tesa® 8853 is made from special tackified acrylic adhesive system which has excellent high temperature resistant property, ideal for demanding FPC mounting applications.

FEATURES

- Sufficient holding power and peel strength even after solder reflow process

- High tensile strength, good repulsion resistance

- Excellent die-cutting properties and very low oozing due to special backing

- High conformability for uneven surfaces

- High aging resistance

- Conforming to RoHS

APPLICATION

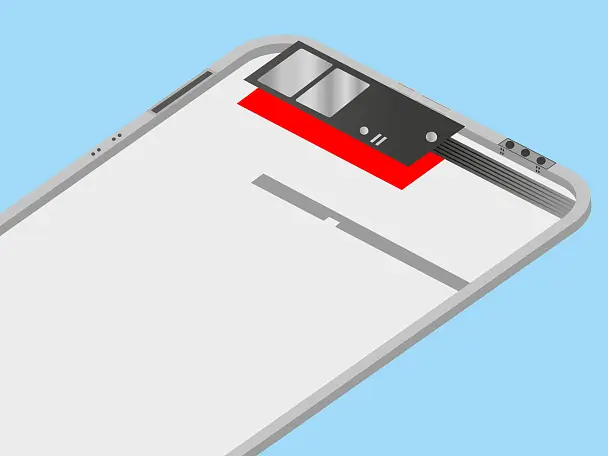

FPC mounting application of electronic components, subjected to high temperature processing and operating environments.

Product Construction

| Backing material | ultra thin non-woven |

| Color | translucent |

| Color of liner | white with tesa logo |

| Thickness of liner | 2.8 mils 71 µm |

| Total thickness | 1.97 mils 50 µm |

| Type of adhesive | type: tackified acrylic |

| Type of liner | type: glassine |

| Weight of liner | 116.63 lbs/in² 82 g/m² |

Properties / Performance Values

| Humidity resistance | very good |

| Chemical resistance | good |

| Ageing resistance (UV) | very good |

| Tack | good |

| Softener resistance | good |

Adhesion to Values

| Adhesion to ABS (initial) | 2.74 lbs/in 4.8 N/cm |

| Adhesion to ABS (after 14 days) | 3.43 lbs/in 6 N/cm |

| Adhesion to Aluminium (initial) | 2.57 lbs/in 4.5 N/cm |

| Adhesion to Aluminium (after 14 days) | 3.37 lbs/in 5.9 N/cm |

| Adhesion to PC (initial) | 3.31 lbs/in 5.8 N/cm |

| Adhesion to PC (after 14 days) | 3.94 lbs/in 6.9 N/cm |

| Adhesion to PET (initial) | 2.86 lbs/in 5 N/cm |

| Adhesion to PET (after 14 days) | 3.08 lbs/in 5.4 N/cm |

| Adhesion to PI (initial) | 3.37 lbs/in 5.9 N/cm |

| Adhesion to PI (after 14 days) | 3.43 lbs/in 6 N/cm |

| Adhesion to Steel (initial) | 3.03 lbs/in 5.3 N/cm |

| Adhesion to Steel (after 14 days) | 3.71 lbs/in 6.5 N/cm |