As electric vehicles (EVs) become more prevalent, the infrastructure supporting them—particularly EV charging point—needs to be reliable, durable, and efficient. Ensuring the reliability of EV charging point involves addressing multiple factors. While software issues like malfunctioning payment systems and app crashes can compromise functionality, another key factor lies in the build quality of the charging units themselves. This is where adhesives come into play.

Effective adhesive solutions can significantly reinforce the structural integrity of charging units, enabling them to withstand both internal stresses and external elements such as extreme weather conditions. Moreover, by reducing the need for frequent repairs and maintenance, the right adhesive helps lower operational costs. Additionally, these adhesives simplify the servicing process, allowing for easier disassembly and reassembly when maintenance is required. Beyond structural reinforcement, many adhesives also offer thermal resistance, a critical feature given the high temperatures generated during charging sessions. Prostech’s range of adhesives is tailored to meet the diverse needs of the EV charging point sector.

Potting Adhesives for EV Charger Connectors

One of the most critical components in EV charging point is the connector. Potting adhesives are used to encapsulate and protect electronic components within these connectors, safeguarding them against moisture, vibration, dust, and other external contaminants.

Key Features:

- Prevents short circuits and enhances safety.

- Reduces mechanical stress on sensitive electronics.

- Moisture and chemical resistance, ensuring long-term durability in outdoor environments.

- Maintains performance under fluctuating temperatures.

Popular potting materials include epoxy, polyurethane, and silicone, each chosen based on the specific requirements of the EV charging environment.

Threadlocking for Fasteners

Threadlocking adhesives are essential for securing bolts and fasteners in charging point assemblies. These adhesives prevent loosening caused by vibrations and thermal cycling, which is common in charging stations exposed to outdoor conditions.

Advantages:

- Maintains integrity despite constant use and environmental factors.

- Creates a seal that protects metal threads from moisture.

- Specialized formulations allow for maintenance without damaging components.

Anaerobic adhesives are commonly used for their ability to cure in the absence of air, providing robust and reliable bonding.

Gasketing (Sealing) EV Charging Point

Gasketing adhesives provide an effective seal between mating surfaces, crucial for preventing water, dust, and contaminants from penetrating EV charging point. These adhesives replace traditional pre-cut gaskets, offering flexibility and better adherence.

Key Benefits:

- Conforms to irregular surfaces for superior sealing.

- High chemical resistance, ideal for exposure to oils and coolants.

- Suitable for both high and low temperature environments.

- Withstands prolonged stress without degradation.

Silicone-based gasketing adhesives are popular due to their flexibility and resistance to temperature changes.

