Electric motors serve as the beating heart of electric vehicles (EVs), propelling them efficiently and precisely. Understanding the fundamentals of electric motors, including their mechanisms and diverse types utilized in EVs, is pivotal in grasping the innovative technology driving the future of transportation. We delve into the essence of electric motors, their operational principles, and the array of variants powering the electric revolution in automotive engineering through this article provided by Prostech.

1/ What is an electric motor and how does the E-motor work in electric vehicles?

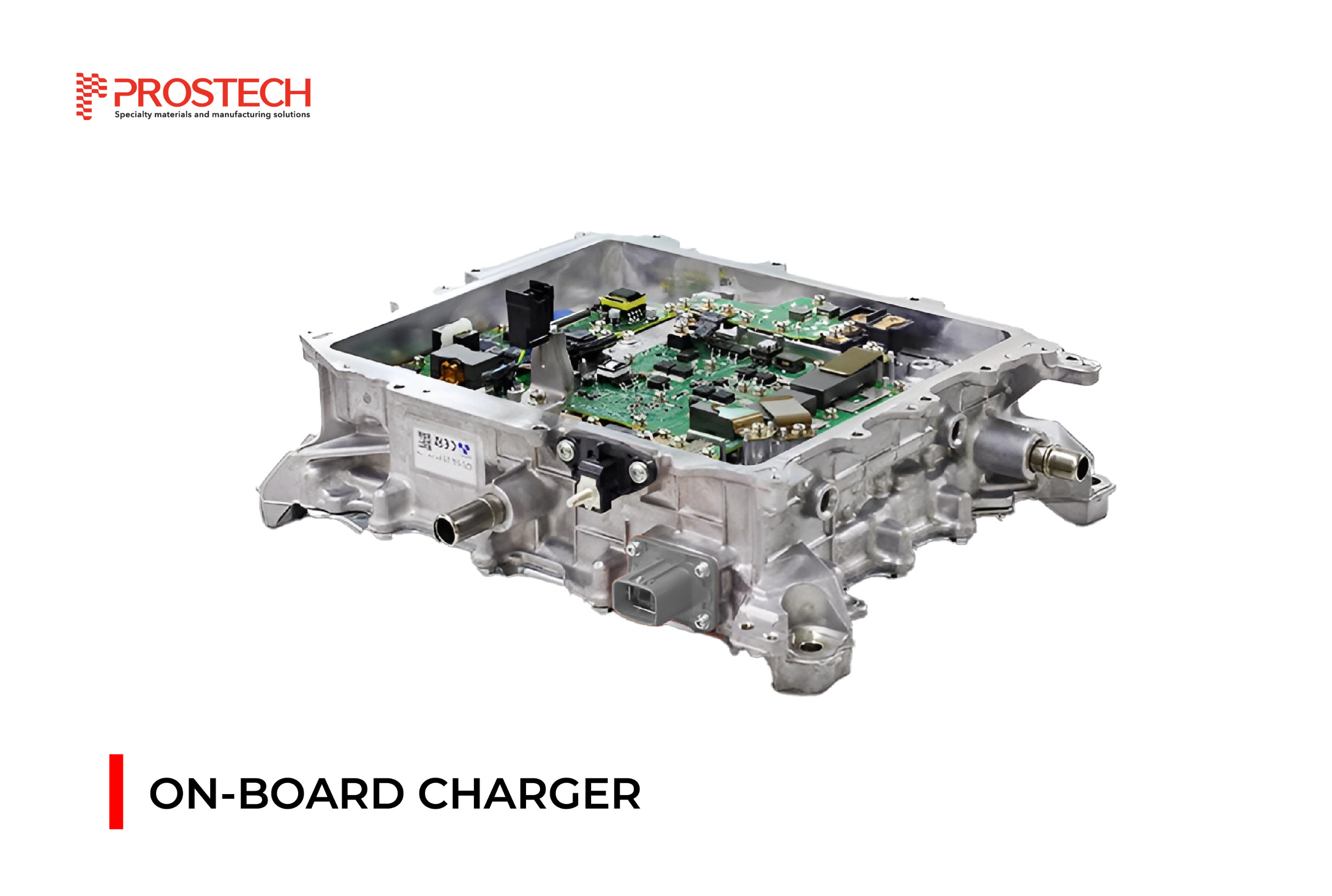

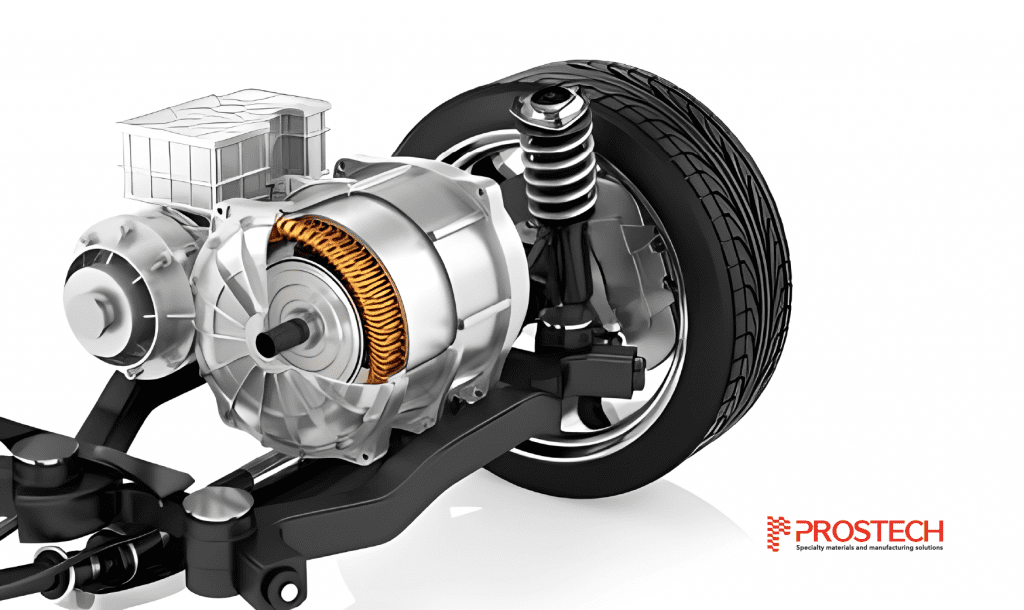

Electric motors are the heart of EVs, which convert electrical energy into mechanical motion. Specifically, when the electrical energy from the battery system is supplied to the motor, the coils create a rotating magnetic field that pulls the conducting rods on the outside of the rotor along behind it. That spinning rotor is what creates the mechanical energy needed to turn the gear of the car, which in turn rotates the tires.

Once the driver presses the accelerator pedal in an Electric car, the power is converted from the DC battery to AC for the e-motor. The accelerator pedal sends a signal to the controller which adjusts the vehicle speed by changing the frequency of the AC power from the inverter to the motor. The motor then connects and turns the wheels via a cog. When the brakes are pressed or the car is decelerating, the motor becomes an alternator and produces the power sent back to the battery. Indeed, understanding how an EV works, the importance of an E-motor is more obvious.

‘Prostech specializes in providing solutions for electric motors, both specifically for e-motors and electric vehicles in general. With successful test cases, Prostech’s technical team has developed potting solutions for electric motors. Click on this article to receive comprehensive and detailed information about this solution from us.’

2/ E-motor configuration in Electric vehicles.

