- 1/ What is an EV sensor?

- 2/ Why Do We Need Sensors in Electric Vehicles?

- 3/ Types of EV sensors and their features.

- 4/ PROTECTING EV SENSORS FROM EMI

- 5/Common symptoms of the battery current sensor in EVs and ways to address them

- 6/ Solutions of Prostech for common EV sensors

- 7/ Frequently asked questions about sensors in electric vehicles

Welcome to our comprehensive exploration of EV sensors and Prostech’s advanced solutions. As electric vehicles (EVs) redefine the automotive landscape, the role of sensors becomes increasingly pivotal in enhancing performance, safety, and efficiency. Join us in delving into the intricate world of EV sensors and uncovering Prostech’s innovative approach to providing effective material and design solutions for electric vehicle sensors. From sensor technology advancements to customized solutions, this article promises to provide deep insights into sensors in electric vehicles. Let’s embark on this learning journey together with Prostech.

1/ What is an EV sensor?

a/Understanding about car sensors.

A car sensor is one of the essential parts of an advanced car. It is an electronic system that monitors different parameters (temperature, coolant system, etc.), faults, and obstacles, alerting the driver and sending the signal to the ECU (Electronic Control Unit) to make appropriate adjustments.

b/What is a sensor in electric vehicles?

In the upcoming year, with advanced technology, the adoption of electric vehicles (EVs) will continue to rapidly accelerate. More than 10 million EVs were sold worldwide in 2022, as reported by the International Energy Agency. It cannot be denied that the EV supports us toward a more sustainable way of life, reducing carbon emissions. As with traditional cars, EV sensors are also key components for controlling the EV system and ensuring safety and performance. However, as the energy source for EVs comes from the battery system, EV sensors are also changed accordingly.

‘For more in-depth insights and a clearer understanding of EV sensors, delve into this article with Prostech.’

2/ Why Do We Need Sensors in Electric Vehicles?

In the rapidly evolving landscape of electric vehicles (EVs), sensors serve as the backbone of vehicle functionality and performance. These sophisticated devices are integral to monitoring and controlling various aspects of EV operation, ensuring optimal efficiency, safety, and reliability.

– Firstly, sensors play a crucial role in managing the intricate ecosystem of the EV’s powertrain, constantly monitoring battery status, temperature, and energy consumption to maximize performance and extend battery life.

– Secondly, sensors enable advanced safety features such as collision avoidance systems, blind-spot detection, and autonomous emergency braking, mitigating the risk of accidents and enhancing overall driver safety.

– Furthermore, sensors provide real-time feedback and data analytics for dynamic adjustments in vehicle components like motor speed, regenerative braking, and power distribution, optimizing driving dynamics and energy utilization.

– As the automotive industry continues its shift towards electrification, the significance of sensors in EVs cannot be overstated, driving innovation and ushering in a new era of sustainable transportation. Consequently, this leads to a more enjoyable and efficient driving experience for everyone.

‘Prostech specializes in providing material solutions for electric vehicles. If you are interested in it, please refer to the article here for more information.’

3/ Types of EV sensors and their features.

There are several parameters about measurement principles to consider in the sensor system of electric vehicles, such as position, current, voltage, and temperature.

a/The types of sensors involved in position.

- General Features

Gathering the mechanical motion data from the traction motors to guarantee that the system runs in harmony. After the angular position data is recorded, a motor controller or motor control unit (MCU) converts it into electric impulses to start the feedback loop.

- Types sensor

– Motor control position

– Motor control position

– Motor control speed

b/The types of sensors involved in the current.

- General Features

Showing us how much energy, we used and avoiding the overcurrent. In BMS, it provides charging and discharging cycle information by reporting the status of battery SOH.

