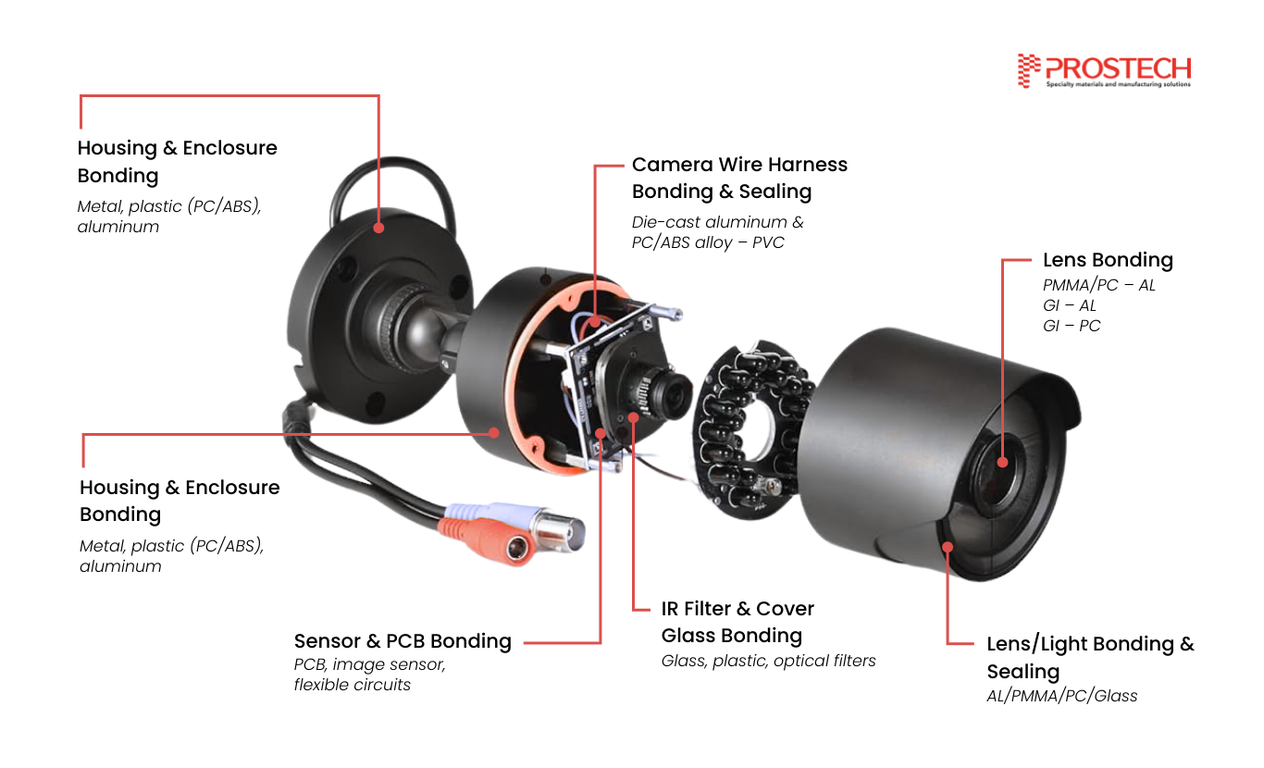

Security cameras are crucial for surveillance in both residential and commercial environments. To ensure long-term reliability and performance, manufacturers must use high-quality bonding solutions that can withstand extreme conditions such as humidity, temperature variations, and mechanical stress. This blog explores various bonding applications in security camera assembly, the essential requirements for adhesives, and recommended products for optimal performance.

Bonding Applications in Security Camera Assembly

Security camera assembly requires precise bonding and sealing solutions to enhance durability and protect sensitive components. Here are some critical bonding applications:

1. Lens Bonding

Bonding substrates: PMMA/PC – AL, GI – AL, GI – PC

Benefits of our bonding solution:

- Excellent bonding adaptability with multiple substrates.

- Provides suitable strength for secure lens attachment.

- High elongation (400–500%), ensuring flexibility and durability.

- Superior weather resistance, including resistance to boiling water, high humidity, and temperature variations.

2. Lens/Light Bonding & Sealing

Bonding substrates: AL/PMMA/PC/Glass

Benefits of our bonding solution:

- High strength after curing, ensuring long-term adhesion.

- Strong adaptability to various substrates.

- Excellent sealing performance, preventing moisture and dust intrusion.

- Exceptional aging resistance, extending product lifespan.

- Excellent water resistance, crucial for outdoor security cameras.

3. Camera Wire Harness Bonding & Sealing

Bonding Substrates: Die-cast aluminum & PC/ABS alloy – PVC

Benefits of our bonding solution:

- Short clamping time, simplifying production and increasing efficiency.

- High hardness after curing (up to 75D), ensuring durability.

- Excellent bonding strength and performance.

- High and low-temperature impact resistance, enhancing longevity.

- Superior aging resistance, increasing the service life of security cameras.

- Good air tightness, preventing internal corrosion.

- Meets UL 94-V0 (117FR has yellow card certification), ensuring flame retardancy.

4. Housing and Enclosure Bonding

Bonding substrates: Metal, plastic (PC/ABS), aluminum

Benefits of our bonding solution:

- Creates a strong and durable bond between housing components.

- Reduces mechanical fasteners, ensuring a lightweight and seamless design.

- Improves resistance to impact, temperature variations, and harsh environmental conditions.

- Prevents water and dust infiltration, maintaining camera integrity.

5. Sensor and PCB Bonding

Bonding substrates: PCB, image sensor, flexible circuits

Benefits of our bonding solution:

- Ensures secure attachment of PCBs and image sensors inside the camera.

- Provides mechanical support while maintaining electrical conductivity.

- Prevents vibrations and misalignment, ensuring stable camera performance.

- Offers high thermal conductivity, reducing overheating risks.

6. IR Filter and Cover Glass Bonding

Bonding substrates: Glass, plastic, optical filters

Benefits of our bonding solution:

- Ensures high optical clarity for infrared filters and cover glass.

- Provides strong adhesion without interfering with camera vision.

- Prevents dust, moisture, and contamination from affecting the optical path.

- Quick UV curing reduces production time and increases efficiency.

Selecting the appropriate adhesives and tapes depends on the materials, application, and required performance. We provide a diverse range of solutions designed to meet different security camera assembly needs. Reach out to us for expert guidance in finding the ideal bonding solution for your project.

Requirements for Adhesives in Outdoor Security Camera Assembly

Outdoor security cameras require weatherproof construction and corrosion-resistant materials to withstand rain, snow, and prolonged UV exposure. Key requirements include:

Weather resistance: Outdoor security cameras must endure rain, snow, and extreme temperatures, requiring weatherproof construction. Adhesives should provide waterproof sealing and UV resistance to prevent degradation from prolonged sun exposure.

Strong adhesion to used substrates: Bonding solutions must securely adhere to metals, plastics (PC, PMMA, ABS), glass, and rubber. They should also accommodate thermal expansion and contraction of different materials to prevent bond failure.

Chemical & corrosion resistance: Outdoor conditions expose cameras to salt spray, pollution, and cleaning agents. Adhesives should provide chemical resistance to prevent material breakdown and ensure long-term performance.

Thermal conductivity for heat management: Thermally conductive adhesives improve reliability by transferring heat away from sensitive parts like processors and image sensors.

Prostech’s Adhesive Portfolio for Security Camera Assembly

Prostech’s electronics bonding solutions ensure the secure installation of indoor and outdoor security devices by:

- Providing reliable shock absorption

- Protecting components from water ingress and UV exposure

- Enhancing durability and stability with strong adhesion to rubber and TPU,

- High shear strength, a pull force exceeding 50N

Here are some of our top-performing adhesives and tapes designed to enhance durability, efficiency, and aesthetics in security camera assembly:

|

|

|

| Insulcast 116/117FR | Dymax 3069 | Tru-Bond UB6500T |

|

|

|

| Tru-Bond UB15000 | 3M™ Scotch-Weld™ 6101 OW | 3M™ VHB™ Tape 4914 |

Can’t find the right product? Let our experts help! Contact us today for a free consultation and discover the best adhesive solution for your security camera assembly needs.