Create. Enhance. and Sustain.

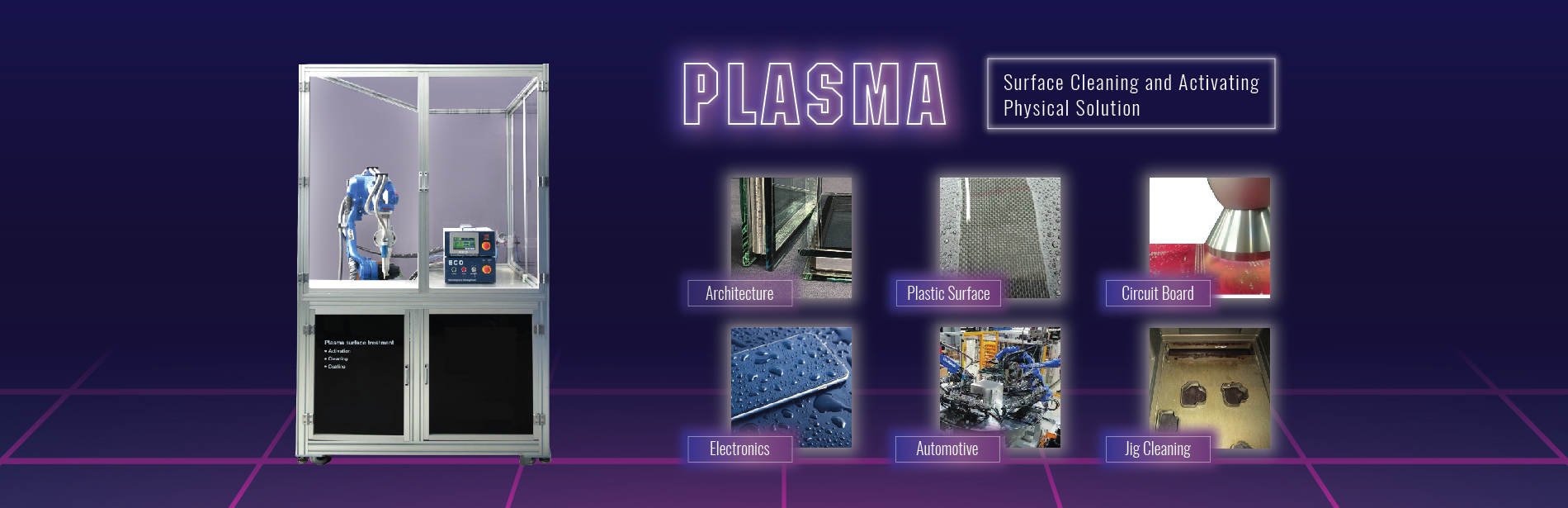

SERVED INDUSTRIES

Deeper Understanding.

Better Solutions.

Base on variable experiences in wide range of industry, PROSTECH is confident to deeply understand customers demand and promised to deliver the appropriate solutions.

NEWS & EVENTS

Industrial Manufacturing Fair VIMF Binh Duong 2023 – Prostech x Partner Ecosystem

THANK YOU! VIMF Binh Duong 2023 has ended with many successes and new opportunities. Prostech would like to express

What to expect this June? – Prostech X VIMF Binh Duong 2023

Dear valued customer, Prostech cordially invites you to join us in VIMF 2023 Exhibition in Binh Duong: ✅Booth: No. 105

PROSTECH x VIMF BAC NINH 2022- SPECIALTY MATERIAL-What we can offer you?

SPECIALTY MATERIALS Serving a wide range of industries from Electronics, Automotive to Medical devices as well as other industries, we

VIMF BAC NINH 2022 – Understand the ebb and flow of your industry

VIMF BAC NINH Show Information Exhibitions are familiar events with every business in various industries, especially manufacturing one. It cannot