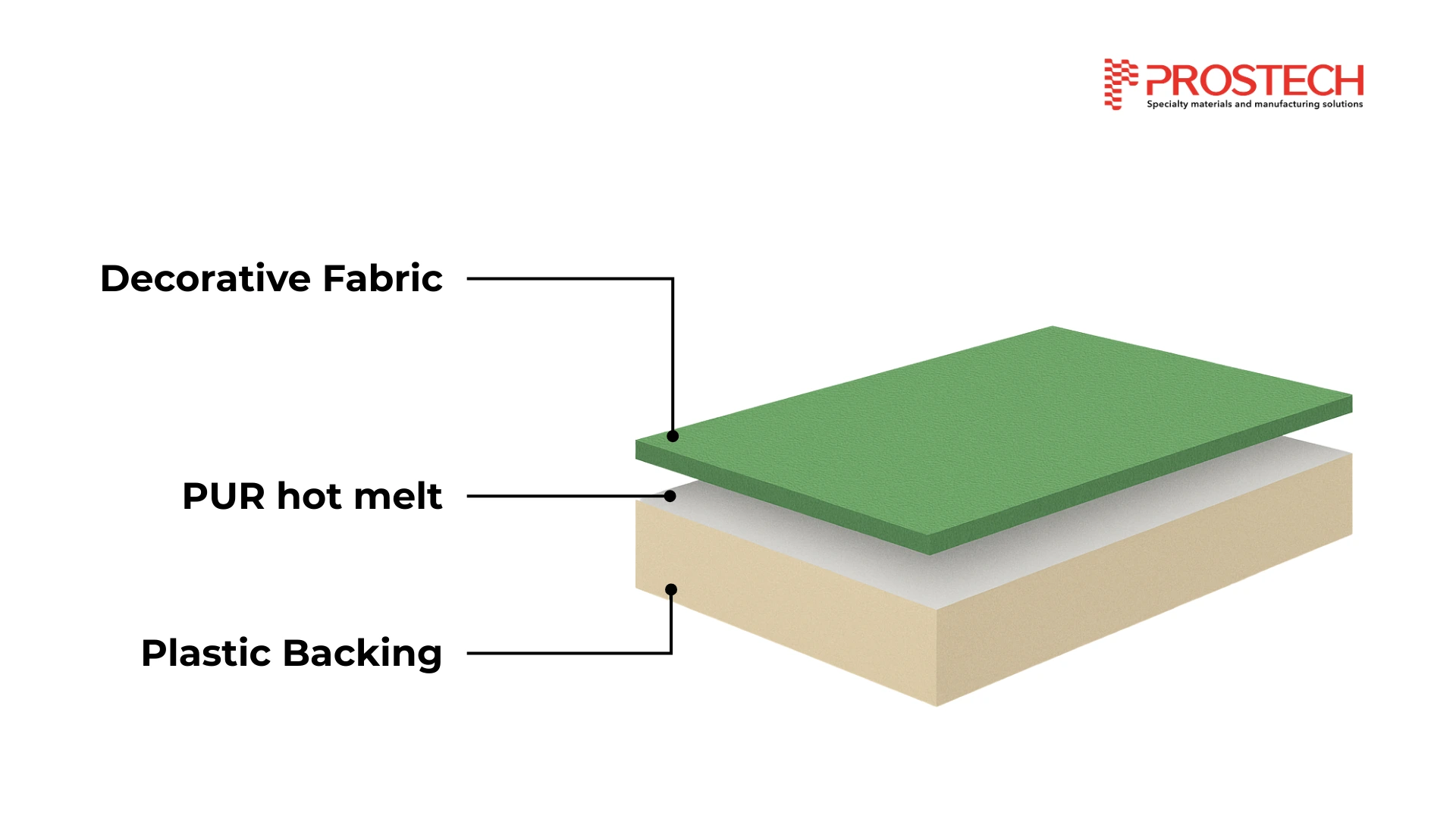

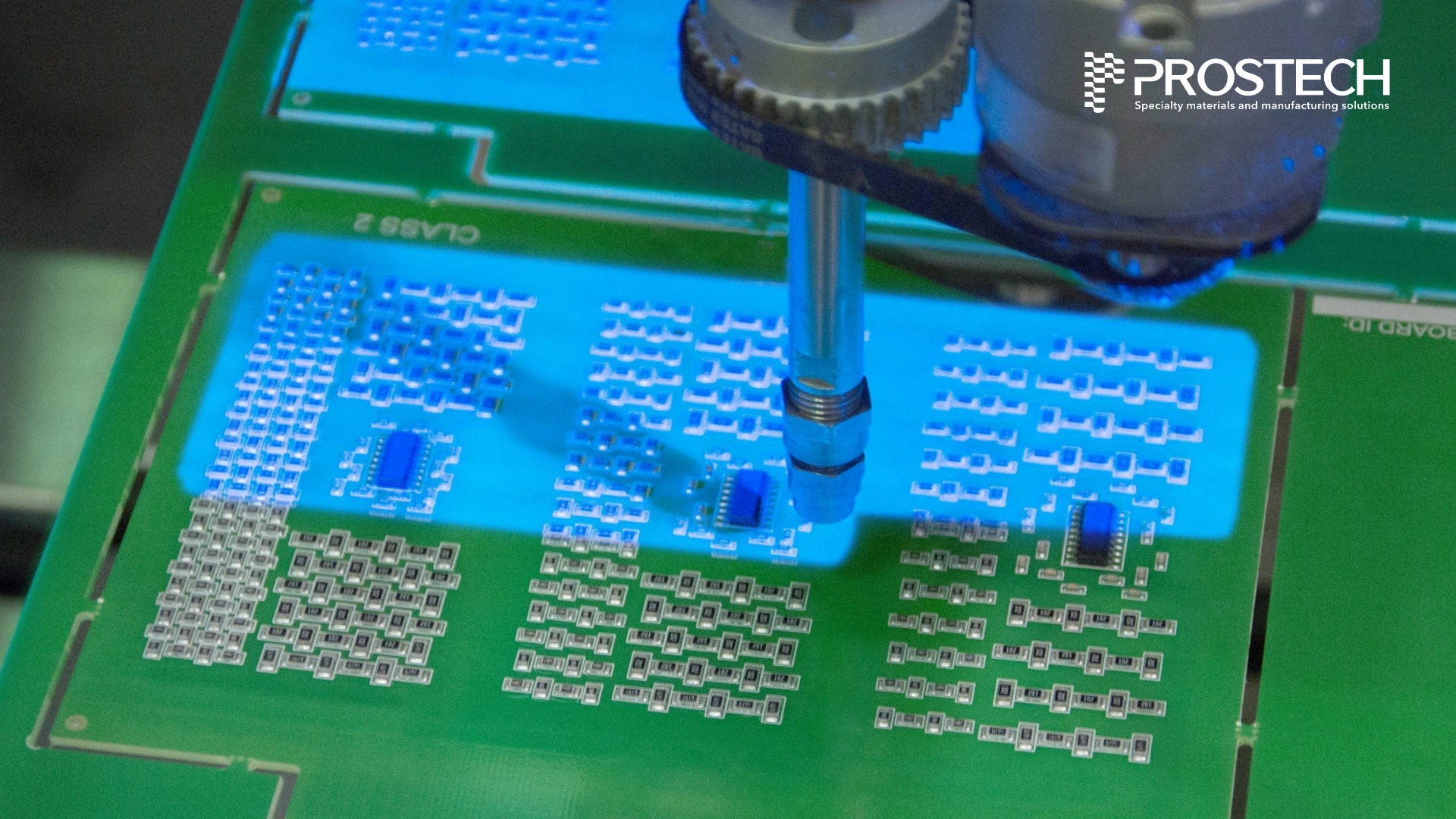

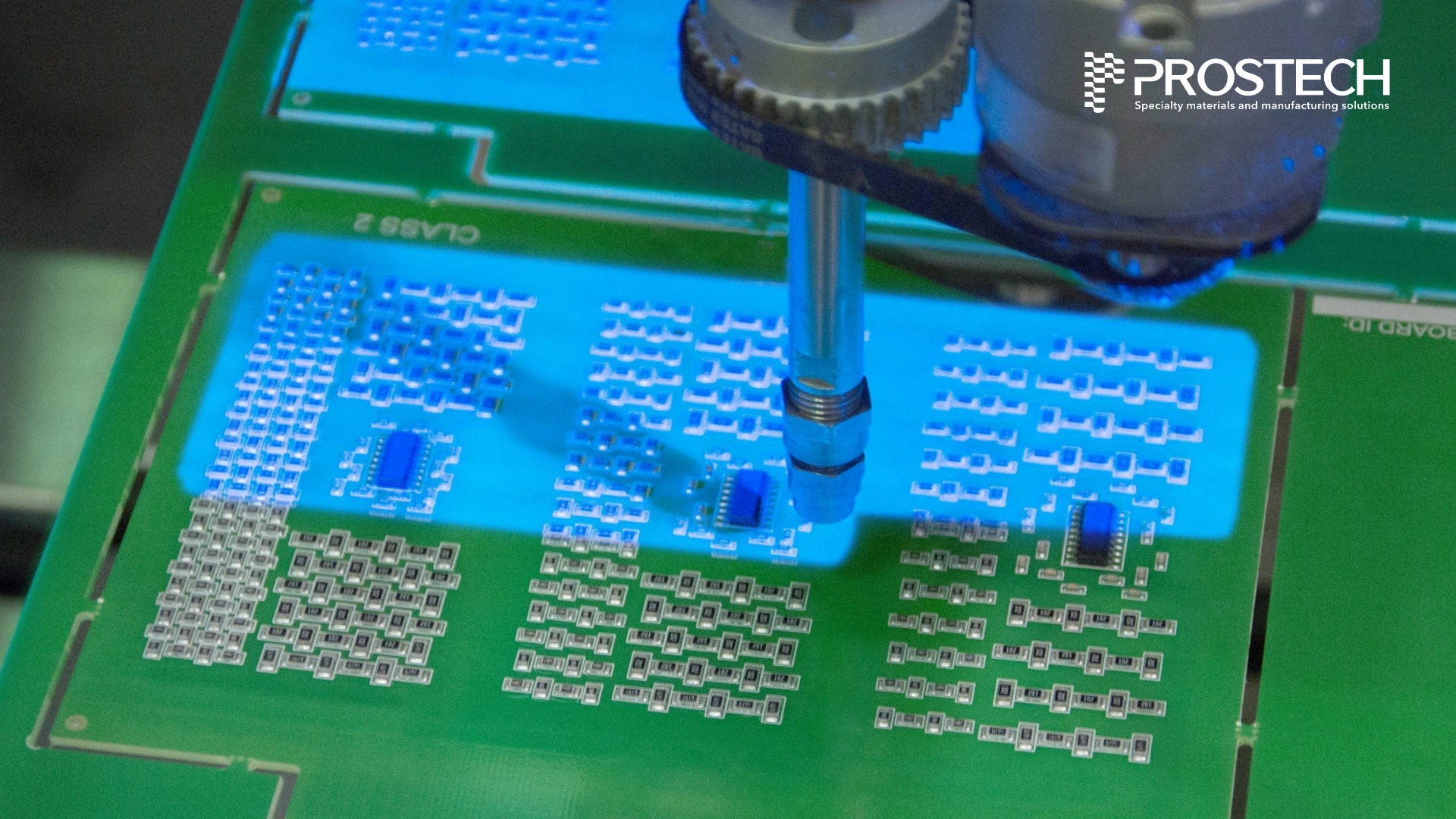

Conformal Coatings for PCB Protection

Conformal coatings are thin layers applied over electronic components to protect against environmental stress. These coatings are crucial in EV charging point where circuit boards are exposed to moisture, dust, and temperature fluctuations.

Advantages:

- Minimizes corrosion and short-circuit risks.

- Maintains performance across a wide temperature range.

- Guards against abrasion and mechanical damage.

- Ensures electrical insulation and stability.

Common materials include acrylic, silicone, and polyurethane, each offering specific protective features for charging equipment.

Thermal Management for EV Charging Point

As EV chargers operate, they generate significant heat, which can impact performance and longevity. Thermal management solution help dissipate this heat efficiently, maintaining operational stability and extending the lifespan of components.

Key Benefits:

- Transfers heat away from sensitive components.

- Maintains a secure connection between the heat sink and the component.

- Prevents short circuits while managing thermal loads.

- Maintains performance even in high-humidity or high-temperature environments.

Thermally conductive adhesives such as epoxy and silicone-based formulations are typically used, as they balance heat transfer with electrical insulation.