the Toxic Substances Control Act (TSCA), at 88 Fed. Reg. 70516 (October 11, 2023) – requiring manufacturers of PFAS since January 1, 2011, to report extensive data on production, uses, disposal, exposures, and known health and environmental effects. The EPA’s structural definition of PFAS is specific, covering substances that meet one of the following criteria:

- R-(CF2)-CF(R’)R’’, where both the CF2 and CF moieties are saturated carbons;

- R-CF2OCF2-R’, where R and R’ can either be F, O, or saturated carbons; and

- CF3C(CF3)R’R’’, where R’ and R’’ can either be F or saturated carbons

Only “manufacturers” (discussed below) that satisfy one of the three structural definitions of PFAS must report. EPA also intends to provide a list of substances that meet the definition at its CompTox Chemical Dashboard. However, even if a substance is not on the list, but still falls under EPA’s definition, it remains subject to this rule if manufactured for a commercial purpose since 2011. Therefore, achieving PFAS-free certification under EPA standards is challenging due to stringent analytical testing methods.

Prostech’s PFAS-Free Solutions (U.S. EPA)

At Prostech, we are proud to offer world-leading PFAS-free cleaning solvents, TS-3900 and TS-3910, which are certified to meet the strict standards of the U.S. EPA. These solvents are 100% manufactured in the U.S. and provide a safe, effective alternative to 3M Novec products.

|

|

An ideal replacement for 3M Novec 7100, 7200, and 7300, Precision-V 3900 is suitable for oxygen service, heat transfer, electronics testing, and precision cleaning applications. Key benefits include:

|

|

|

As a superior alternative to 3M Flux Removers and cleaning solvents (71DA/DE, 72DA/DE, 73DE), PWR-4 Solvent 3910 is highly effective in removing grease and grime. Key benefits include:

|

For more information, refer to the article: Key Criterias for choosing 3M Novec Replacements

Download our 3M Novec and Fluorinert replacement guideline to find out how our innovative solutions can help you adapt to the phase-out seamlessly:

Prostech understands the technical issues related to industrial materials. We offer a complete range of solutions, including consulting, materials, and automation equipment. We have a nationwide network of storage facilities and provide support for logistics procedures. Positioned as a comprehensive supplier, Prostech is committed to becoming a trusted partner for manufacturers in the international market. Please contact us by leaving your information below: