Battery Cell Assembly Process depends on the cell format and the individual manufacturer designs. They are manufactured in many sizes to fit the product. The most common shapes are cylindrical and rectangular (pouch and prismatic cell). While the use of either shape is dependent on the battery pack design, securing the cells into their larger battery modules or trays, takes different adhesive and dispensing approaches.

Cell to cell bonding

Inside prismatic or pouch module design, cells are firmly bonded to each other to create cells stacks and to provide insulation and protection against vibration or movement.

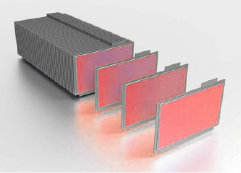

Pouch cell lamination

|

|

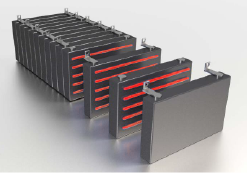

Prismatic cell bonding

- Prismatic cells are bonded with 2-component urethanes or silicones which need to be light and flexible to allow the cells to expand during charging and discharging.

- To provide complete insulation and avoid short circuits, the application needs to be precise to avoid air gaps during the dispense.

Method

|

|

Dispensing System – Common Challenges

- Air entrapment – Air can become trapped around the battery cells during an encapsulation fill or pour.

PROSTECH Solution

- Hot melt pressure-sensitive adhesive

- Two-component polyurethane adhesive

- Two-component silicone adhesive

- Programmable dispense speeds allow for mid-shot adjustments in material flow rate, which allows air to escape from the fill. Speed can be adjusted back to full speed once the material is past the point of concern, which allows production speed to be achieved.

Cell to frame bonding – Pouch and Prismatic cell

In many cases, modules are enclosed in a lightweight polycarbonate or ABS enclosure that is sealed closed.

Cold plate bonding

Cold plate bonding involves bonding cells or other electronic devices to a cooling plate. This generally involves a structural bond that provides good thermal conductivity and dielectric strength. These materials are often abrasive and require the right dispensing solution. Two-component meter mix with precision control is of critical importance in these applications.

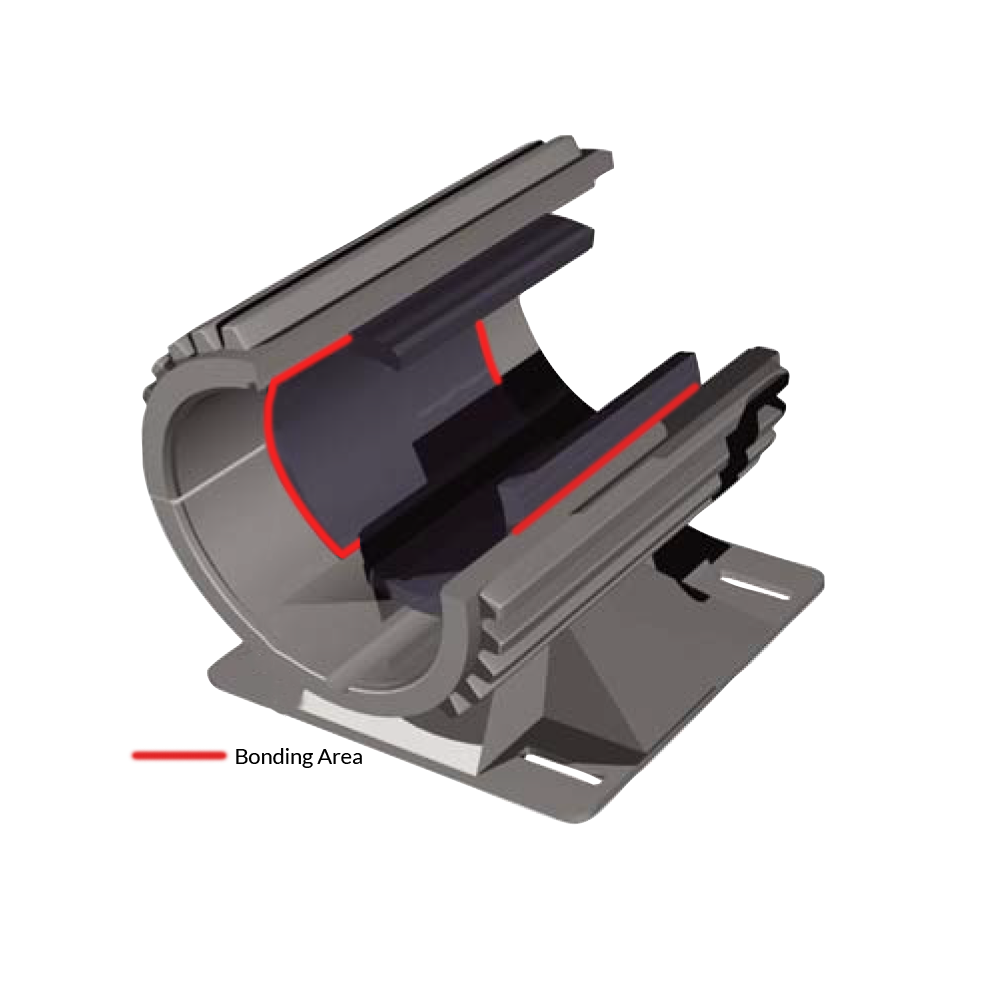

Frame bonding

Cells are bonded with the frames around them to protect against outside contaminants. The sealing surfaces are generally very small and require precise bead dispensing.

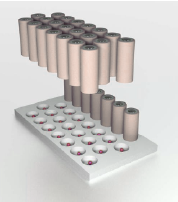

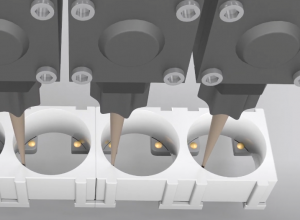

Cell to carrier bonding

|

Cylindrical cells are often bonded to a polycarbonate carrier during module assembly. This holds the cells stationary through the tab welding process and provides structural integrity to the module. A variety of adhesive chemistries can be used in this application including UV and 2-component acrylics. |

Methods

|

|

Common Materials Dispensed

- Single component epoxies

- Two-component curing epoxies

- Single component UV curing materials

Common Challenges

- Production Speed – When dispensing beads or dots in small spaces, such as a battery cell housing, a needle or nozzle is used that requires very accurate robot movement, which can lead to a lengthening of cycle time.

- Solution: Multiple dispense heads per dispensing meter can allow for more cells to be complete before the need to move the robot dispensing arm location

- Location Accuracy – moving quickly from place to place can result in beads or dots slightly off from the desired location, or beads left incomplete.

- Solution: our material and application knowledge, coupled with our robotic automation experience, enable us to design engineered solutions that provide the correct number of dispense heads at the flow rate and robotic speed the application needs.

Depending on the type of battery cell, the adhesive and dispensing solution will be different. Contact us for more information: