UV adhesive is a common type of adhesive in use today, employed across various manufacturing industries due to its superior properties compared to traditional adhesives.

However, this type of adhesive still has many limitations in its usage. This article aims to analyze these limitations and provide specific solutions from experts for each of them.

1. Disadvantages of UV Adhesives

UV adhesives have significant benefits such as curing on demand, versatility, low VOCs, high precision, … so it is applied to many industries as electronics, automotives, medical devices, … In order to know more about the outstanding advantages of UV adhesive, you can refer to this article: Outstanding Advantage of UV Adhesives

Besides those advantages, UV adhesives also have some disadvantages such as:

1. Needing UV curing system

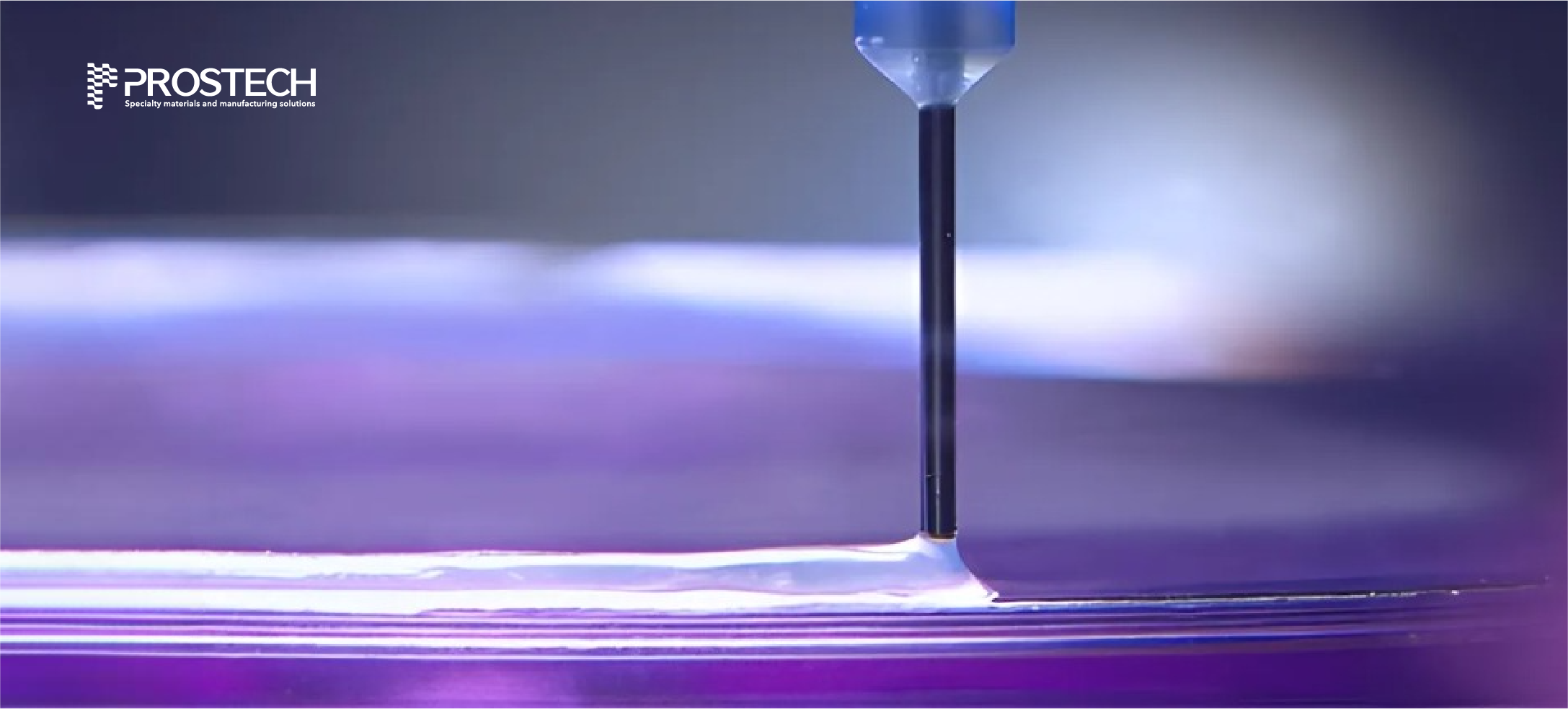

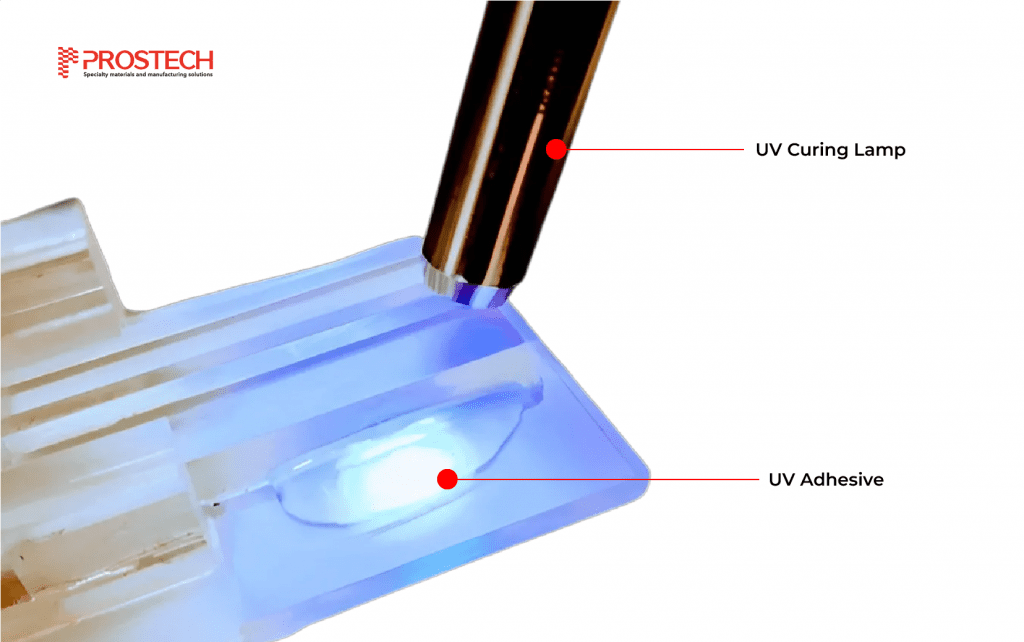

To activate the photopolymerization process, the most important thing we need is a system providing UV light. This can be a limitation in cases where the structure is complex or the accessibility of the UV light to the area to be cured is limited, especially for applications with hidden internal bonding.