- Types sensor

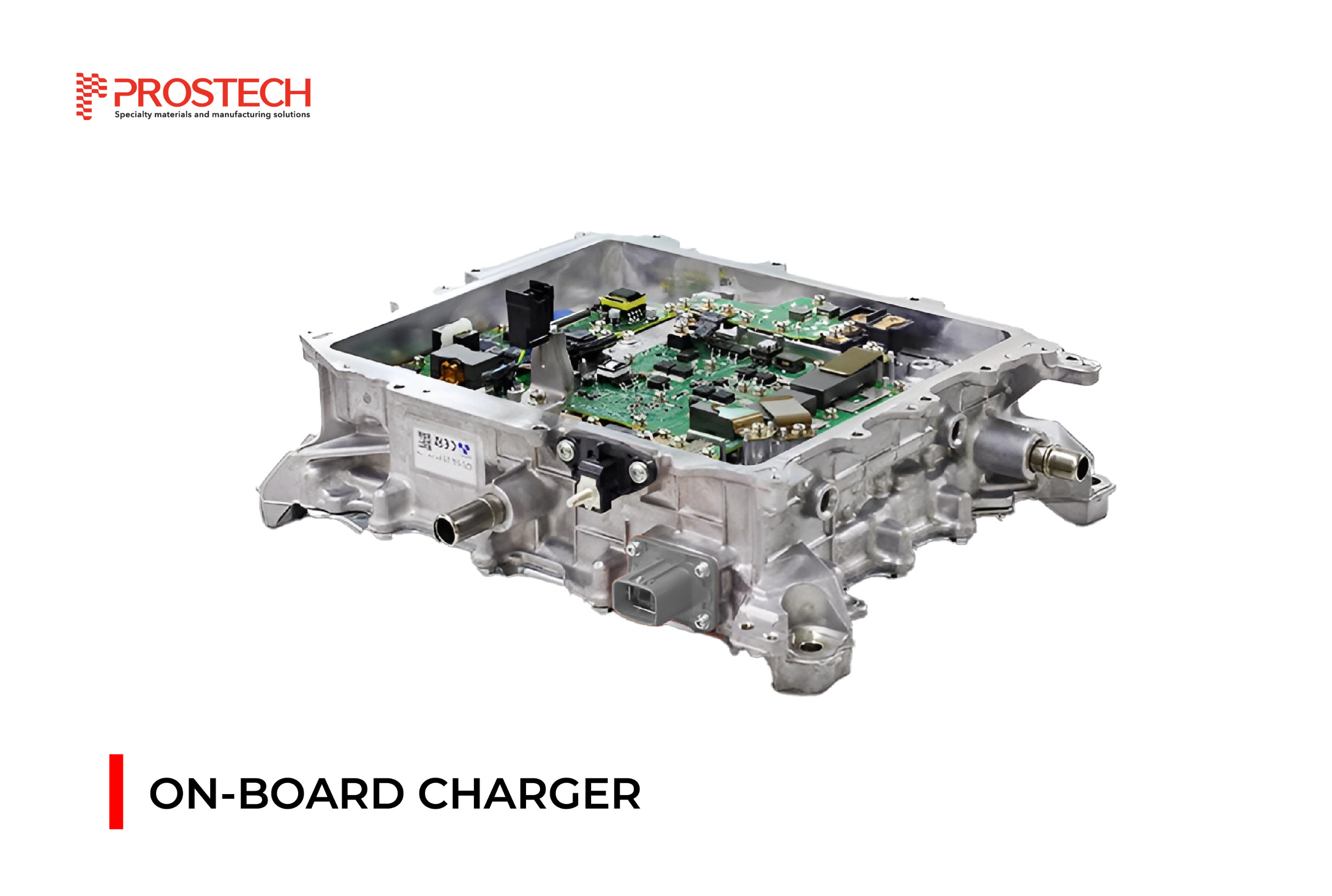

-Onboard charger current sensor

– DC/DC current sensor

– Battery-management current sensor

– Traction motor current sensor

– Motor current sensor

– Transmission current sensor

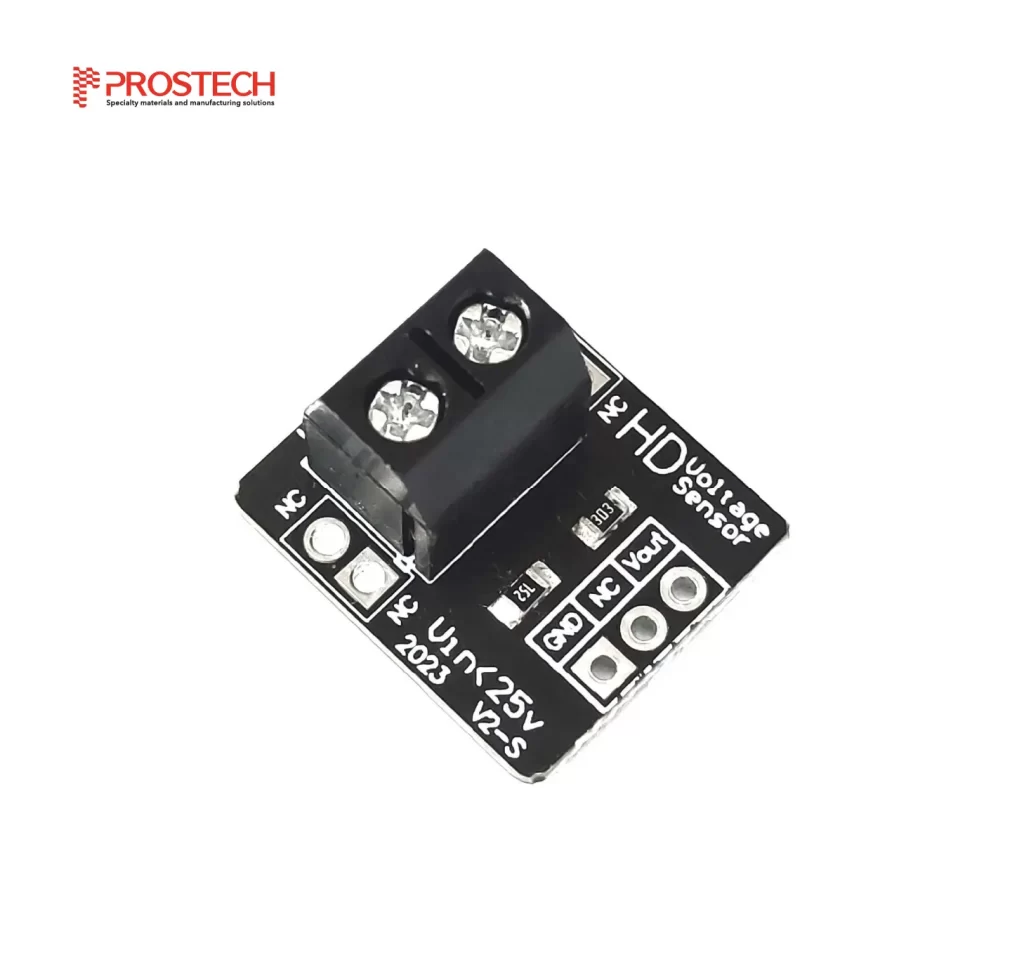

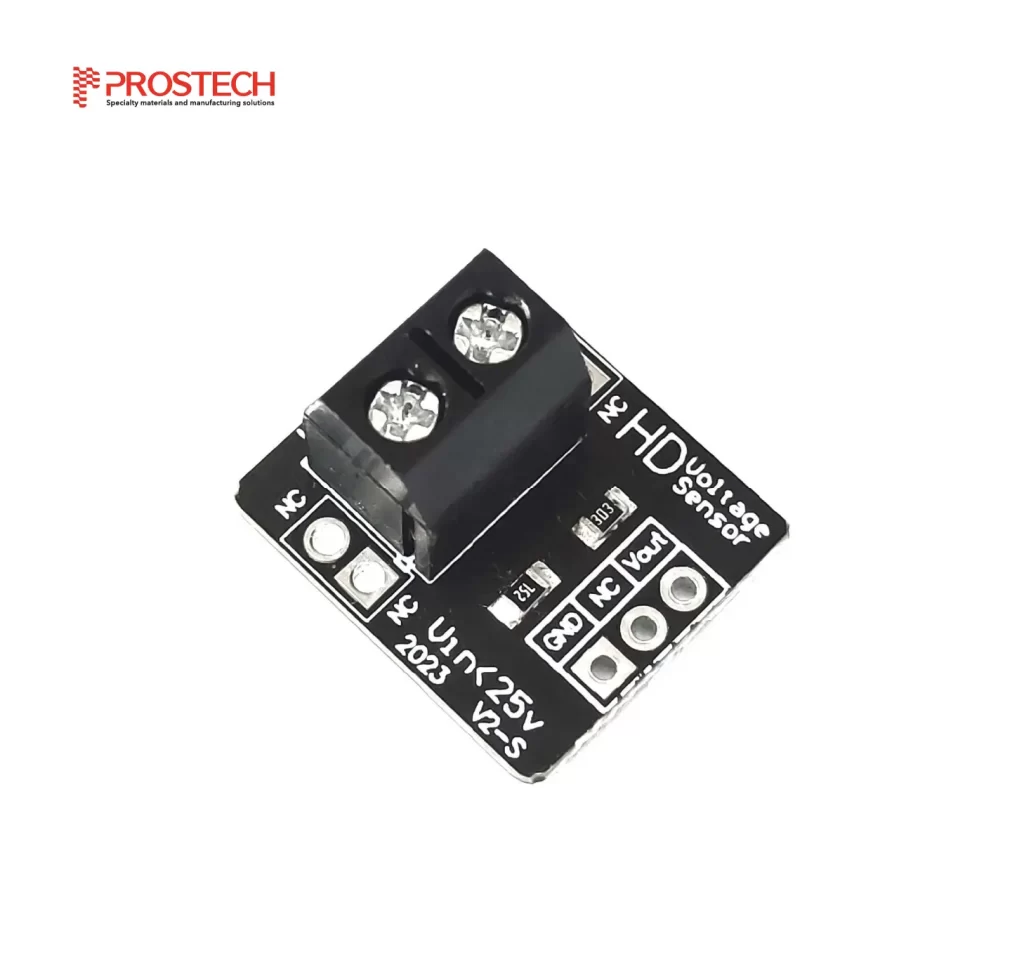

c/The types of sensors involved in Voltage

- General feature

Measure the voltage in various ways, from measuring high voltages to detecting low current levels, which ensures no insulation damage in the battery pack and each cell.

- Types sensor

– Onboard charger voltage sensor

– DC/DC voltage sensor

-Battery-management voltage sensor

d/ The types of sensors involved in temperature

‘The temperature sensor holds immense significance within electric vehicles, ensuring enhanced safety and comfort for passengers throughout their travels. At Prostech, we’ve dedicated our efforts to researching and refining a holistic solution tailored specifically for temperature sensors in electric vehicles. Kindly follow this post for further details.

- General feature

–In a battery system, it is installed directly into the battery cells, giving accurate temperature measurements and regulating the heating and cooling processes to keep each cell operating within a safe range. In the case of overheating, continuous monitoring can initiate safety steps, such as disconnecting the battery or lowering charging rates, and enable the assessment of battery health.

– In an e-motor, it is used to measure the temperature of the motor windings (sensors with shrink tube insulation), the temperature in the bearings, and other parts of the motor. They also ensure the motor’s dependability and ensure that there are no defects relating to torque production, control, or efficiency.

- Types sensor

– Onboard charger temperature sensor

– DC/DC temperature sensor

– Battery-management temperature sensor

– Traction motor temperature sensor.

‘The common types of sensors and their key characteristics will be provided in this article by Prostech. With just a simple click here, you will receive highly detailed information and a deeper understanding of sensors in electric vehicles.’

e/ Types of Sensors Enhancing Safety for Self-Driving Electric Vehicles

- Lidar Sensors

Lidar, short for “light detection and ranging,” uses infrared light pulses emitted by a rotating laser to detect objects. It provides precise measurements of object locations around a vehicle by calculating the time taken for pulses to bounce back. This data enables the creation of detailed 3D maps without relying on additional lighting. However, lidar’s high cost and reduced performance in low-light conditions due to weather interference are notable drawbacks.

- Radar Sensors

Long-range (77 GHz) radar sensors assist in automated distance control and braking, while short-range (24 GHz) radar sensors handle blind spot monitoring, lane-keeping assistance, and parking aids. Radar systems outperform camera sensors in fog or rain but have limitations; they only detect objects in front of the sensor and struggle with frequency-dependent detection, making pedestrian detection challenging. Radars are usually placed closer to the vehicle for more accurate detection within their range.

