High-power EV battery modules consist of numerous cells connected in series or parallel to achieve voltage levels approaching 400V. These connections demand a material that excels at both conducting electricity and providing insulation—qualities that go beyond what traditional insulated cables offer. Conventional cell connections (welded wires, strips, or lugs) are susceptible to failure when the cells even slightly dislocate during operation, for example, due to the vibration of a moving vehicle. This is where busbars – a specialized electric conductor paired with an insulating layer come into play.

What is a Busbar?

Busbars are metallic strips or bars, typically made of copper, aluminum, or their alloys, designed to conduct and distribute electrical power within a system. They are compact, robust, and capable of carrying substantial current loads while maintaining minimal electrical resistance. Busbars serve as a key connecting element in electrical systems, replacing traditional wiring for higher efficiency and reliability.

In the context of EVs, busbars play a pivotal role in connecting individual cells within a battery pack. An EV busbar functions like the blood vessels, conducting electrical currents and distributing them to various systems and subsystems. It provides a reliable and efficient connection method compared to conventional insulated cables, which can be prone to failure due to factors like vibration and heat generation.

Benefits of Busbars in EVs

Busbars increase the mechanical capacity of EV batteries

- Compact and Lightweight: EV busbars are more compact and lighter compared to traditional cables, the lower size & weight, the better for car performance.

- Structural Integrity: Their rigid design helps maintain the structural integrity of the battery module or pack, even in dynamic conditions.

- Flexibility: Busbars are engineered to withstand elastic stress, thermal expansion, and G-forces encountered during vehicle operation.

- Service & Maintenance: EV busbars facilitate safe and quick replacement of components, minimizing downtime and maintenance costs.

Busbars enhance the electrical capacity of EV systems

- Conductivity: Fabricated from materials like copper or aluminum, busbars can carry more current than cables with the same cross-sectional area while minimizing resistance and power loss.

- High Voltage Handling: Designed to handle the high-voltage requirements of EV battery systems, busbars ensure efficient power delivery and safety. As EV manufacturers aim to reduce charging times, busbars enable efficient power flow to accommodate higher charging speeds.

Busbars contribute to effective thermal management

- Support for Cooling Systems: Busbars integrate seamlessly with both air-based and liquid cooling systems, improving the overall thermal regulation of EV battery modules.

- Effective Heat Dissipation: The large, flat surface area of EV busbars allows for better heat distribution, preventing hotspots and improving battery safety.

Main types of Busbars

Busbars come in various designs, each with unique properties and functionalities based on customer requirements. Common types include:

|

Laminated Busbar:

Product: ROLINX Easy |

|

Compact Busbar:

Product: ROLINX® Compact |

|

PowerCircuit Solutions:

Product: ROLINX PowerCircuit Solutions |

|

Hybrid Busbar:

Product: ROLINX Hybrid |

|

Housing Solution:

Product: ROLINX Housing Solutions |

|

Flex Busbar:

Products: ROLINX Flex |

|

CapLink Busbar:

Products: ROLINX CapLink Solutions |

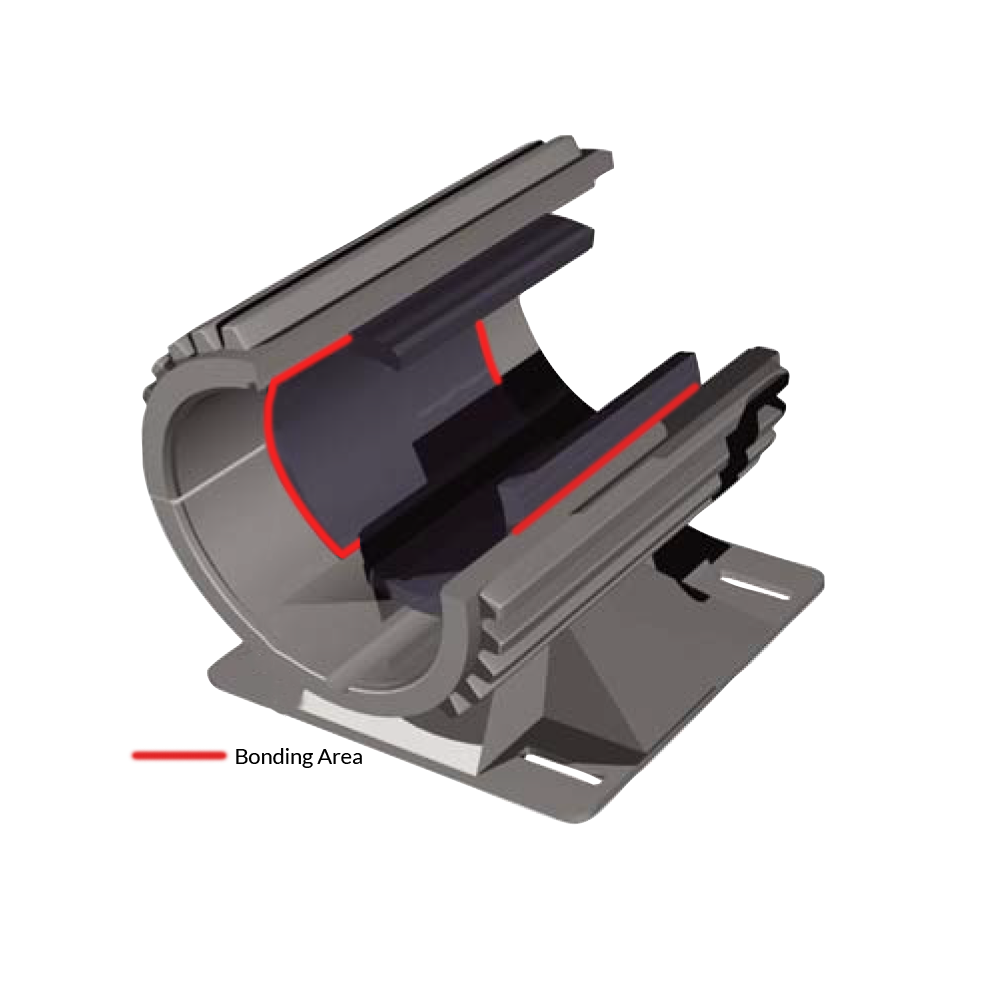

The assembly of busbars in EV battery system

EV busbar assembly is a critical process in EV battery systems, ensuring efficient, reliable, and safe power distribution. It involves designing and shaping conductive materials like copper or aluminum, adding insulation for safety, and integrating components such as connectors, sensors, and thermal management systems.

Methods like welding or fastening secure the busbars to battery terminals, while testing ensures electrical and thermal efficiency. The assembly is compact, durable, and resistant to vibrations, meeting the demands of high-power EV applications. Alongside our EV busbar offerings, our automation solutions help manufacturers achieve faster, more accurate assembly processes while maintaining high-quality standards.

Prostech understands the technical issues related to EV systems. We offer comprehensive solutions, including consulting, materials, and automated application equipment. We have a global warehousing network to assist customers with logistics procedures. Positioned as a comprehensive supplier, Prostech is constantly striving to become a trusted partner for manufacturers around the world. Contact us for free consultation and full version of battery module solutions as well as busbar customization service.