Effective thermal management is crucial for high-performance electronics, and graphite thermal interface materials (TIMs) are at the forefront of this technology. From enhancing thermal conductivity to providing mechanical flexibility, the right graphite TIM can make all the difference. Explore our concise guide to the types of graphite thermal interface management and discover how these innovative materials keep your devices cool and efficient.

What is Thermal Conductive Graphite

Thermally Conductive Graphite is created from a high-temperature sintering process, heating a polymer film to its decomposition temperature in a vacuum and allowing it to carbonize and then graphitize until ultimately left with a highly oriented graphite material

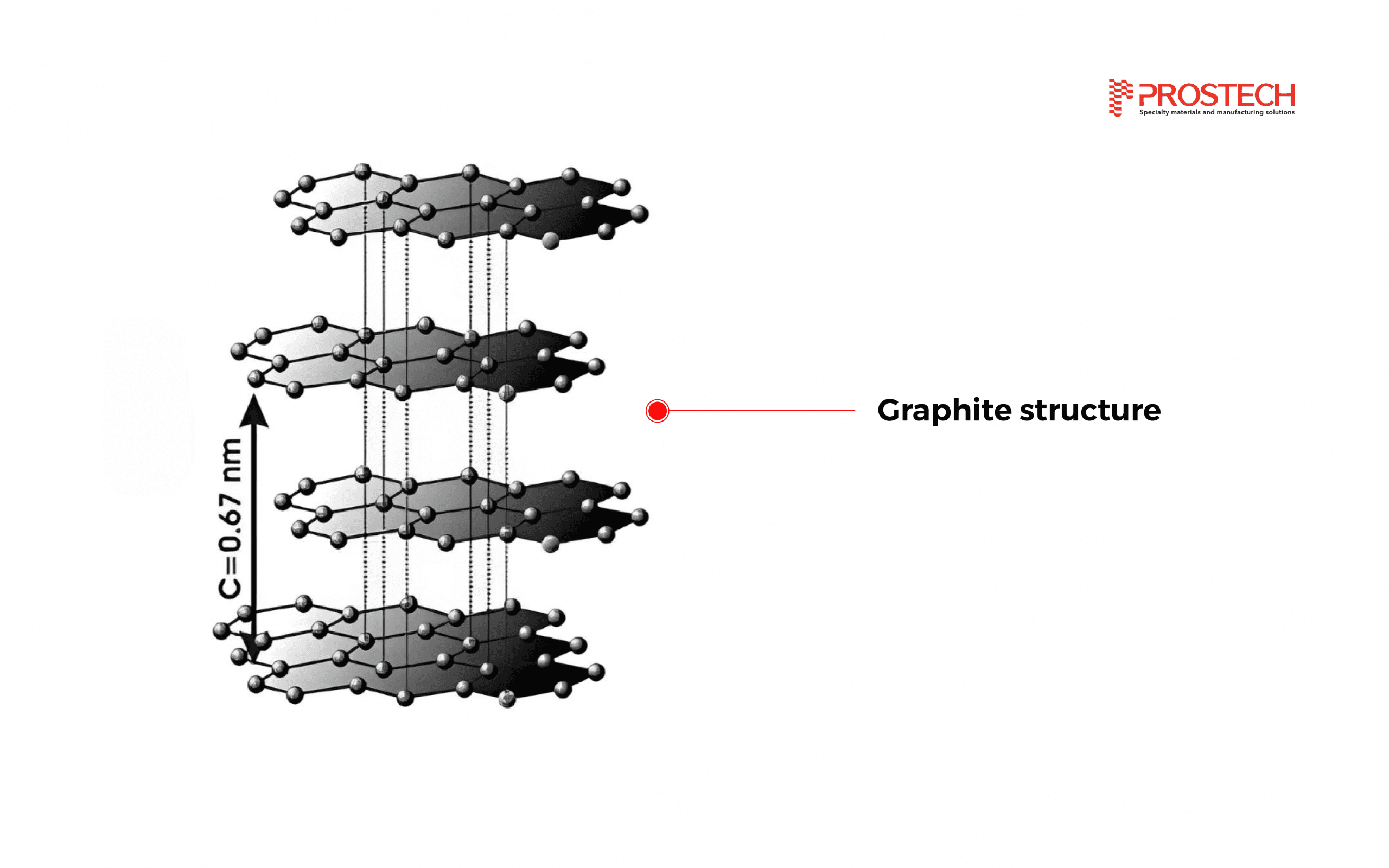

Graphite is formed of a layered structure with strong covalent bonds within the layers, and weak van der Vaals bonds connecting the layers.

