Conformal coating – also known as conformal coating – is one of the most effective and widely used methods of protecting electronic circuits today. This method uses protective adhesive to create a coating, helping the circuit to be waterproof, moisture-proof, anti-corrosion, anti-chemical, and insulating,…

Of course, like other PCB protection measures, PCB protection glue also has its own advantages and disadvantages. This article will provide all the information from overview to details about PCB conformal coating solutions, from how to choose materials, advantages & difficulties of this method and how to overcome, to different methods and coating processes. From there, manufacturers can make appropriate choices depending on their specific application and operating environment of the product.

What is Conformal Coating?

Conformal coating is a thin layer of polymer material applied to an electronic printed circuit board to protect the circuit board and its components from the operating environment and corrosion. This layer is typically applied in a thickness of 25-250µm, “wrapping” the shape of the circuit board and protecting the circuit board and its components.

Prostech’s Conformal Coating Solution

Benefits and purposes of Conformal Coating

Conformal coating serves many different purposes in protecting and enhancing the performance of electronic devices such as:

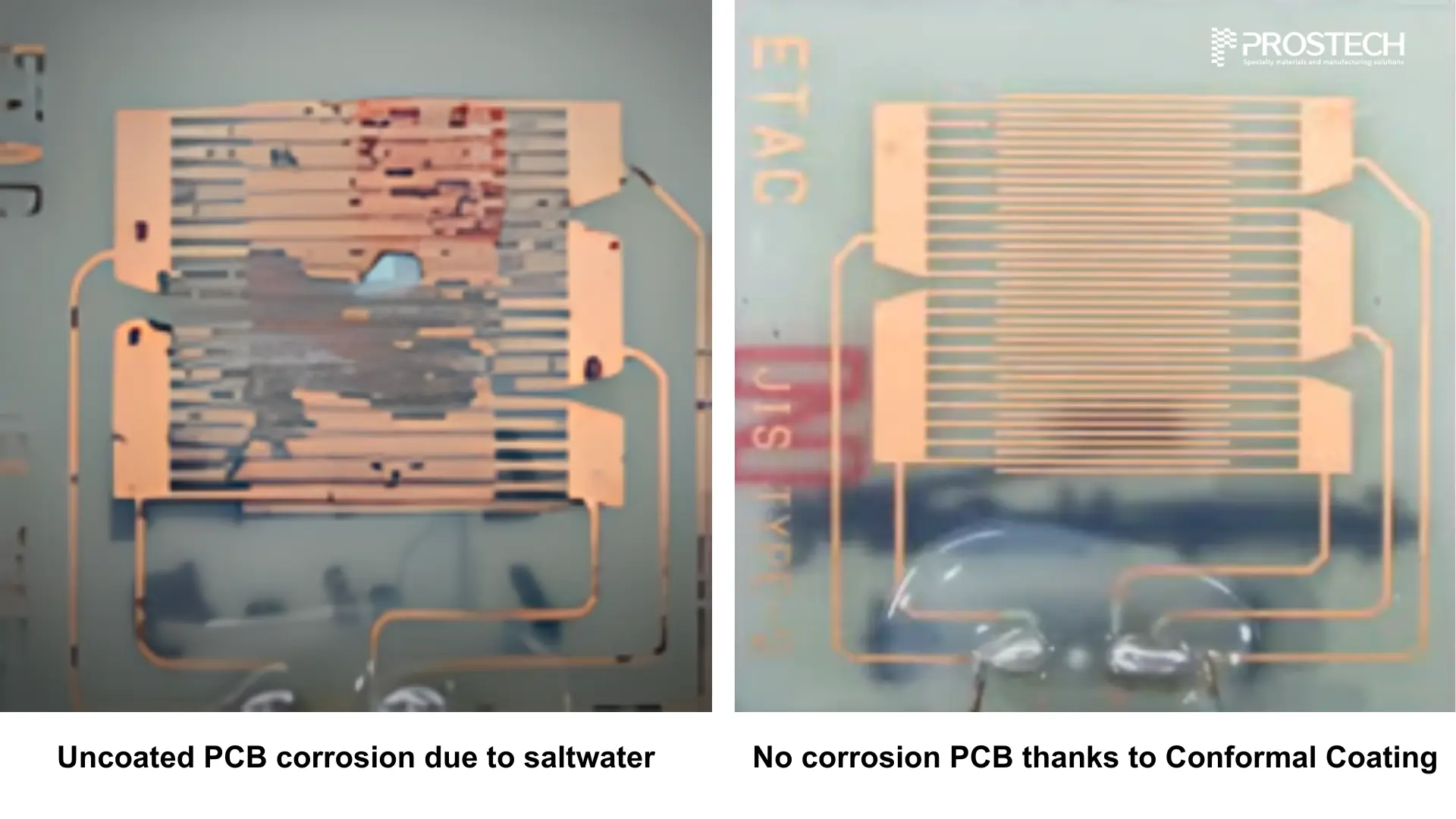

- Protecting PCBs from Harsh Environments: Conformal Coating is designed to protect PCBs from moisture, dirt, mold, high temperatures, and other contaminants. This coating can also withstand many types of solvents, aggressive chemicals, and heat. Normally, a PCB exposed to these harsh environments will degrade in quality and lifespan, but conformal coating can help slow down this process or prevent those factors from affecting the PCB. If the PCB is not protected, leakage and corrosion can occur at any time, causing sensitive components to be easily destroyed.

- Improving the dielectric properties of circuit boards: Printed circuit boards (PCBs) are becoming increasingly compact but must perform increasingly complex functions, resulting in dense and complex electrical connections on the board. The circuit coating layer for the circuit also provides mechanical support for the electronic components soldered on the circuit and their solder joints. In addition, the conformal coating also helps to condense the footprint of the circuit, allowing the distance between electronic components to be tightened. This can help reduce the overall size of the device and save space. The coating helps reduce electrical leakage, increase surface resistance, improve insulation performance and reduce electromagnetic interference, protect components from discharge and maintain stable performance even in harsh environmental conditions. As a result, the circuit board is better protected, operates stably and has higher reliability.

- Thermal management: Temperature is the most common cause of damage to electronic components, so it is important to have an effective thermal management solution. Organic coatings are rarely used for the primary purpose of heat conduction because they have low thermal conductivity. Fillers can be added to the coating material to increase thermal conductivity, but this also reduces the insulation efficiency because these particles are usually metals, non-metals. Therefore, this method of increasing thermal conductivity is only used in some special cases. Usually, the coating of the circuit board is used with the thinnest possible thickness to facilitate heat transfer, because the amount of heat transferred is inversely proportional to the thickness.

- Design information security: Some black PCB coatings help to mask surfaces containing markings, labels, or other identifying information as well as confidential information that appears on the surface of the printed circuit board, thus providing better information security.

Because of such outstanding features and utilities, conformal coating is now applied in many industries such as automotive, electric bicycles, consumer electronics such as refrigerators, televisions, washing machines,…

Read more at: Basic Guideline to Conformal Coating

Advantages and disadvantages of conformal coating

Among the PCB protection methods such as potting/encapsulating and low pressure molding, PCB protective coating is different in its ability to protect the PCB with only a thin layer of material. Therefore, this method has the following advantages:

- Effective protection with thin layer: Reduce the volume and size of PCB, suitable for compact and precise design.

- Easy to inspect and repair: Flexible in choosing transparent or colored coating, easy to observe and secure design.

- Less stress on components: Especially useful for components with thin or small leads.

- Diverse application methods: From manual spraying to automatic dispensing, suitable for production scale and technical requirements.

- Save time and cost: Reduce the need for molds and circuit boards, saving repair time, labor and production costs.

Besides the above advantages, there are some disadvantages of circuit board coating that need to be carefully considered such as:

- Limited protection: PCB coatings are also not very effective in protecting PCBs from vibration and shock due to their thin film. For applications that are directly exposed to vibration and shock, potting/encapsulating and low pressure molding are often preferred.

- High initial costs: Initial investment in spray equipment or automated systems can be high, although production costs may decrease in the long run.

- Technical Requirements: If the coating process is not performed correctly, the coating may be uneven. It is also important to avoid coating sensitive components or components that need to be modified later for optimal performance. During the coating process, the manufacturer may use masking to shield components.

The use of conformal coating to protect circuit boards depends on the specific requirements of the application and production conditions. With many years of experience in the field of adhesives, Prostech is ready to support our customers in providing conformal coating solutions and integrating them into the production line to overcome the challenges of this method. Contact us for free consultation.

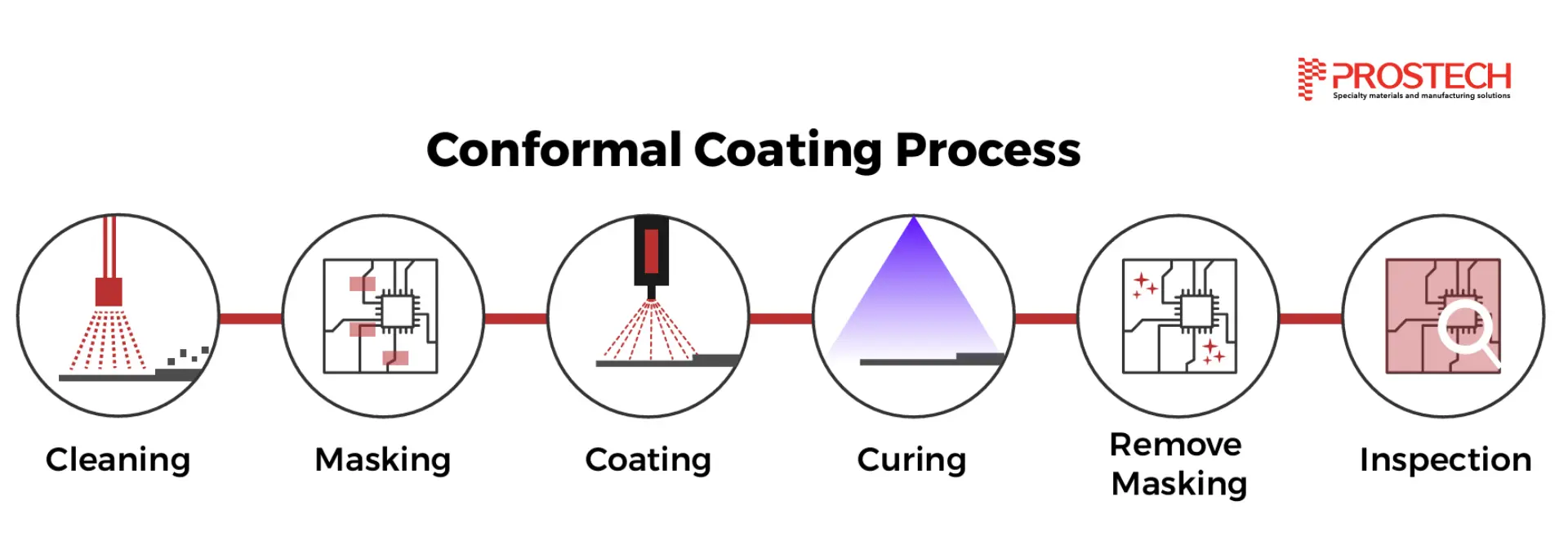

Conformal Coating Process

Despite the benefits of PCB coating, it is undeniable that PCB coating is not a simple process. Understanding the process of this method helps manufacturers and production engineers make the most out of it and avoid possible problems later.

The conformal coating process can be summarized in the following diagram:

Read more at: Conformal Coating Process – How to make perfect Conformal Coating Layer

Conformal coating methods

There are many methods for coating electronic circuit boards, and the choice of the appropriate method depends on factors such as production capacity requirements, circuit board design, equipment requirements, pre-coating treatment, and quality requirements. Common methods for coating electronic circuit boards include:

- Manual spraying

- Automated spraying

- Selective coating

- Dipping

- Brushing

- Vapor Deposition

Read more at: Common methods to apply Conformal Coating

Materials for conformal coating

Các sản phẩm keo phủ mạch hiện nay trên thị trường rất đa dạng như keo phủ độ nhớt cao/ thấp, màu sắc trong suốt/ có màu, keo phủ sấy khô bằng tia UV, nhiệt hay độ ẩm cùng với các gốc hóa học khác nhau như:

Current coating products on the market are very diverse with high/low viscosity coatings, transparent/colored coatings, coatings cured by UV rays, heat or humidity along with different chemical radicals such as:

- Acrylic (AR) Conformal Coatnig

- Silicone (SR) Conformal Coating

- Polyurethane (PUR) Conformal Coating

- Epoxy Resin (ER)

When choosing a conformal coating adhesive, the most important thing is to understand the advantages and disadvantages of each type of material for circuit board coating, and to consider several properties to choose the right type of conformal coating adhesive. With many years of experience in the field of specialized materials, Prostech understands the technical issues related to PCBs conformal coating adhesives. We provide a complete comprehensive solution, including materials, automation equipment and a nationwide warehouse network, supporting customers with logistics procedures. Positioned as a comprehensive supplier, Prostech always strives to become a trusted partner of manufacturers around the world. Contact us today for free consultation!