EVs can come in different configurations such as single, dual, triple motors, or separate motors for each wheel. For instance, Tesla normally uses a single or dual-motor setup where the wheels are directly connected to the motors by eliminating transmissions.

| Features | Pros | Cons | |

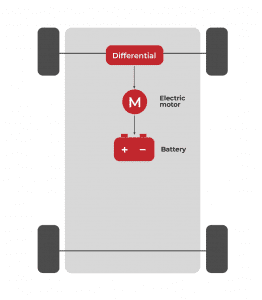

Single motor configuration

| Single motor configuration: the motor is charged and produces torque to the engine, this e-motor is mounted at the front wheel drive. The differential allows the wheels to rotate at different speeds. It also acts as a generator that sends energy back to the energy source. | A single-motor configuration offers cost-effective construction, which can lead to more affordable production and pricing for electric vehicles. | A single-motor configuration is not as efficient as others, potentially leading to suboptimal performance and reduced range. |

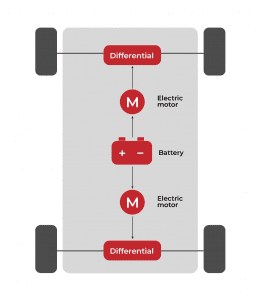

Dual motor configuration

| A dual motor configuration is one to power the front wheels and another to power the back. | Offering more power, a significant boost in acceleration for the driver, and smooth drive, batteries can be recharged and when an axle loses traction (either the front or rear axle), the EV can select which axle to reduce power | A dual motor configuration is more expensive due to the complexity and lack of standard transmission. |

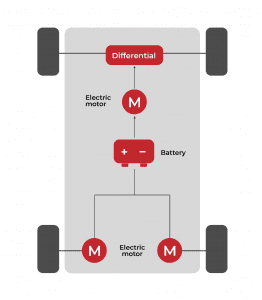

Triple motor configuration

| Triple motor configuration: The 2 motors drive each wheel of the rear axle to improve efficiency, corresponding to the wheel via a single-speed transmission. | Triple motor configuration improves handling, stability, and grip, delivering a sportier driving experience with enhanced traction and control, especially during cornering and acceleration. | The intricate power distribution among the three motors may amplify the risk of drifting, particularly in demanding driving scenarios, and contribute to a higher upfront cost. |

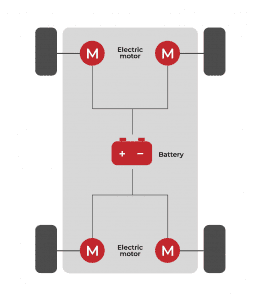

Four motor powertrains

|

| Four motor powertrains are more energy efficient, with proper torque vectoring offering sharper, tighter turns, more flexible | One notable drawback of four-motor powertrains is their high production costs, which can potentially hinder widespread adoption due to affordability concerns. |

‘What solutions are available for magnet bonding in e-motors? How to select the right adhesive for e-motor magnet bonding. These inquiries from you will be addressed by Prostech in this post. Contact us to receive the most specific solutions.’

3/ Types of Electric motors in EVs

Electric motors can be simply classified into 2 types: DC and AC.

| AC | DC |

|   |

-Simple, Robust, Cost-effective. -No brushes and commutators, no gearbox required -> reduce frictional losses, low maintenance. -High torque-to-weight ratio -> improve acceleration and overall performance. -Operate over a wide range of speed | -Simpler design, less complex and more affordable, suitable for E-scooters, and 2-wheelers. -High starting torque -> suitable for frequent acceleration and deceleration application -Less expensive. |

-Require a more complex control system than DC. -Higher cost | -High maintenance (e.g: brushed DC it requires brushes and a commutator which can wear out over time) -Heavy and hefty in size. |

‘Through successful experiments and collaborative efforts within the electric vehicle industry, Prostech has acquired tailored material and design solutions aimed at improving different aspects of electric vehicles. Accessing this valuable information is just a click away within the scope of this article.’

CONCLUSION

In conclusion, electric motors serve as the heart of electric vehicles (EVs), converting electrical energy into mechanical power with remarkable efficiency. Understanding their configurations and types is pivotal in optimizing EV performance and sustainability. As the automotive industry increasingly embraces electrification, mastering the nuances of electric motor technology will continue to drive innovation and shape the future of transportation. With comprehensive solutions regarding materials and components, Prostech enables e-motors in EVs to operate more efficiently, providing you with an exceptional driving experience.