To find out more technical information about Thermal Conductive Graphite, you can refer to this article: What is Thermal Conductive Graphite and Its Applications?

2 Main Types of Thermal Conductive Graphite

Graphite can both be found in nature and be produced synthetically. The synthesis can be done through carbonization of polymers or pyrolysis of hydrocarbons. This article explores two main types of graphite: natural graphite and synthetic graphite.

1. Natural graphite

Natural graphite of varying crystallinity can be found in mesomorphic rocks in nature and is divided into amorphous, flake, and high crystalline graphite. The natural graphite used in thermal management contains up to 98 % crystalline graphite and is a soft material. The layered structure gives the anisotropic character of the physical properties. The electrical conductivity, thermal conductivity, and CTE are different in the plane through the thickness. For thermal management, the material is used in heat sinks, heat spreaders, and TIMs. The feature that makes natural graphite attractive as a TIM, is its high thermal conductivity in combination with the ability to conform well to the surfaces under moderate pressures. Natural graphite can be formed into thin sheets of more ordered graphite structures. This can be done by first inserting ions between the weakly bonded layers in the graphite. The ions decompose and volatile as the material is heated, creating a high internal pressure between the graphite layers. Due to the overpressure, the layers are pushed aside as the ions escape the structure. Interstitial graphite particles are expanded in an accordion-like way, making the particles look like worms. The material can then be mechanically treated and formed into a thin flexible sheet that can be used as a TIM or a heat spreader. Compared to aluminum and copper, graphite has a large advantage with its low density. The density ranges from 1.1-1.7 g/cm3 compared to copper’s 8.89 g/cm3 and aluminum’s 2.7 g/cm3.

Some advantages of natural graphite TIMs we can see that

- Simple to handle and cut, requiring minimal preparation before use

- More affordable compared to synthetic alternatives in general

- Can be processed into flexible sheets and films, which conform well to irregular surfaces and improve thermal contact between components

Despite its remarkable advantages, natural graphite also has some drawbacks, including its lower thermal conductivity and its limited suitability for high-performance applications. Natural graphite has thermal conductivity around 140-500 W/(m∙K) in the plane and 3-10 W/(m∙K) through the thickness. This may not be sufficient for applications with high heat generation. For demanding electronics or applications requiring exceptional heat dissipation, natural graphite might not be powerful enough.

2. Synthetic graphite

Synthetic graphite is manufactured through several methods. One method is the graphitization of non-graphitic carbon. This involves heating non-graphitic carbon at temperatures above 2500 K. Another method is the chemical vapor deposition (CVD) process, where hydrocarbons are used to deposit graphitic carbon onto a substrate at high temperatures. Synthetic graphite can also be obtained by decomposing thermally unstable carbides or by crystallizing from metal melts that are supersaturated with carbon. Synthetic graphite is designed to offer superior performance compared to natural graphite, especially in applications requiring high consistency and purity.

Unlike natural graphite, synthetic graphite isn’t simply extracted from the ground. It’s meticulously crafted through various processes, including de-oxidation, high-temperature treatment, shaping, and finishing. Some advantages of synthetic graphite TIMs:

- Higher thermal conductivity

- Higher degree of purity, which can contain impurities that can affect its performance

- Can be customized to meet specific application requirements because the manufacturing process of synthetic graphite allows for greater control over the material’s structure.

While synthetic graphite offers significant advantages over natural graphite for thermal interface materials (TIMs), it does come with some drawbacks to consider. Compared to natural graphite, synthetic graphite is generally more expensive to produce. The manufacturing process is also more complex compared to natural graphite mining which can lead to potential challenges in terms of scalability and consistency of production. Besides, the production process has a larger environmental footprint due to the high energy consumption and industrial activities involved.

Conclusion

Both natural and synthetic graphite have distinct properties that make them suitable for various industrial applications. Natural graphite offers cost-effectiveness and natural abundance, while synthetic graphite provides higher purity, consistency, and tailored properties for high-performance needs. Understanding the advantages and disadvantages of each type can help in selecting the appropriate graphite for specific applications, and balancing performance, cost, and environmental considerations.

With a comprehensive range of chemistry platforms, Prostech offers the most application flexibility for thermal conductive graphite solutions such as:

|

|

|

|

|

Prostech ensures optimal performance and reliability in these critical materials solutions through advanced technology and meticulous attention to detail. With a focus on improving efficiency and improving the quality of life, Prostech’s thermal conductive graphite solutions will bring you great experiences when using our products.

—————————————–

For more information, contact us to talk with our glue experts: