The more type of adhesive technologies are invented, the more difficult it is for manufacturers to make decisions. To choose the right adhesive for your application, it depends on many factors. The following questions will help you narrow adhesive choices to a few possibilities for evaluation.

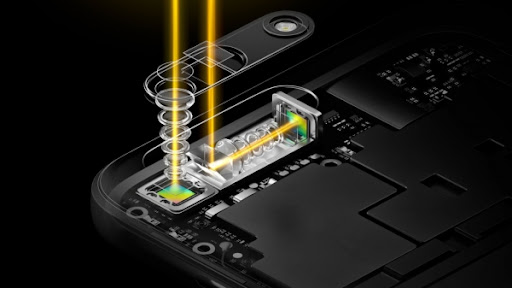

1. What materials will be bonded?

| Adhesive work by adhering to the top surface of the bonded parts, so it’s important to know the exact material and condition on those surfaces. For metals, will the adhesive be applied to bare metal, or will there be a paint or coating on the surface? For plastics, exactly which base resin? Could there be residual release agents on the surfaces used for mold release? |   |

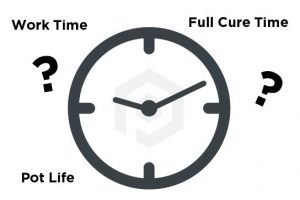

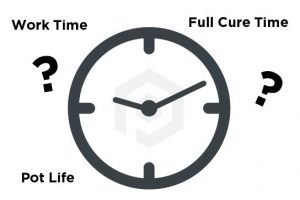

2. What is preferred cure speed?

| The chosen adhesive must have enough work life (open time, pot life) to allow proper mixing and application of the adhesive and assembling of the bonded parts. Smaller assemblies or shorter cycle time production processes may be able to use a faster curing adhesive with a work life of only five minutes or less, while larger assemblies that require alignment and clamping will probably need a work life of 20 minutes or more. |   |

3. What surface preparation will be required?

| Structural adhesives generally prefer clean, rough, dry surfaces for highest bond strength. This typically means either light abrasion and solvent cleaning of the surface, or solvent cleaning followed by chemical etching or applying a primer. Adhesion tests should be performed to determine the adequate surface preparation for a specific application. |   |

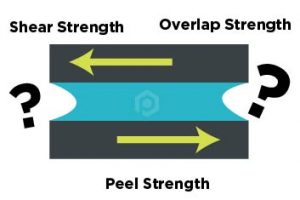

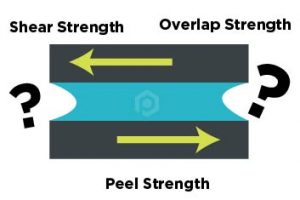

4. What types of joints are best for adhesives?

| Joint designs that put the adhesive bond under shear, tension, or compression forces will provide the highest strength. Designs that tend to apply peel or cleavage forces to the adhesive, where the applied stresses are not distributed over the entire bond area, will have lower bond strength, but the bond may still be sufficient for the needs of the application. In addition, optimum bond line thickness typically ranges from 0.005″ to 0.020″. The adhesive qualification process should always include testing of prototype assemblies to ensure the adhesive will provide enough performance. |   |

5. How are adhesives used and applied?

| Structural adhesives come in many forms, including low viscosity liquids and non-sag pastes, one- and two-component formulations, short and long work lives, and various package sizes and shapes. Most two-part structural adhesives are available in both bulk containers and convenient, easy-to-use cartridge mixing systems. |   |

6. What are the general characteristics of the different types of adhesives?

| All structural adhesives provide at least 1,000 psi of overlap shear strength to aluminum, but the different adhesive chemistries have various properties. |   |

To have more information and receive advice from experienced engineers, please help to contact Pros Technology through

For more information, please contact us through: