There are many methods to apply Conformal Coating. The choice will depend on the following variables:

- Production throughput requirements: The necessary prep work, the speed of the coating process, and how quickly the boards can be handled after the coating process.

- Board design requirements: Connector-laden designs, solvent-sensitive components, and other issues impact your decision.

- Equipment requirements: If a coating is only sporadically required, tying up capital and floor space with additional equipment may not make sense.

- Pre-coating processing: Some processes require masking or taping before coating in order to prevent coating of unwanted surfaces.

- Quality requirements: Mission-critical electronics that require a high degree of repeatability and reliability will generally require more automated application methods.

Common methods to apply Conformal Coating

Manual spraying

|

|

For low volume production when capital equipment is not available, the conformal coating can be applied by an aerosol can or handheld spray gun. This can be time-consuming and may need to be masked. Also, the quality and consistency of outcome are operator-dependent, so variations are common from board to board.

Automated spraying

Programmed spray systems can move PCBs on a conveyor under a reciprocating spray head. Different from Selective Spraying, this method will help to coat full PCB.

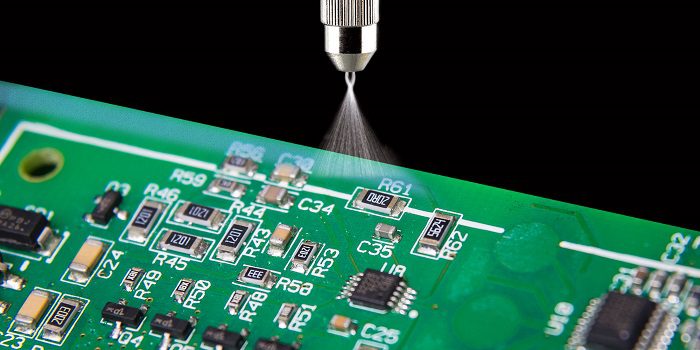

Selective coating

An automated spray system can actually be programmable, with a robotic spray nozzle applying the conformal coating to specific areas on the PCB. This is popular for high volume assembly because it eliminates the laborious masking process.

Dipping

This is a popular conformal coating method for high-volume assembly. Masking is usually necessary before PCBs are coated. Dipping is only practical when coating both sides of the board. Immersion speed, withdrawal speed, immersion time, and viscosity determine the resulting film formation.

Brushing

Brushing is used mostly for repair and rework. Conformal coating is brushed onto specific areas on the board, not generally the entire PCB. While low-cost, brushing is both a labor intensive and highly variable method, so it more appropriately suits small production runs.

Vapor Deposition

The application procedure is specific to parylene conformal coatings. When heated, parylene is transformed into a gaseous state. It is then cooled and introduced to a vacuum chamber where it polymerizes and becomes a film, which is deposited on the entire circuit board. The process requires specialized equipment and training, so is often outsourced.

Each application method has its own pros and cons to meet specific requirements of various conformal coating lines. Please contact us for further consultants about conformal coating method as well as processes.