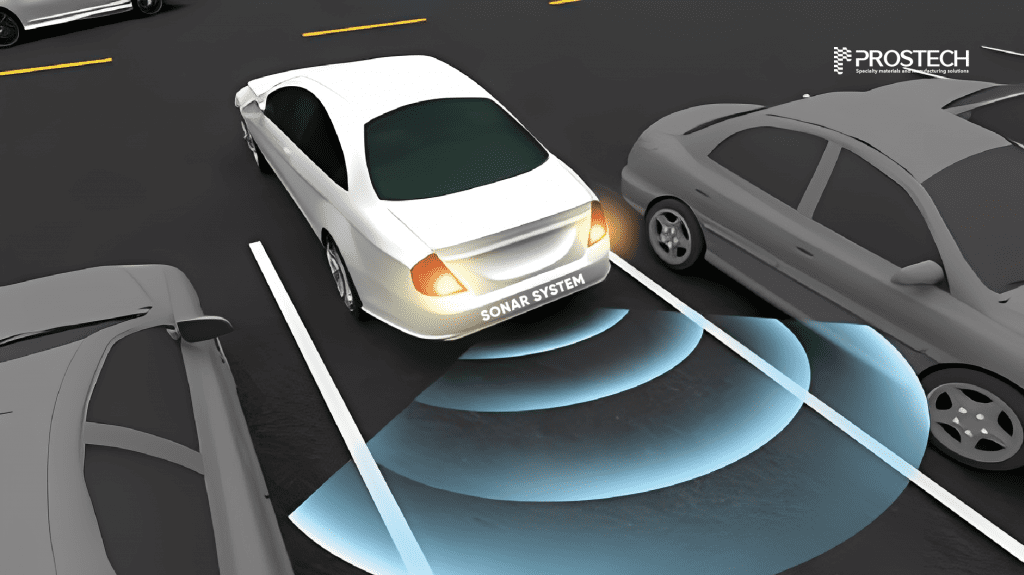

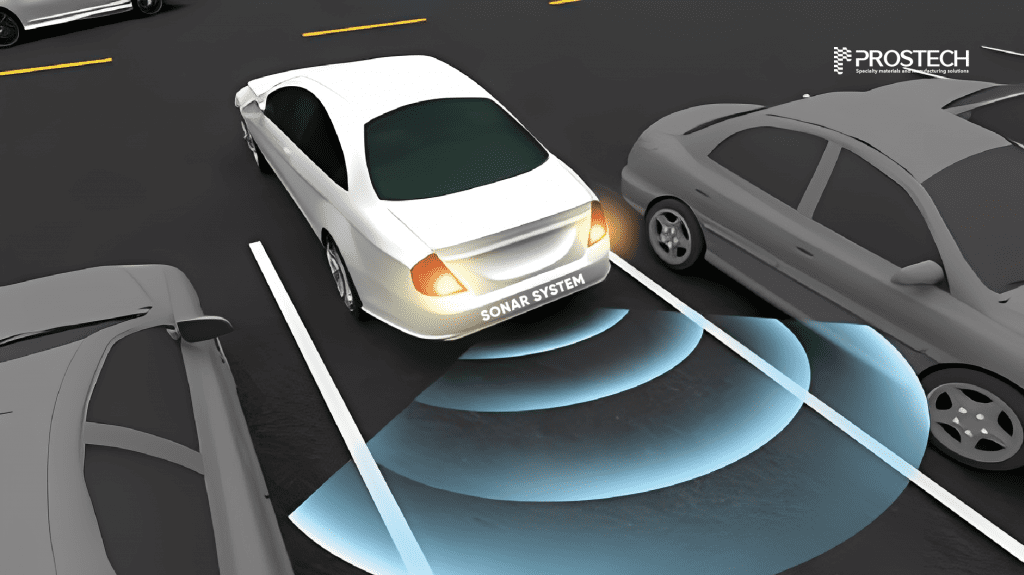

- Sonar

Sonar can operate in low visibility, but its operation is limited by the speed of sound in real time. It can detect large objects at short range but cannot recognize or classify them; sometimes it falsely detects non-existing objects. Sonar is only helpful in unexpected situations while attempting to prevent collisions.

- Cameras

The mono or stereo camera sensor types are the two types that are employed. A single lens and image sensor are features of the mono camera. Though it can identify objects, people, and traffic lights, it can only capture two-dimensional photos. Finding an object’s depth or distance, however, is not possible with 2D photographs.

‘Click on this article to explore a comprehensive and detailed source of information about silicone material solutions for components in electric vehicles researched and provided by Prostech.’

4/ PROTECTING EV SENSORS FROM EMI

a/What is EMI in EV sensors?

Electric vehicles are the way of the future for transportation, which not only provide a significantly better driving experience than conventional internal combustion engine (ICE) vehicles but also have zero fuel consumption and are environmentally friendly. Since the electrical and electronic architecture involves high voltages, this increases the potential sources of electromagnetic inference (Electromagnetic interference) and the number of vulnerable systems. Briefly put, EMI in EV sensors is any undesirable electromagnetic field that may interfere with the smooth functioning of an electronic circuit.

‘To gain a thorough insight into EMI, please visit this link to explore the detailed information customized to your preferences.’

b/Types of EMI in EV Sensors

- Conducted EMI

Conducted EMI in electric vehicles refers to any electromagnetic disturbance that travels from the source to the target via a conducting path such as a DC power bus, an AC power bus, cables, wires, traces, etc. EMI, also known as crosstalk between signal lines, is achieved by either inductive or capacitive coupling. Imagine in a DC-AC converter or inverter, IGBT or MOSFETS are used as switching devices at high frequency to reduce the size of the magnetics of other elements such as inductors, transformers, etc. However, this can cause a sudden voltage and current change, resulting in the generation of conducted EMI.

- Radiated EMI

A radiated emission is typically produced by radio frequency signals, such as those from wireless transceivers, clocks, and microcontroller data lines.

c/How to deal with EMI in EV Sensors?

- Using EMI filter to handle EMI problems in EV sensors

-There are two types of EMI filters commonly found in EV sensors: active EMI and passive EMI.

-Active EMI filters are mainly developed using active components, such as op-amps, working in conjunction with passive components to achieve low-frequency attenuation and filtering.

-Passive EMI filters consist of capacitors and inductors that are interconnected in specific circuits to provide the necessary filtering.

- EMI shielding – Essential Solutions for EMI Management in EV Sensor systems

The basic method of EMI shielding is reflection, which attenuates the component of the EMI, functioning based on the Faraday cage theory. According to this principle, a material’s shielding properties improve with its conductivity. Some common products to be used are solid or liquid EMI gaskets, EMI coating materials, EMI shielding tape (aluminum foil tape, copper tape, etc.), and metallic enclosures (metal screening cans, fingering stock, wire mesh, etc.).

‘’Prostech specializes in delivering technical solutions in the field of materials, with a specific emphasis on providing EMI shielding solutions for Electric Vehicle (EV) sensors. For those truly interested, kindly click here to explore more detailed articles on the subject.’’

5/Common symptoms of the battery current sensor in EVs and ways to address them

a/ Common symptoms of a bad battery current sensor in Evs

-Inaccurate reading

-Unstable output

-Inaccurate current measurement

-Fault indicator

b/ How to deal with those symptoms of EV sensors – particularly the battery current sensor.

- Regular inspection

To examine the sensor and surrounding elements, such as its connected wiring,…, making sure there is no wear, damage, corrosion, loose connection, etc. A faulty circuit component or power supply problem could also affect the sensor.

- Regular calibration and attentive monitoring

Regular calibration and attentive monitoring are essential to guarantee accurate measurements, assist in identifying and resolving any deviations from the predicted value, and preserve the abnormal operation.

‘Please feel welcome to explore this article for a thorough and detailed examination of silicone material solutions customized specifically for electric vehicles.’

- Replace the sensor

It could be essential to think about changing the battery current sensor if the aforementioned solutions are ineffective. Prompt sensor replacement can help mitigate these unplanned shutdowns and the operational and financial fallout from false alarms.

- Professional consultants

It is advised to get professional diagnostic assistance from a certified technician if you are unsure of how to resolve the issue or require a more thorough diagnosis and repair. They can evaluate the battery current sensor’s performance with specialized tools, figure out the problem, and provide better maintenance service.

‘The solutions provided by Prostech are not only specialized material solutions but also tested component solutions through various projects. Click on this article to obtain specific information about the Solution for the Heating System in the Battery Pack – a crucial component solution that enhances your electric vehicle experience.’

