- Benefits of using Light-Curable Adhesives in Medical Device Assembly

- Light-Curable Adhesives has a fast-curing process

- Light-Curable Adhesives offers strong and durable bonds

- Material compatibility of Light-Curable Adhesives

- Biocompatibility of Light-Curable Adhesives

- Light-Curable Adhesives enhance Aesthetic

- Precision and control of Light-Curable Adhesives

- Light-Curable Adhesives improve Quality Control

- Applications of light-curable adhesives in medical device assembly

As in-home patient care becomes more common, material regulations tighten, and the demand for safer, less invasive devices increases, selecting high-quality adhesives and materials for medical devices is essential for optimizing operations and enhancing product reliability and safety. Light-curable adhesives have gained popularity among manufacturers due to their distinct properties and benefits. In this article, let’s explore why light-curable adhesives are ideal for various applications in medical device assembly.

Prostech’s Medical Device Solutions

Benefits of using Light-Curable Adhesives in Medical Device Assembly

Light-Curable Adhesives has a fast-curing process

One of the most significant advantages of light-curable adhesives is their ability to cure quickly. Upon exposure to the appropriate wavelength of light, these adhesives can harden in seconds, drastically reducing assembly time. This rapid curing process increases production throughput and efficiency, which is crucial in the high-demand medical device industry. The curing time of light-curable adhesives is also influenced by the curing system used.

Light-Curable Adhesives offers strong and durable bonds

Medical devices need adhesives capable of enduring diverse stresses and strains. Light-curable adhesives create robust and durable bonds that outperform traditional fasteners, ultrasonic welding, or solvent welding. They effectively distribute stress across a large area, ensuring the long-term reliability of medical devices. These adhesives are engineered to withstand mechanical stress, thermal cycling, and chemical exposure, making them perfect for challenging medical environments.

Material compatibility of Light-Curable Adhesives

Light-curable adhesives are extremely versatile, capable of bonding various substrates frequently used in medical devices, such as medical plastic (ABS, PVC, PC, PMMA, etc.), metals, glass, and ceramics. They are particularly effective for bonding irregularly shaped parts and dissimilar materials. This versatility enables manufacturers to rely on a single adhesive for multiple applications, streamlining the assembly process and lowering inventory costs.

Biocompatibility of Light-Curable Adhesives

The safety of patients is paramount in the medical field. Light-curable adhesives are formulated to meet stringent biocompatibility standards, ensure they are safe for use in medical devices that come into direct or indirect contact with the human body. Biocompatibility is essential for maintaining patient safety and meeting regulatory requirements.

Light-Curable Adhesives enhance Aesthetic

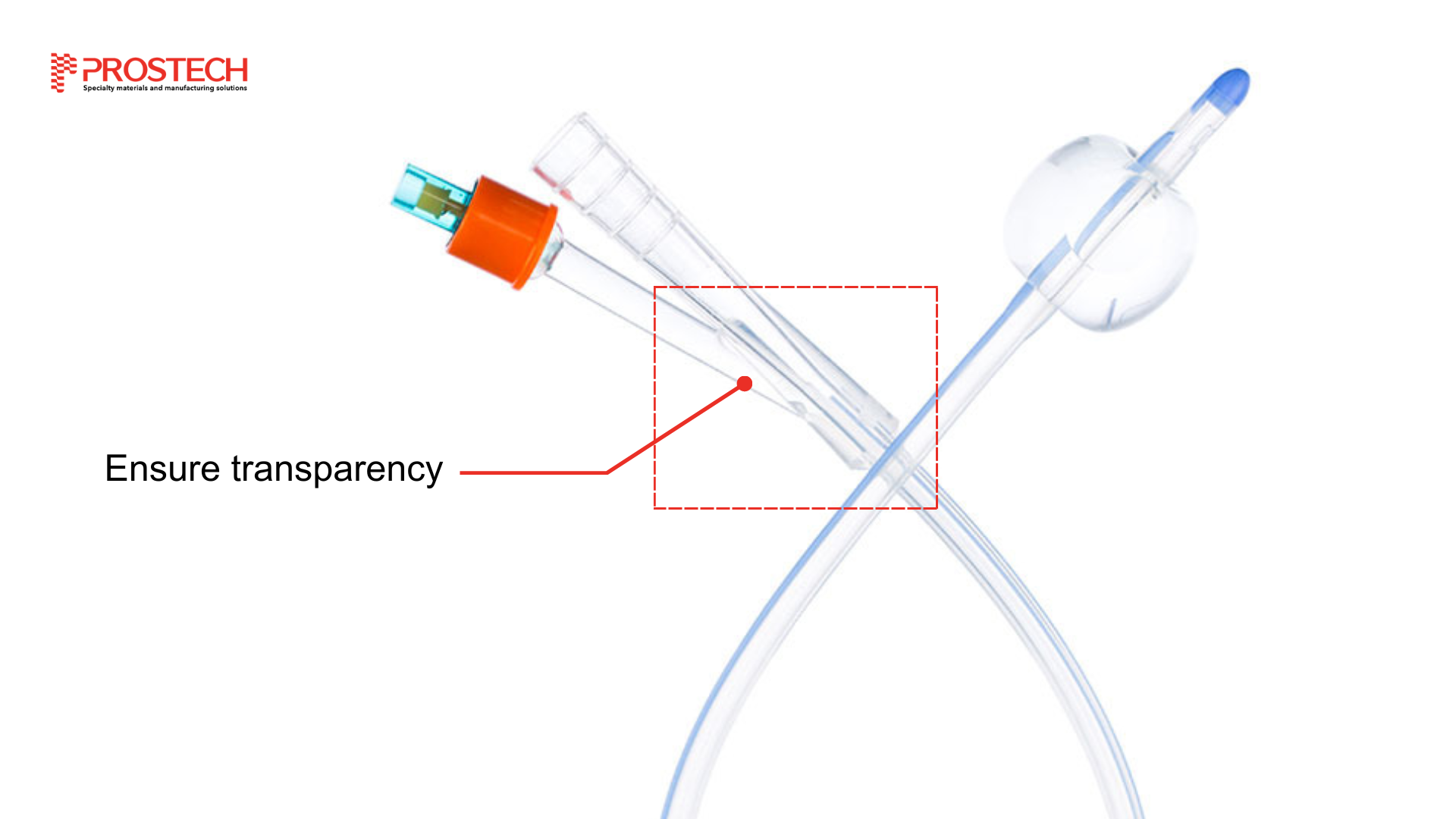

Light-curable adhesives enhance the aesthetics of medical devices by providing clear, invisible bonds and allowing for precise application, resulting in a clean and professional finish without the need for mechanical fasteners.

Precision and control of Light-Curable Adhesives

Light-curable adhesives offer exceptional control during the assembly process. Since they remain in a liquid state until exposed to light, manufacturers have ample time to align components accurately before curing. This precise application is particularly beneficial for complex and delicate medical devices where exact positioning is critical.

Read more at: Curing Mechanism of UV Adhesive

Light-Curable Adhesives improve Quality Control

The capability to instantly cure adhesives with light allows for immediate inspection and quality control. Some adhesives feature fluorescent technology, aiding manufacturers in quickly verifying bond integrity post-curing. This real-time quality control greatly improves the reliability and safety of medical devices.

Light-curable adhesives present several benefits that make them ideal for medical device assembly. Their rapid curing times, precision, strong bonds, biocompatibility, versatility, aesthetic enhancement, and improved quality control are just a few reasons they are becoming the preferred choice for many medical device manufacturers. Prostech offers a portfolio that includes light cure acrylic adhesives, light cure cyanoacrylate, light cure silicones for products in a wide range of medical applications including tube assemblies, connectors, and housing,…