|

|

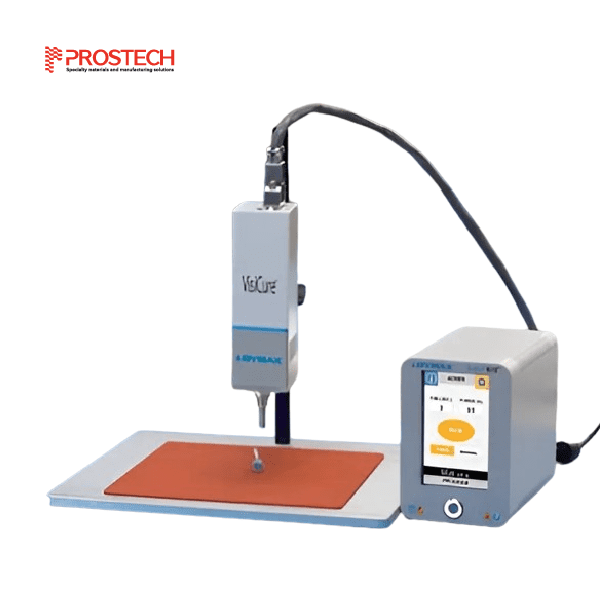

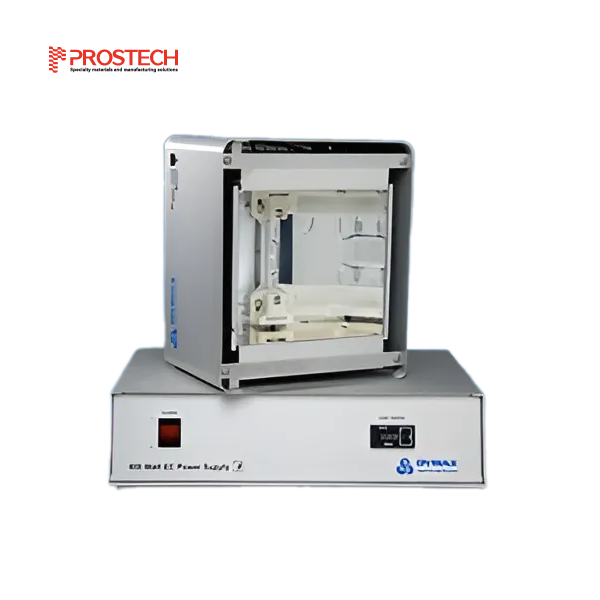

FIND OUT now to Choose the suitable UV Curing Systems for your manufacture

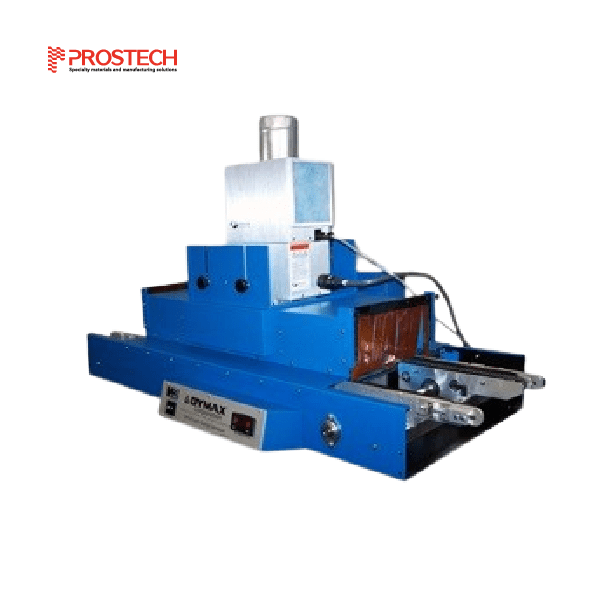

These systems use special lamps that emit UV light with desired wavelengths, so the production of these lamps requires more specialized UV lamp and processes than regular lamps. If you are using UV adhesive and facing the problems of UV adhesive curing process, please contact Prostech for consultation, with many years of providing specialty material for manufacturing, we can advise you comprehensive solutions of applying UV adhesive process, help you to improve your production efficiency, quality, and long-term benefits. Please refer to our Inline UV Curing Systems

2. The limitation of curing ability

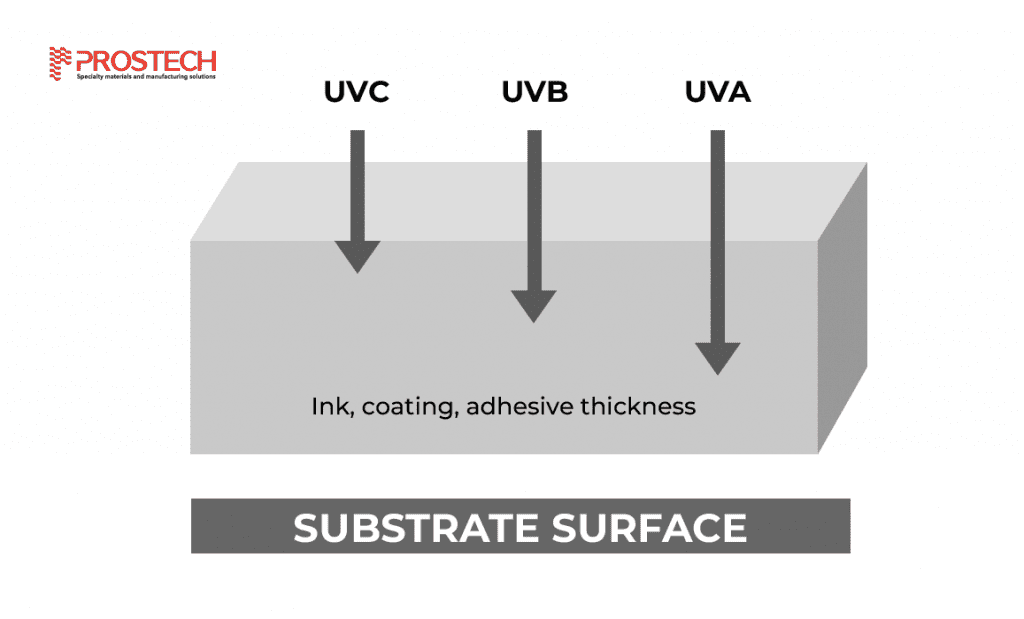

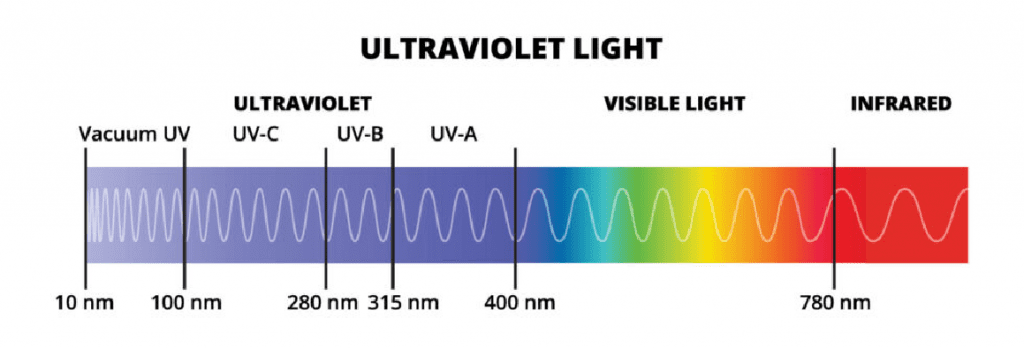

The penetration depth of UV light decreases as it passes through material. The thicker the adhesive layer, the less UV light will reach the bottom surface of the layer so it can lead to partial curing on the surface only, resulting in uneven curing and weak bond strength.

The absorption capacity of materials with each type of UV light is different. To bring the best effect, it is necessary to choose the proper type of UV lamp for the purpose of us, or you can ask glue experts before making decisions.

Prostech offers a wide range of UV lamps and UV Curing Systems which can deliver clearer results, faster drying times, and improved adhesive bond quality, helping to save on production costs and materials. Contact us to receive valuable information and consultation from our qualified experts.

3. Substrate compatibility

- UV Transmission

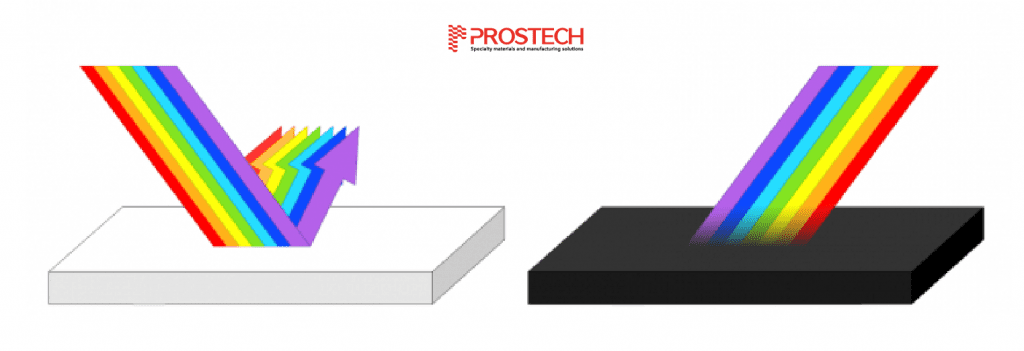

Opaque substrates: These substrates will block the UV light, preventing it from reaching the adhesive layer that can lead to incomplete or uneven curing, especially for thick adhesive layers.

Transparent substrates: These substrates have high optical transmittance, so they allow UV light to pass through easily, so the curing process is fast and uniform.

- Light absorption and reflected wavelength

Dark substrates: These substrates absorb a significant portion of the UV light. With less UV light reaching the adhesive, the curing process can become incomplete leading to uneven curing and weak bond strength.

Light substrates: These substrates tend to reflect more UV light, allowing for better penetration and deeper curing of the adhesive.

However, to overcome the limitations of traditional UV adhesives, UV dual-cure adhesives such as UV-heat, UV-moisture, and UV-anaerobic have been developed. These are perfect combinations of UV curing and heat, moisture, or anaerobic curing. Please refer our solutions for dual curing methods adhesive here: Thermal Cure UV Adhesive

The UV curing mechanism allows for rapid shaping of the adhesive bead, making it suitable for applications that require temporary solidification during the transfer process, ensuring efficiency and productivity. The heat, moisture or anaerobic mechanism helps to complete the curing process, penetrating hidden areas that UV light cannot reach, ensuring the bond strength.

2. Alternatives Recommendation of UV adhesives

Besides traditional UV adhesives and UV dual-cure adhesives, Prostech also provides alternative solutions to UV adhesives such as:

Each alternative mentioned above is utilized in various applications across different manufacturing industries. To select the appropriate type for your application, please contact Prostech to receive guidance from experienced adhesive specialists.

3. Conclusion

UV adhesive is widely used due to its advantages and prominent characteristics compared to traditional adhesives. Although there are limitations such as the need for curing systems, curing lamps, and compatibility with surfaces, we can all mitigate these drawbacks with the above solutions from Prostech.

PROSTECH is a reputable partner, providing a wide range of UV products and curing systems suitable for various applications across different manufacturing industries.