6/ Solutions of Prostech for common EV sensors

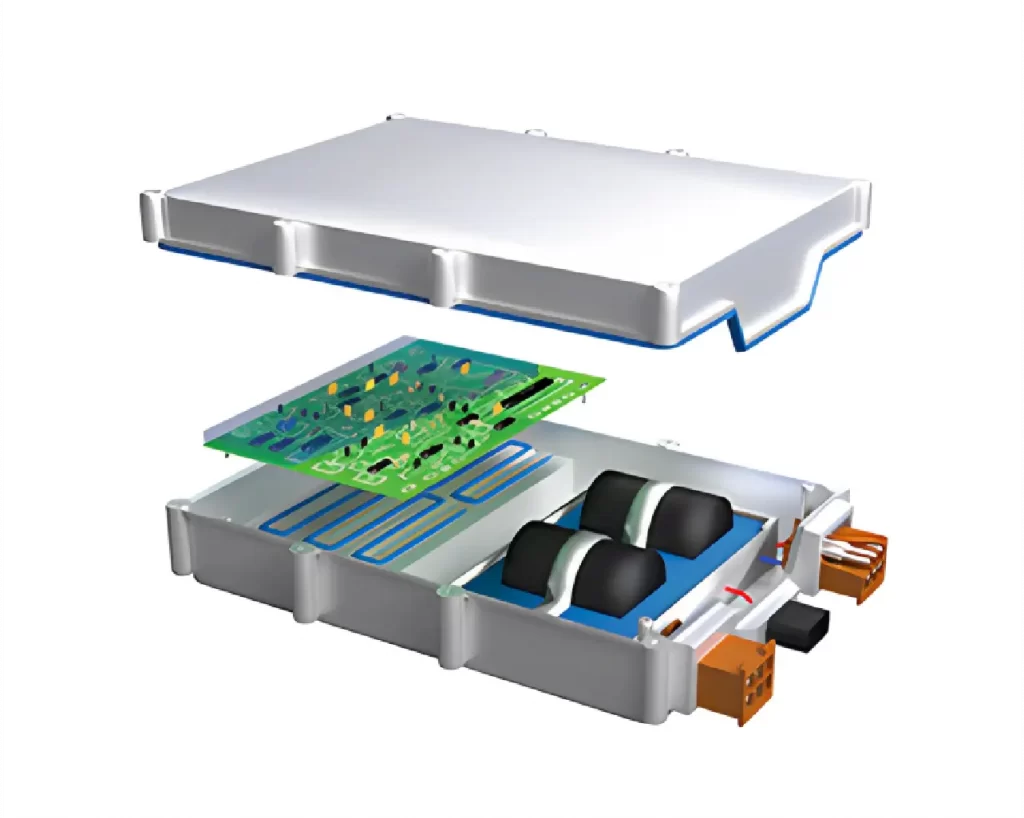

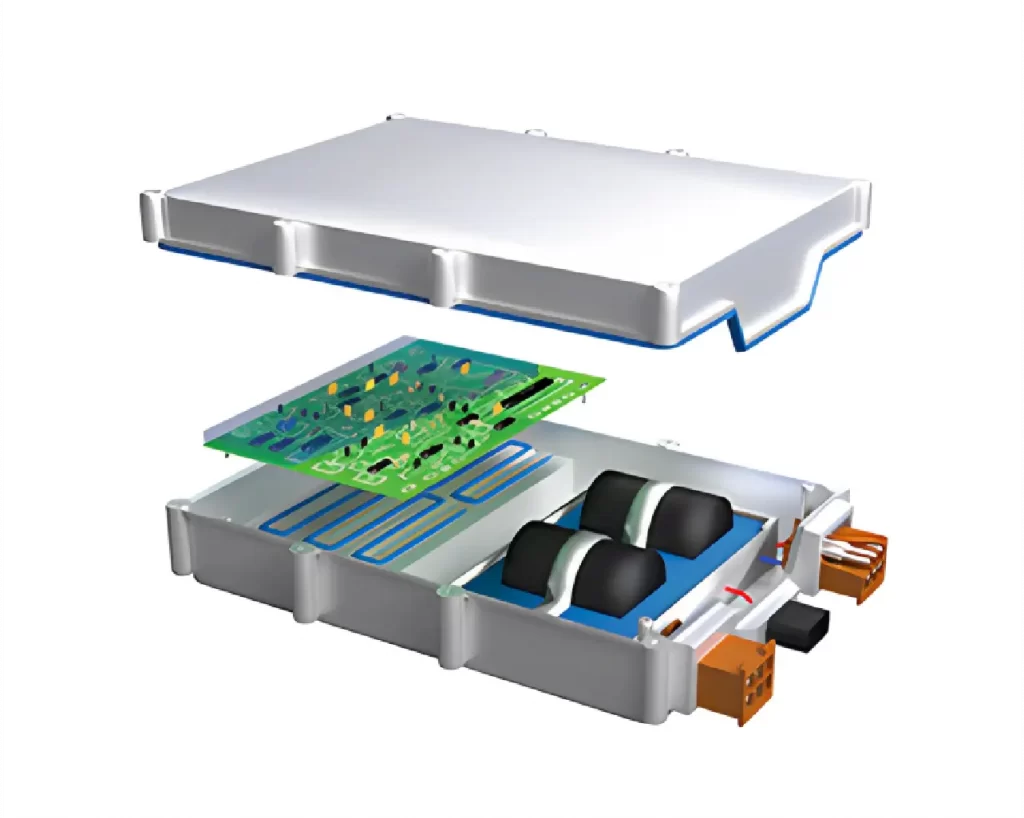

a/ The solutions for the current sensor.

- Soldering material

This material is used to connect different components to the PCB to create the circuit of the current sensor. Prostech offers various types of soldering materials, including wire, bar, paste, ball,… supporting different processing: SMT is wave soldering. We provide both leaded and lead-free materials that suit different industries (automotive, electronics, aerospace, etc.).

‘Prostech offers material solutions, particularly in soldering materials, for the fabrication of sensor circuits. Click on this article for more in-depth information regarding soldering materials.’

- Bonding/mounting housing

A structural bonding adhesive is ideal for bonding housings to substrates that provide uniform load distribution and light-weighting for sensors. Epoxy, acrylic, or polyurethane-based adhesives are good candidates to consider.

– High adhesion to the different substrates (PC, ABS, FR4,…)

– Low-temperature curing

– High tensile strength and shear strength

– Non-sagging

– Low outgassing

‘Through thorough research and meticulous testing, Prostech’s technical team has developed specialized material solutions for sensors in electric vehicles, especially temperature and current sensors. Join us as we explore these useful solutions through this post.’

b/ The solutions for the current sensor

- Low-pressure molding

While standard production cycles with bonding and encapsulation take time and have design limitations, Low-Pressure Molding (LPM) uses thermoplastic materials with very low viscosity, allowing for over-molding and encapsulation of even the most sensitive circuit board assemblies, providing a protective layer against dirt, dust, moisture, heat, or up to IP68 in some cases.

– One part material

– No material mixing needed.

– Reworkable

– 30 – 120s cycle time: saving time, improving productivity

– VOC-free

‘Access this article and reach out to Prostech for consultation and to receive the most comprehensive information about Low Pressure Molding.’

- Wire routing reinforcing

The adhesive in this position is used for insulating, sealing, reinforcing, and chemical resistance to the wire hardness of the sensor.

– 2K epoxy

– Acrylic or Modified silicone

– Hot melt

– Low viscosity wicking action to form a complete seal around the incoming wire

‘Prostech specializes in providing various types of adhesives for a wide range of applications, particularly for sensors in electric vehicles. Please contact us to receive comprehensive and valuable information about suitable adhesives from our technical team.’

- Bonding, fixing, sealing, reinforcing by using bonding adhesive

Reinforcement, sealing, and vibration protection are the main purposes of using adhesive in this position.

– Fast-setting adhesive (epoxy, silicone) or cure-on-demand (UV)

– High tensile strength

– Non-sagging

- – Shielding, protection

During operation in the end product, wire harness is subjected to harsh conditions such as:

-Mechanical stress: External pressure can deform or damage components.

-Vibration, abrasion: Continuous shaking or rubbing causes wear over time.

–EMI and noise affect the signal: Interference disrupts signal clarity.

-Water, chemicals, dust: Exposure leads to corrosion or contamination.

-High temperature: Elevated temperatures degrade materials.

-Electrical leakage: Unintended current release due to insulation failure

Different application requires different types of protection:

-Conductive tape for shielding

-Insulating tape for insulating

-Cloth tape, PVC tape, rubber tape, Filament tape for sealing, reinforcing

‘To gain a better understanding of how to protect sensors in electric vehicles from the effects of EMI, let’s explore our solutions through this article.’

7/ Frequently asked questions about sensors in electric vehicles

a/How do sensors contribute to the battery management system (BMS) in electric vehicles?

Sensors play a crucial role in the Battery Management System (BMS) of electric vehicles by providing essential data for monitoring and controlling the battery’s health, performance, and safety. The importance of sensors is detailed as follows:

-Voltage and Current Monitoring: Sensors measure the voltage and current levels of individual battery cells or modules. This data helps in balancing the charge among cells, preventing overcharging, or undercharging, and optimizing the battery’s performance and lifespan.

-Temperature Sensing: Sensors monitor the temperature of the battery pack to ensure it operates within safe limits. High temperatures can degrade the battery, while low temperatures can reduce its efficiency and power output. Temperature sensors help in thermal management and prevent overheating or freezing of the battery.

-State of Charge Estimation: Sensors estimate the State of Charge, which indicates the remaining capacity or energy level of the battery. SoC information is crucial for accurately predicting the vehicle’s range and managing energy consumption.

-State of Health Monitoring: Sensors assess the State of Health of the battery by analyzing its degradation over time. By monitoring parameters like internal resistance and capacity loss, sensors help in identifying battery degradation and scheduling maintenance or replacement.

b/What is the difference between normal sensors and sensors in electric vehicles?

– Same as traditional cars, EV sensors are also the key component for controlling the EV system, ensuring safety and performance, however, as energy source of EV comes from the battery system, EV sensors are also changed accordingly.

– Generally, in an EV, out of position and speed sensors, three are common: one for temperature, a second for voltage measurement, and a third for current. Among those, the temperature sensor becomes more essential. While in traditional vehicles, it is used to measure the temperature of the engine (fuel, air intake, and cooling system), in EV cars, it can assist in eliminating disastrous incidents like battery explosions, motor overheating, malfunctioning power components, and fires under severe conditions. The two common temperature sensors are:

- Battery temperature sensor: The battery temperature sensor is the core of an electric vehicle, as the temperature of a battery can be impacted by malfunctions in the circuits that are connected to it.

- Motor controller temperature sensor: The motor controller temperature sensor is an indispensable element to prolong the lifespan of an electric vehicle.

c/ How do sensors contribute to the overall safety of electric vehicles?

Sensors Boost Performance As Well As Safety

– Integrated sensors in EV battery packs and other systems help owners monitor the power supply, helping gauge driving range and battery life. An intelligent energy management system can ensure confidence that, despite challenging conditions, a vehicle has enough energy to get to its destination.

– Sensors that monitor the battery pack’s energy intake during charging and how much energy the vehicle consumes are crucial for maintaining consistent performance. Fast charging, a highly desired attribute of an EV, also requires sensor monitoring, as it can cause overheating in rare instances. Sensors designed to manage a variety of systems—from HVAC to regenerative braking—are key to getting more from an EV with the least amount of worry.

– Lidar sensors and radar sensors play crucial roles in ensuring the safety of vehicle motion. Lidar sensors provide environmental information and generate 3D maps, enabling autonomous systems to recognize and avoid obstacles, maintaining a safe distance. On the other hand, radar sensors measure the speed and distance of surrounding objects, supporting functions like automatic distance control and braking assistance, thereby minimizing collision risks and enhancing overall safety during vehicle movement.

‘By conducting effective experiments and engaging in collaborative initiatives in the electric vehicle sector, Prostech has obtained specific material and design solutions geared towards enhancing various facets of electric vehicles. Accessing this valuable information is as simple as clicking within the confines of this article.’

CONCLUSION

In conclusion, the exploration of EV sensors underscores their pivotal role in enhancing the performance, safety, and efficiency of electric vehicles. Prostech’s material and component solutions stand out for their integration of advanced sensor technologies, offering heightened accuracy and reliability in monitoring various aspects of EV operations. As electric mobility continues to evolve, the seamless synergy between EV sensors and the solutions of Prostech promises to drive further advancements, propelling the industry toward a more sustainable and intelligent future.