Applications of light-curable adhesives in medical device assembly

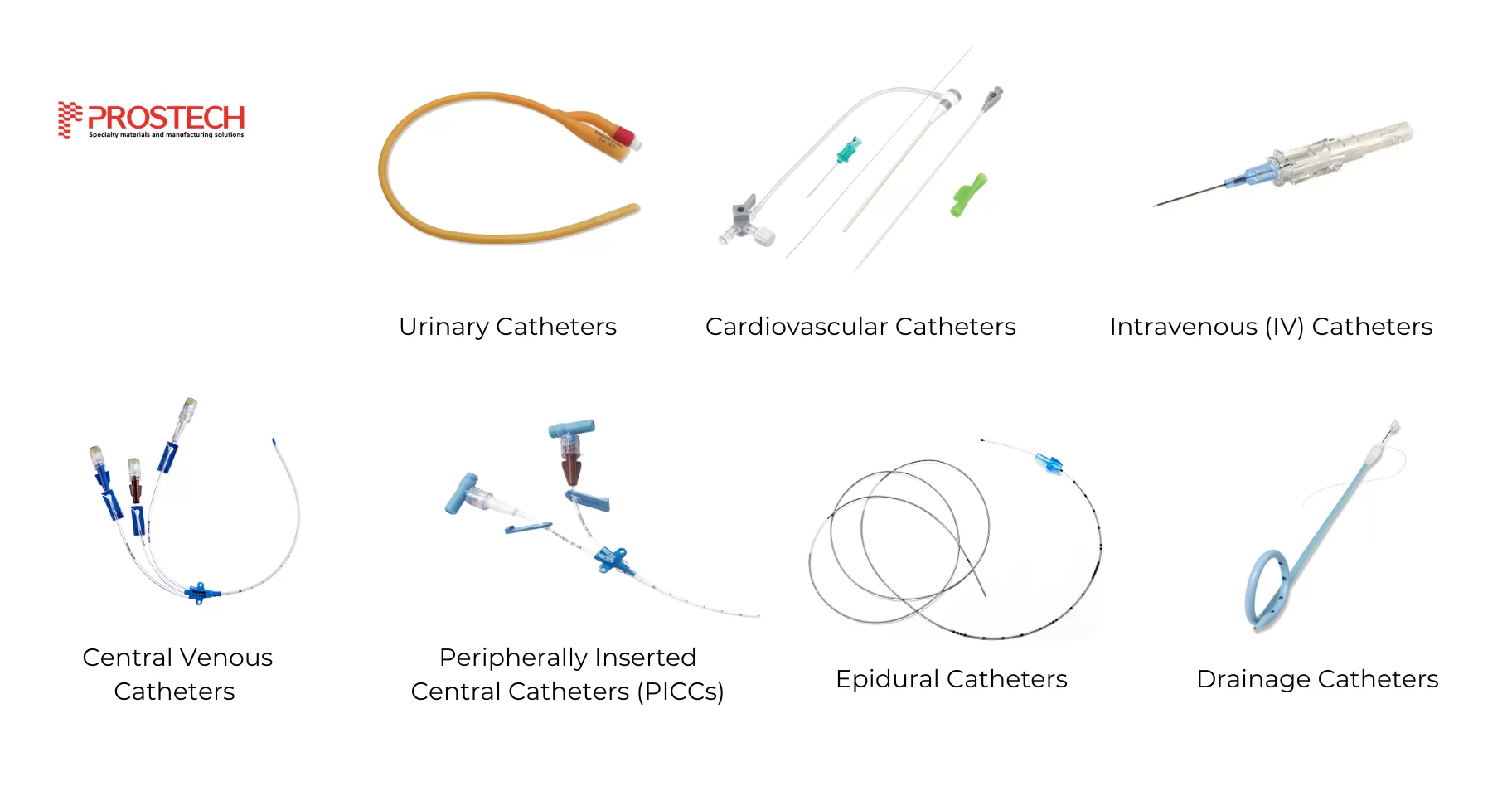

These medical-grade UV adhesives are utilized for both disposable and reusable medical devices. Typical applications include:

- Catheters Assembly: Ensuring biocompatibility.

- Fluid Bag and Tube Set: Ensuring secure and leak-free connections.

- Syringes and Needles: Providing strong bonds for safe and reliable use.

- Respiratory Devices: Enhancing the durability and performance of breathing apparatus components.

- Diagnostic Equipment: Offering precise and dependable bonding for various diagnostic tools.

- Orthopedic Devices: Strengthening and stabilizing joint and bone repair devices.

- Wearable Medical Devices: Ensuring comfort and longevity for continuous patient monitoring systems.

Read more: Catheter Assembly: Choosing the Right Medical Adhesive Grade

For medical disposable device assemblies, Prostech provides a comprehensive selection of adhesives that have applications encompass needles, syringes, catheters, tubes, connectors, and more. These medical device adhesives are rigorously tested to protocols based on ISO 10993 biocompatibility standards (ISO 10993-5, -10, -11, -4, -6). With experience in medical device assembly and deep understanding of adhesive technologies, Prostech offer tailored medical device adhesive solution to address challenges and optimize processes. Contact us today to get free consultations!